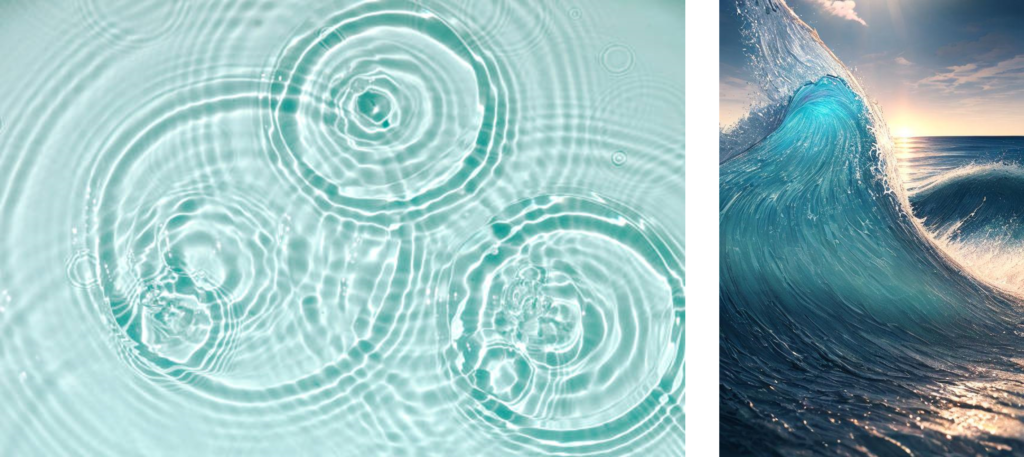

The underlying theme that drove the designs for this seminar was “flow”. Inspired by the flowing movements of water in particular, our forms were developed from ripples, waves, and whirlpools.

Laser Cutting | Tessellations 3D Printing | Droplets CNC | The Twist

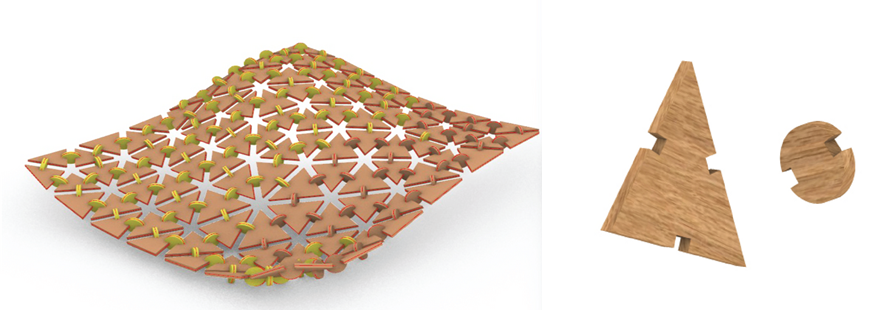

Laser Cutting | Tessellations

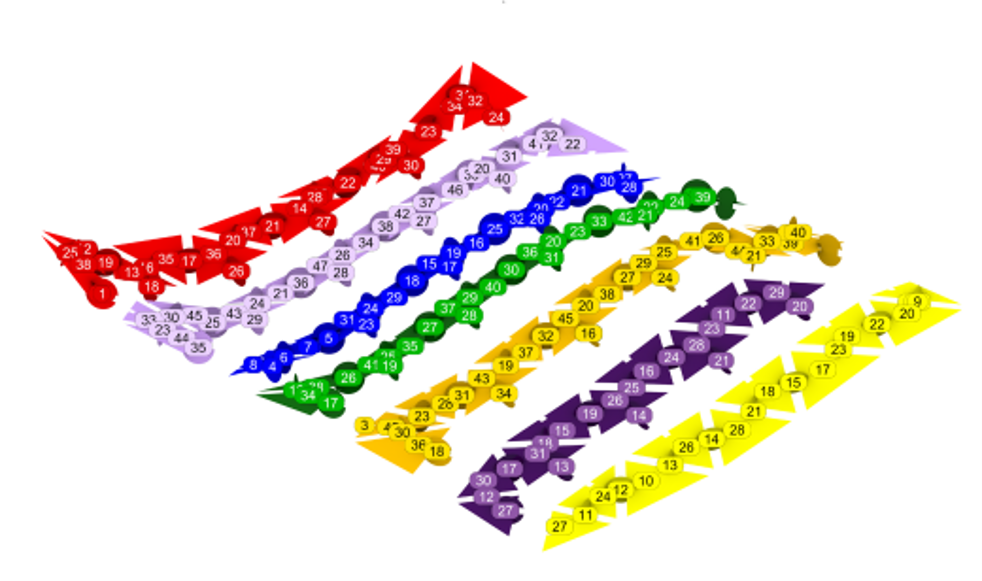

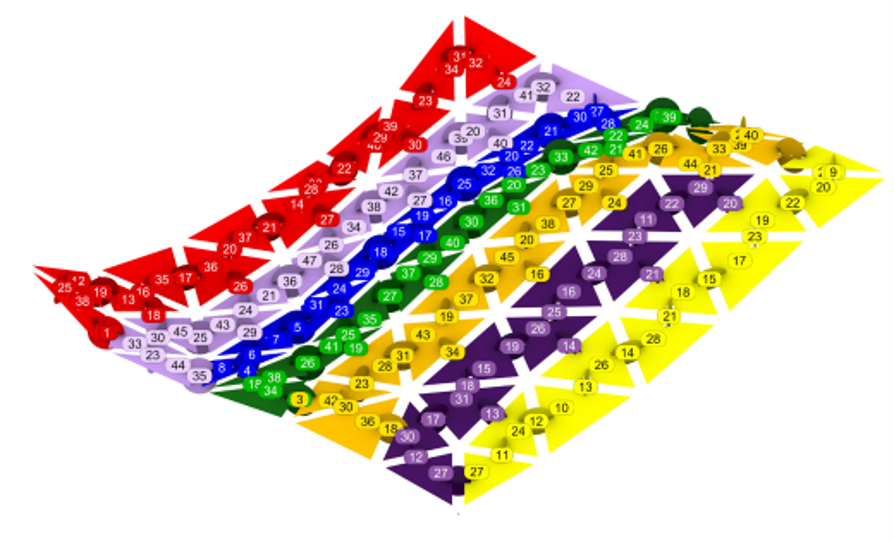

A simple tessellated surface with small gaps in between panels can allow for a dynamic surface that twists and bends in numerous directions.

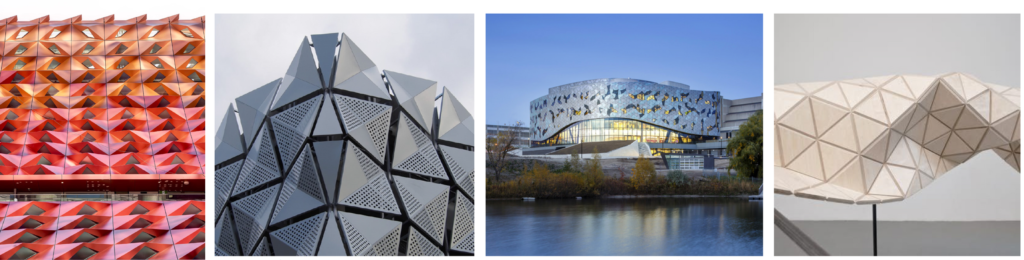

CONCEPT AND REFERENCES:

PHIVE Civic Center University of Leeds MSCP -SCC Design ZAS Architects – The Bergen Center for Engineering Mammafotogramma – WoodSkin

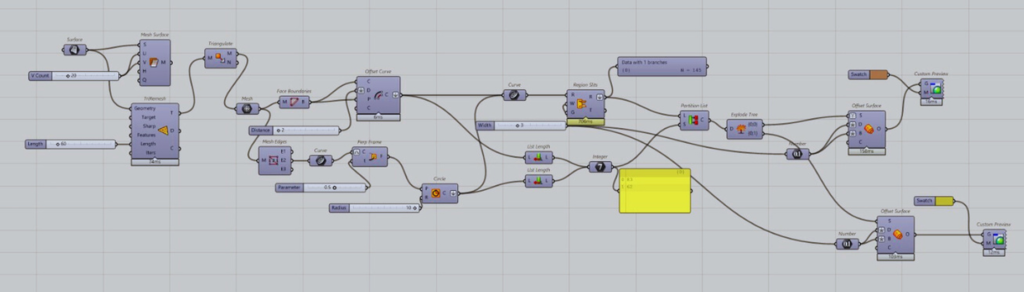

Laser cutters offer a multitude of enticing prospects for creative expression. Within the realm of fabrication, one particularly intriguing method involves the application of tessellations. This process has the remarkable capability of transmuting two-dimensional materials into elegantly flexible and undulating surfaces, which can then be skillfully manipulated to yield doubly curved forms. The artful utilization of tessellations ushers in a realm of limitless design opportunities, exemplifying precision and sophistication in fabrication.

PROCESSES :

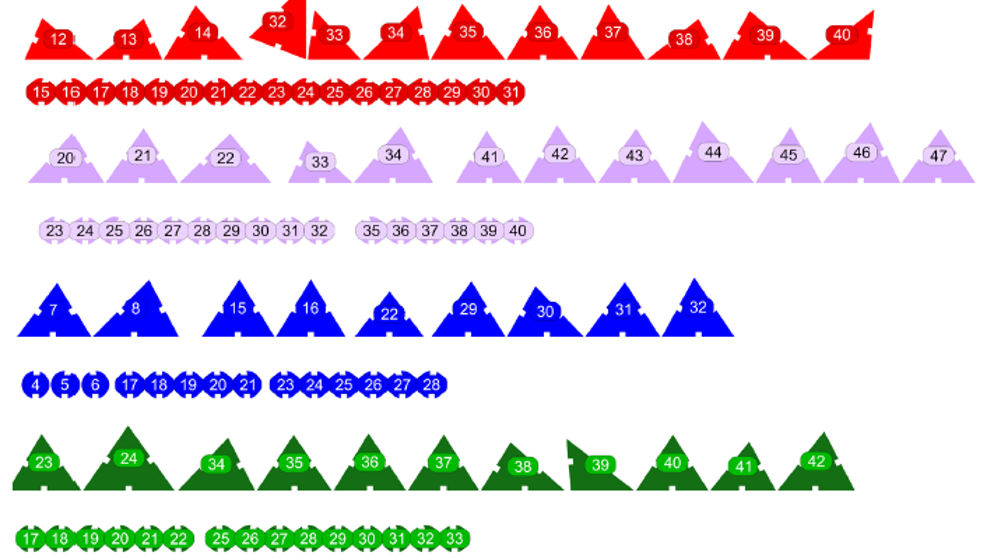

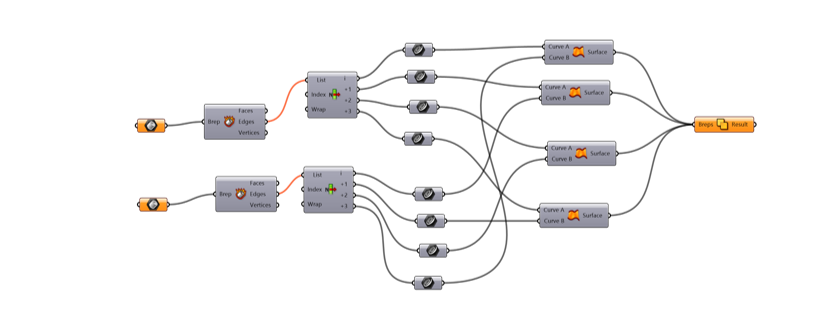

To initiate the fabrication process, the surface was initially partitioned into seven distinct strips. Each of these strips incorporated a combination of panels and biscuits, with the biscuits seamlessly linking to the strip immediately below. Following this, all the components were meticulously unrolled and thoughtfully organized for precise laser-cutting.

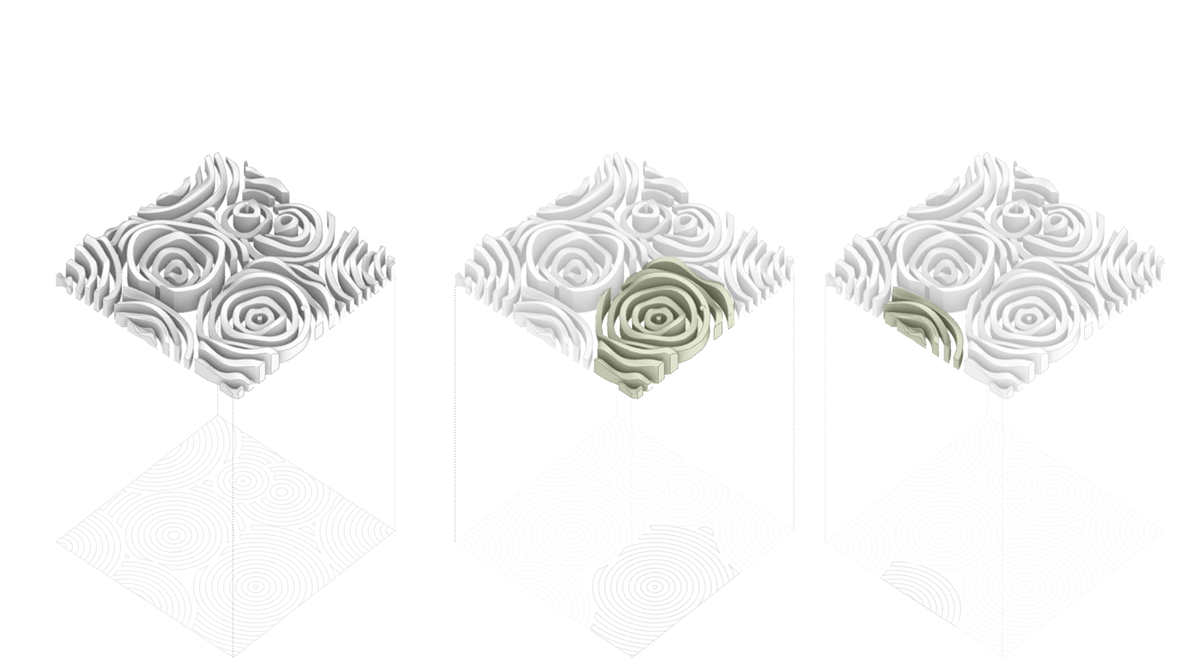

3D Printing | Droplets

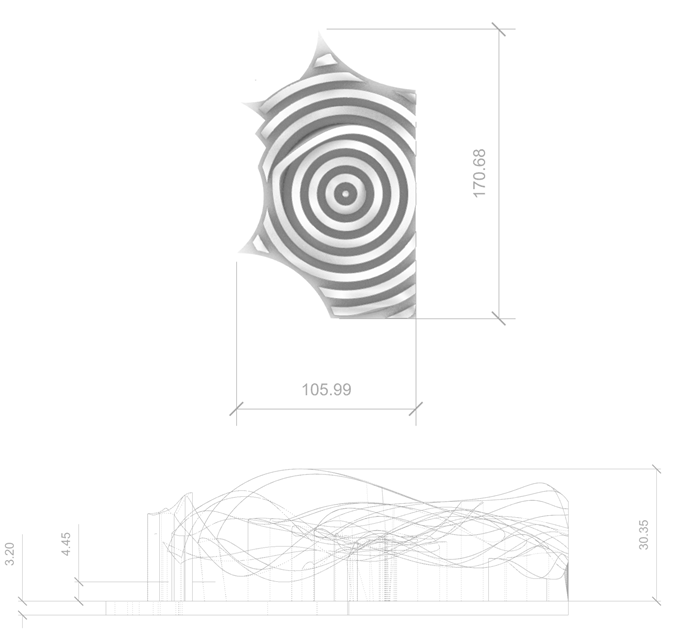

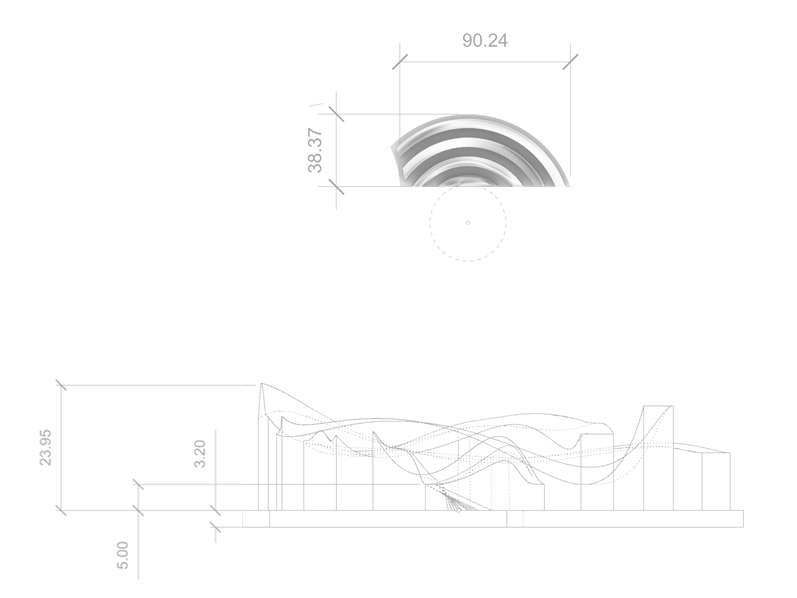

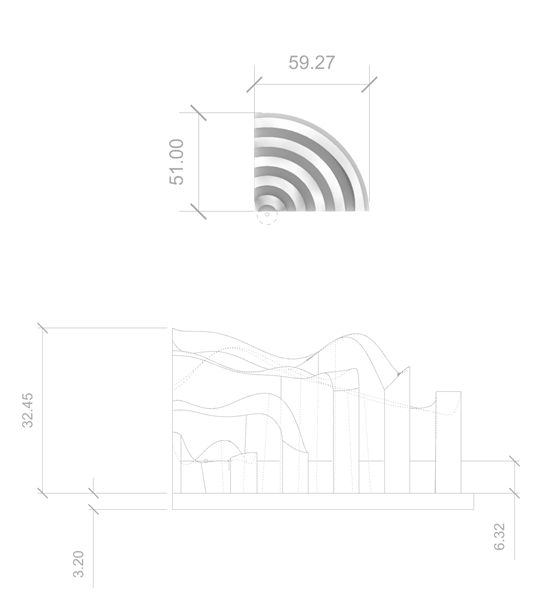

To use the curves formed by the movement in water; Ripple and Wave to create an effective 3D printed module for facade panel. The printing strategy was dividing the overall module into seven parts to prevent failure during the mass printing which could save printing time and material in case any failures occur.

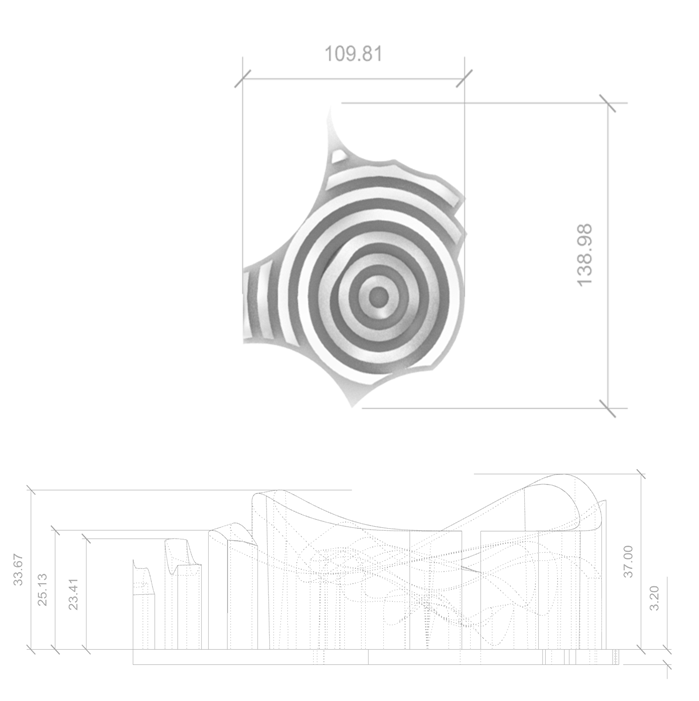

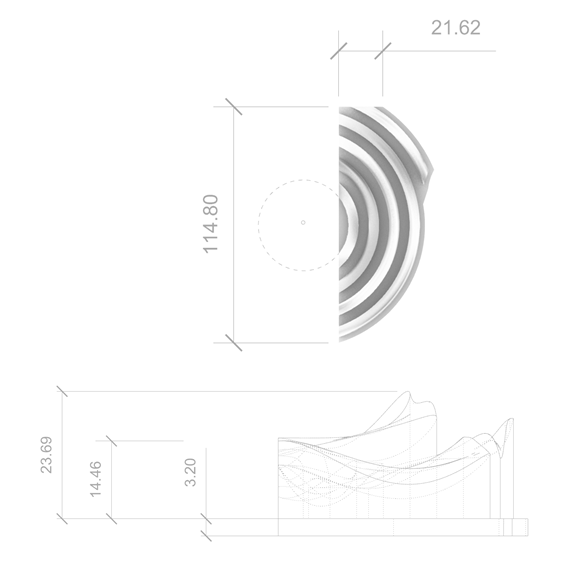

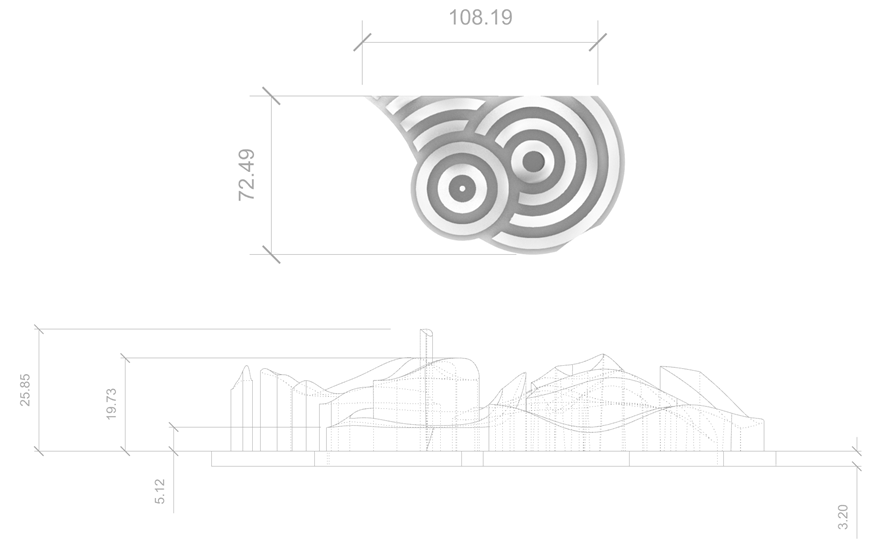

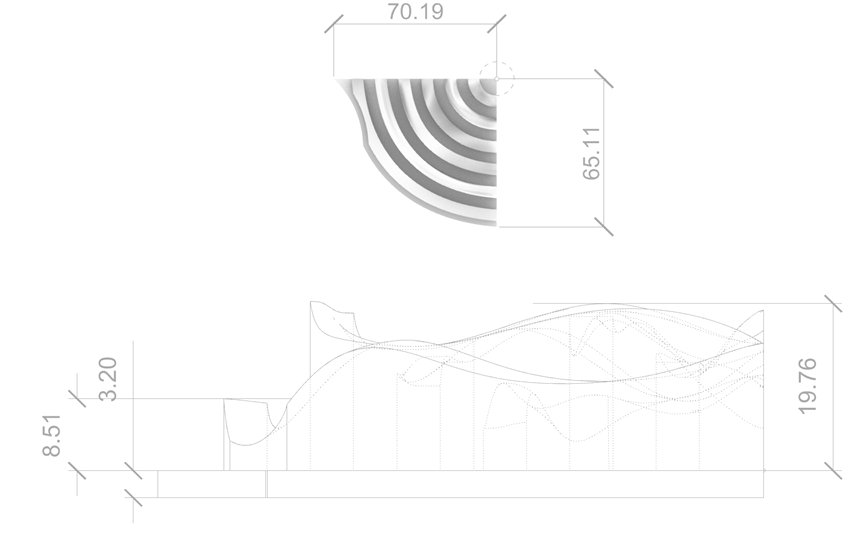

Technical Drawings

The dynamic manifestation of the ripple effect is intricately expressed through meticulously generated module heights, employing Grasshopper scripting for precise control. The deliberate randomness introduces an element of organic complexity, while the gradual descent in heights gracefully directs attention towards the central droplets.

The total printing time was roughly seven hours. However, several attempts were made over three days due to multiple issues with the printers. This led to multiple color variations of the components.

Droplets

The modules were sharing the exact same line of fabricating. However, the printing ability of the machines can cause an unprecisely edge finish. The solution is to print with a smaller nozzle but at the same time will increase the printing time and material use. Therefore, on a larger scale of the artwork, the connecting line could be seamlessly connected with the cooperation of another construction method.

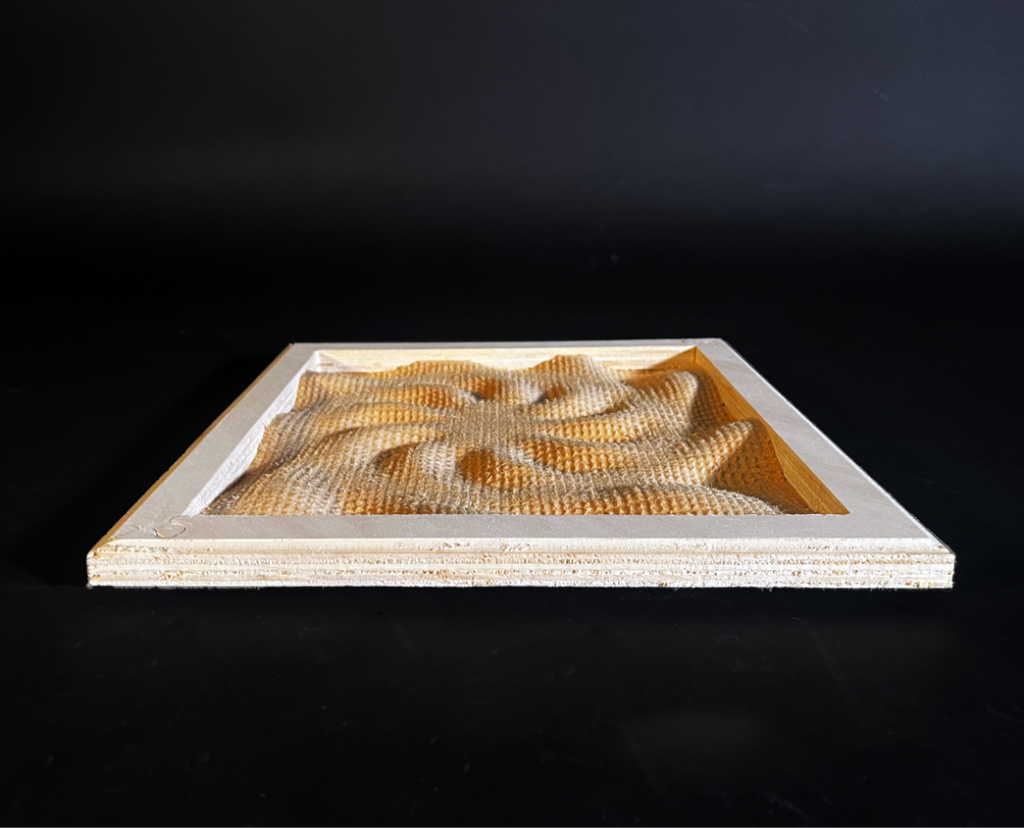

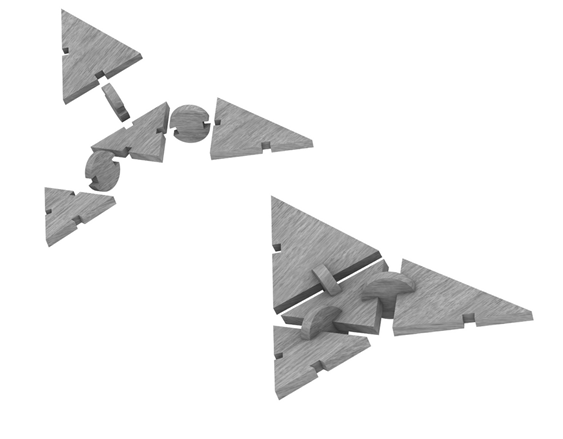

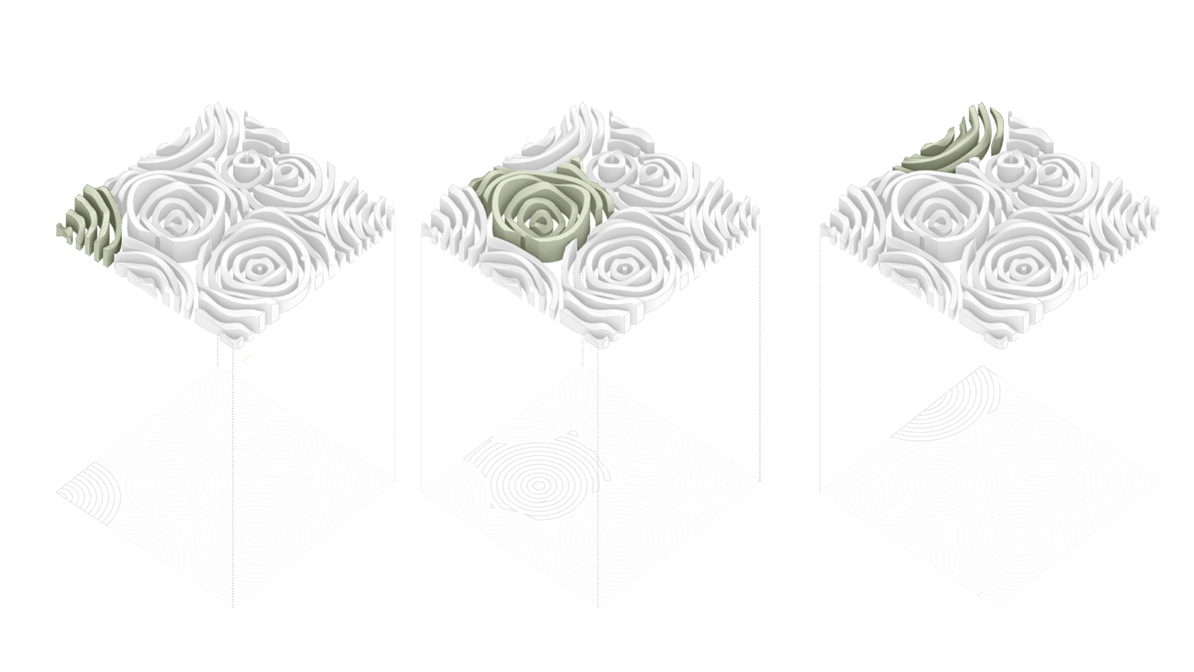

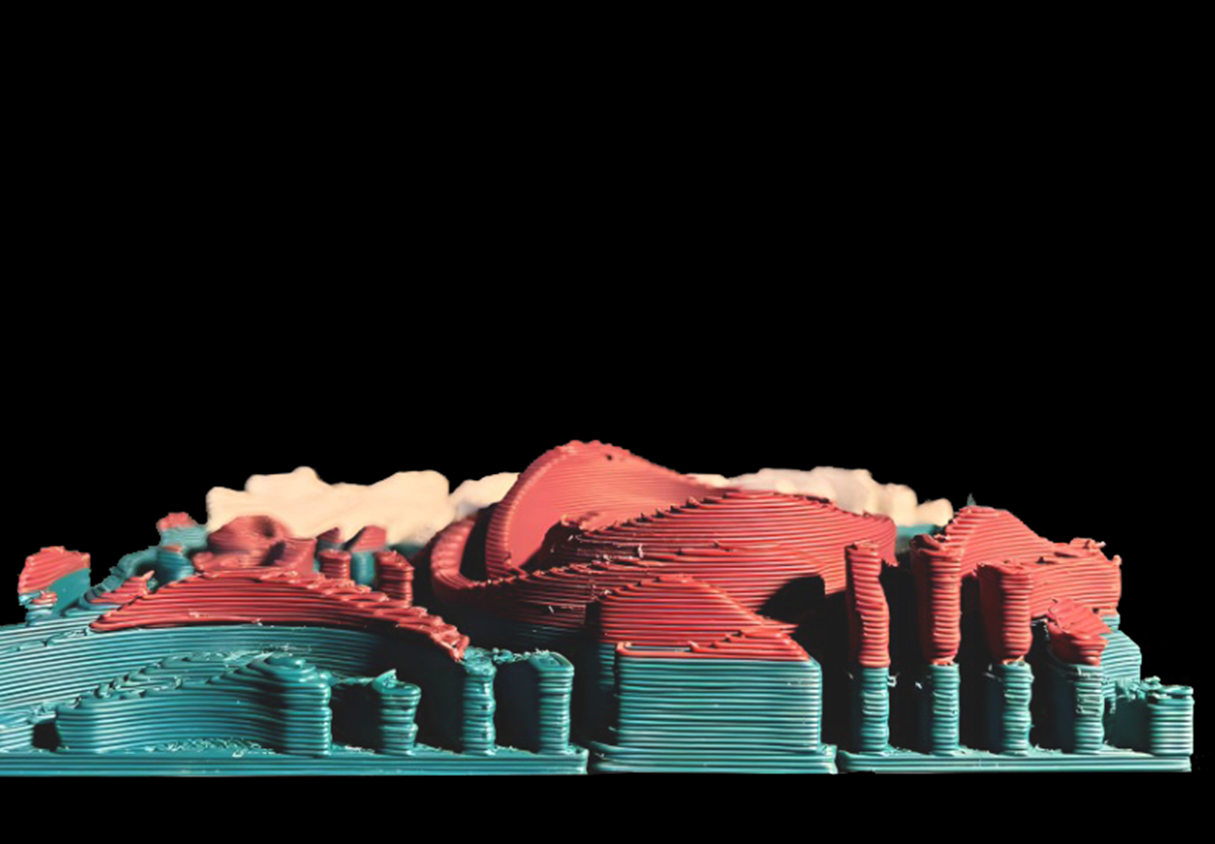

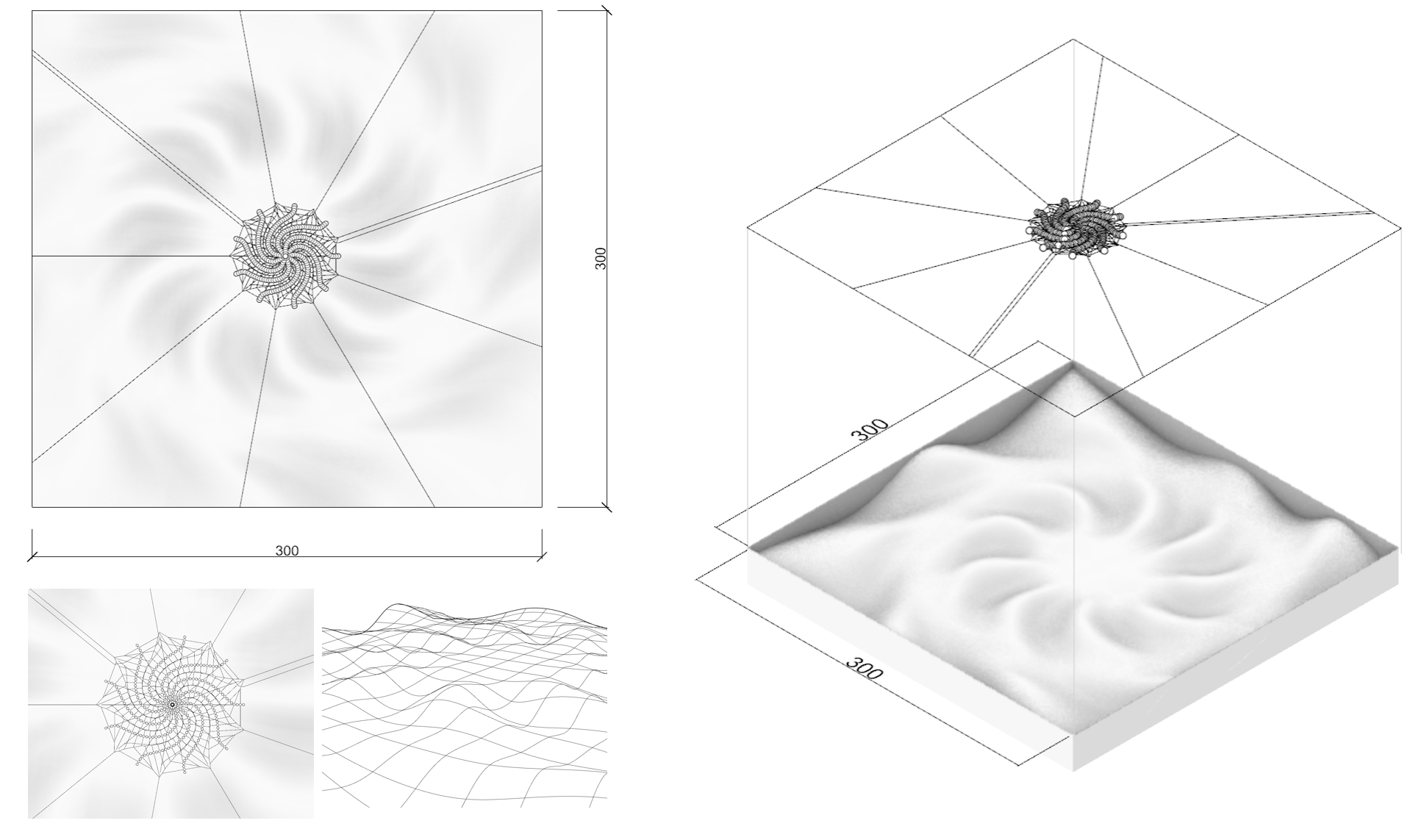

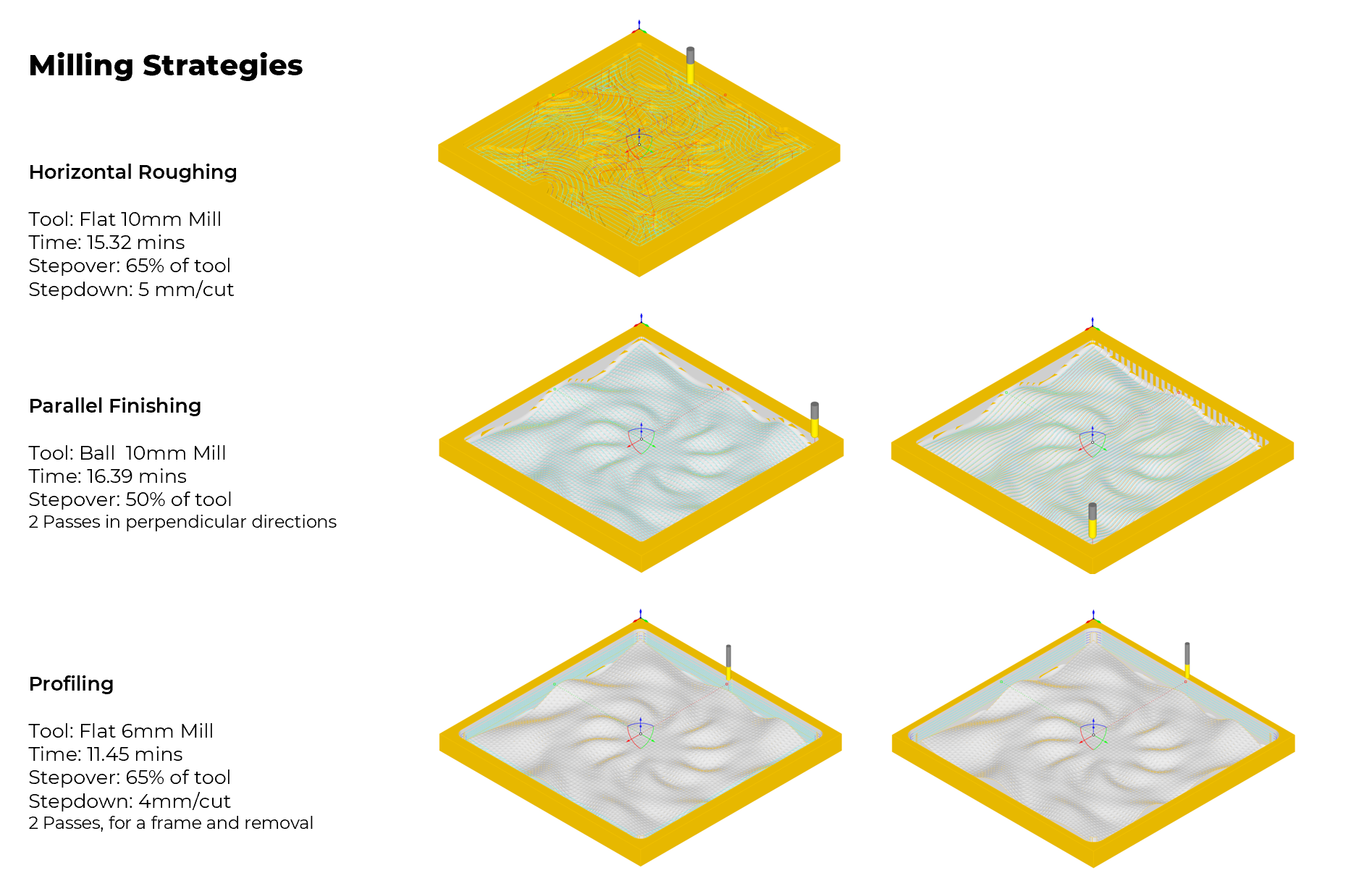

CNC | The Twist

Mesmerizing twist found in natural phenomena like whirlpools and the visionary designs of Antonio Gaudi. Through CNC milling, we transform the innate hardness of wood into a canvas for soft, swirling gestures.This fusion of organic movement and rigid materiality creates a visual symphony, encapsulating the grace within the wood’s inherent strength.

The entire process concluded within 45 minutes, producing a result marked by a scale-like texture, a consequence of the parallel finishing applied along both axes.