l STUDIO BRIEF

The focus of this group was to design a space terminal on Mars.

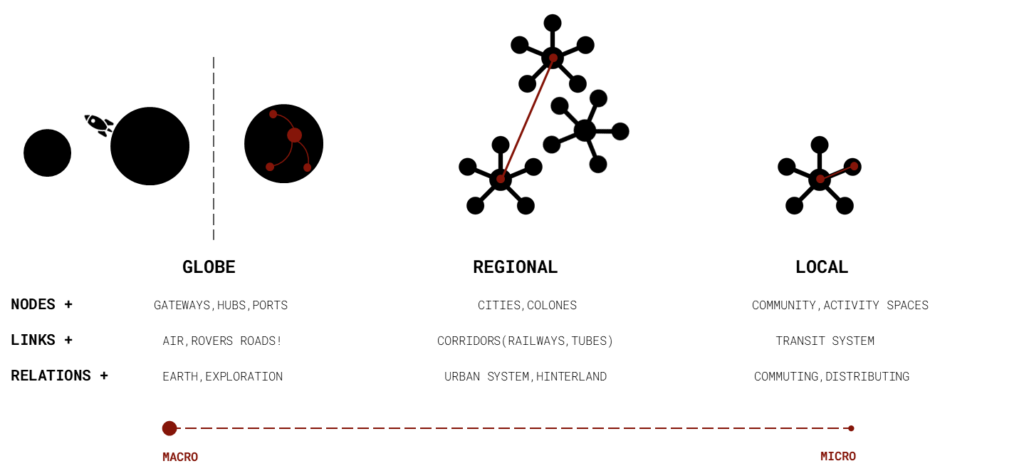

The scale of transportation can be global, regional and local. Space terminal falls into the global category with Terminal as a hub and launching/ landing pads as nodes.

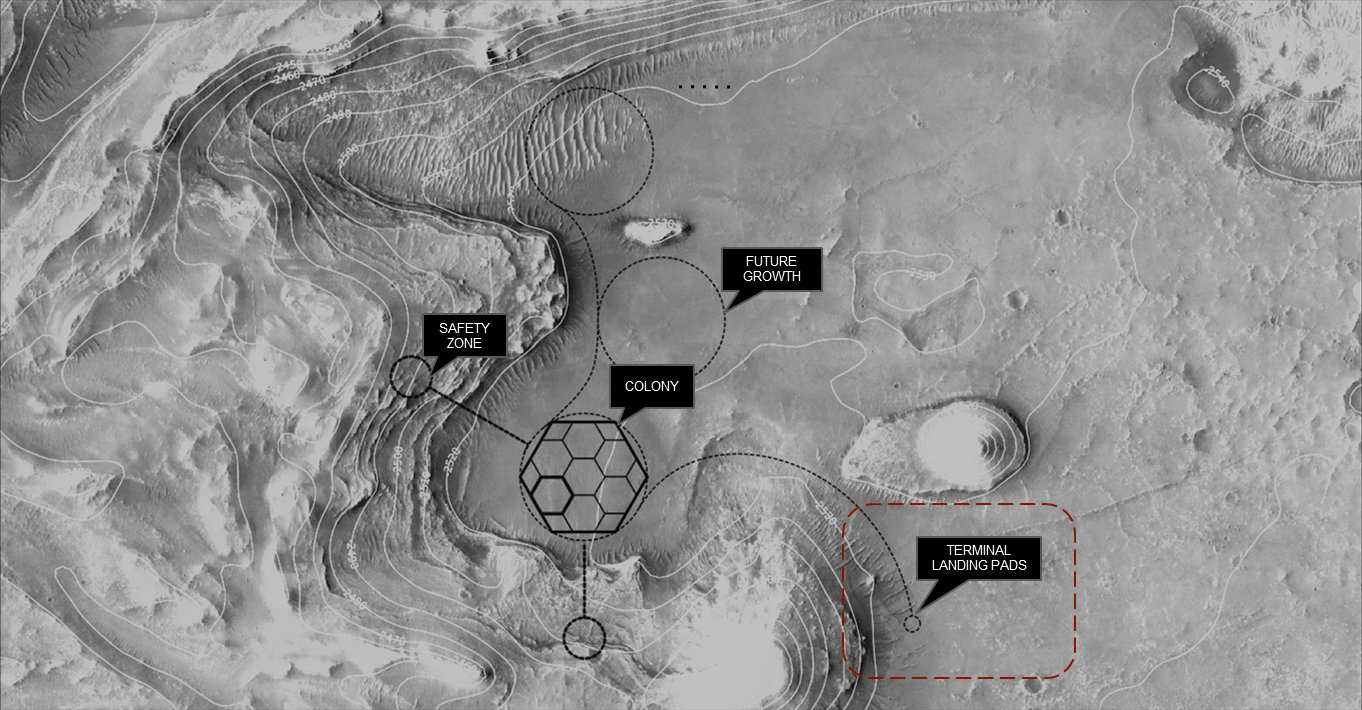

Masterplan: Following the hexagonal grid concept of the colony, A Main grid of 100m and a sub grid of 50m is made. The terminal is located in the middle and heavy lift landing pads 200m away from it. The cargo terminal is only 100m from the terminal and from heavy lift landing pads and 50m apart from each other. A monorail connects the terminal with the human settlement. The main terminal is connected landing/ launching pads.

Terminal: Inside the terminal. The staged maintenance facility acts as the focal point of design for the entire terminal. The hexagon concept is again replicated to offset the stage. Arches of 10m height are offsetted, slanted and lofted to create vaults. These vaults house storage area, a service area and a civilian departure and arrival zone. The vault is 3D printed to have waffle structure that offers strength and lightweight. The printing starts at an angle of 60* and continues inward. Then we have the waffle 3d printed structure. The vault is covered with regolith and offers better protection from the harmful radiation.

l INTEGRATIVE MODELLING

We used Rhino and grasshopper during the design phase. Then used Rhino.inside to detail the Rhino model in Revit. The model involves using different components in Rhino.inside like – Adaptive components, direct shapes, walls and structural framing.

l PLANS

l SECTIONS

The tower is composed of 2 shells, The outer and the inner shell. The outer shell is 3D printed while the Inner shell has a structural framing and glass panels which are adaptive.

The vaults are 3D printed at an angle of 60* above a support. For this, The contoured surfaces were first made vertically and then given an angle as element parameter to make is slanted. The support above which the vaults are 3D printed were made of adaptive panels.