Overview

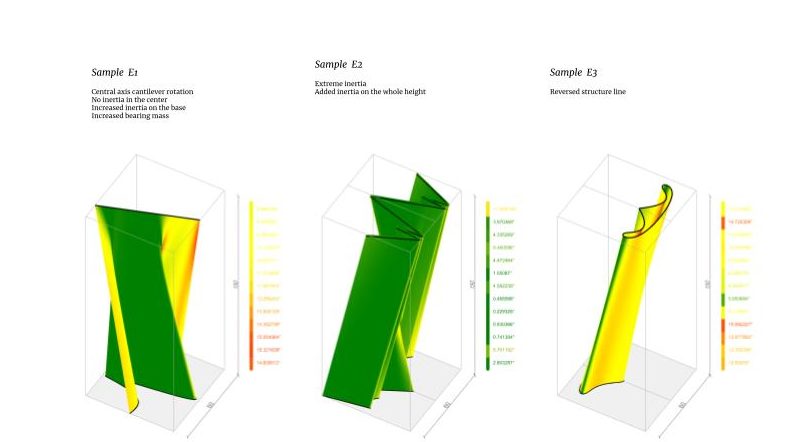

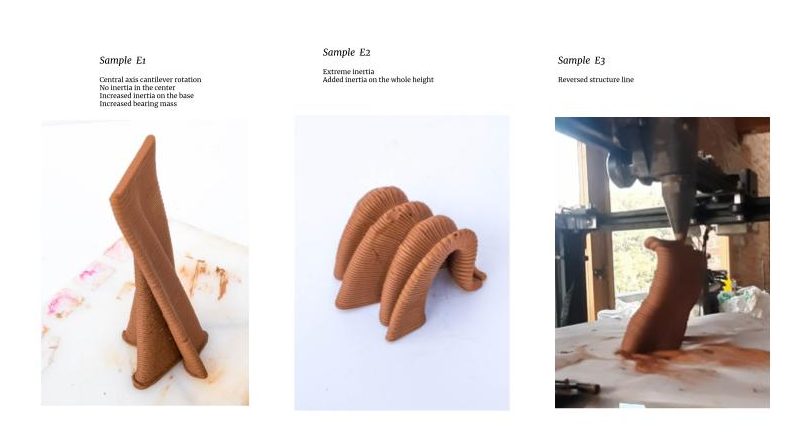

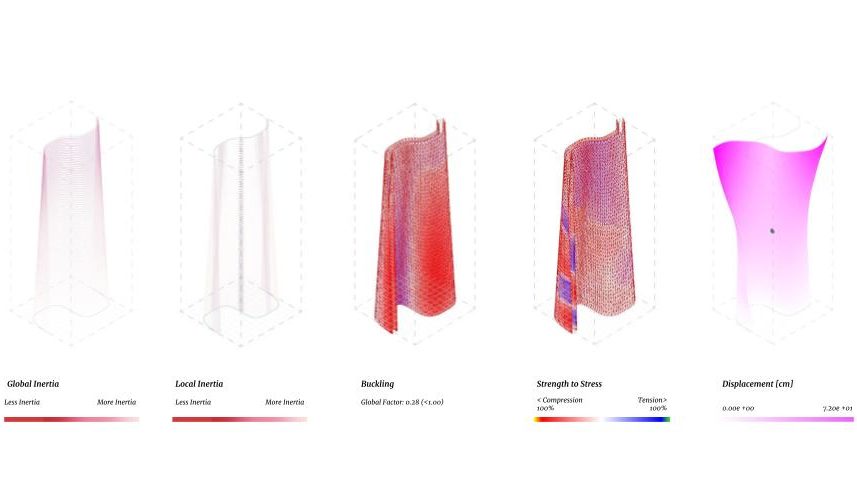

In 3d printing with earth, structural integrity is a factor that carries on from the onset of design until the finalization of the print itself. There are many tools that manifest the realization [pre-printing] and assessment [post printing] of structure in 3d printing. The purpose of these tools varies between the optimization of mass, geometry, resistance to deformation, inertia, reaction of loads, and other attributes.

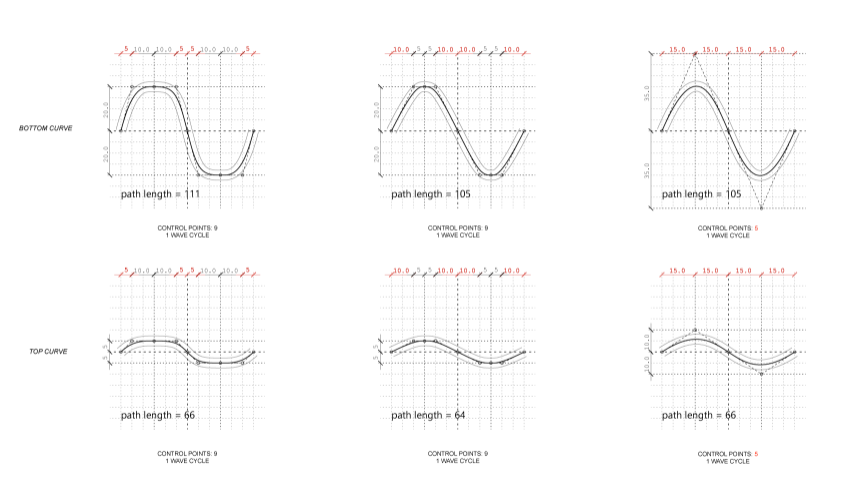

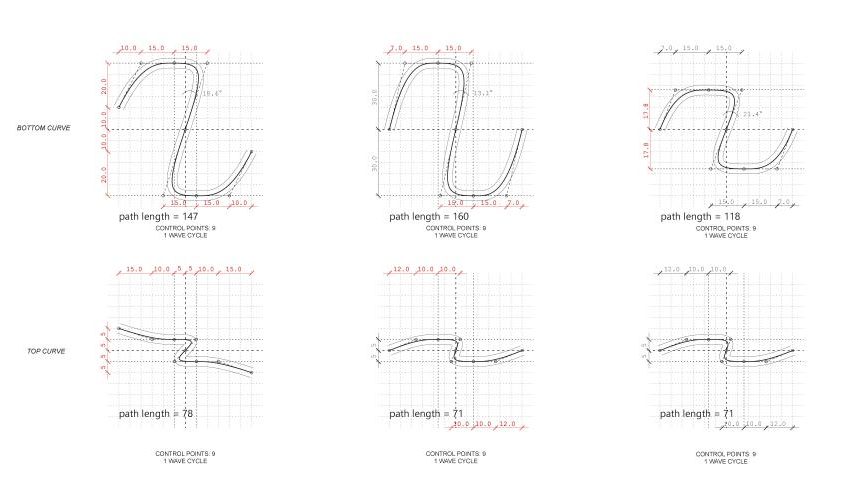

Geometries that have good structural properties are designed by optimized parameters which can be many. Some of these parameters vary between inclination of the print, pattern sizes, path lengths, control points, curve widths, amplitudes…

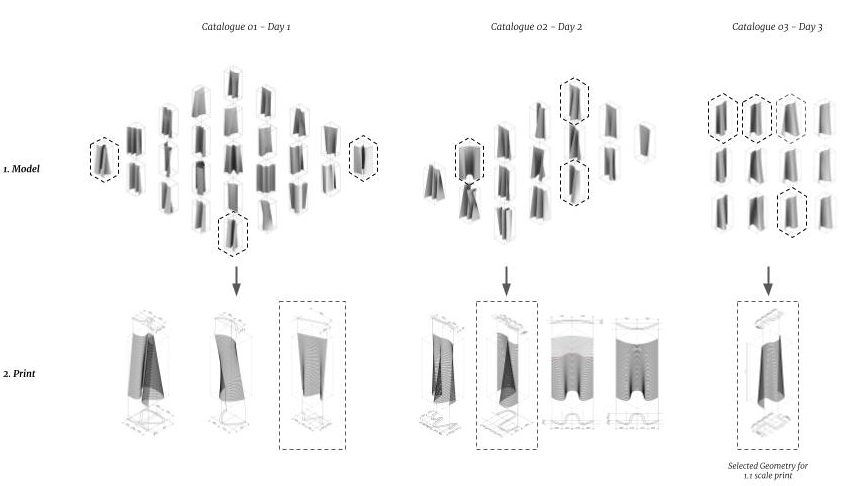

Catalogs & Iterations

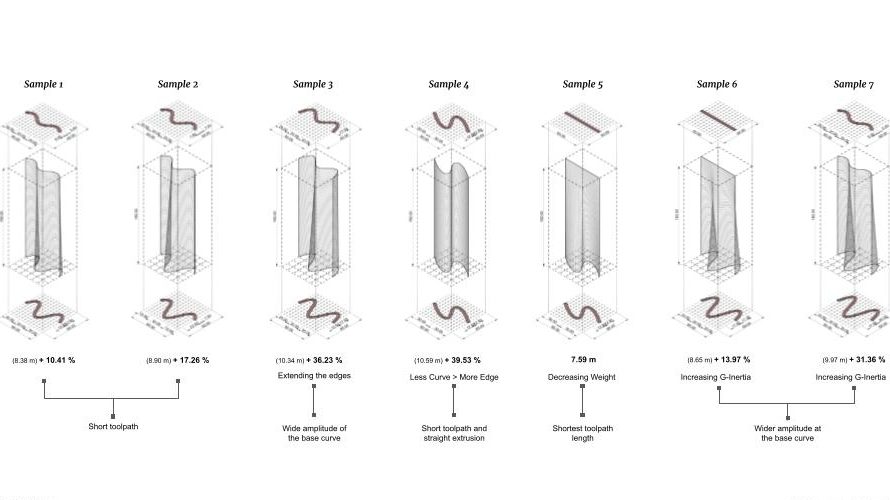

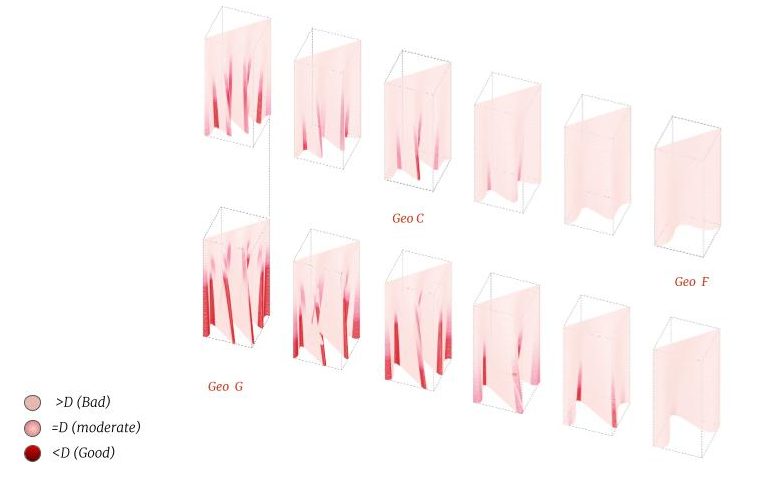

After understanding the characteristics that fail a print, a set of options were drawn and printed. The selection of seven walls was parameterized according to tool path length, edge extension, amplitude width, optimized global inertia, abundance of curves, and weight optimization.

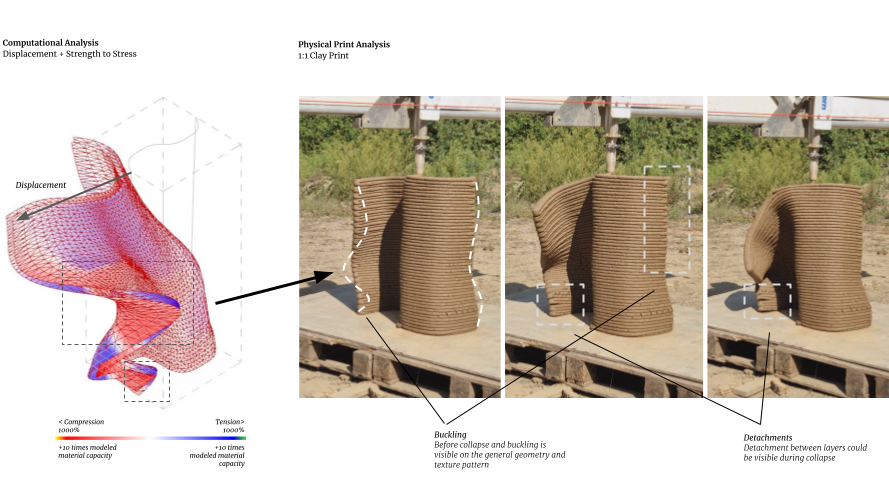

Sample 6 from the set of 7 tests showed to be more successful but began to recline backwards due to the lack of necessary inertia in the body of the print. This requires the slight corrugation of the flat curve at the top pattern. Nevertheless, the print buckled and twisted at the 1:1 print.

Tapered Structures

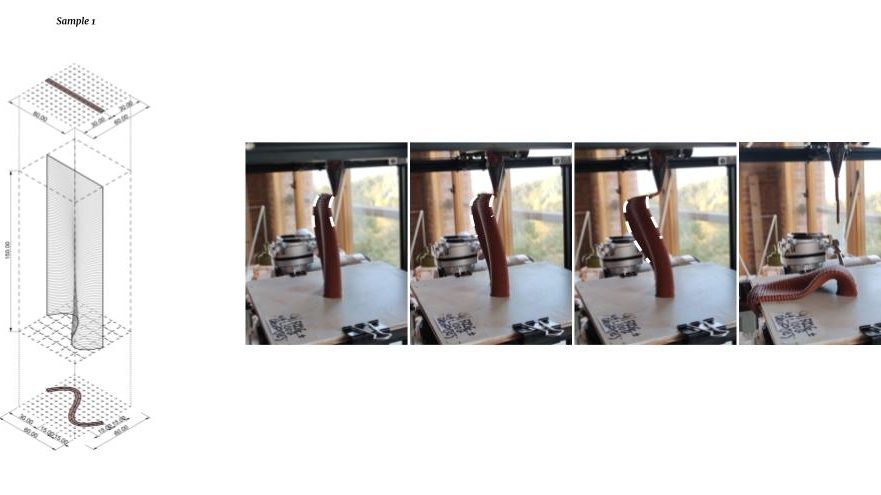

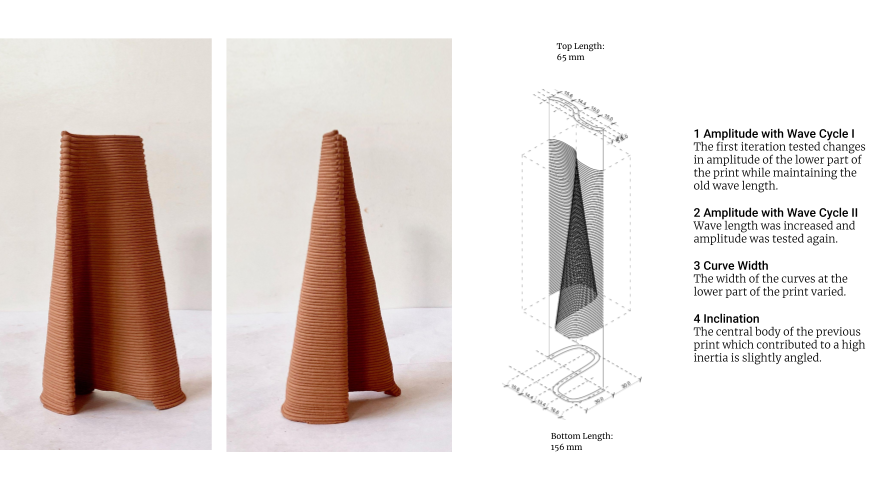

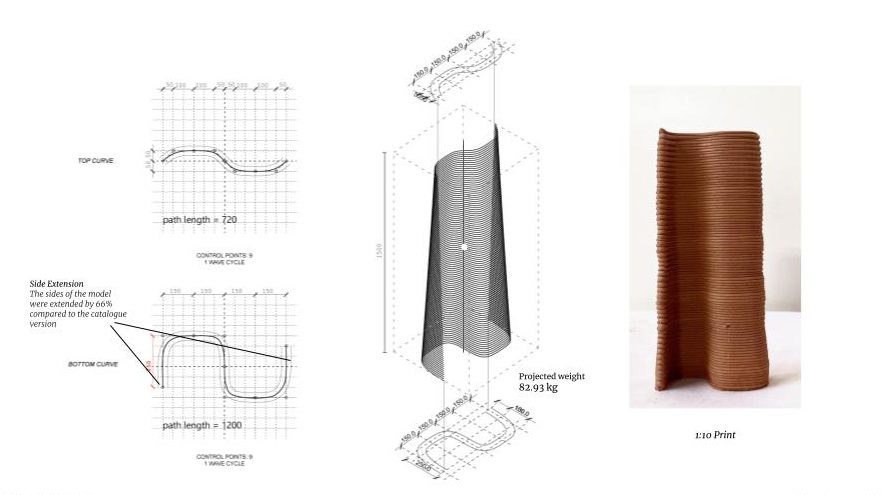

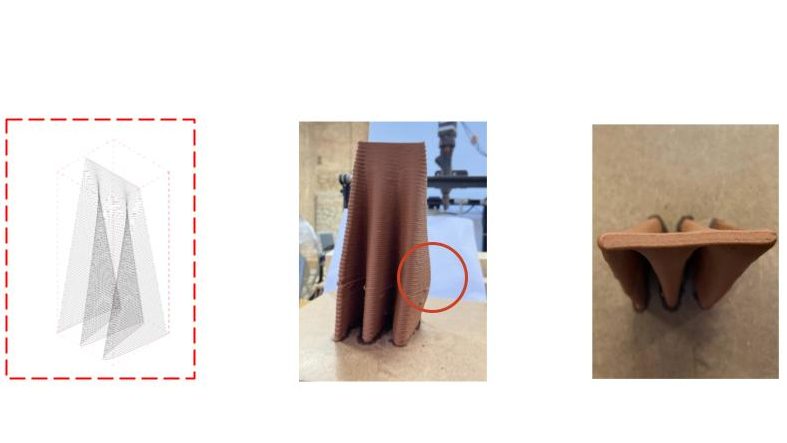

This print was selected from a catalog of computational iterations. It was printed at 1:10 and later taken to 1:1. It is characterized by its strong central body due to the breadth of the curves in the bottom pattern. This contributes to a larger global inertia. Number of control points were kept constant in order to discover what implications resulted from the changes in inclination by just moving the control points. The bottom curve is intended to have a large width and get narrowed as one curve above the other.

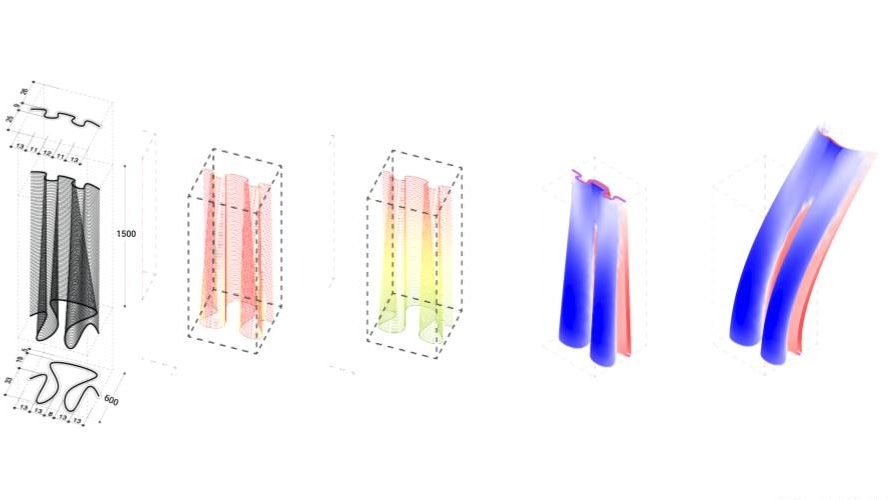

Prior to printing on the CASP crane, the structural tests that were conducted on all computational iterations in the catalog were reconducted on the final design to be tested. It experienced a slight extension of the wings on the side in order to avoid buckling. The Strength-to-Stress and displacement test revealed a displacement in some points of the print due to unbearable compression.

Extended Edges

Despite the heavy corrugation and multi-amplitudinous of the bottom curve of the print, the edges of the form were too extended to avoid buckling. This was a failure in the test print. Vertical forces have adverse effects on free-end extensions and this requires a slight inward curve.

The inward curve can be achieved by decreasing the number of curves, reducing and/ or increasing the control points, or simply moving the existing control points. After iterations, assessments must be conducted to facilitate the choice of a better option. Local inertia tests are one of many that attest to the durability of these edges.

The corrugation of the top curve avoids the buckling that was experienced in the previous print and curving the bottom of the extended edges slightly inwards was achieved by reducing the number of curves and widening the width of the central curve.

Nevertheless, the global inertia weakened the body of the print and toppled it down from the inside.

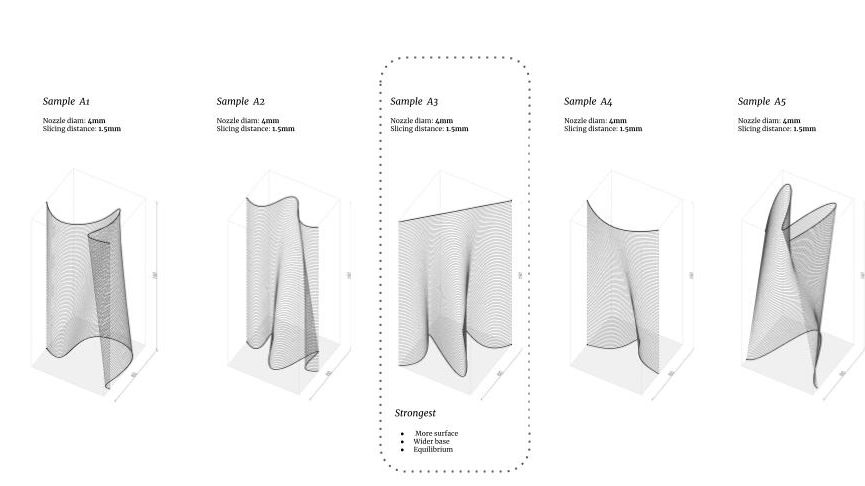

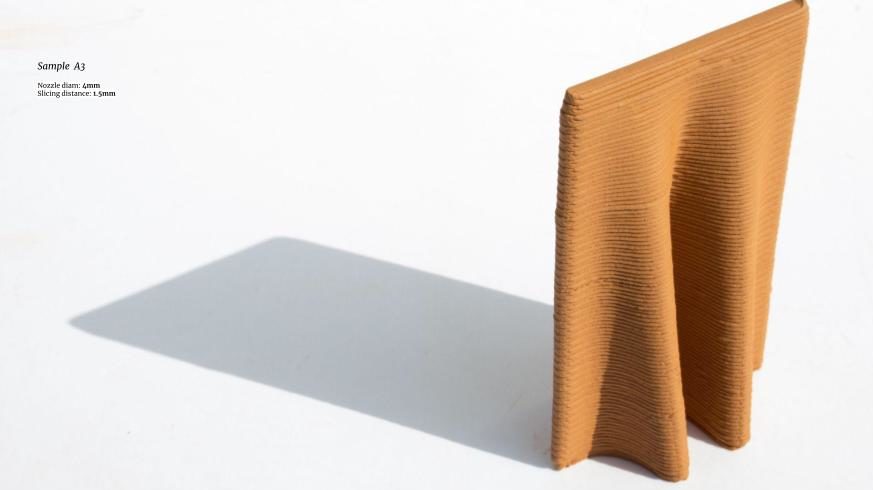

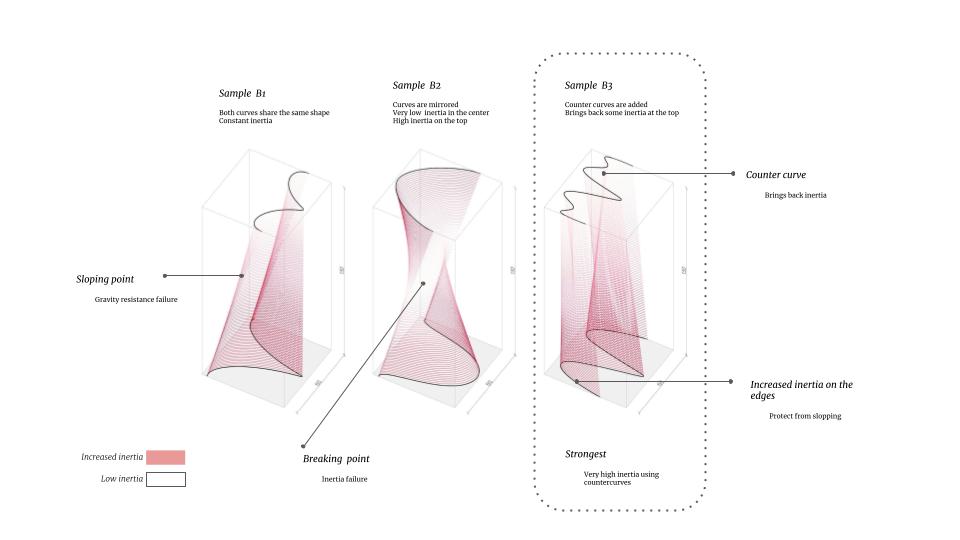

Straight Curve vs Multi-curve Test

The selection from the catalog had a flat top curve, larger surface area, a larger base, and higher equilibrium. A maximum of 7 control points were used and both the nozzle diameter and slicing distance were maintained at 4 mm and 1.5 mm respectively.

Global inertia digital analysis was conducted over another set of geometries. Since sample B1 cannot carry itself because of self-weight in gravity, and sample B2 does is not characterized by the necessary local inertia hence experiencing a breaking point in the middle, sample B3 was the strongest choice because of its high inertia, curved extended edges, and counter curve characteristic which stabilizes the print.

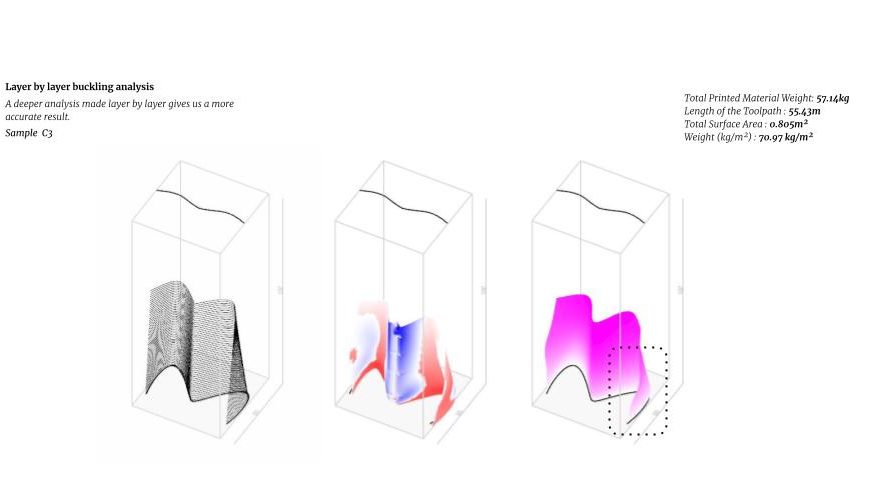

However, the sample was not light enough, so the following sample was chosen since it carries less weight which gives more efficiency in terms of mass and time to print. The same qualities as the previously presented form were attempted to be achieved but with the adjustment at the top curve. The layers were studied more closely.

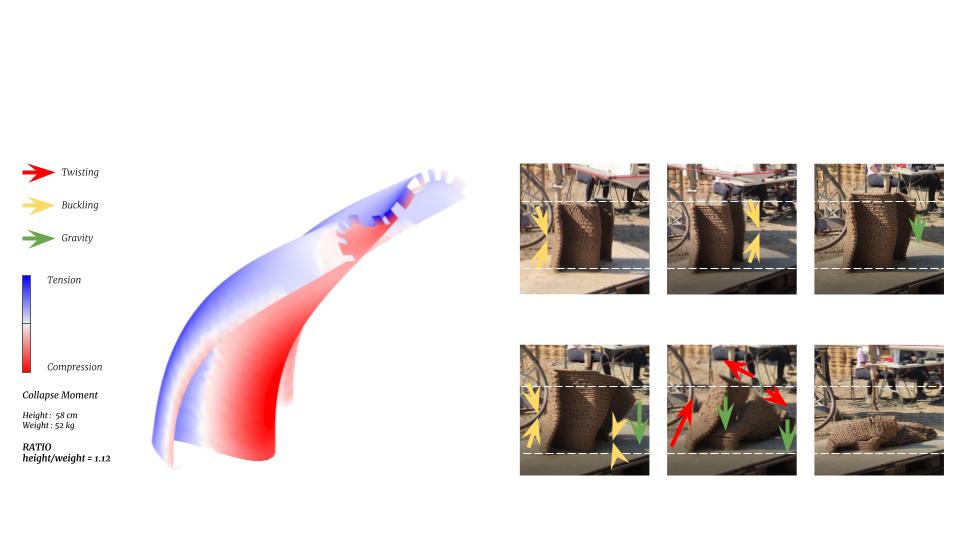

Cantilevers

The mission to challenge gravity and cantilevering was conducted with the possibility to loop the curve of the print.