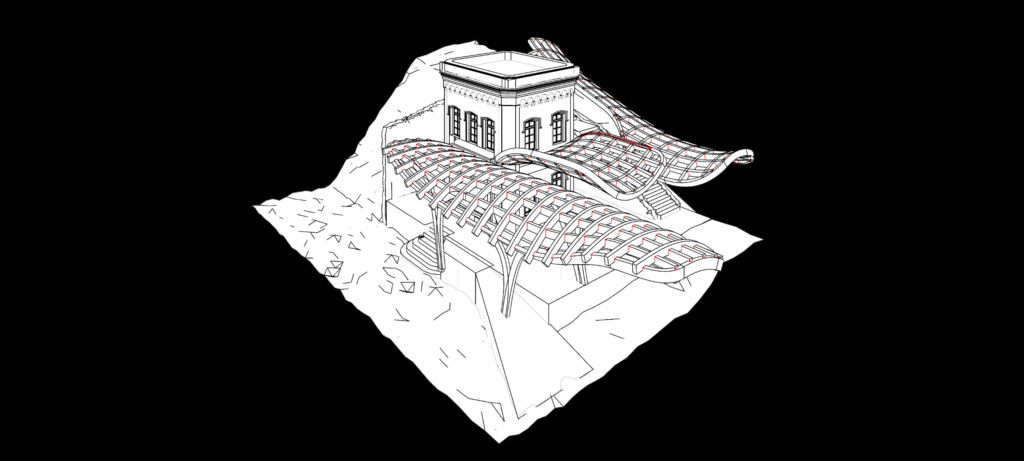

This term, we concentrated on learning new fabrication techniques. From our previous site, we selected the Keeper’s Lodge as the focus for reimagining with timber structures. Our goal was to design a structure that would envelop and enhance the existing Keeper’s Lodge.

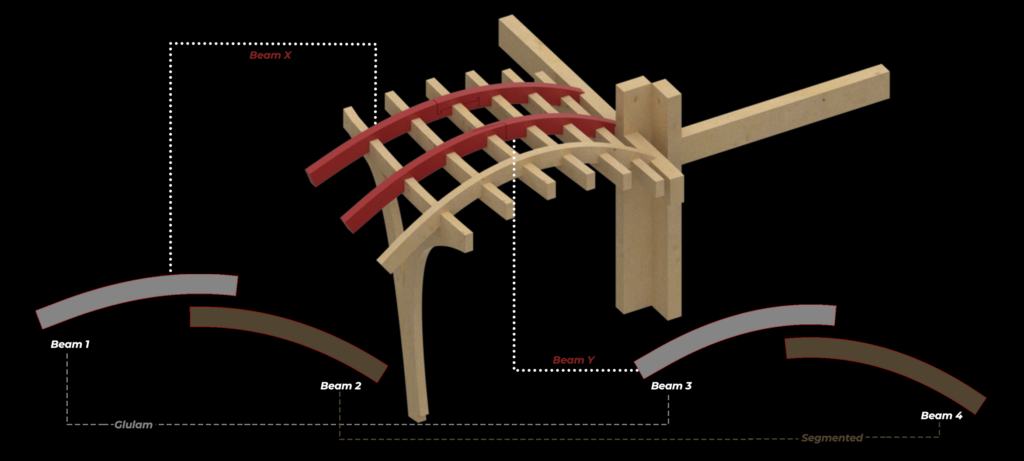

The section below was selected to be fabricated at a 1:2 scale. The model was divided into several components, which were further subdivided into clusters for each group. Our group focused on the beams highlighted in red.

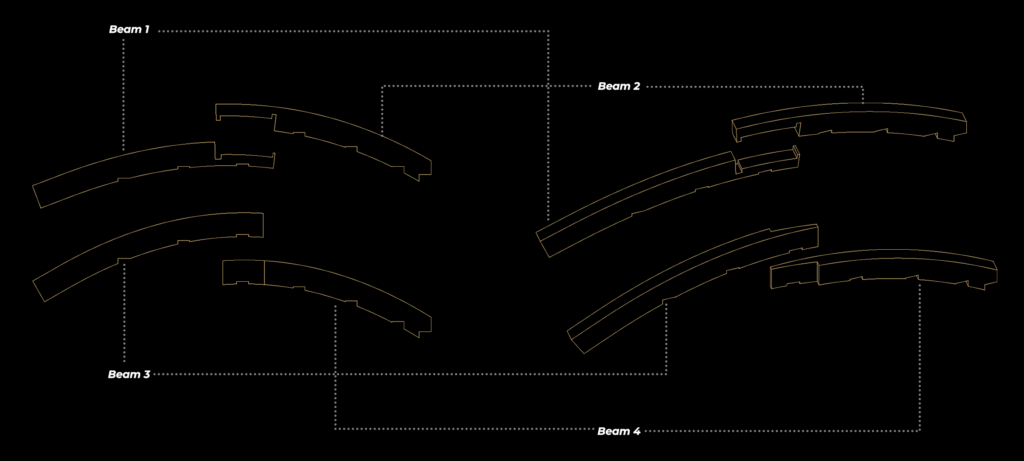

The two beams highlighted in red were intended to be fabricated in two parts and then joined together using joints, allowing us to learn the joinery details. Thus, there were a total of four beams. Out of these four beams, beam numbers 1 & 3 were fabricated using the glulam technique, while beam numbers 2 & 4 were constructed using segmented sections.

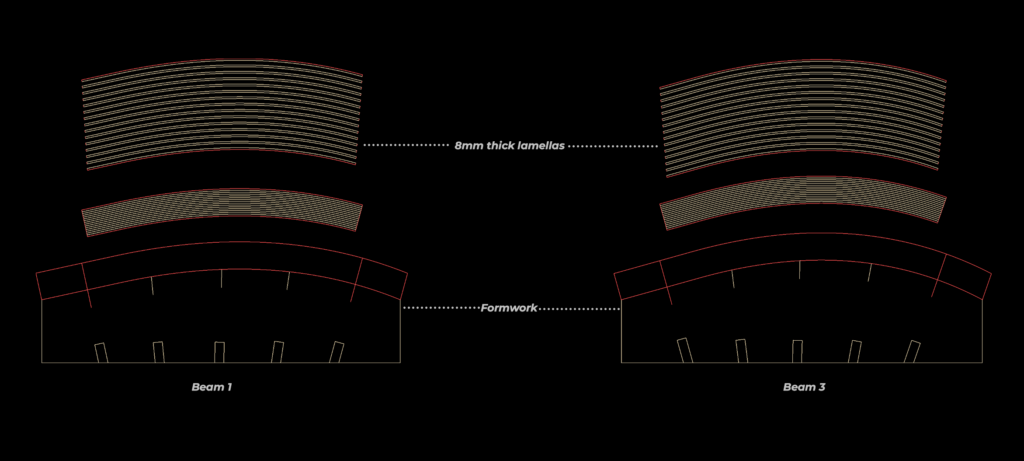

For the glulam technique, two formworks were created by cutting plywood boards using the CNC machine. For the beams, wood planks were cut into 8mm thick lamellas. These lamellas were stacked on the formwork with glue applied between each layer and secured in place using several clamps. In the spring weather, with an average temperature of 18 degrees Celsius and relative humidity of 55 percent, the beams took 1 hour to dry and were then ready for use.