SYNFORM – Pitch Deck

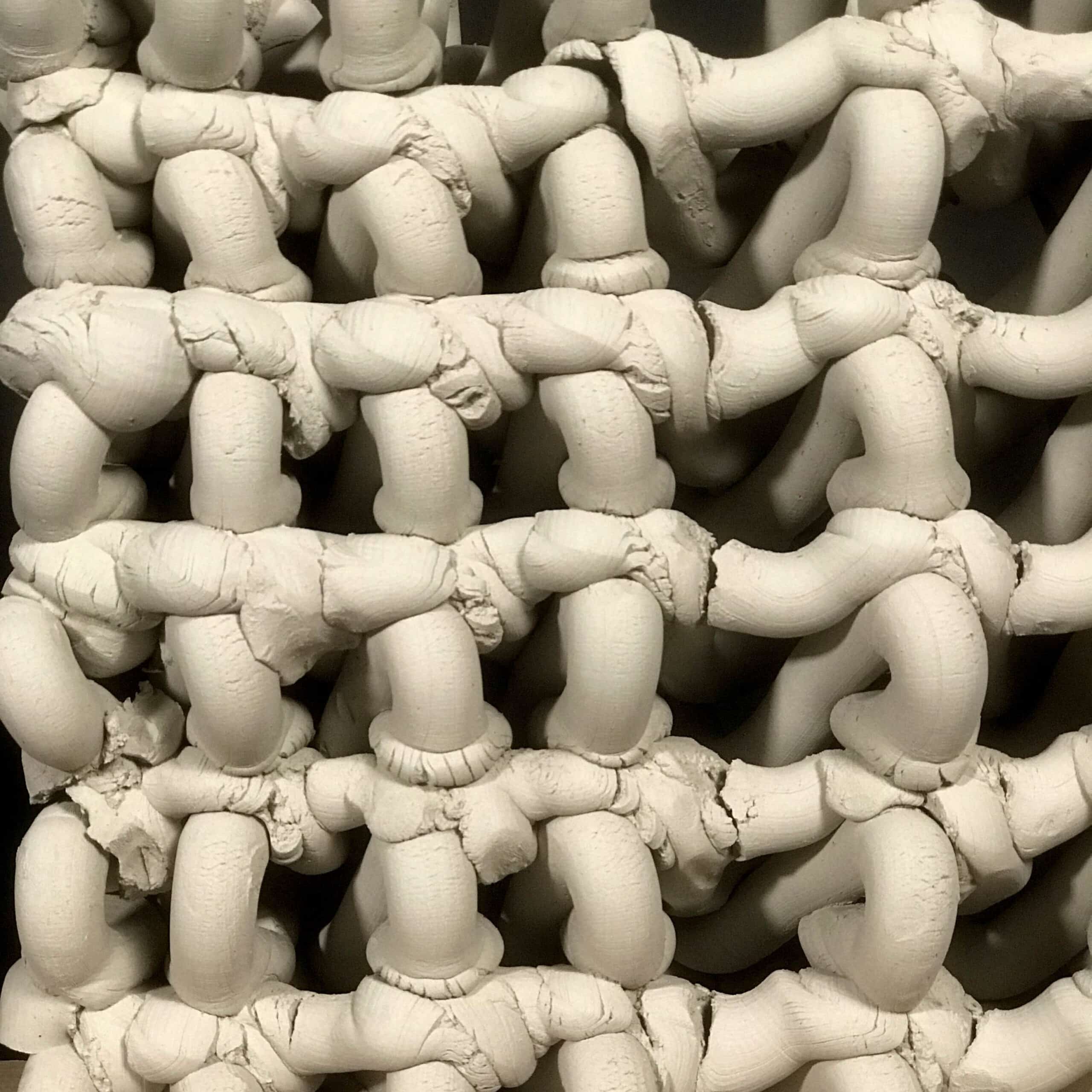

SYNFORM is a design-to-fabrication studio that fabricates luxury scenography and architectural surfaces that are parametric, modular and reconfigurable through large-scale 3D printing using recyclable plastics. Market Context According to Precedence Research, the global 3D printing market is estimated at around USD 29.29 billion in 2025 and is projected to grow to USD 134.58 billion by … Read more