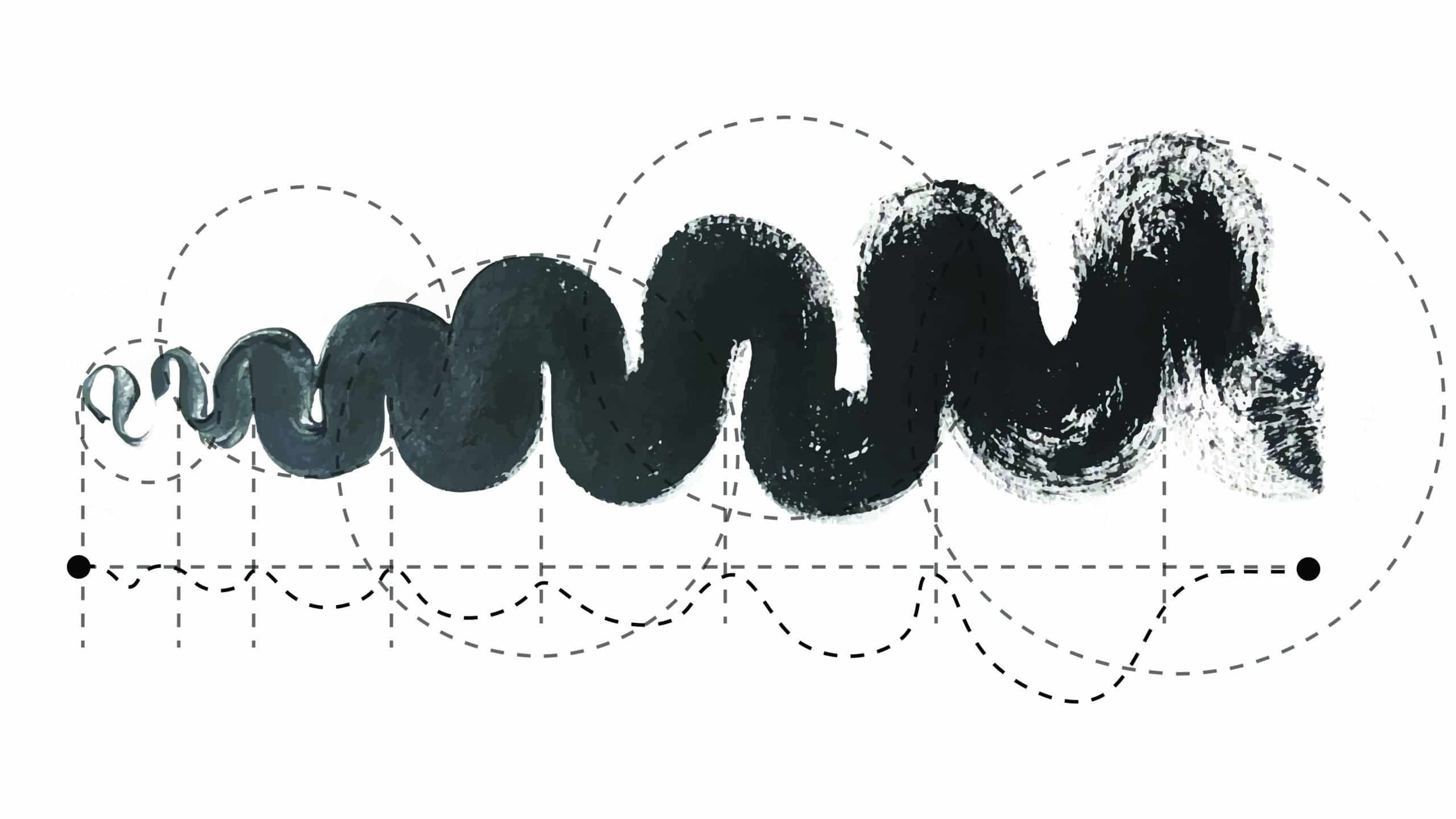

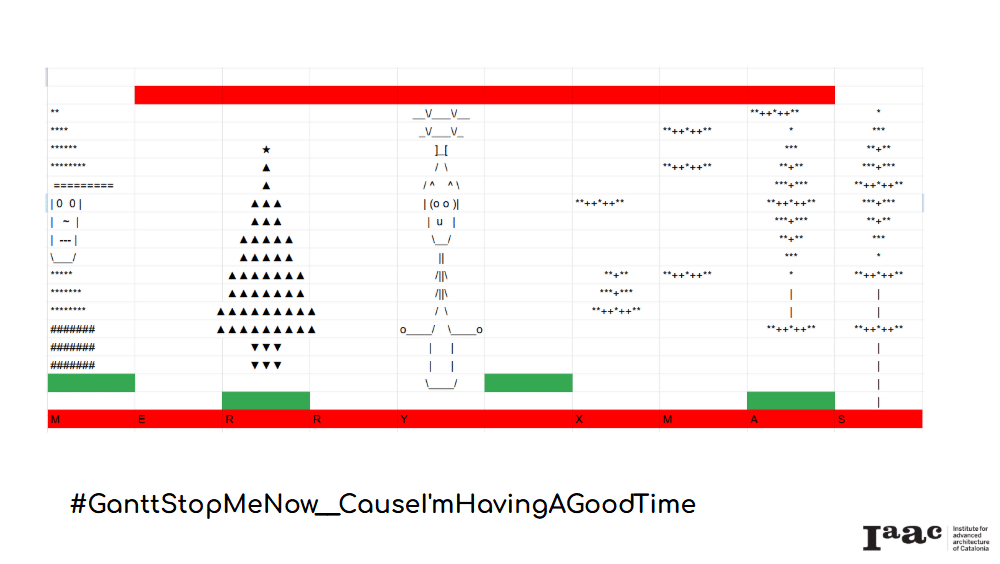

Anatomy of a Machine: Stroke

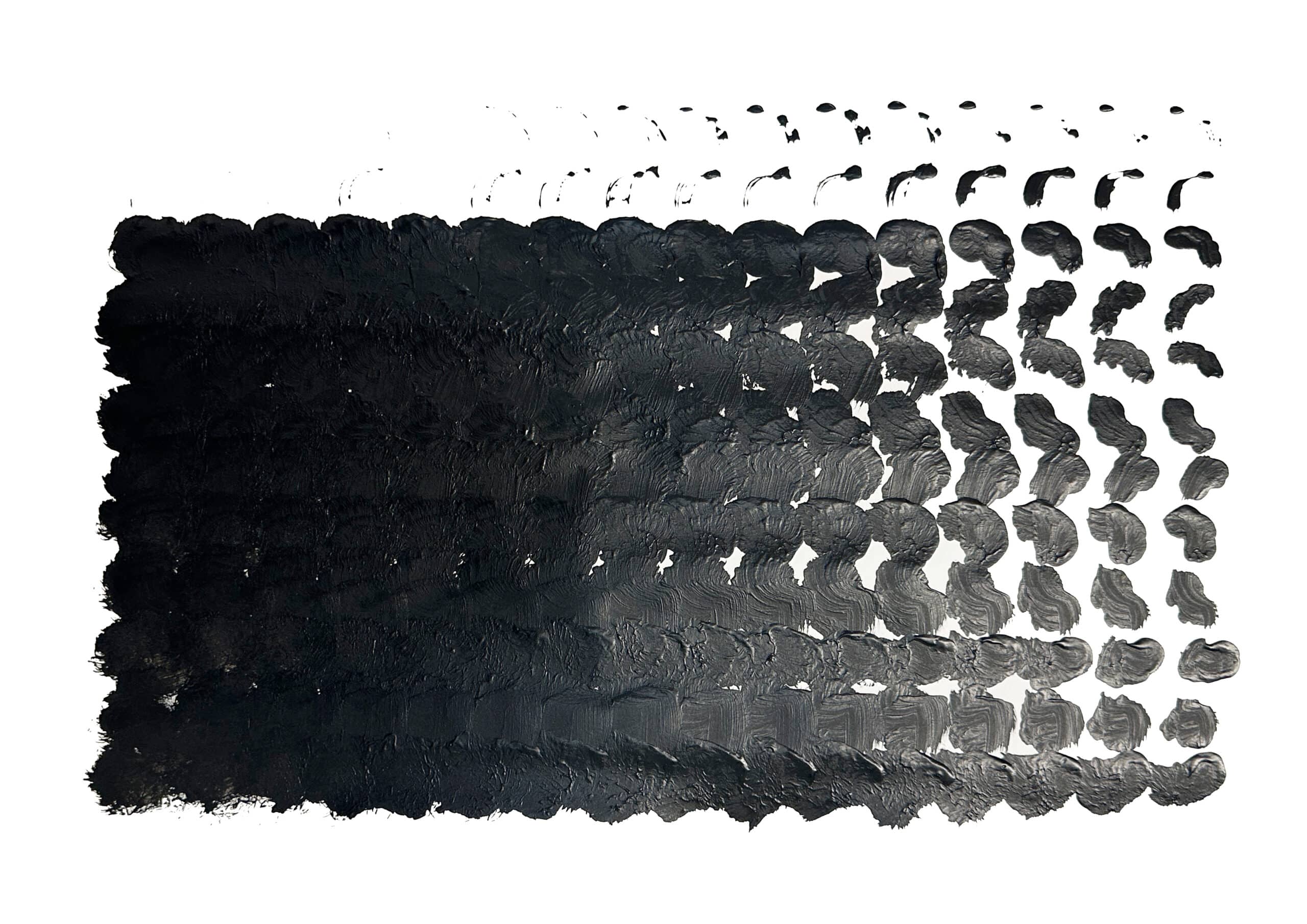

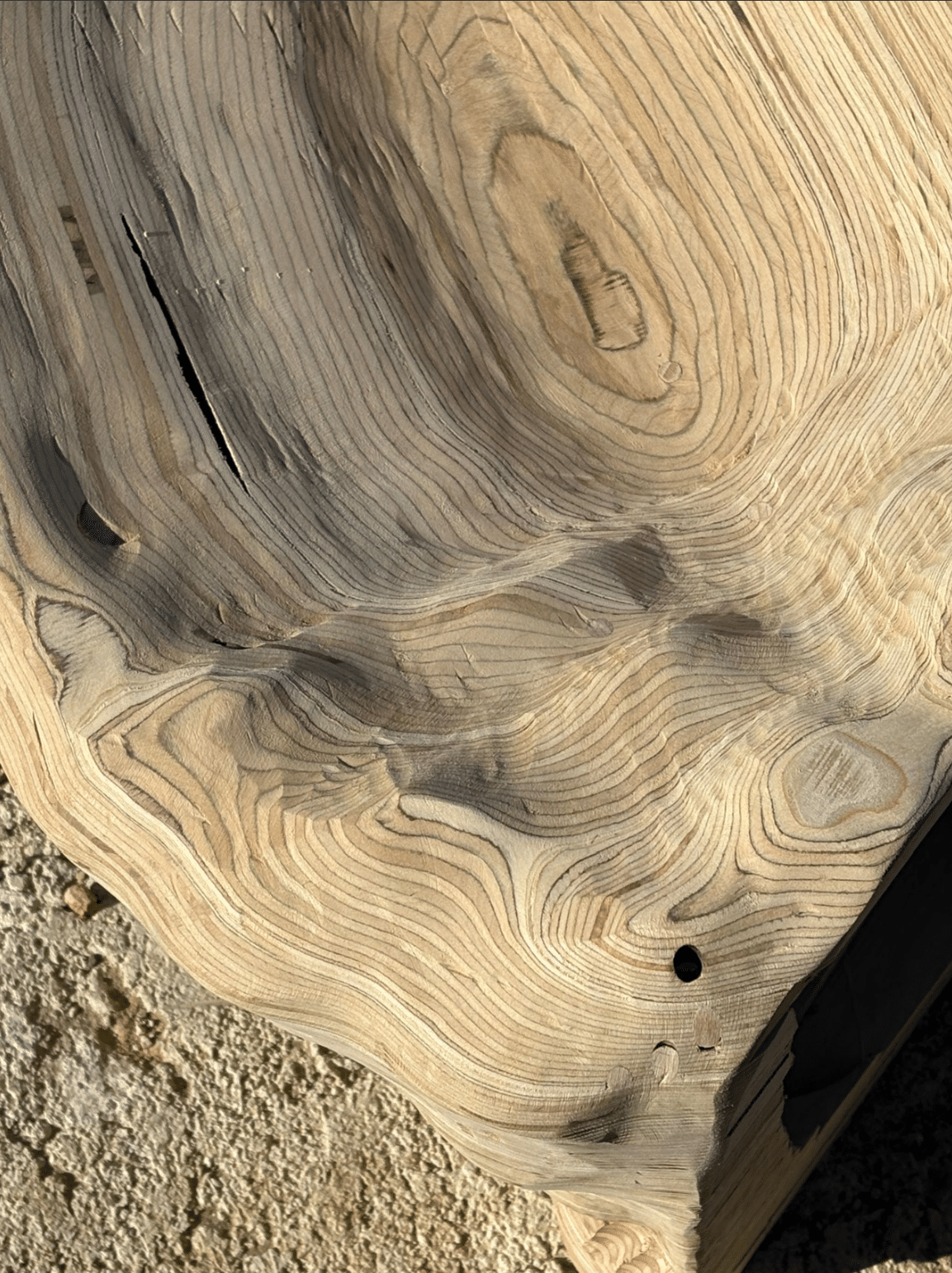

Introduction This project investigates the dialogue between human gesture and robotic motion through painting. Over three weeks, students study brush behavior, paint flow, and stroke dynamics, beginning manually and progressively translating gestures into robotic trajectories. The final outcome is an A2 robot-made painting, accompanied by a vectorial drawing and a 60-second video, reflecting the anatomy … Read more