3D PRINTING

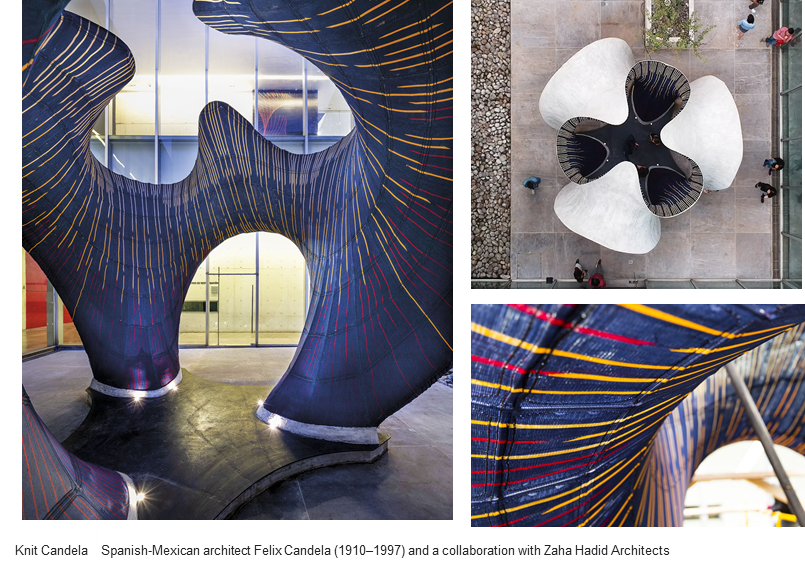

REFERENCES

Inspired by the interplay of flexibility and precision , this concept captures the merging of fluid fabric forms with the structured intricacies of 3d printing and laser cutting . By layering printed patterns onto pliable textiles , this project explores the seamless integration of hard and soft elements , creating a form that embraces both structures and adaptability

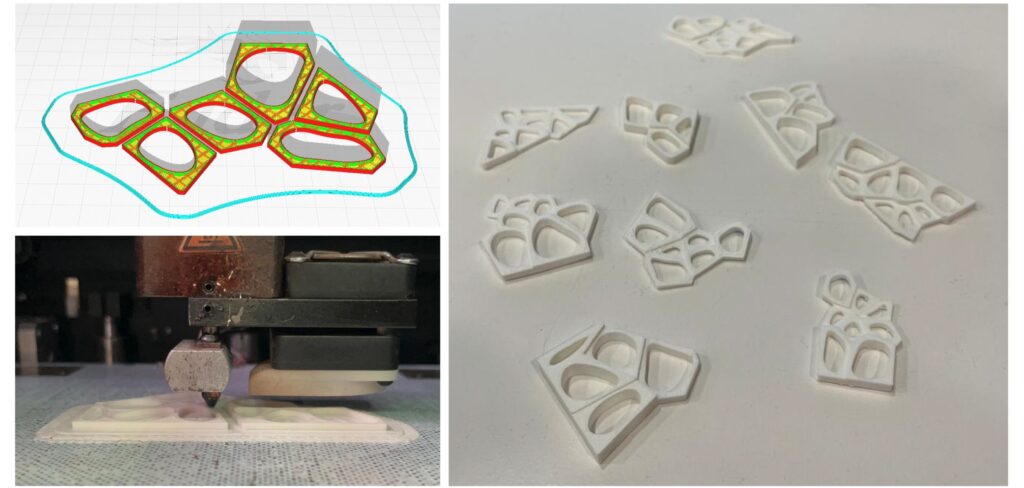

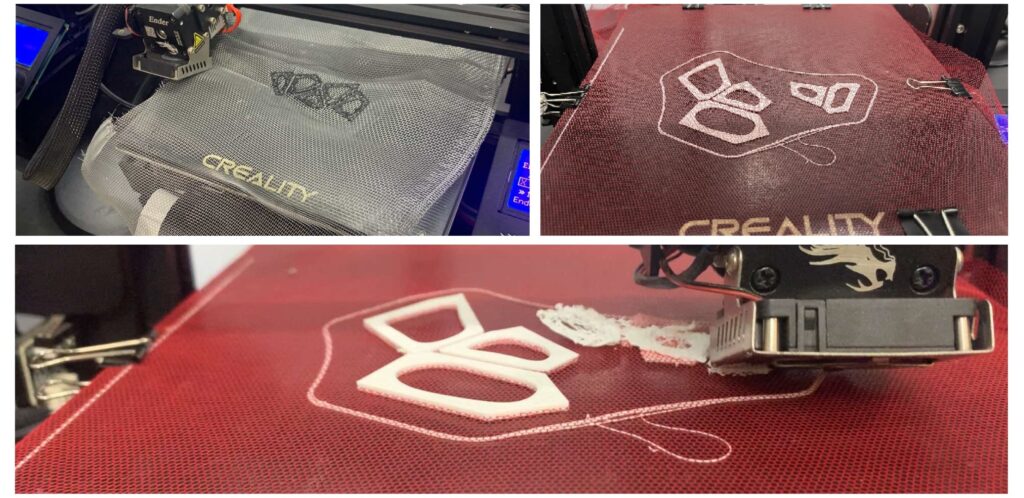

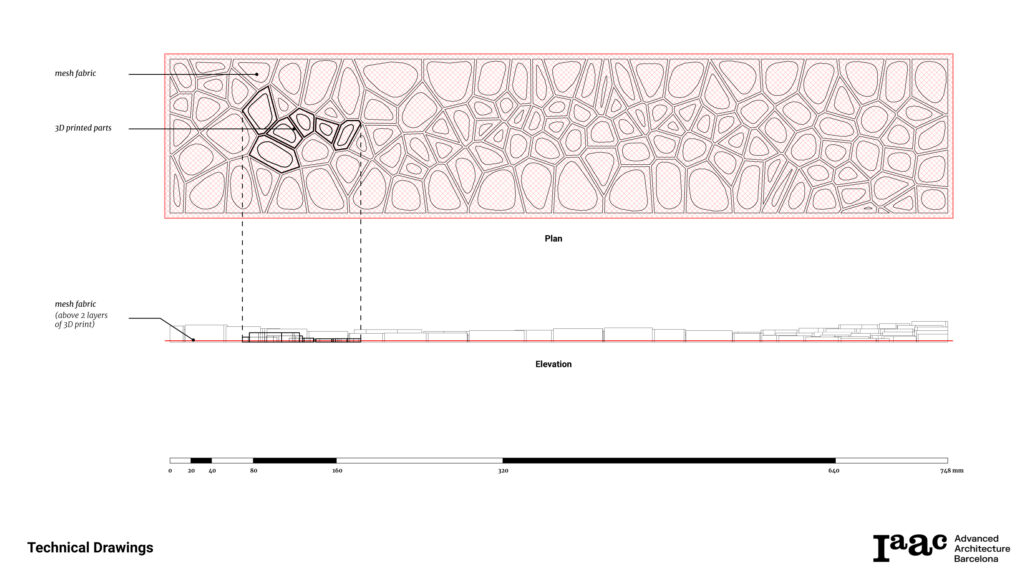

We delved into the untapped potential of 3D printing on textiles in architecture trying to stitch nature’s complexity into fabric. Through numerous trials with varying settings, materials, and configurations—along with some friendly warnings from our instructors and even breaking one machine—we finally achieved a working prototype that deepens our understanding of this technique’s possibilities.

PROTOTYPING

Experimenting with Different Printing Settings and Infills

Experimenting with Different Types of Fabric (metal mesh, fabric mesh)

Final Printed Piece

CNC MILLING

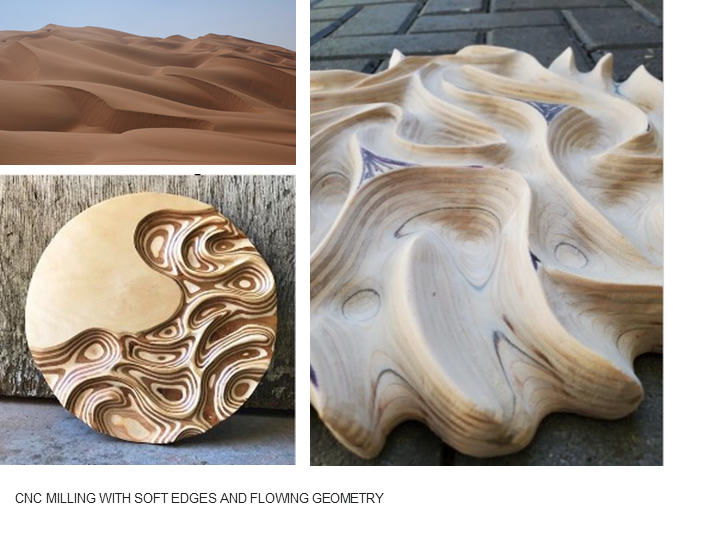

REFERENCES

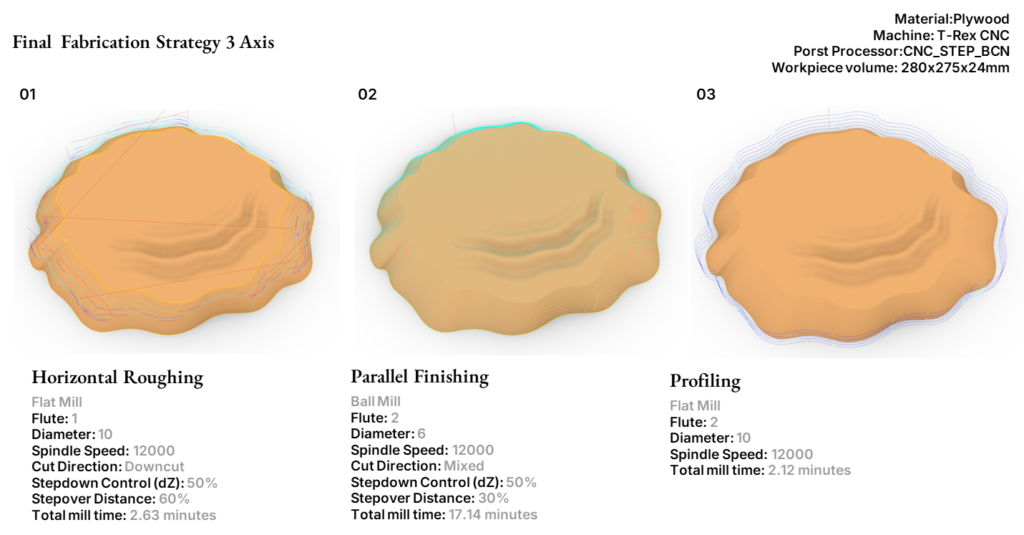

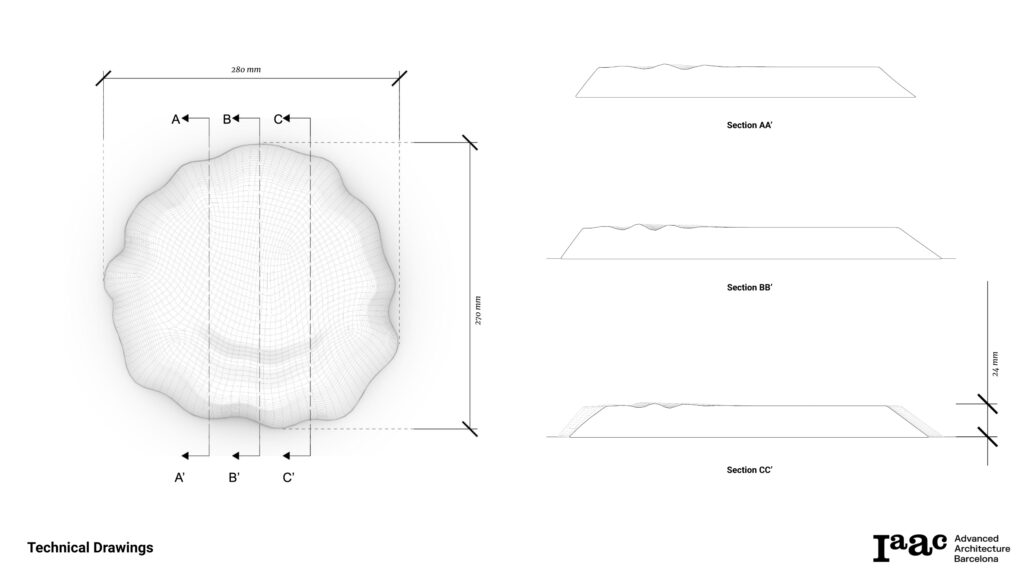

Inspired by the Synergy of adaptability and precision , this concept extends into CNC milling , where rigid materials are sculped into fluid forms. The milling Patterns that blend structure with movement , creating a harmonious balance of strength and flow

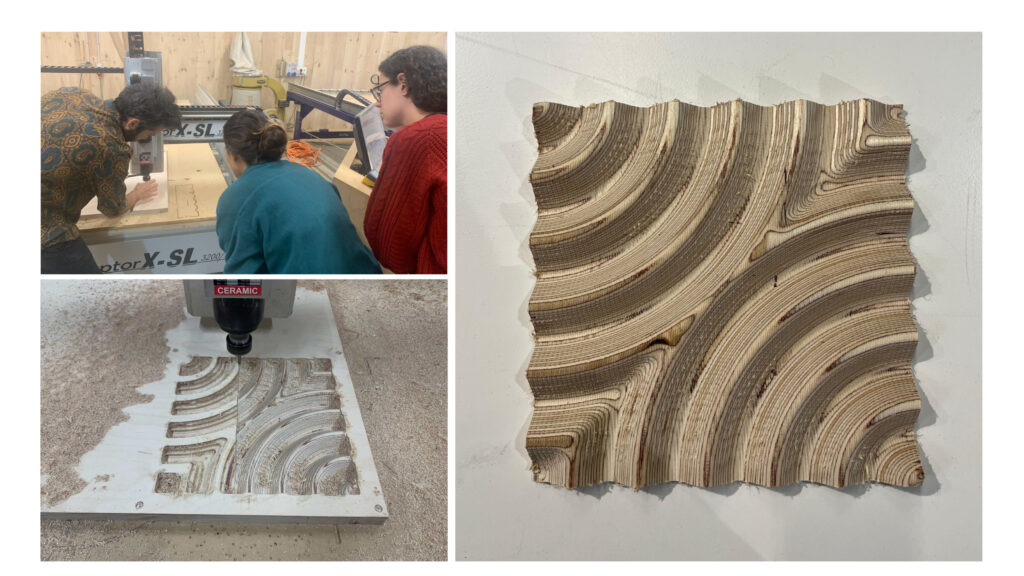

We explored easing the transition between flat surfaces and organic waves, focusing on how a CNC mill manages the flat areas. The resulting piece turned out imperfect due to the wood’s characteristics, but this exploration allowed us to push past design concerns and truly understand the capabilities of the machine.

PROTOTYPING

First Prototype

Final Piece

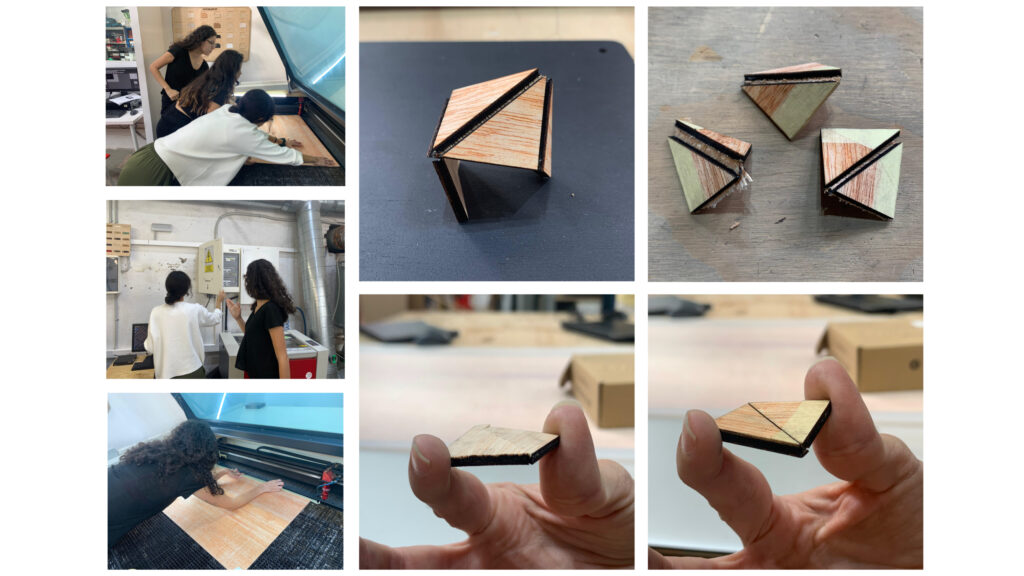

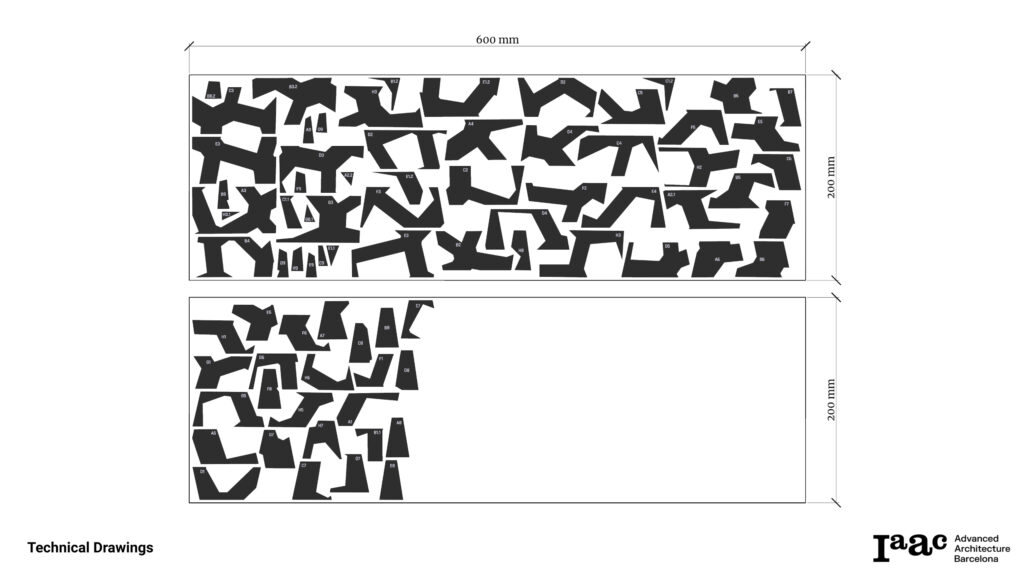

LASER CUTTING

REFERENCES

For our laser-cutting project, we started by testing ways to fold 4mm plywood, pushing our limits with a material not easily bent. Following our professor’s advice, we switched to mesh fabric to join the pieces, but its softness couldn’t fully support the structure. After pushing the limits through multiple prototypes, testing different starting points—beginning from the base, connecting the strips first, etc — and exploring both fabric and taped configurations, we completed half of the structure due to limited time frame.

PROTOYPING

Exploring Different Folds

First Prototype

Second Prototype

Final Piece

FINAL GEOMETRY

THE CABIN