The idea of ‘craft’ for us is a blend of traditional hands-on skills and modern digital techniques. The experience reinforced that craft is an evolving dialogue between hand and machine, where both bring unique strengths to the process.

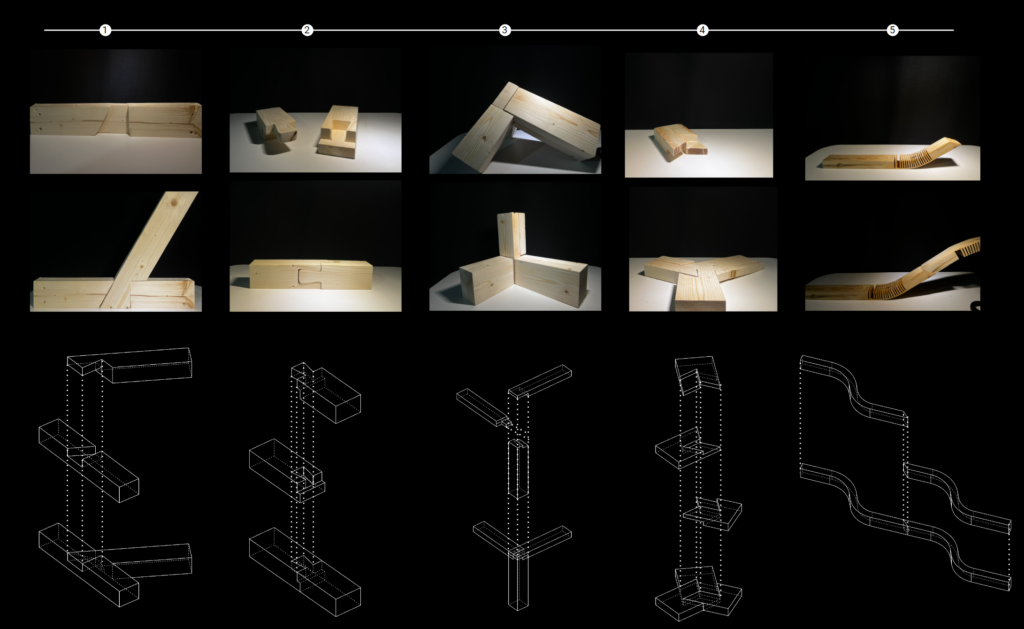

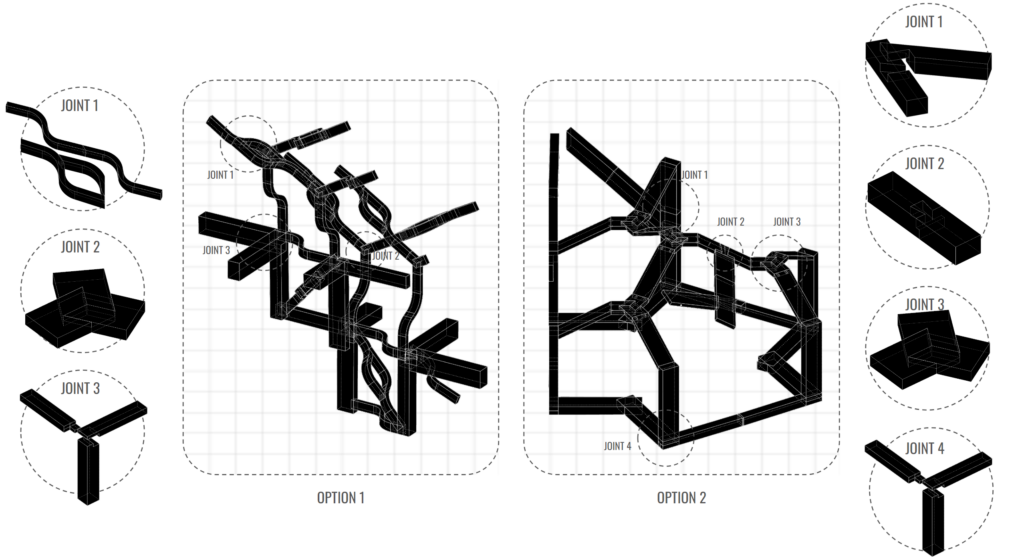

PROCESS – JOINT PROTOTYPES

JOINT 1 (CNC)

JOINT 2 (CNC)

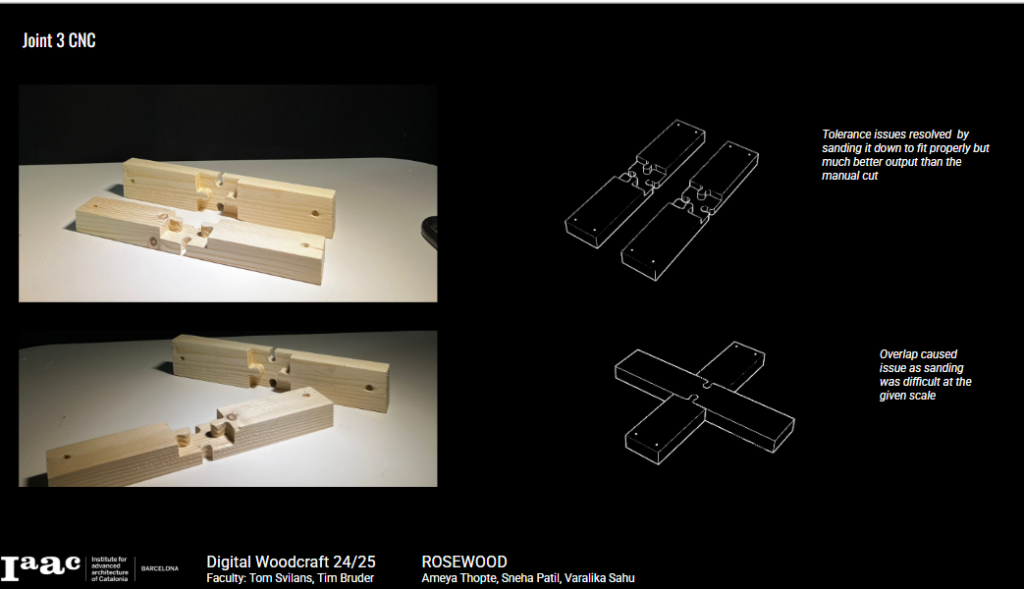

JOINT 3 (CNC)

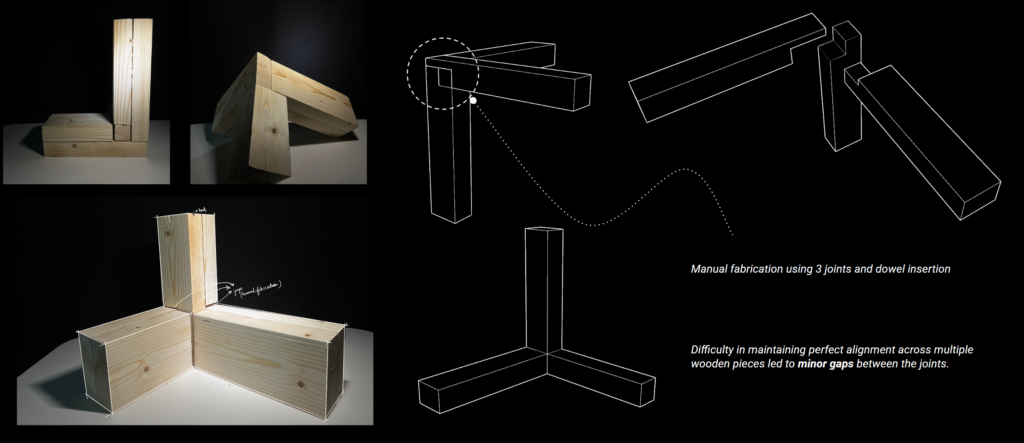

JOINT 4 (MANUAL)

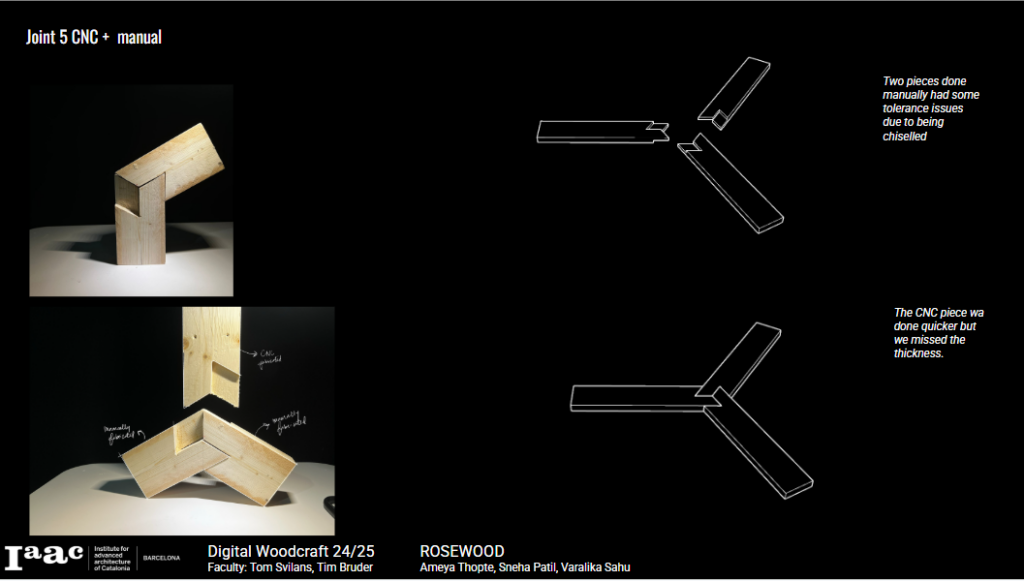

JOINT 5 (CNC + MANUAL)

KERFING

REFERENCES

ABSTRACT

LEARNINGS

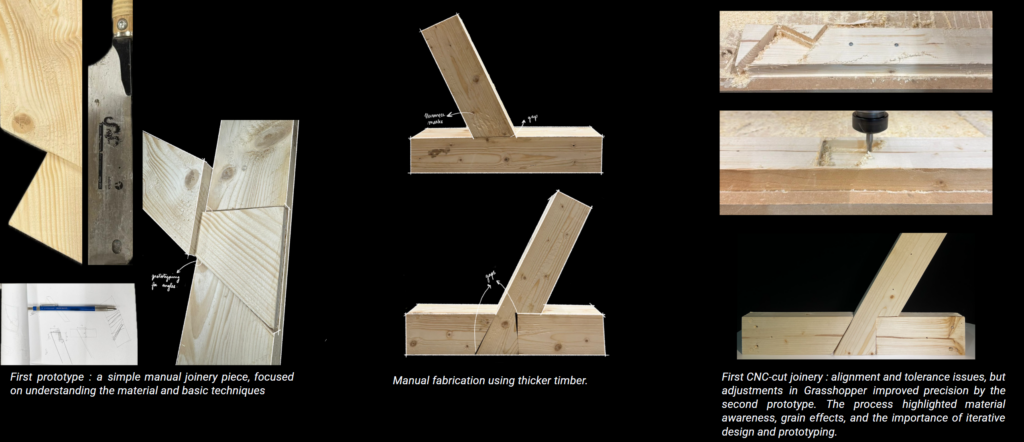

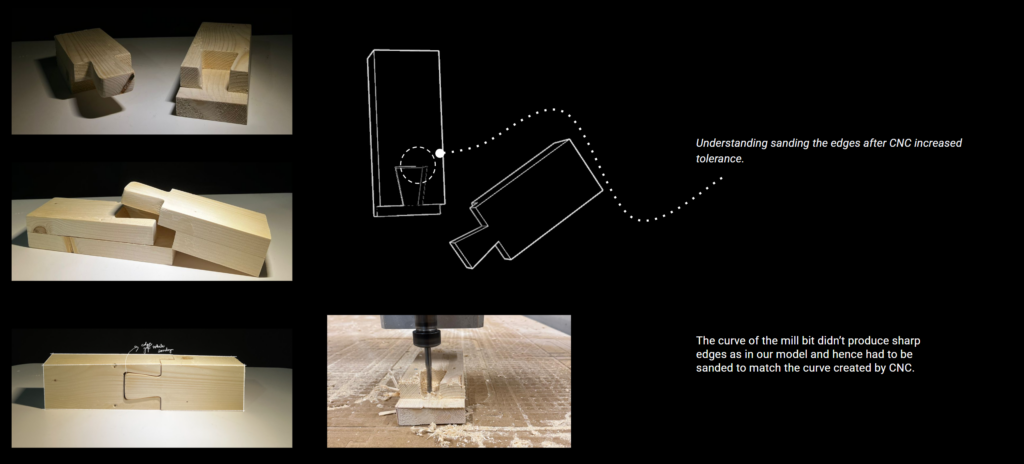

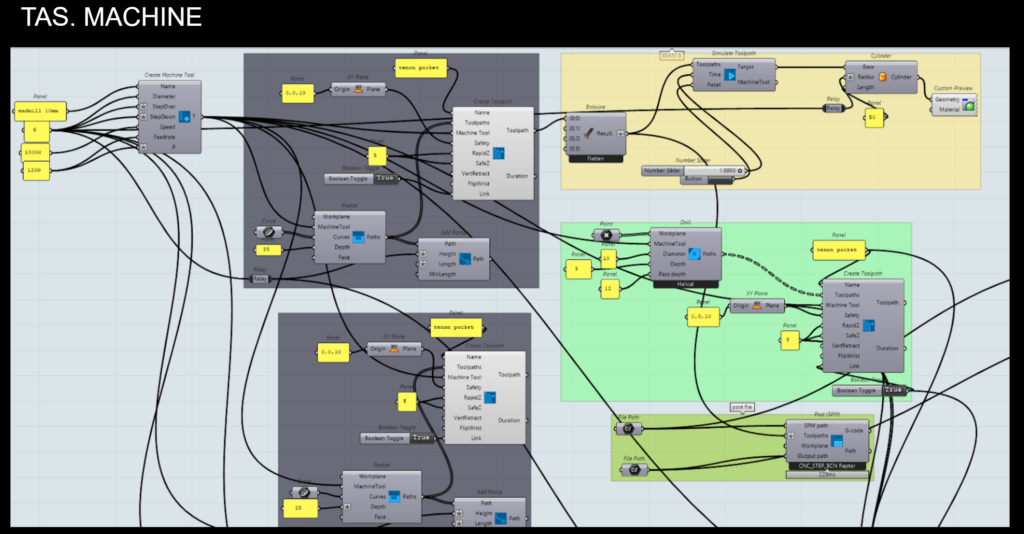

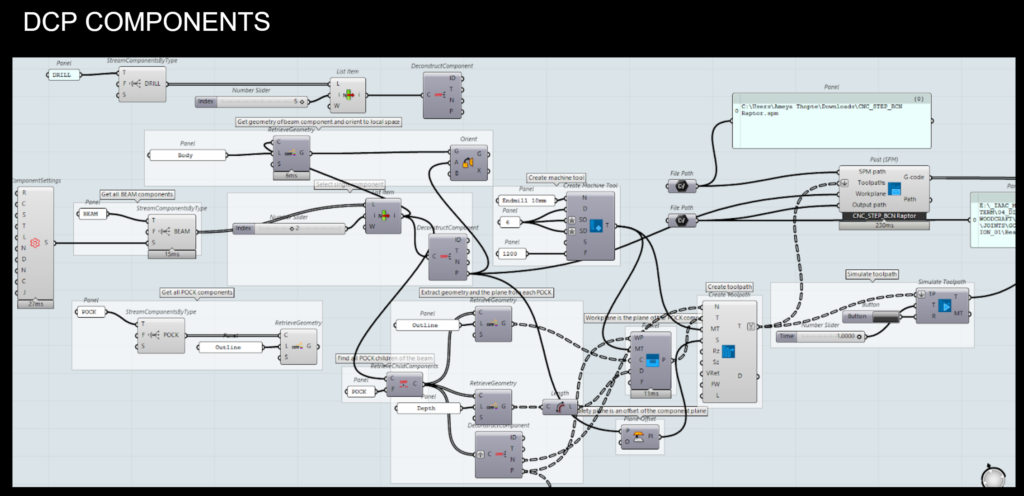

At start, we struggled with dimensions and tolerances, especially during CNC fabrication. This made us realize how critical it is to set up digital models accurately and understand the relationship between digital design and physical output. Over time, we learned to adjust tolerances in Grasshopper and calibrate the CNC machine. The tolerances in CNC milling required constant calibration, and our early dimensioning issues revealed the importance of understanding how digital and physical workflows interact. Now, we see digital tools as more than just a means of automation—they require an active, iterative approach, much like manual craft, to truly refine a design.

The issues we faced with dimensions and tolerances have shaped our practice by making us more detail-oriented and iterative in our approach. We now consider fabrication constraints early in the design process and prioritize prototyping and testing. For example, after struggling with CNC alignment, we started building small-scale prototypes to test tolerances before moving to CNC fabrication. This experience has also made us more aware of the importance of understanding fabrication processes, whether I’m working with digital tools or manual techniques. As a result,our practice has become more collaborative and grounded in the realities of making