Nidra chair – MRAC & MAEB Workshop 1.1

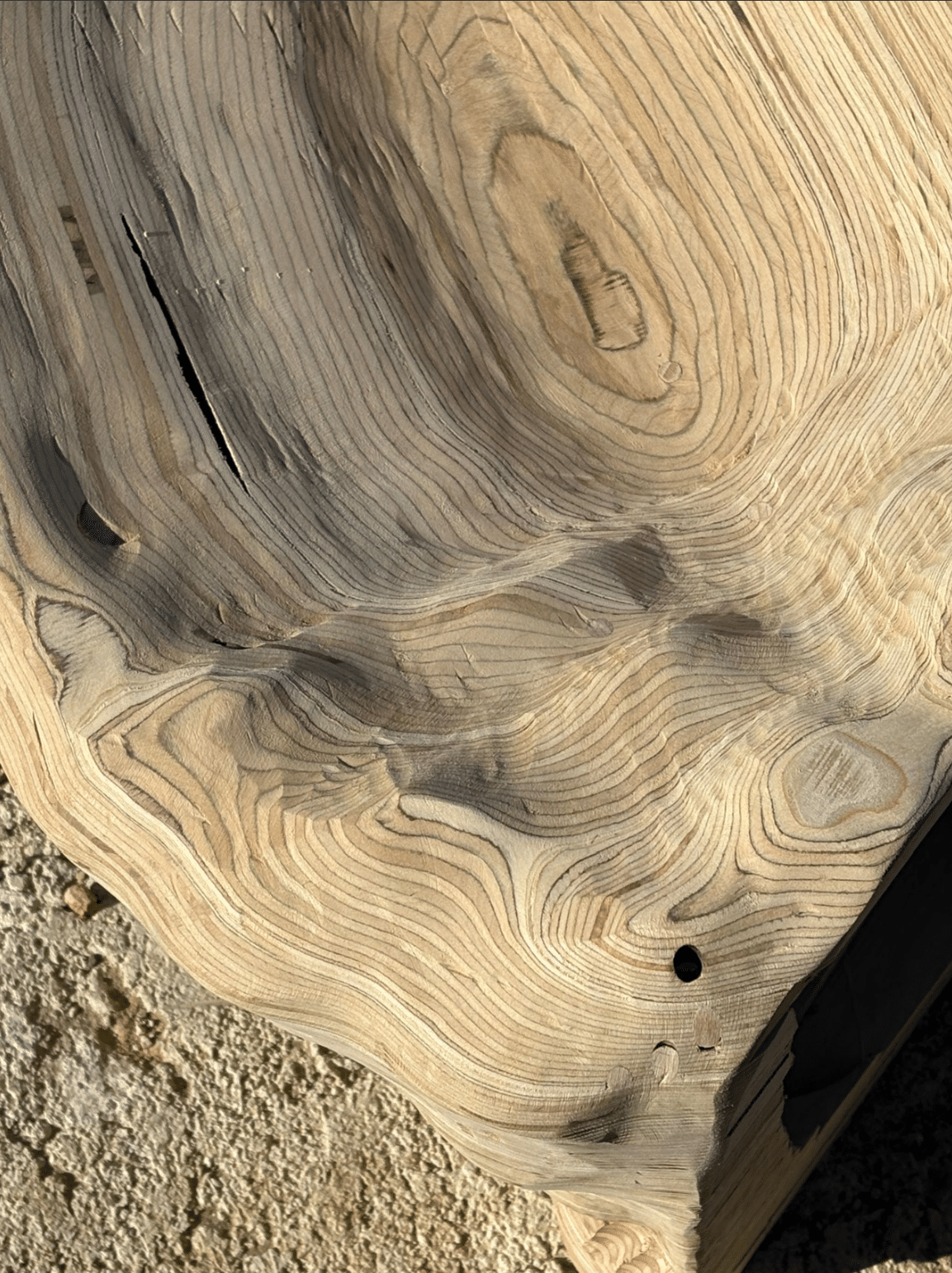

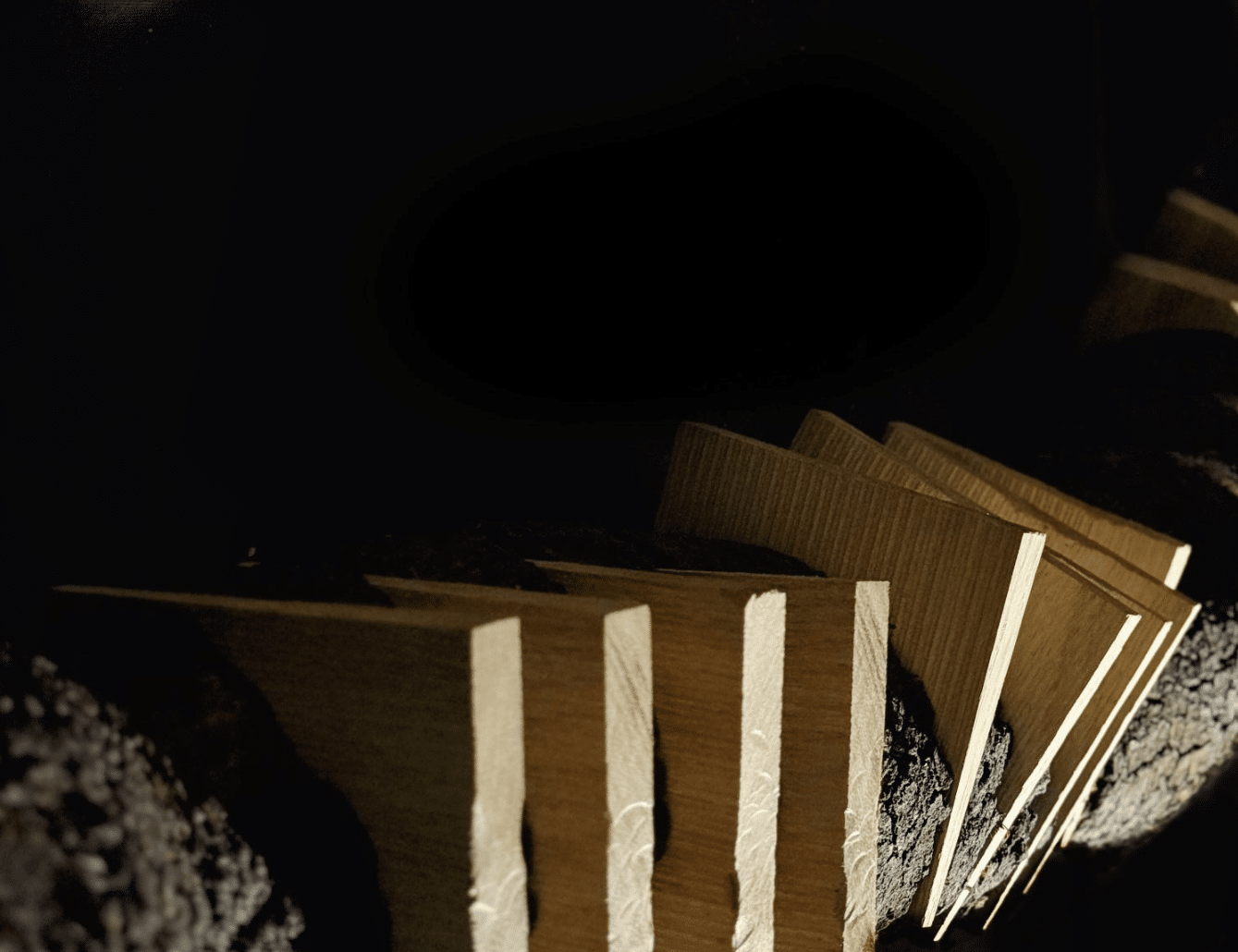

The Nidra Chair was developed within the framework of Workshop 1.1, where we explored robotic milling using the KUKA robotic arm. The design process was guided by a set of conceptual ideas—texture, nest, wings, and storage—which shaped the formal and tactile language of the piece. Inspired by notions of protection, warmth, and well-being, Nidra seeks … Read more