Our CLT Factory embodies a boutique ethos: modest in scale yet purposeful in intent. Serving as a research and innovation hub for new CLT products, it represents a vision for sustainable work-life integration and thoughtful wood construction, with a commitment to sustainable design practices.

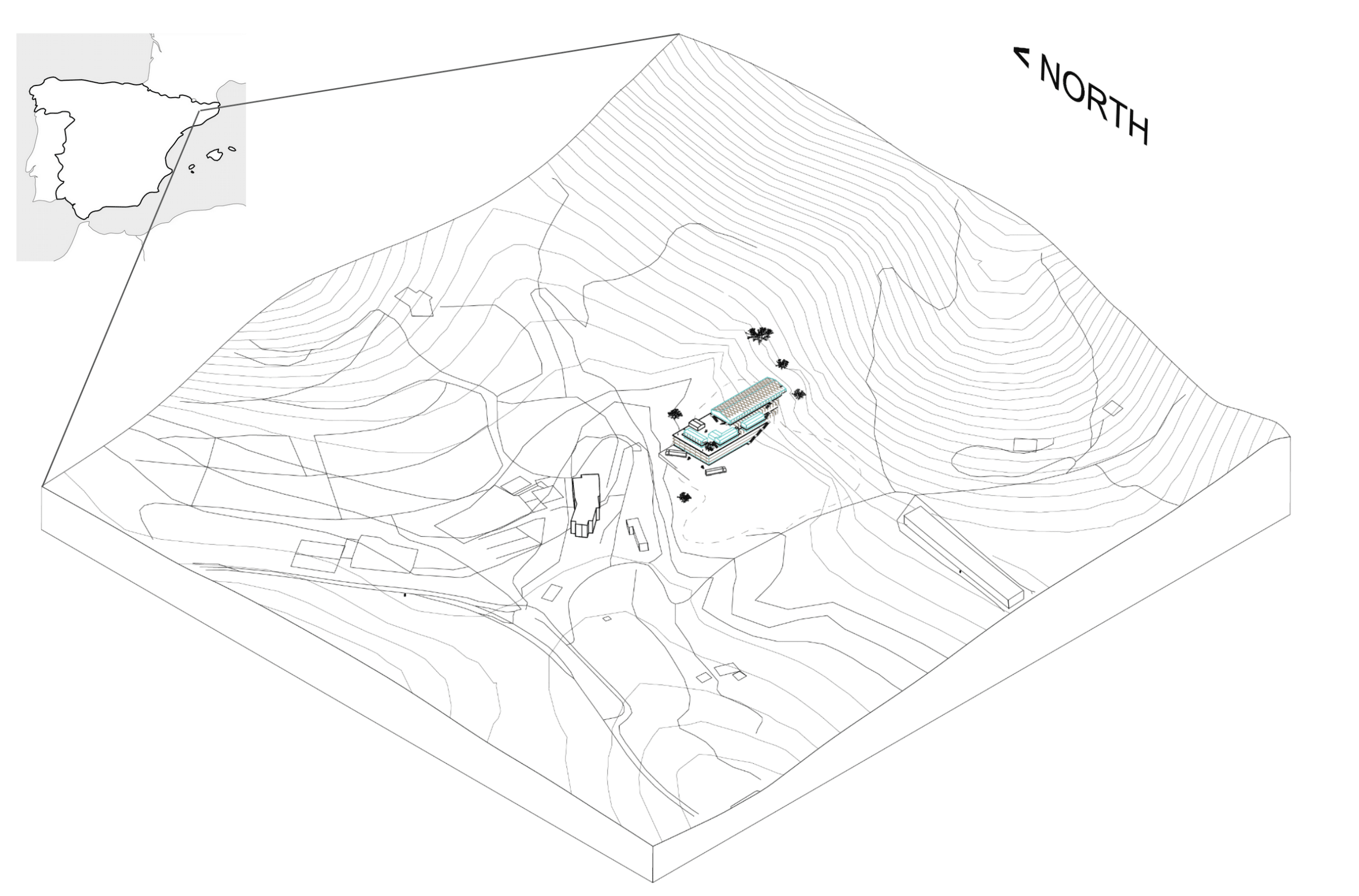

In contrast to sprawling industrial complexes, this boutique factory seamlessly integrates with its surroundings. Its stepped, terraced roof incorporates urban farming, communal spaces, and housing, creating an environment that promotes productivity, well-being, and a connection to nature. The first terrace includes offices surrounded by greenery, fostering creativity. The second terrace, featuring a communal plaza with a canteen and amenities, serves as the heart of social interaction. Above, the third terrace offers housing that overlooks the Pyrenees and connects directly to the mountain slope.

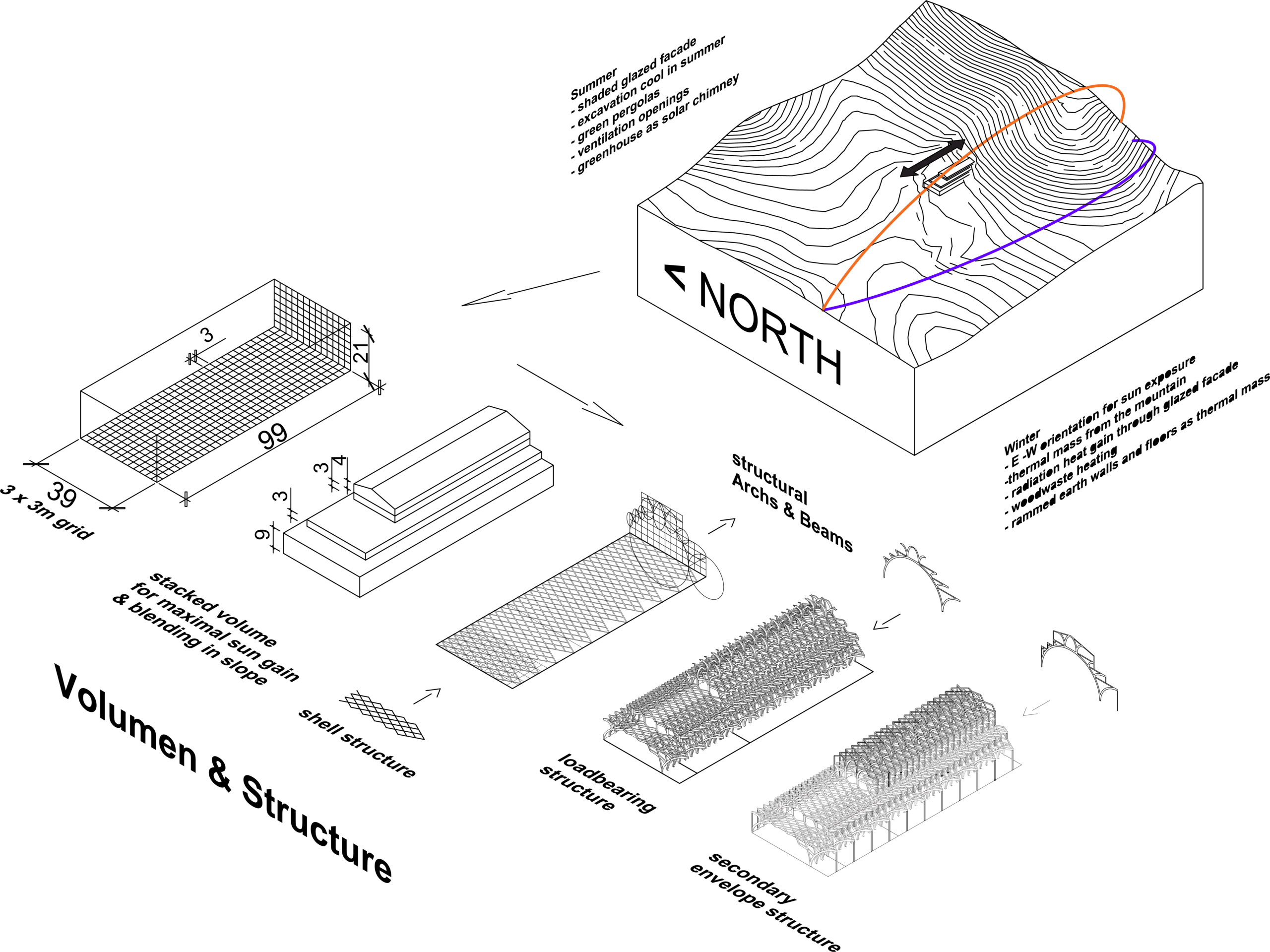

At its core lies a vaulted gridshell structure made from local wood, striking a balance between practicality and sustainability. By using timber as much as possible, we aim to reduce our environmental footprint while cultivating a warm and inviting atmosphere. This compact yet thoughtful design is tailored to the local climate, ensuring comfort throughout the year. The factory’s design exemplifies that architecture, much like fine craftsmanship, thrives on innovation, attention to detail, and harmony with its context.

Formfinding

Program & Function

.

Floorplans

Sections

Longitude section

Section with forces Diagram

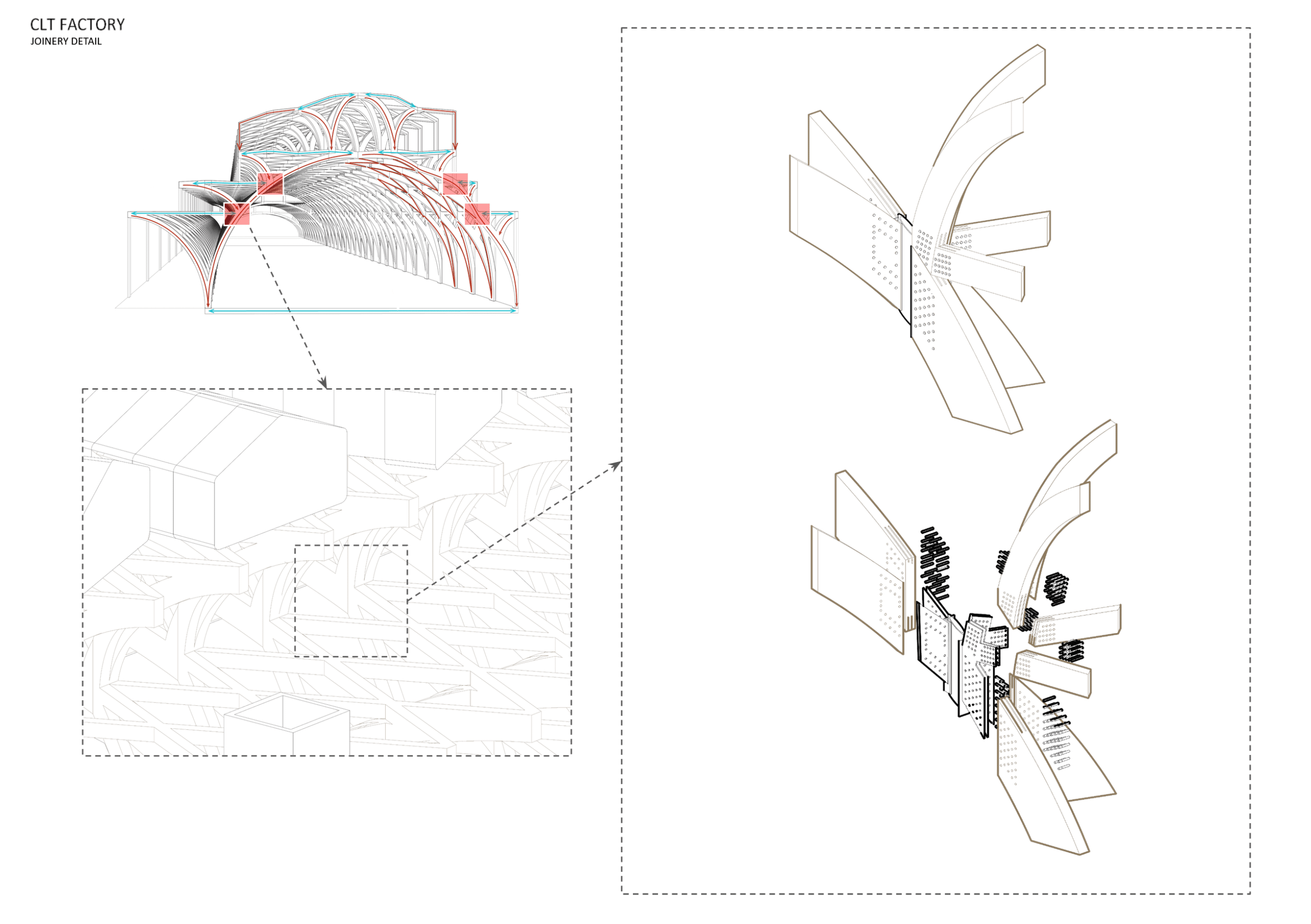

Detail

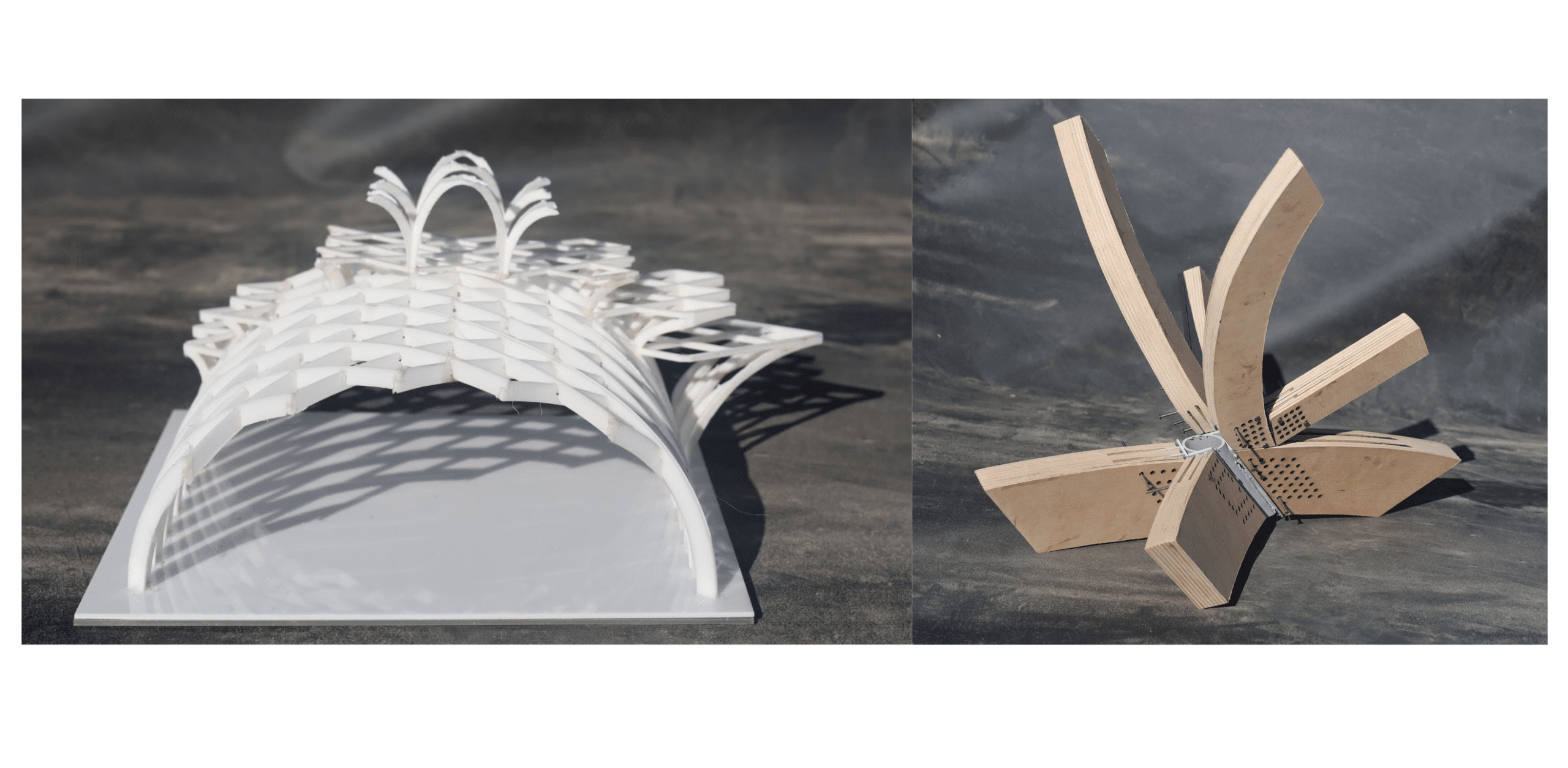

Model

Building the Model was a interesting challenge because of the complexity of the structure. Due to limited time and Model size (1:150) we ended up testing the main gridshell by Lasercutting and the secondary terraces and greenhouse structure by 3D printing. The greatest insight gave us the 1:25 detail model which is manly lasercutted wood and Plexiglass. We noticed that our round/bended wooden pieces are material consuming and dpnt have any structural benefit, just an astetic one. For the nect iteration we plan on using straight gluelam and triangulation without bending pieces.