Anatomy of a Machine: Shape

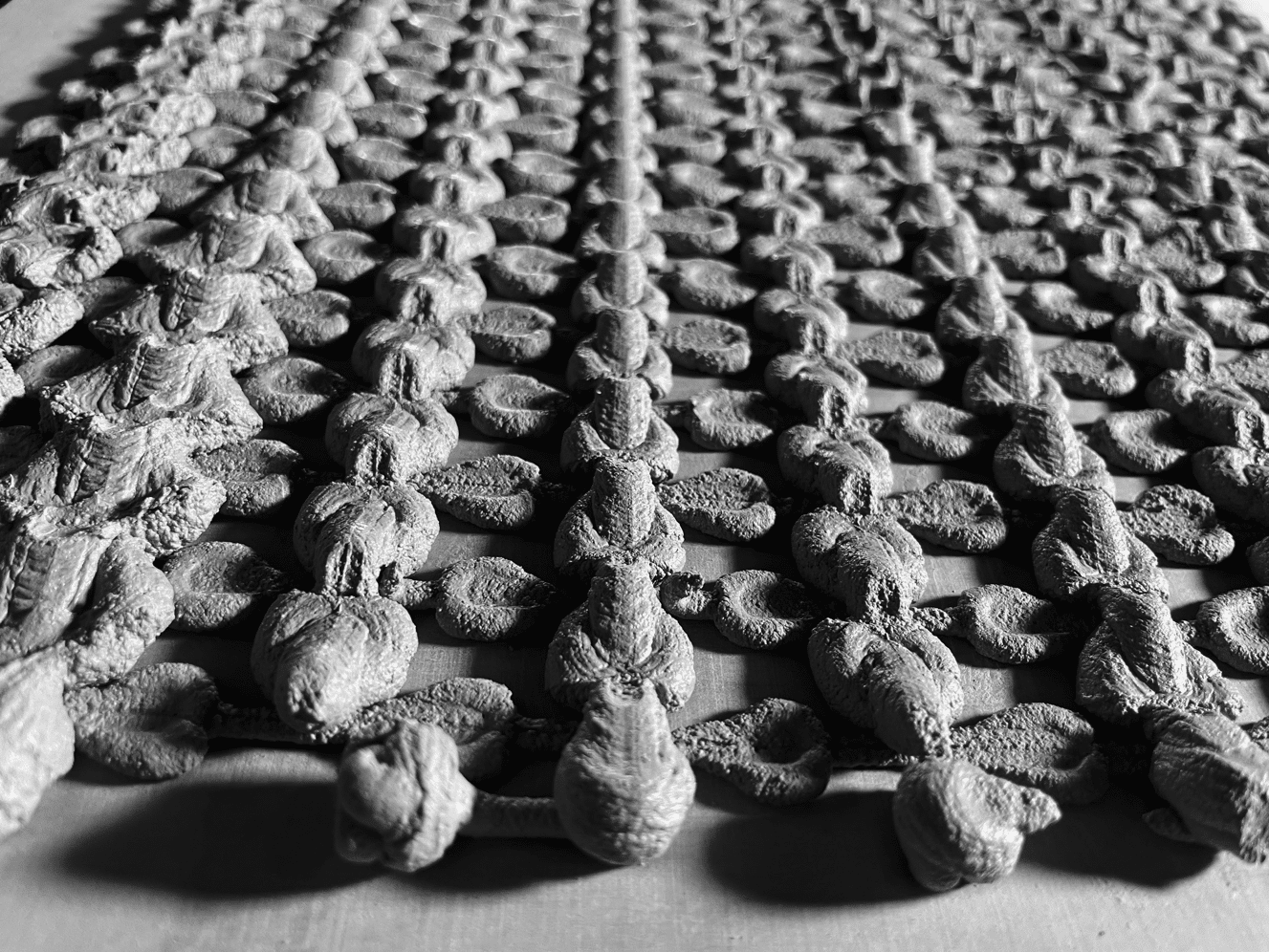

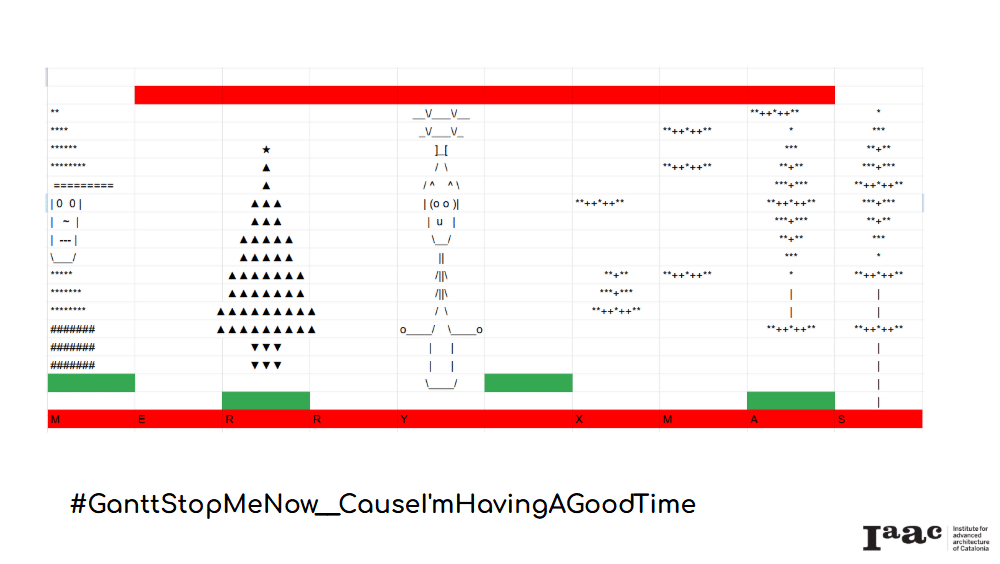

Context This exercise explores robotic fabrication processes through the direct manipulation of malleable materials. The assignment consisted of producing a 2.5D clay piece, measuring 40 × 40 cm with a maximum height of 5 cm, understood as a physical result of a robotically applied force on soft matter.Rather than designing a predefined form, the goal … Read more