Project by Saad Khan , Sai Mohan Satwik and Baran Koc

INTRODUCTION

Our group was assigned to study the TMDC building, focusing on its material composition, spatial qualities, and potential for on-site material reuse. The goal is to explore how the existing structure can become a source for recycled construction materials, which we would then use to design a social housing project built primarily from what we mine and repurpose on-site.

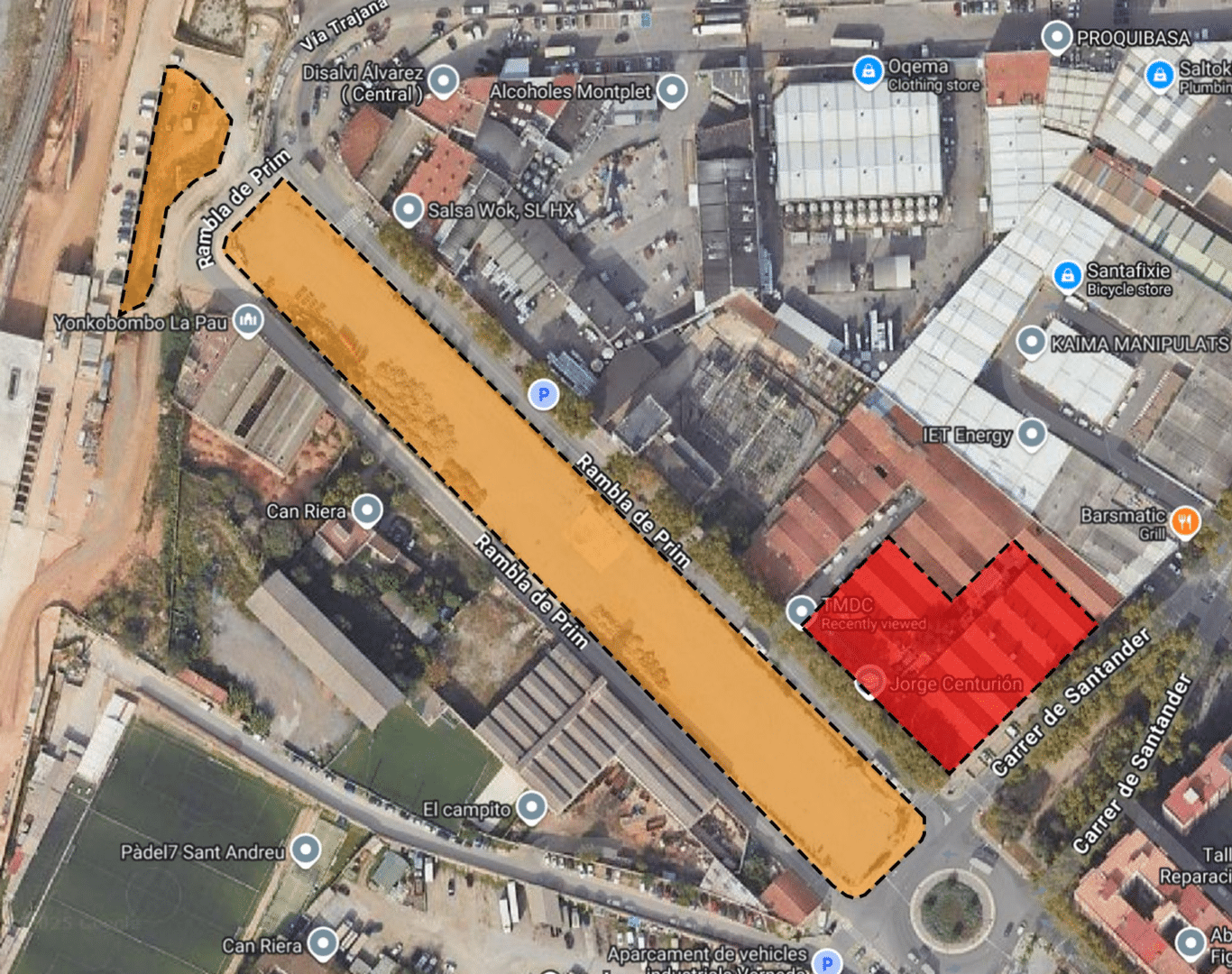

TMDC SITE

TMDC is located at Rambla del Prim, Sant Martí 08020, Barcelona. Right now, it works as a prefabrication warehouse, where different things are made—like furniture, art pieces, and other custom designs. This makes it a good place to look for materials that can be reused or even reworked for new construction. These warehouse units are typically used for industrial storage and logistics. Inside, we found mostly empty spaces, storage sections, and in this specific unit. Colored in yellow, are the two sites from where additional materials can be mined and used. The prime amount of material mined is clay. However, those two sites were no longer of any use to us as it would move away from the idea of utilizing the mined materials from the site as efficiently as possible.

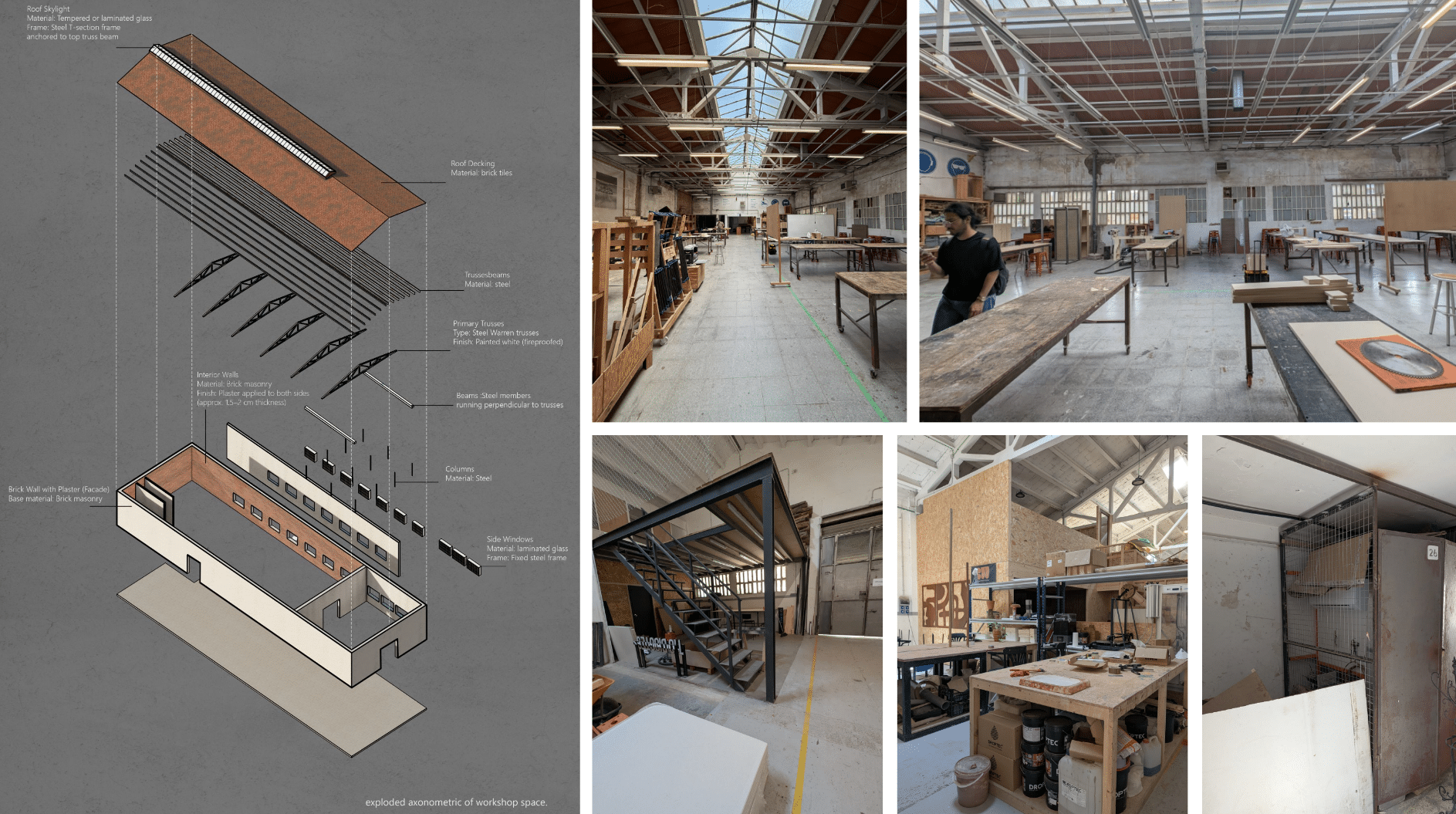

All TMDC warehouse units generally follow the same structural dimensions and typology. The basic structure includes brick walls with a frame system of columns and beams. Trusses span the roof, creating a sloped form, which is finished with roof tiles. However, during our site visit, we observed one unique feature: a mezzanine floor supported by additional columns. These columns vary slightly in height and dimension compared to the primary ones, adapting to support the secondary floor used as an office. We also visited other warehouse units in the area to identify and quantify reusable materials. We cataloged the available resources, including bricks, roof tiles, trusses, and steel elements—materials that we plan to reuse for the new social housing proposal.

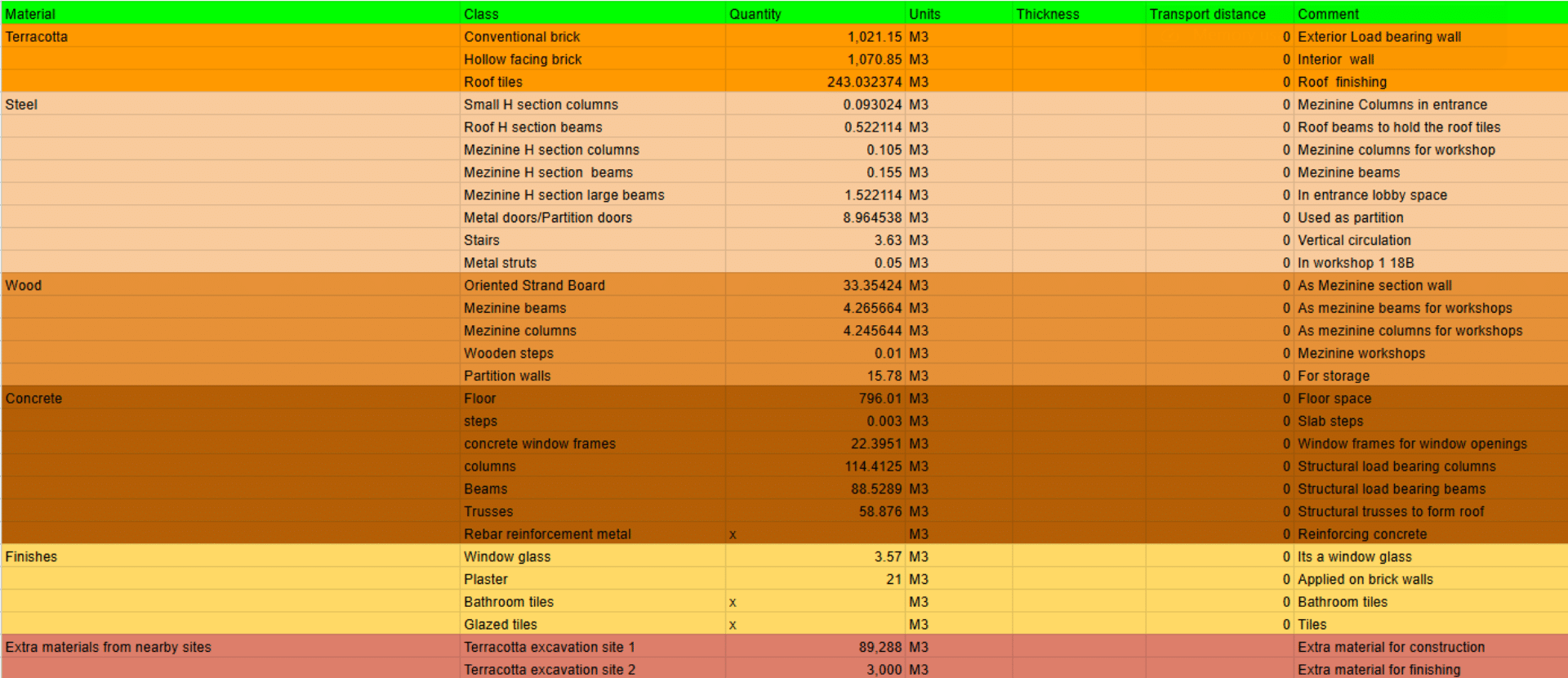

PRESENT QUANTITY OF MATERIALS FROM TMDC

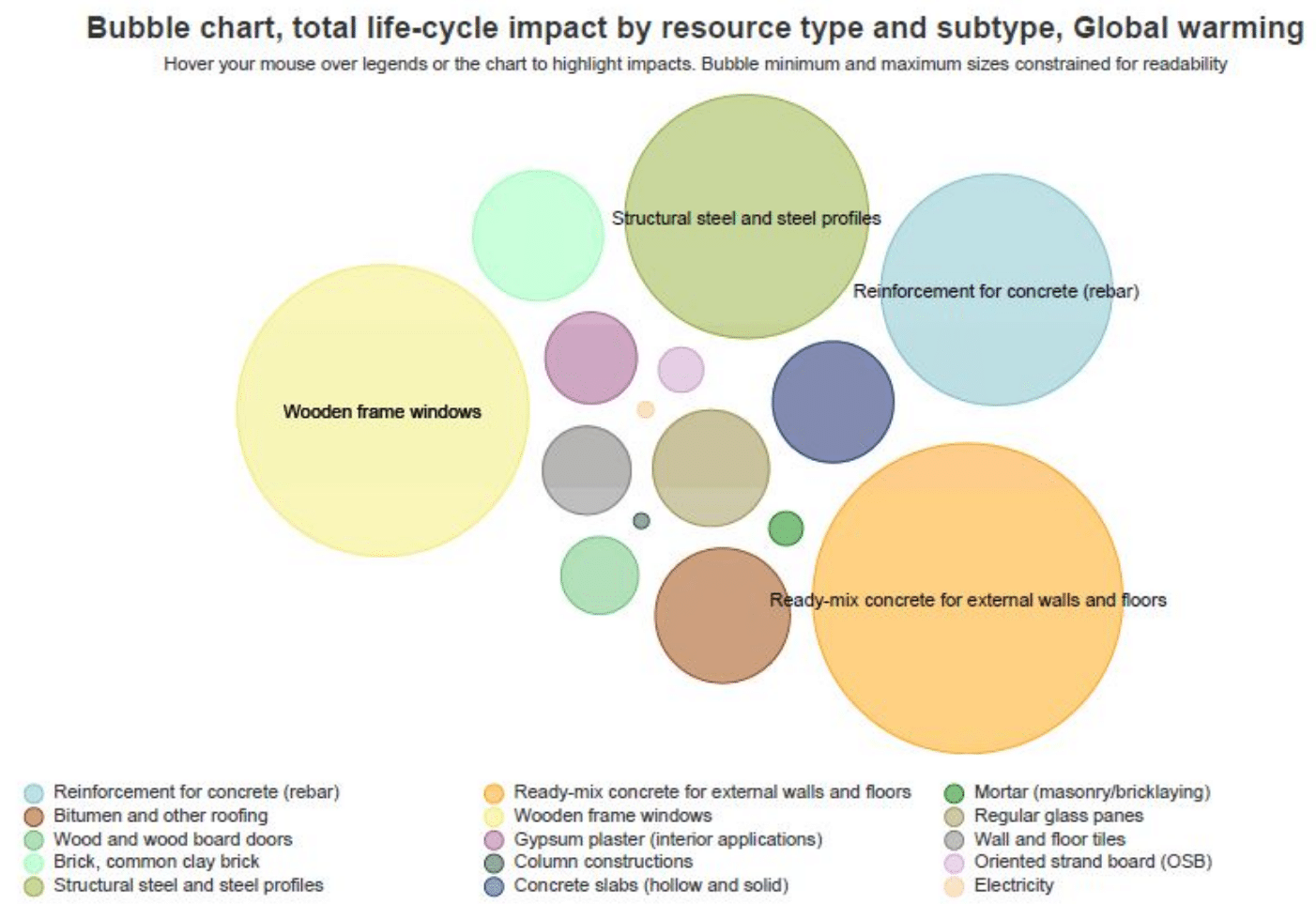

Materials mined show potential to be recycled and reused as well as may be repurposed to be part of the new structure. TMDC Building emits approximately 650–675 tonnes of embodied CO₂e

BUTTERFLY DIAGRAM FOR REUSE MATERIALS

This diagram shows how we can reduce the carbon emissions of a building by reusing materials through two main cycles: the biological cycle and the technical cycle. The biological cycle includes natural materials like bricks and wood, which can be reused, refurbished, or broken down and used again in different ways. The technical cycle includes industrial materials like steel and truss beams, which can be reused, repaired, or recycled into new products. A key step in both cycles is segregation—keeping materials separated during demolition or renovation so they don’t get contaminated and can be reused properly. By following these two cycles, we reduce waste, save resources, and create a low-carbon building that is much more sustainable. Also, forgot to mention this, while we are allowed to not only mine materials from the site, the project has some flexibility, allowing to import materials from outside site, keeping in min the energy used for transport.

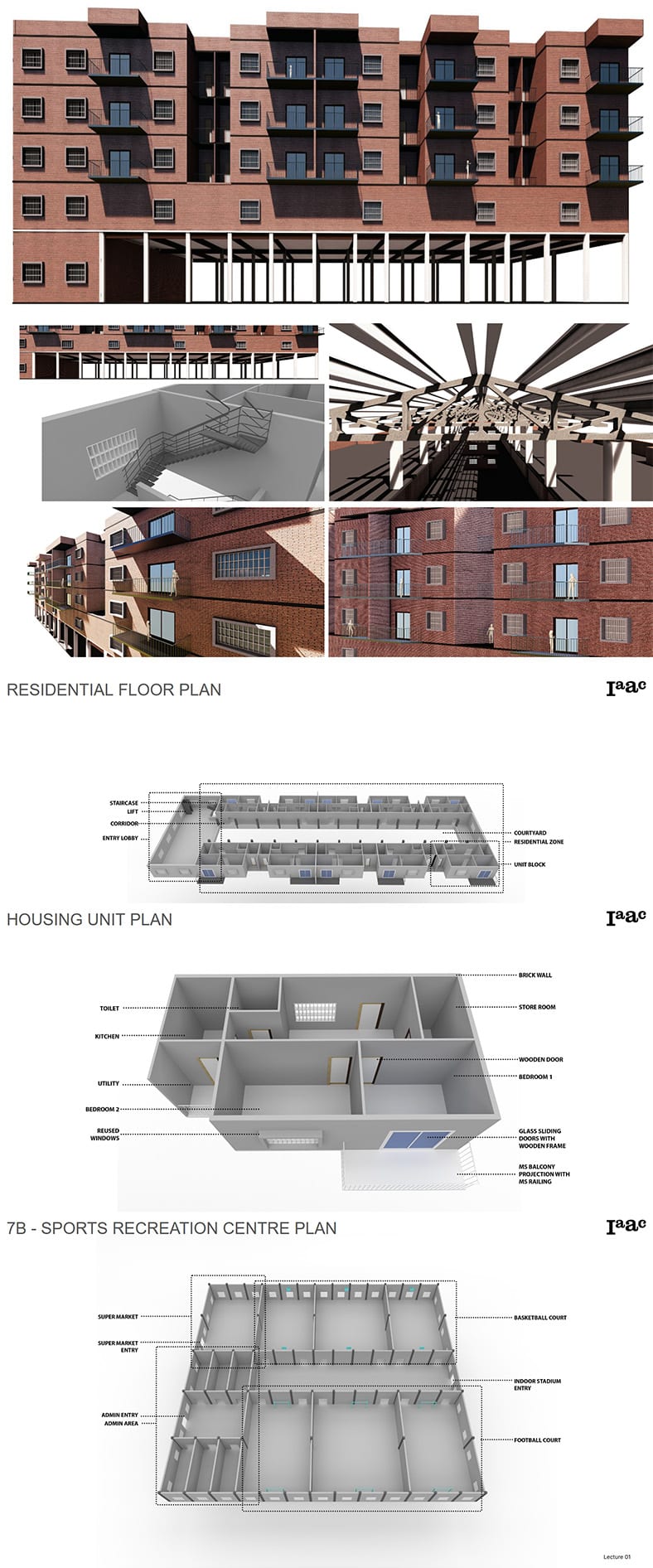

THE SOCIAL HOUSING PROJECT

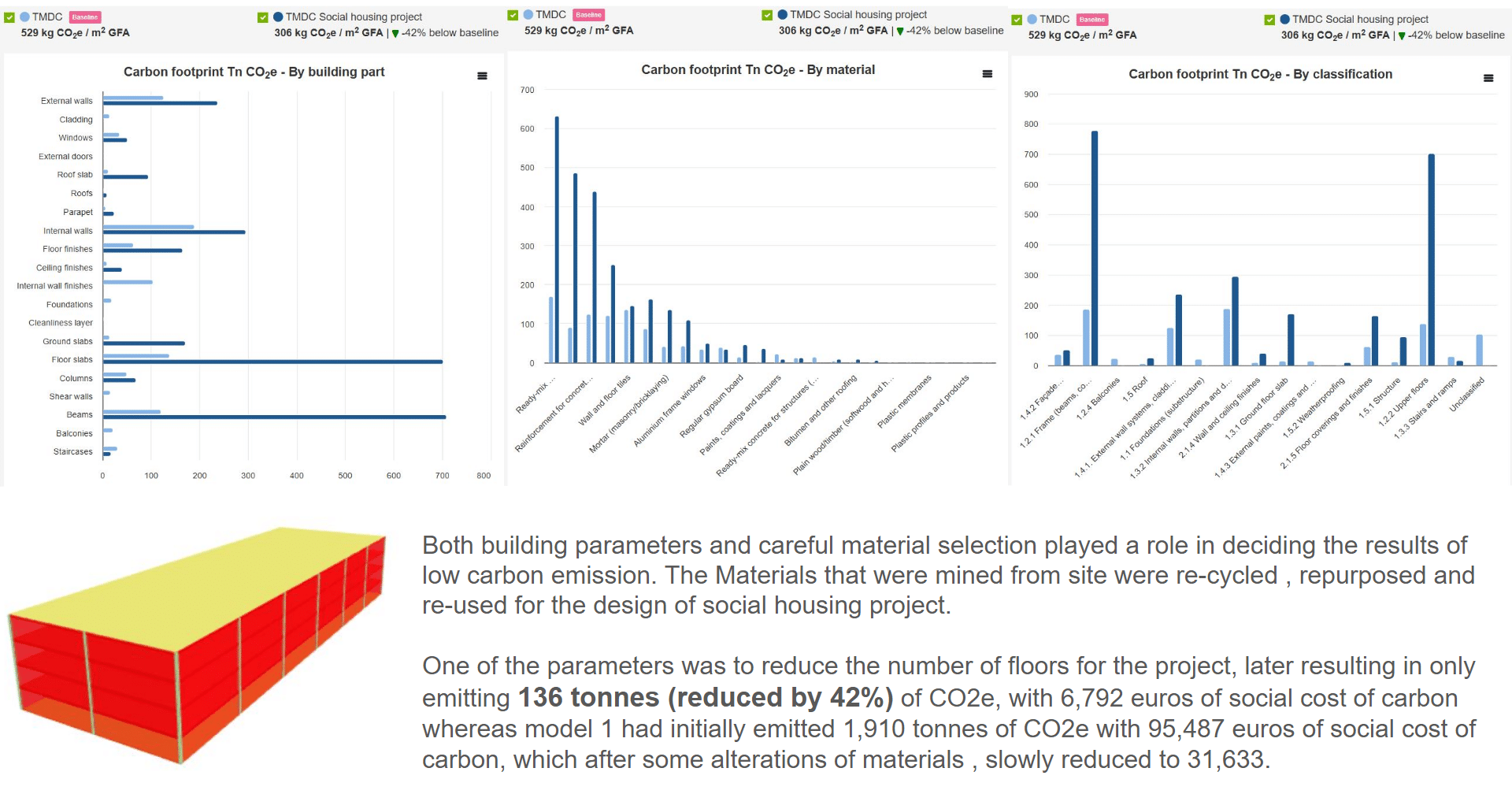

After making careful studies of the building from its structural form and the materials used, we were given the opportunity to use a website software called LCA one click, which calculates the carbon dioxide emissions emitted from the building materials based on the quantitative use in the following quantity values such as kg, m2, m3 etc. The requirements of the project was to design a building or intervention that reduces carbon emissions by reusing and recycling materials. We’re expected to think in terms of circular economy principles—like separating materials during demolition, choosing low-carbon or reused materials, and creating systems that allow parts of the building to be reused again in the future.

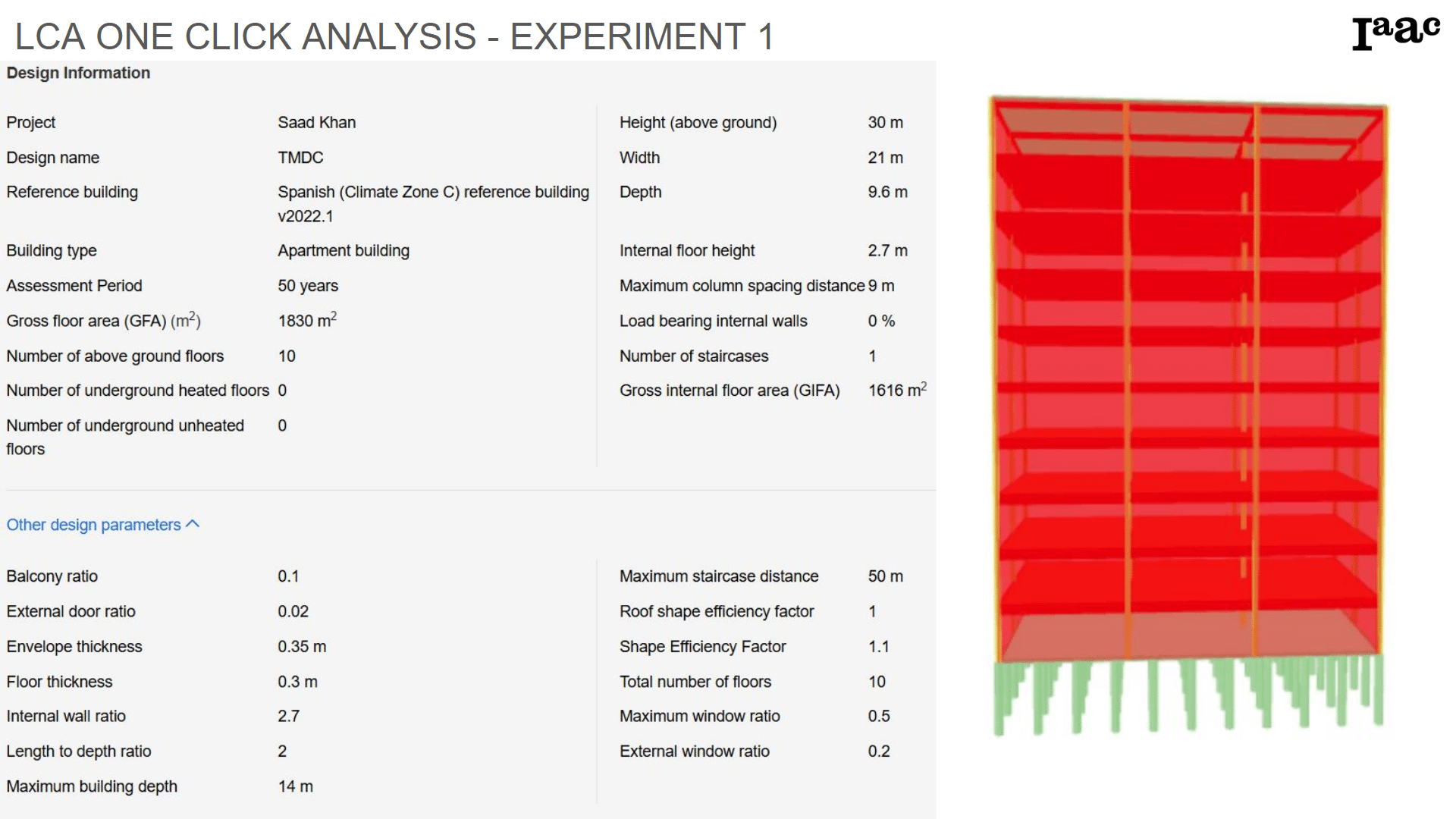

LCA ONE CLICK ANALYSIS – EXPERIMENT 1

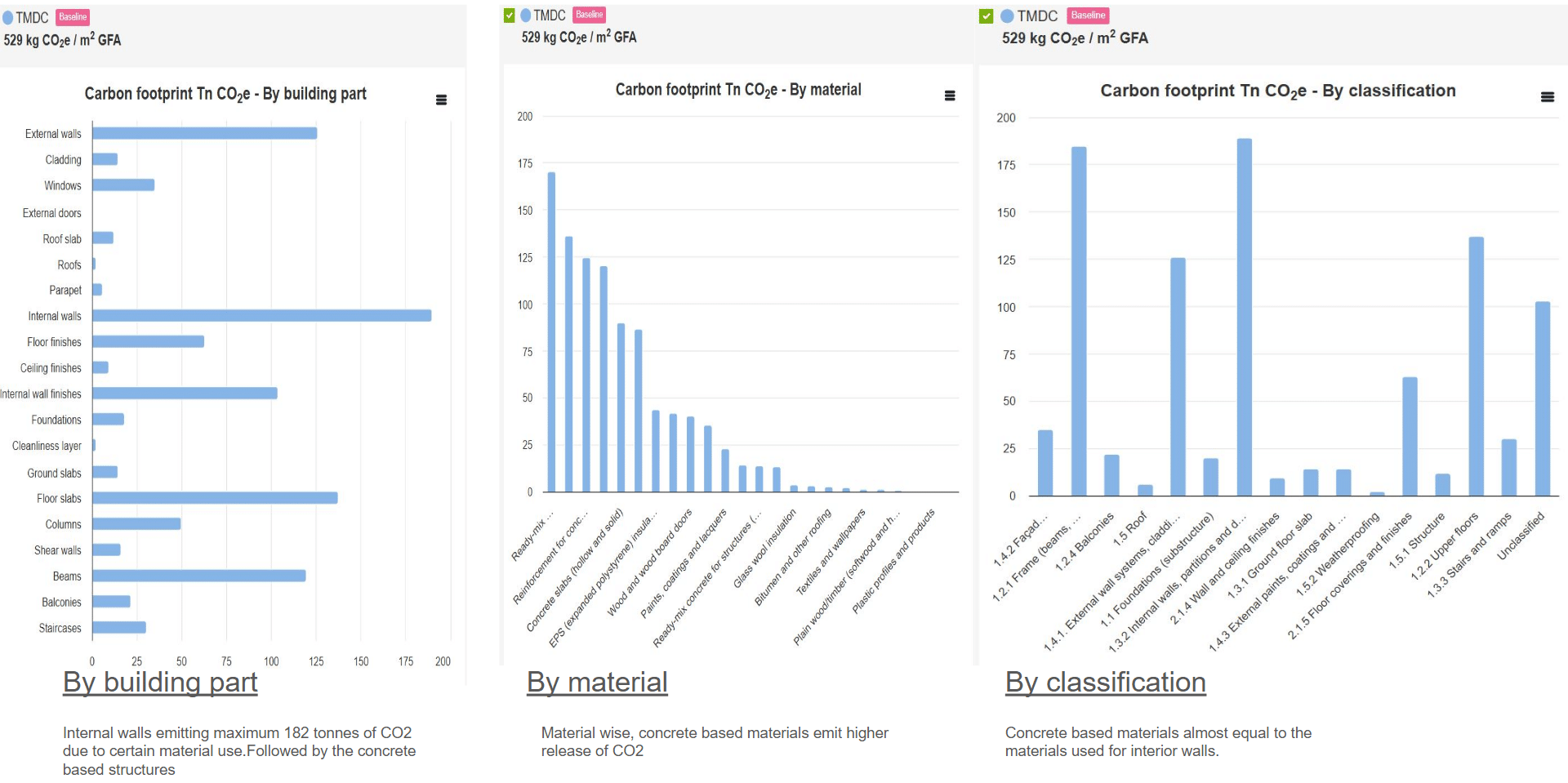

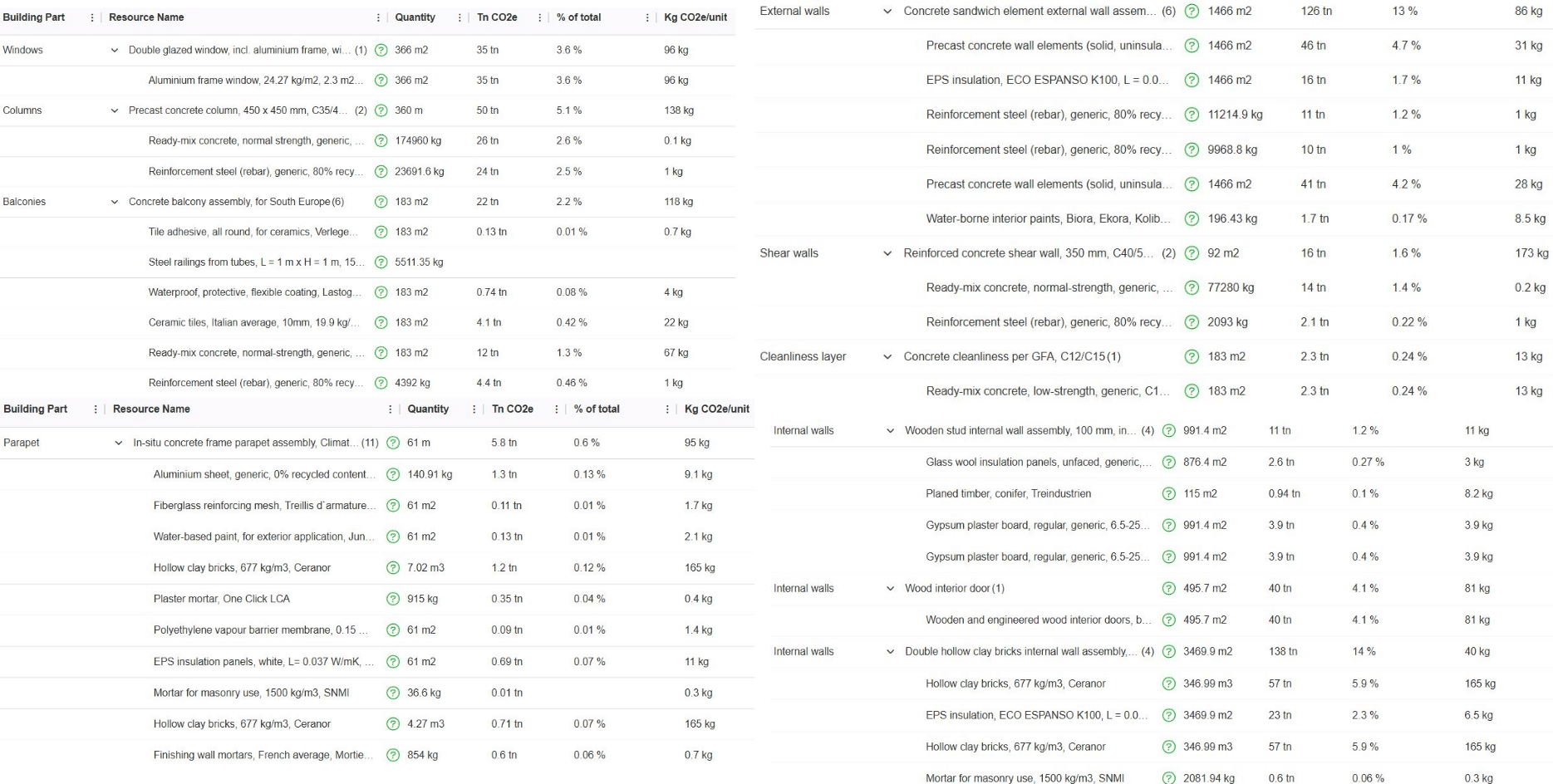

We started off with designing the project with the max. number of floors, 10. From there we not only used the mined materials , but also imported from manufacturers and factories. When selecting from a list of materials provided from the website software, we would check the carbon emissions value and the country it was produced from. It was stressed to use mostly local materials ( made in Spain) , however, it was allowed to import from neighboring countries such as Italy and France.

After application of materials and designing a carbon 3D model, the initial carbon emissions were 1 910 Tonnes CO2e with 95 487 € Social cost of carbon , more than the initial amount of the original building. Further tests were done, reducing the amount of materials to be used, which reduced 18% of the original carbon emissions.

LCA ONE CLICK ANALYSIS – EXPERIMENT 2

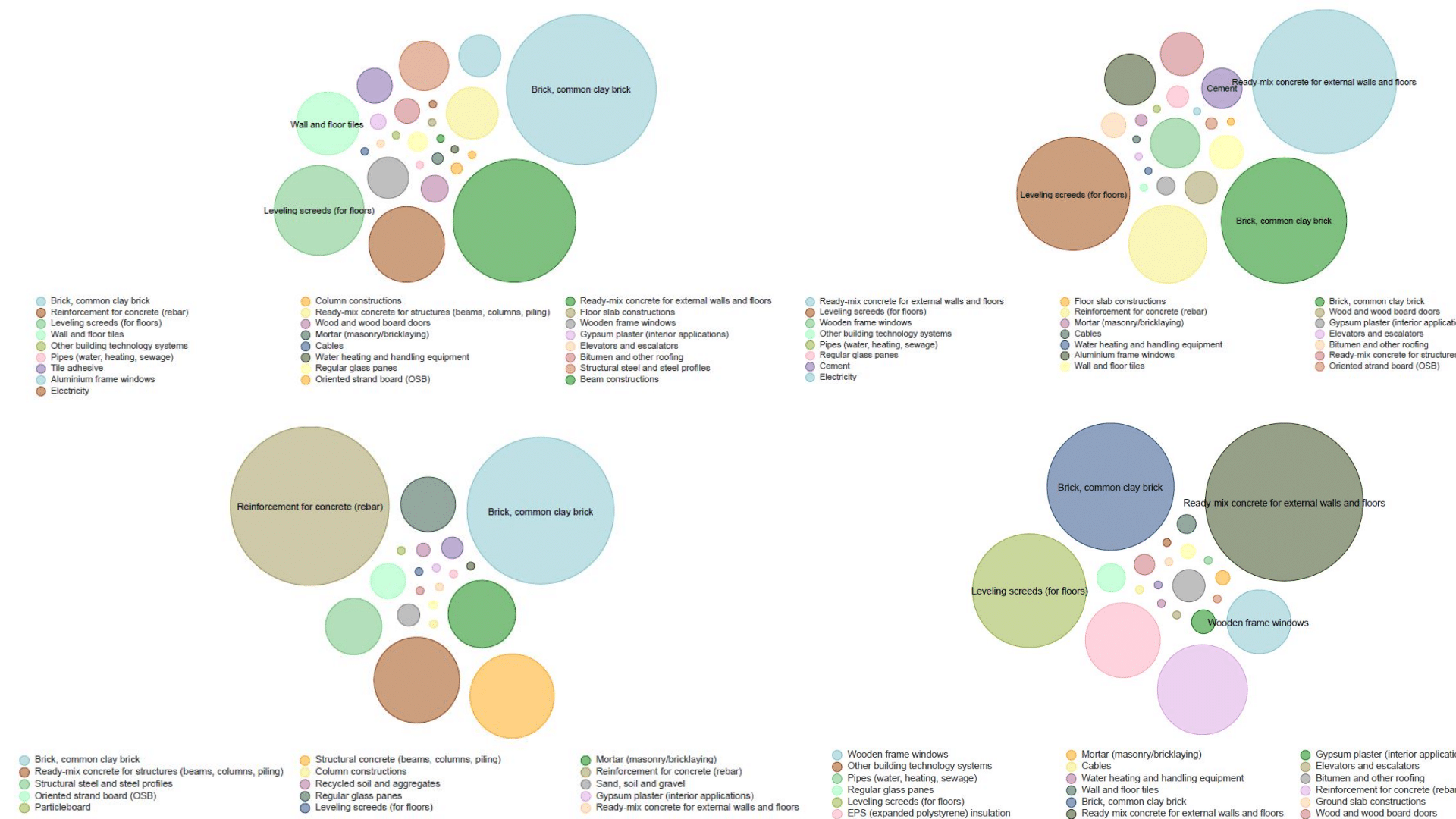

The main aim was to reduce the building carbon emissions to 50%. Drastic measures had to be taken by reducing the floor space from 10 to 4-5 floors. We theorized that the carbon emissions can be reduced floor wise as certain amount of emissions can be emitted per floor with the amount of materials used. We studied that most of the carbon emissions are produced from Cement and concrete based materials because of the production of clinkers, a desired element in concrete mixture. After reducing the floors, and re-using the materials into less carbon emission construction components ( mostly concrete such as precaste concrete and in situ concrete) we have managed to reduce the building’s carbon emissions by 42%, 136 tonnes (reduced by 42%) of CO2e, with 6,792 euros of social cost of carbon.

However, similar issues were faced. We attempted to reduce the amount of carbon max . as possible, the same materials, despite attempting to use recycle the materials and produce construction components being carbon friendly.

TMDC SOCIAL HOUSING AIMING FOR LOW CO2 EMISSIONS