Harnessing parametric design for personalized living spaces

In contemporary furniture markets, there is a growing demand for customized solutions that cater to individual preferences, including personalized dimensions, materials, and other specifications.

Have you ever been in a situation where you went furniture shopping and you see the bookshelf of your dreams, but sadly 125cm in width cannot fit between your TV stand and the window. Or the wardrobe that you have just assembled looks great in your room but that dust corner between it´s top and the ceiling is like a hell for your dust mites allergy.

Even though perfect fitting of every single furniture piece you want sounds breathtaking, especially if you have OCD as I do, not every design should be altered by a customer as usually the perfect blend of functionality and aesthetics can be easily lost.

WHY?

During the design process, the designer carefully selects materials, textures and dimensions, to ensure a combination that makes the design unique and comfortable to use.

And that brings us here:

So the question is – what should people do?

During the research I bumped into one article, an interview with Joris Laarman, one of the first parametric furniture designers, an interesting guy, back then just a student, now selling chairs for half a million dollars… But what he said is that everything he does is parametric, small number of his designs actually can be parametrically customized after it’s final design.

To translate it into something we’re familiar with: grasshopper scripts. Most of his designs don’t have slides for inputs but rather tabs with fixed, calculated numbers which alteration would mutilate the design.

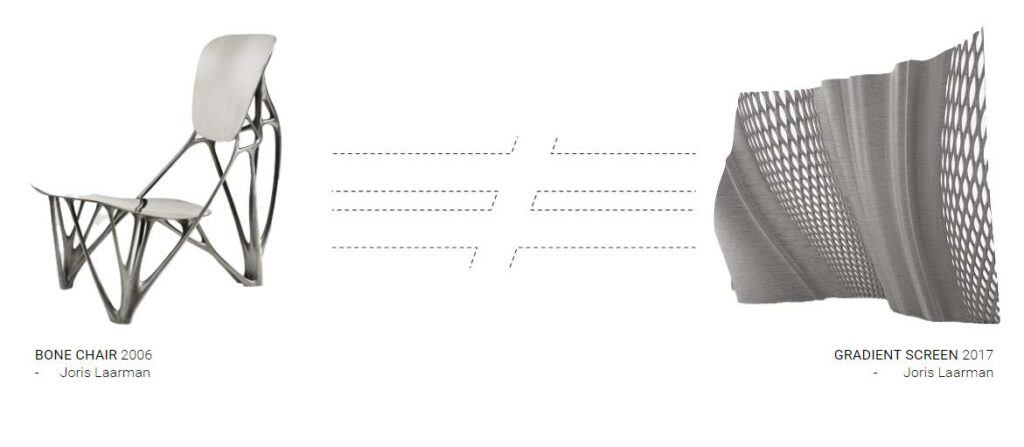

He gave the example on two of his designs:

- Bone chair where small changes would completely ruin the experience of the user, since it would change the ergonomic of the chair.

- Gradient screen – 3d metal printed screen, that, even if changed, if it stands and if it can be printed, it is unique.

That brings us further to what is then “changeable” and what is not?

There Ray Eames helps us.

In the book called The Legacy of Invention by Donald Albrecht, he says that Ray Eames used to differ two types of furniture:

- Actively used – user has direct contact with the design, which lasts

- Passively used – interaction between the design and the user is instantaneous

Altering can reduce utility and ergonomics: chairs, tables, sofas, beds, desks

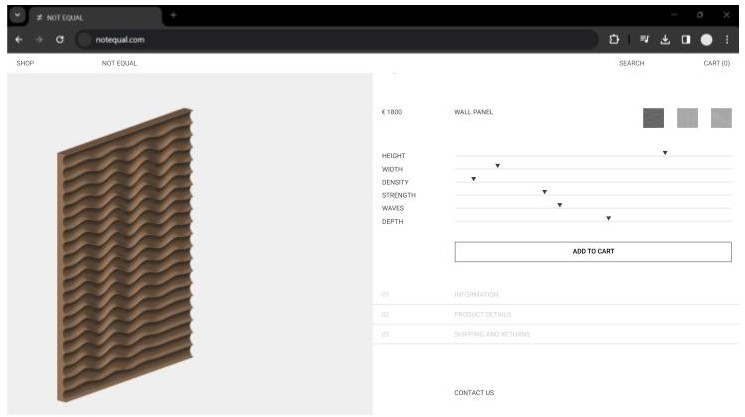

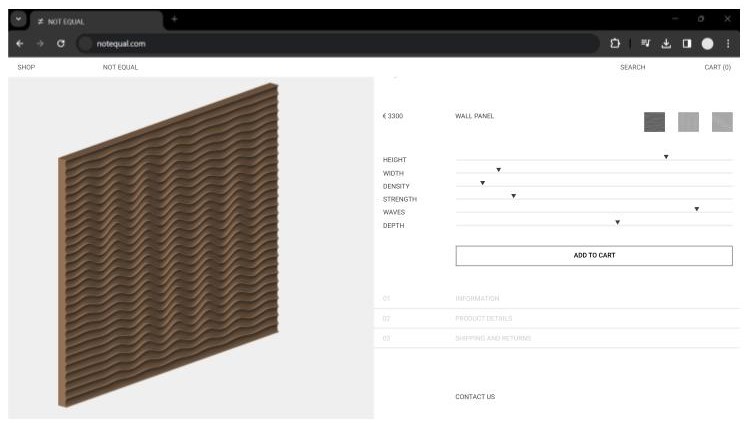

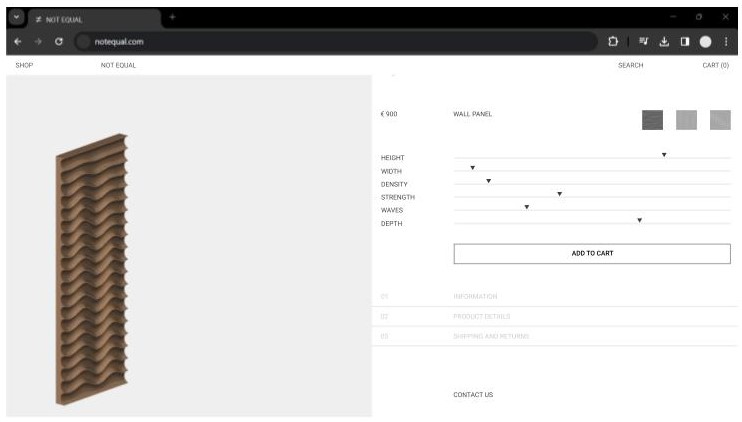

Altering can bring small changes to overall aesthetics but will not damage user’s experience: coffee and side tables, shelves and bookcases, wall paneling systems, wardrobes

Proposal

Interactive website where customers can customize the design and modify dimensions, shapes, patterns, materials, before ordering parametrically designed, passively used, robust furniture piece (bookcases and wardrobes; wall paneling systems).

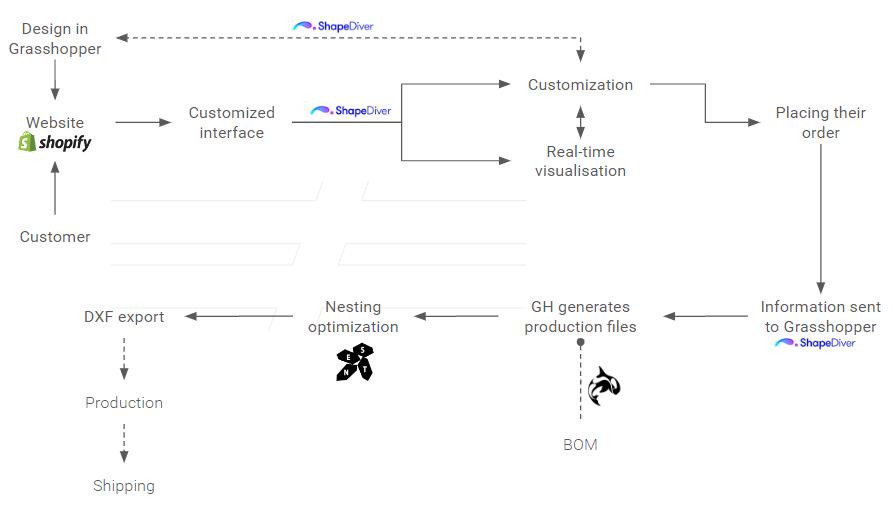

So the plan is that:

- Customers navigate to Shopify website to explore the available, previously designed and parameterized furniture designs and select a product they wish to customize.

- Upon selection, they are directed to the customization interface powered by ShapeDiver, integrated into the Shopify platform.

- ShapeDiver also provides an interactive 3D visualization platform on the Shopify website.

- Customers can modify dimensions, shapes, materials, and other parameters of the selected furniture design and they can visualize their customizations accurately before making a purchase.

- After finalizing their customization, customers proceed to place their orders through the Shopify website’s checkout system.

- Upon order placement, customization parameters are transmitted from the Shopify to Grasshopper, by ShapeDiver.

- Grasshopper receives the transmitted data and initiates the design optimization and production preparation process.

- Orca3D provides exact Bill of Materials

- Grasshopper does the nesting, generates production files, and exports DXF format for CNC machining

According to the roadmap – everything happens in three timeline groups:

- Interface design

- Computational designs

- Interface deployment

INTERFACE DESIGN

a. User Experience (UX) Design:

- Conducting user research to understand user preferences and behaviors.

- Designing wireframes and prototypes for the Shopify website, focusing on intuitive navigation and ease of use

b. Visual Design:

- Developing a visual identity for the website, including color schemes, typography, and imagery

- Designing logo, custom graphics and icons for the interface

c. Customization Interface Design:

- Designing the customization interface powered by ShapeDiver, allowing users to alter dimensions, shapes, materials, etc.

- Ensuring the interface is responsive and accessible across different devices and screen sizes.

COMPUTATIONAL DESIGN

a. Grasshopper Scripting:

- Developing Grasshopper scripts for generating parametric furniture designs based on user input.

- Integrating Grasshopper with ShapeDiver to enable real-time visualization of customized designs.

- Optimization of Grasshopper scripts for efficiency and performance.

b. Production File Generation:

- Develop scripts for generating production files (DXF format) for CNC

- Implement nesting plugin OptiNest to maximize material usage and minimize waste.

c. Testing:

- Testing of Grasshopper scripts and production file generation processes.

- Test production to test final CNC files and their accuracy

INTERFACE DEPLOYMENT

a. Integration with Shopify:

- Integration of the interface powered by ShapeDiver with the Shopify website.

- Ensuring seamless communication between Shopify, ShapeDiver, and Grasshopper for data transfer and order processing.

b. Deployment Preparation:

- Configuring hosting environment and domain settings.

- Implementing security measures to protect user data and transactions.

- Conducting final checks before deployment.

c. Launch and Post-launch Support:

- Making the website publicly accessible.

- Providing support and maintenance for any issues

Interface design – visual proposal

Production plan is that everything is SUBTRACTIVE MANUFACTURING mostly for CNC milling. 3D printing needs different scripts and there are changes in ShapeDiver functions as well.