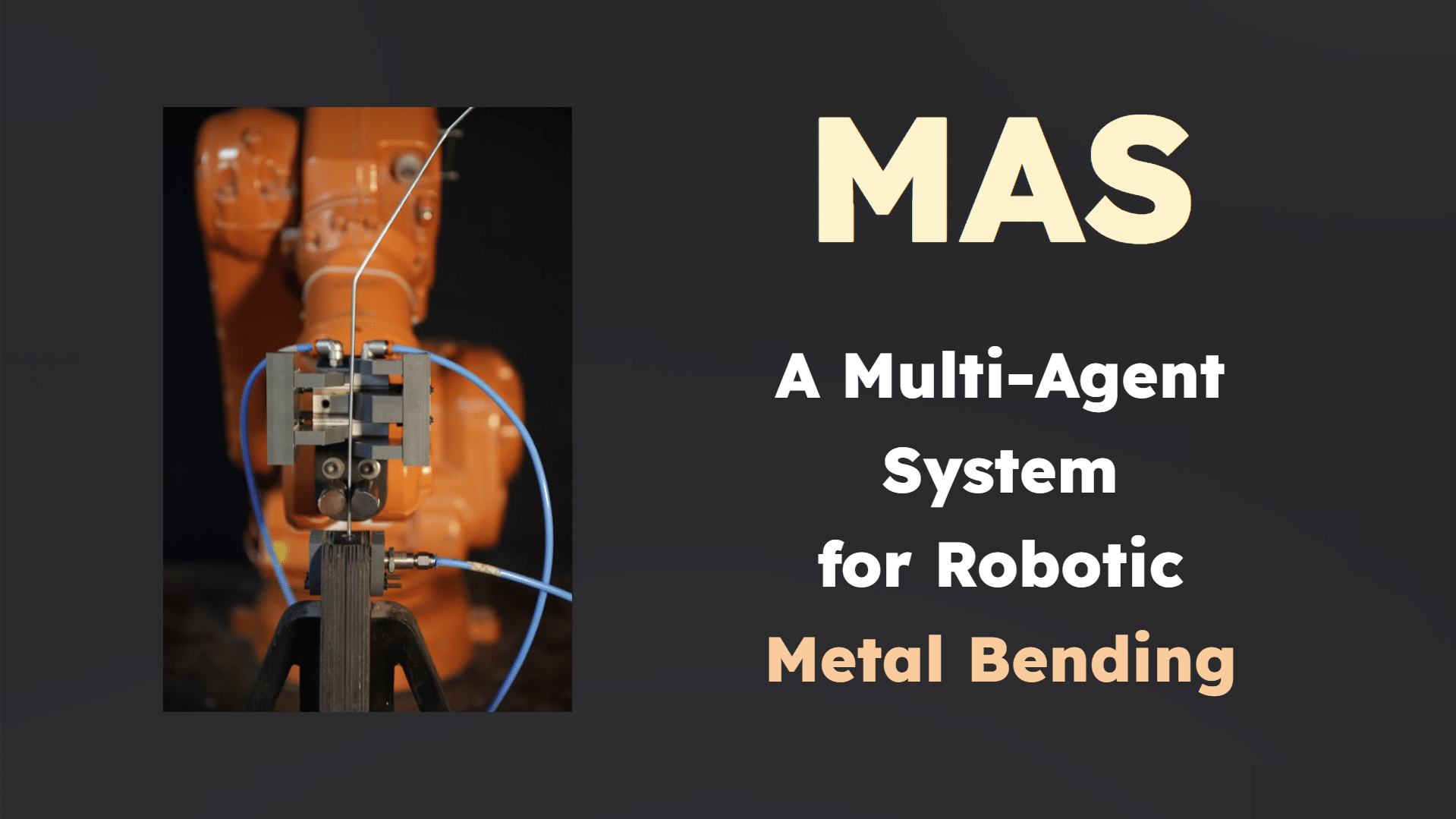

Crafting Balustrades with Robotic Bending : Studio III

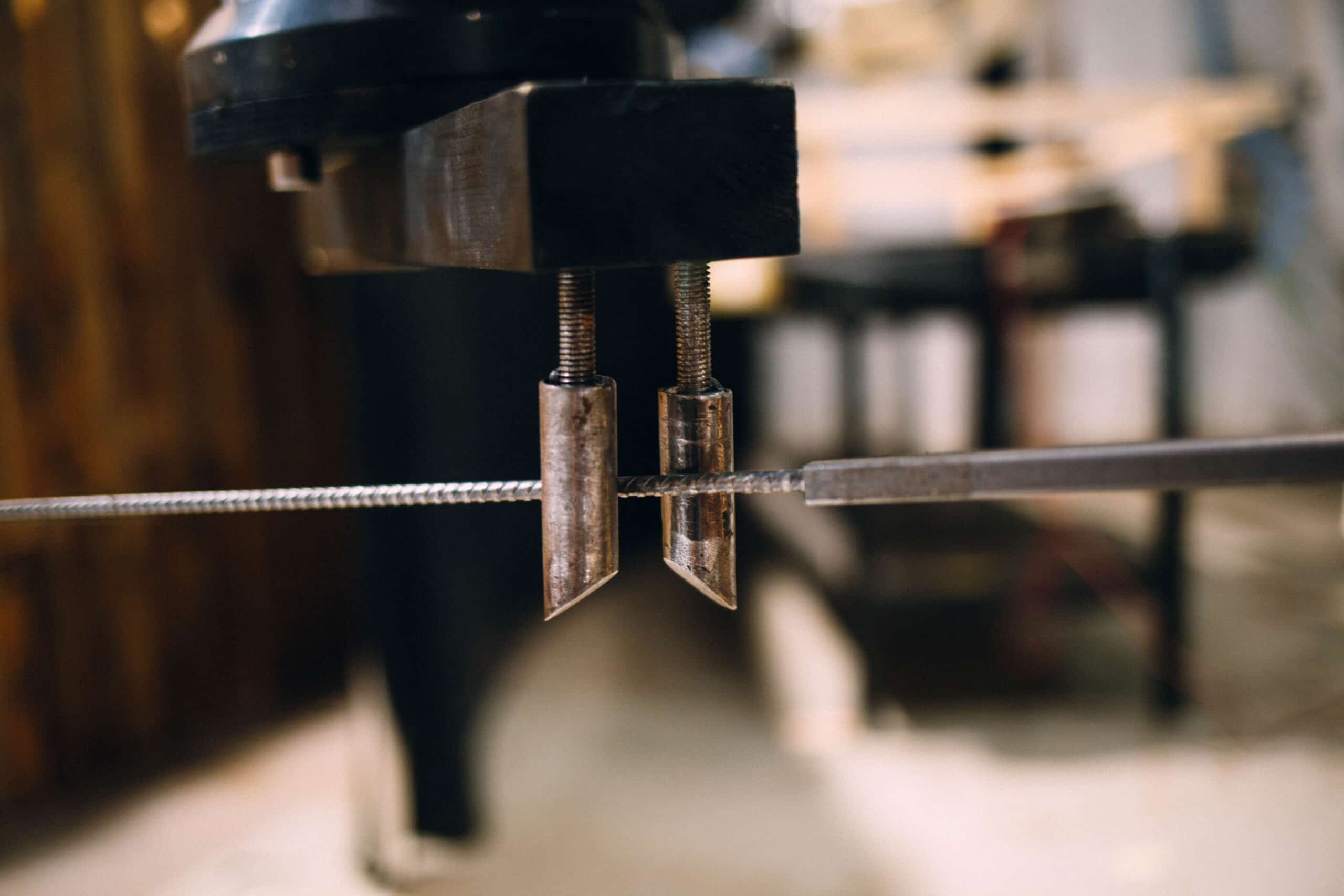

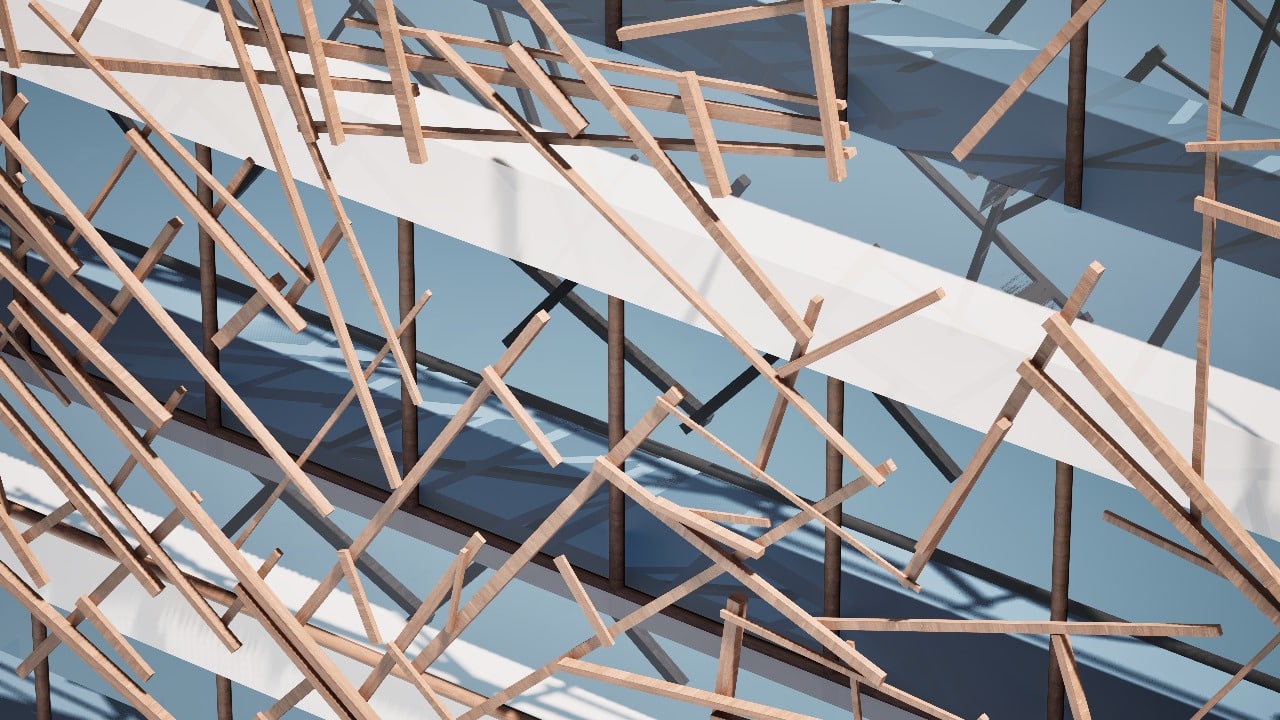

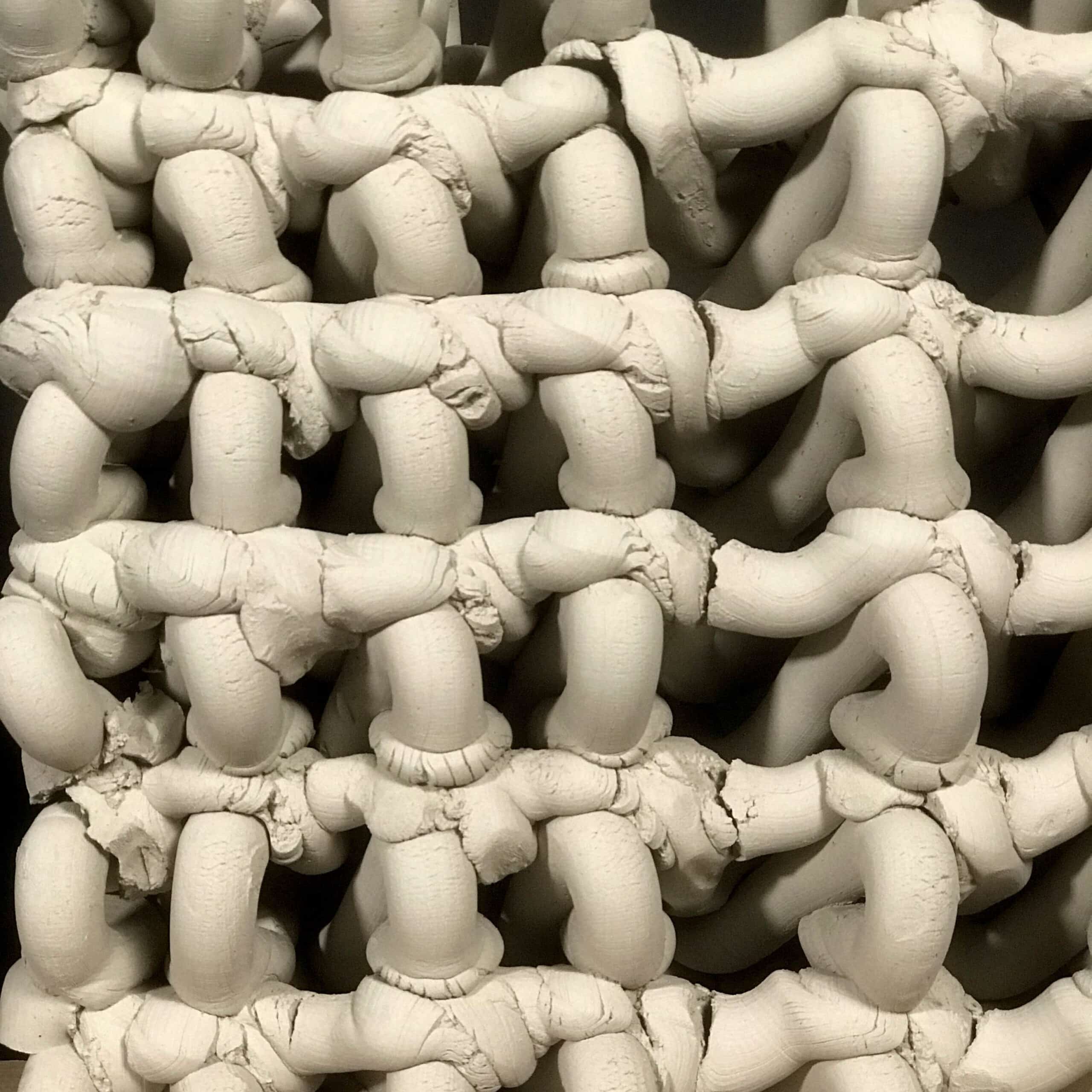

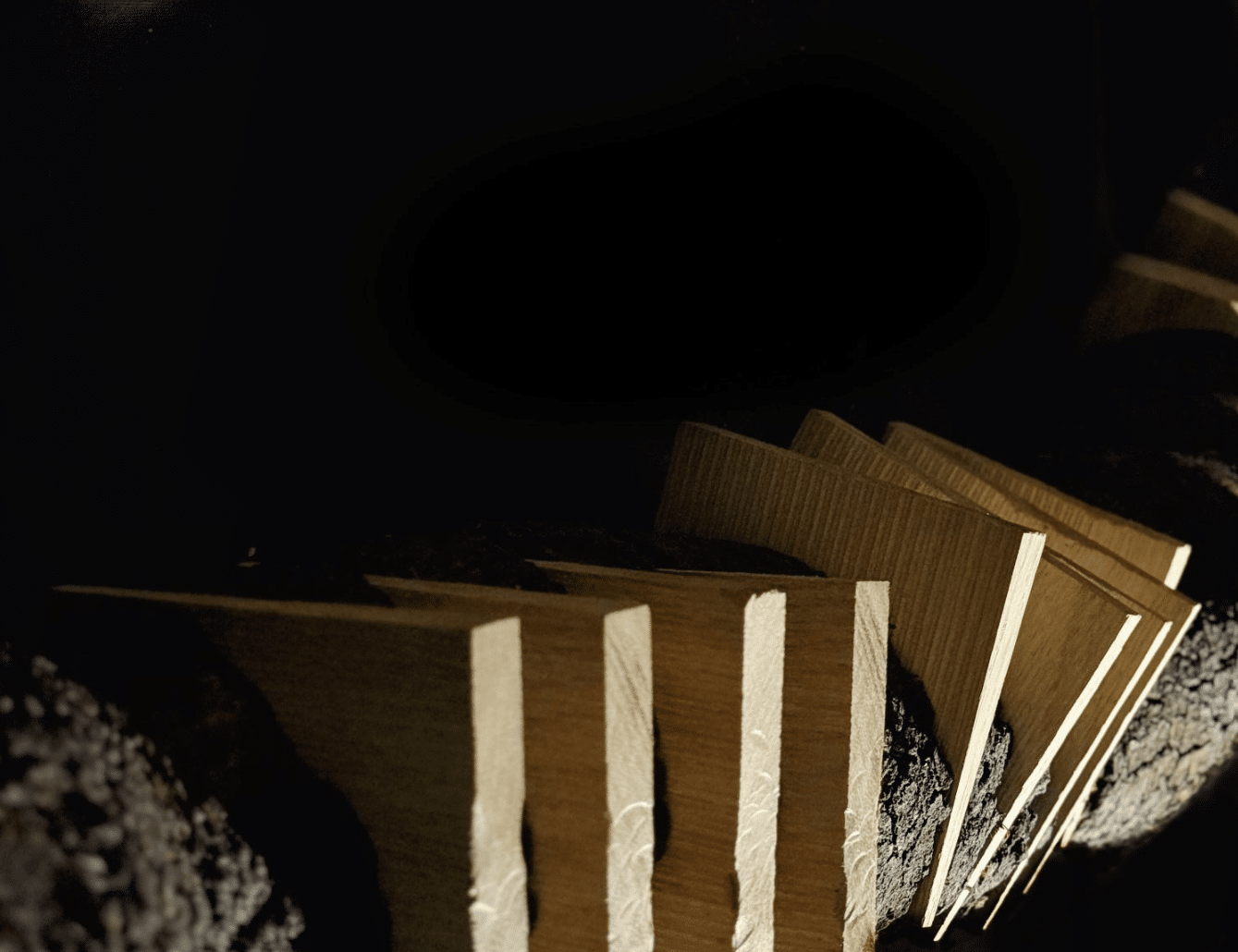

INTRODUCTION: In today’s era of mass customization, robotics play a key role in shaping a variety of materials. This research investigates the capacity of the ABB IRB 6700 robotic arm to perform metal forming operations on 6 mm steel rebars. Despite axis torque limitations, the process successfully yields horizontal balustrade components intended for architectural integration at … Read more