This research explores the optimization of glulam in architectural design by aligning material grading and grain orientation with force trajectories. Combining glulam offcuts and higher-grade timber, the study minimizes waste while maximizing structural efficiency. Computational workflows and generative algorithms are used to design force-aligned components for scalable applications. Prototypes demonstrate enhanced performance and sustainability, offering a circular, data-driven approach to timber construction that redefines material value in architecture.

Unlike isotropic materials like steel, which behave uniformly in all directions, wood is anisotropic and orthotropic—its properties vary significantly based on fiber orientation. This makes understanding and designing for wood’s orthotropic nature crucial. For instance, raw logs cannot be relied upon for construction due to irregularities like knots and internal flaws. This challenge led to the development of engineered wood products, where lamellas are layered and bonded in controlled alignments. This process not only stabilizes the material but also ensures consistent mechanical performance and stronger components for construction.

The material usage efficiency is low since only high-quality lamellas are selected for glulams—those without notches and with perfect alignment. As a result, 40% of the wood is unsuitable for producing standardized lamellas. However, it is proposed to use this wood to create smaller parts and align them with the direction of the main stress to achieve greater strength.

State of the art

Throughout history, glulams have been optimized to create high-value architectural spaces, enabling longer spans, enhancing natural light entry, and improving overall performance. Computational advancements and fabrication techniques have also evolved to streamline manufacturing and assembly.

Cutting-edge tools such as robotic fabrication, 5-axis CNC machining, and topology optimization have opened new frontiers, making once-impossible designs feasible and cost-effective.

The key question now is: how can these technologies be harnessed to maximize structural performance and unlock new design possibilities?

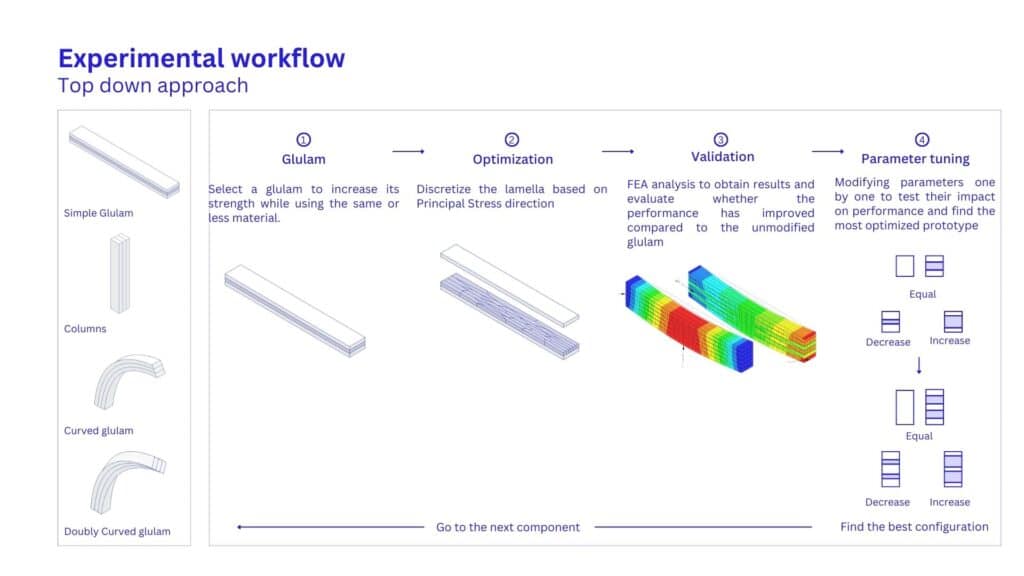

Top down approach

Starting with glulams to optimize performance while using the same amount of material by aligning the wood along the principal stress directions. Then, modifying parameters such as configuration, lamella thickness, discretization levels for aligning lamella segments, and other factors to determine the most optimal configuration.

Bottom up approach

Exploring alternative methods to connect key points, manipulating loads and supports to generate new forms based on force trajectories. Then, rationalizing geometries and discretizing them into optimized glulam components.