OBJECTIVE. streamlining circularity

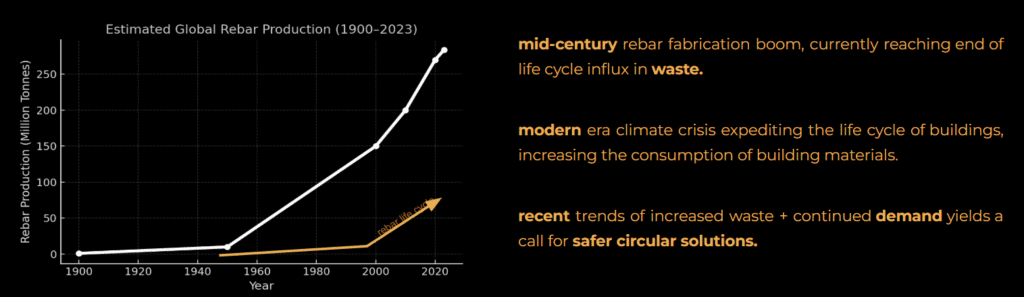

The initial investigation began with selecting a material or trade relevant to Barcelona. Barcelona’s scrap metal trade offers a readily available supply of materials with scrap metal being collected just blocks from the institution. Our initial investigation began with identify costs, consistency and availabilty of various types of scrap metal. After World War II, rebar manufacturing surged. Now, the first big production has met the of its end-of-life, making rebar waste in high supply worldwide.

- CHALLENGE. Recycling rebar typically downgrades its structural potential.

- OBJECTIVE. Find ways to reuse scrap rebar as a structural element by automating its transformation into space‑frame-like assemblies.

APPROACH.

automated bending

Initial investigations involved bending 3mm steel wire frame into a collapsable, tensile frame intended to add strength to masonry construction by internally loading them, reducing the need for chemical binding agents.

This assembly debuted the speed and transportability of the metal while exploiting the precision and repetition from robotic bending. Perhaps the greatest advantage of combining metal members with robotic bending is the diversity of form that can be created with minor adjustments to the bending g-code.

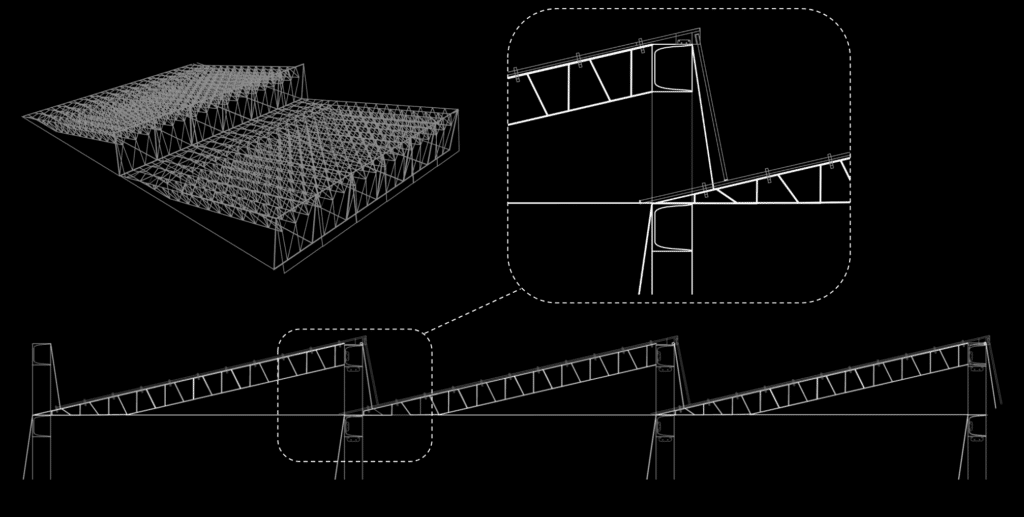

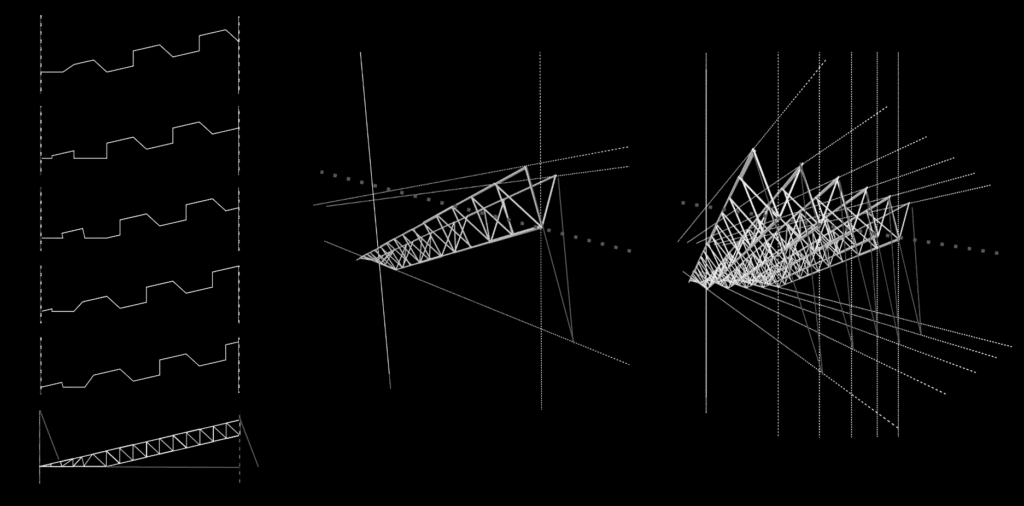

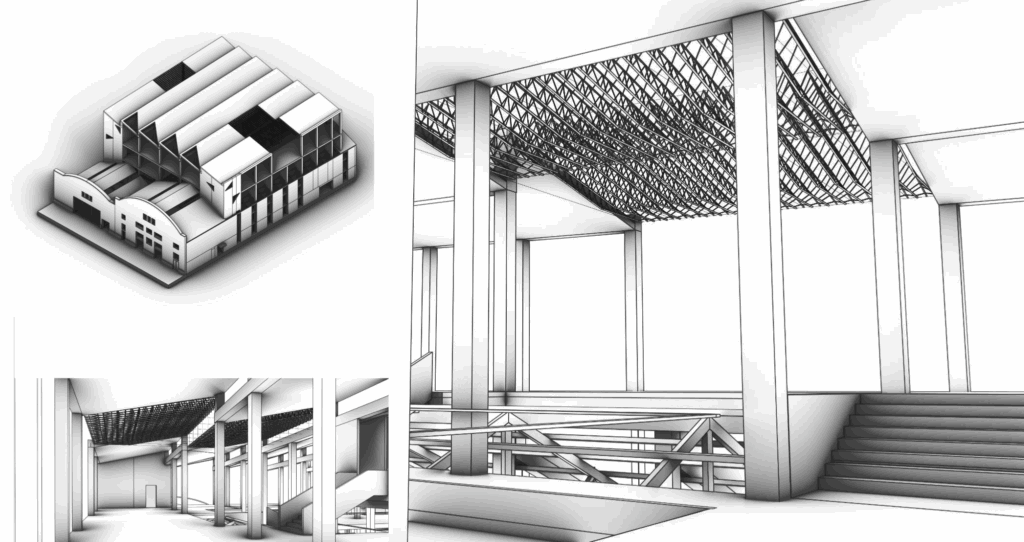

Because the tensile strength of rebar gives it a unique advantage over alternative building materials and the robotic bending g-code was so adaptive, the form easily morphed from a load-baring wall to a horizontal support structure, intnnded to support a sawtoot roof structure, with only minor changes in the module’s proportions and dimensions.

form finding + structural optimization.

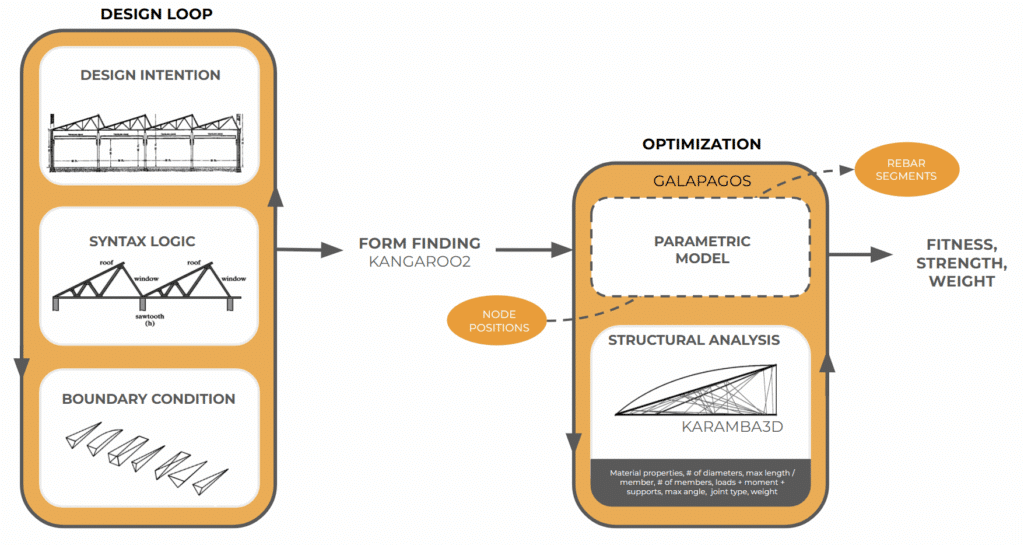

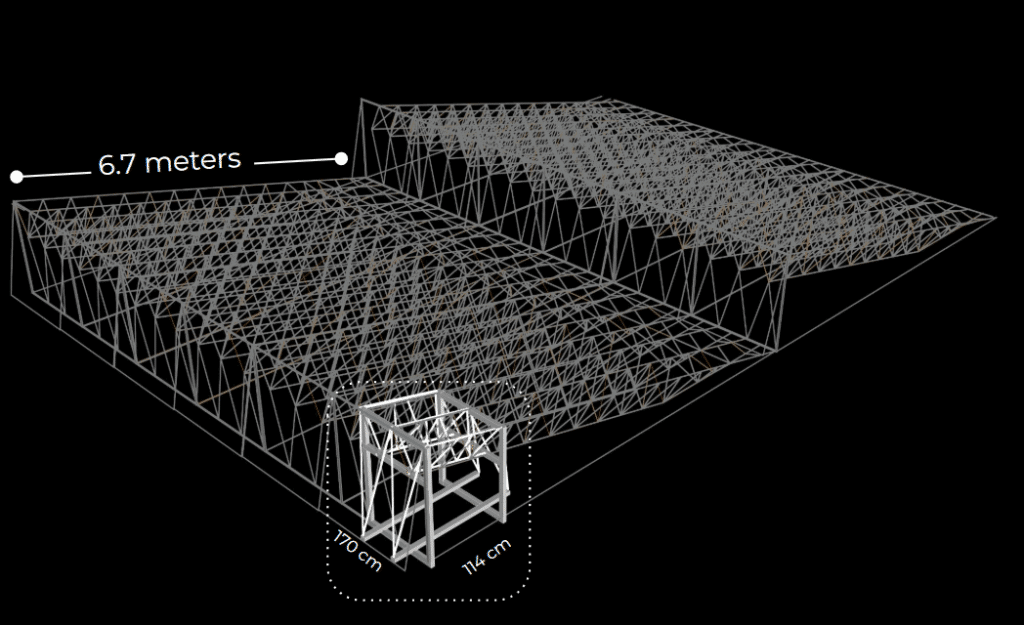

Bound by the architectural dimensions of the existing structure, parametric design, form finding, and structural analysis (optimized with Rhino 3D using Grasshopper and its plug-ins Galapagos, Kangaroo, and Karamba) optimized the rebar assembly.

Ultimately, the final rebar frame design was adapted to emphasize the consistent precision and efficiency of robotic bending.

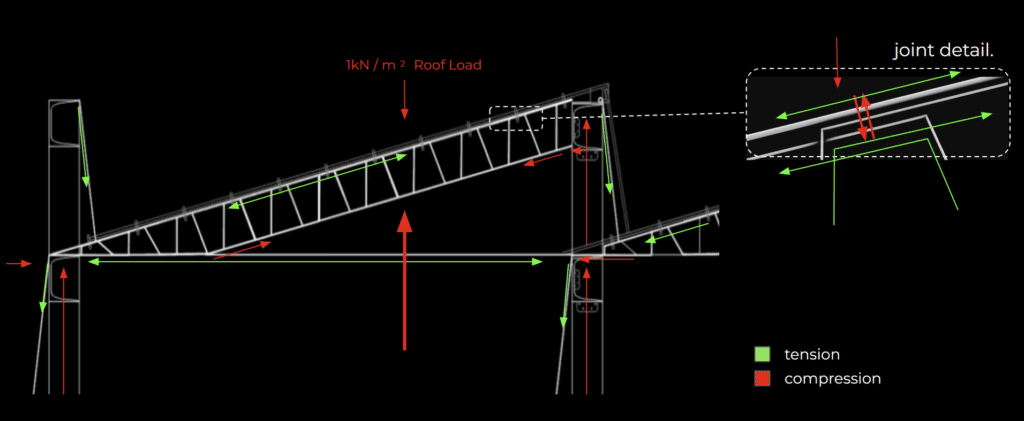

While the rebar used is intended to be recycled, the demand for steel is still high, so special consideration was taken to remove redundant members, and introduce post tensioning wherever possible to strengthen the frame and offset gravity, live loads, and roof loads.

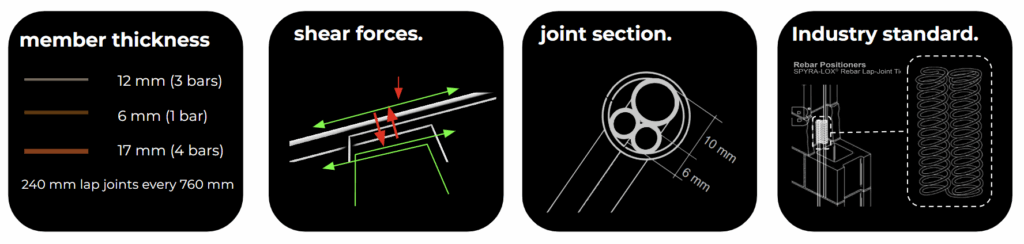

Linear bent members connected via multi-planar lap-joints reduced the dependence on multi-fasceted nodes, enhancing overall strenght, expediting assembly. By staggaring the “webbing” or cross-members and allowing bars to overlap on the top and bottom “chords,” the thin frame is better reinforced to span longer distances and receive greater loads. The amount of lapping will depend on the individual member thickness, the span and load specific to the architectural application.

While true load testing requires structural analysis beyond the current capabilities of the simulated structures, a physical 1:10 model will test actual deflection, weaknesses in connections, and opportunities for structural optimization. The 1:10 model demonstrates the assembly required to make a single span. The top cords are pulled down, anchored to the structure and the bottom cord is pulled into tension between bays, ,creating an upward lift to oppose gravitation and roof loads, common in bridge design.

Structural strength is only good as the joints that support it so a detailed investigation was done to ensure the best connections to address shear forces and the diversity of lap joint thicknesses.

A fastener shaped like a spring or coil alloes for a quick screw on connection that can be automated with the a power drill. Once the coil is in place around the rebar,

robotic bending process.

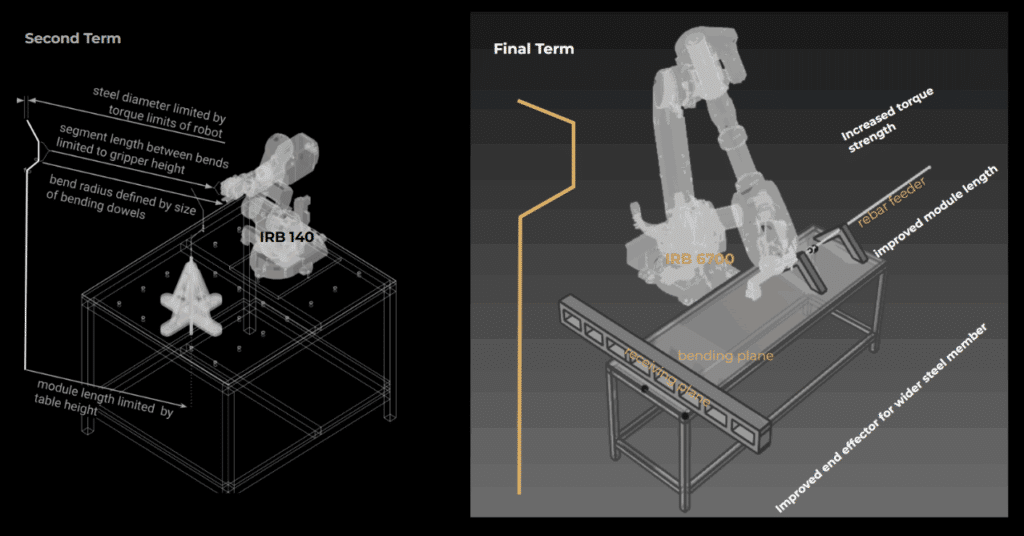

To increase scale to as architectural design element, the 3mm steel wire used in the initial wall investigation was traded for the thickest rebar IaaC´s robotic equipment could (safely) bend. With the ABB IRB 6700, 6mm rebar was used. To span a theoretical column bay of 6.7meters, longer rebar pieces would also reduce the number of joints, enabling a stronger lighter system. The vertical bending model was limited by the height and reach of the bar from the floor and ceiling. Contrarilly, a horizontal feeder and receiving plane (to offset deflection caused by gravity on the cantilevered member), allowed for a much longer (2 meter) piece of rebar to be bent (up to 85) degrees in either direction.

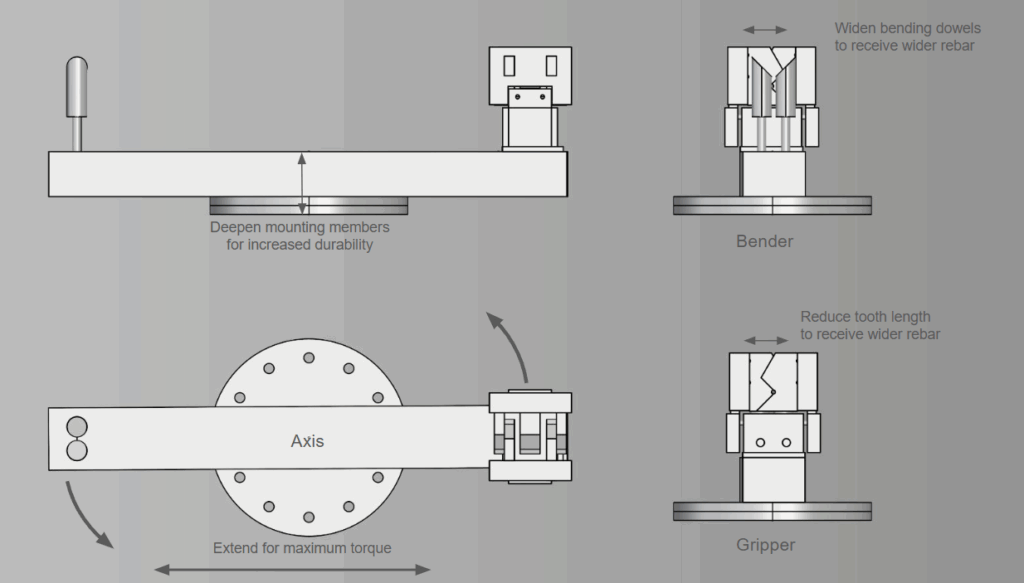

The end effector was also modified to receive a thicker material. The distance between the gripper and the bender were also separated to assist the robot with torque.

Robotic motion is pre-programmed to follow a pattern that creates an undulating shape. The shape creates a 2D pattern from a linear element that can then be assembled in 3D. The motion or pseudo code is as follows.

home > set > pick > grip > bend right > pull length 01 > release > retract >

>>>

set > pick > grip > bend right > pull length 02 > release > retract >

>>>

set > pick > grip > bend left > pull length 01 > release > retract >

>>>set > pick > grip > bend left > pull length 02 > release > retract > repeat

Variations in the lengths of the pulls and angles of the bends will yeild the greatest changes in scale of the pattern. Planar bending proved ideal for a single arm and feeder arrangement where deflection was difficult to manage at this scale.

While prototyping required (12) 2-meter long, 6mm thick pieces of straight rebar to accomplish a fraction of the overall assembly, the final result would invariably resemble a spaceframe with double cleristory lights and opportunity for skylighting on the main planes.

Conclusion

The rebar project addressed several key challenges inherent to light-guage metal construction, particularly the use of smaller structural components, the need for complex structural analysis, ensuring joint strength, and the traditionally labor-intensive nature of assembly. By refining connection techniques with stronger, smaller fasteners and optimizing structural layouts, the project successfully reduced assembly time while maintaining or improving overall strength and scalability. Significant improvements were achieved through the integration of robotic precision and computational structural optimization. This investigation shows promising new opportunities for rebar’s integration into a more efficient circular economy. The (re)BAR initiative demonstrates how robotic bending and smart design can elevate recycled rebar from scrap to high-performance structural frames—laying the groundwork for more efficient, sustainable architecture.

Looking ahead, minor G-code tweaks allowed swift reconfiguration—from load-bearing walls to roof supports. The next steps of development might be to focus on the geometric and structural limiitations of any given design when modifications to scale, dimensions and bend angle are integrated to the robotic process and number of members and geometric assembly is again modified. These steps aim to not only enhance structural performance and sustainability but also push the boundaries of what is architecturally and economically feasible in rebar-based construction systems.