unlocking the potential of reclaimed timber

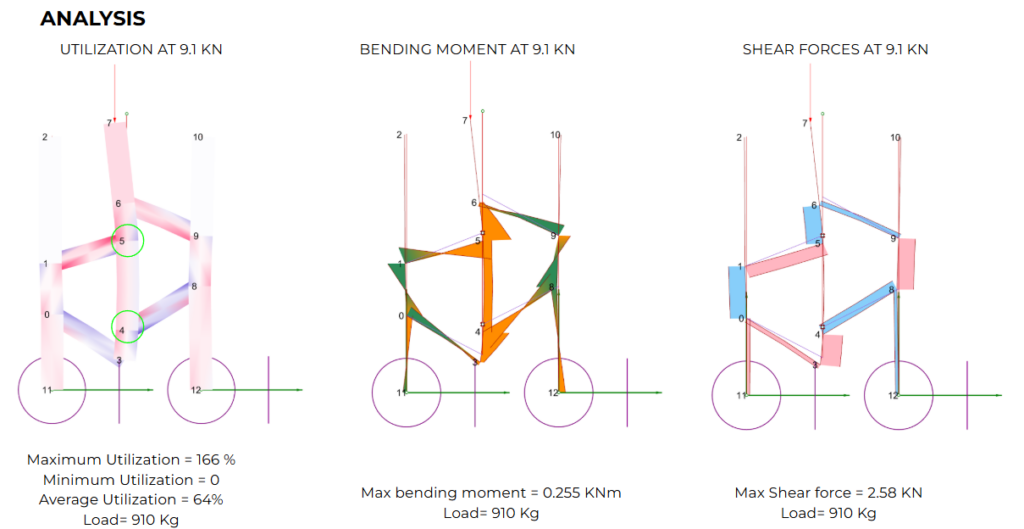

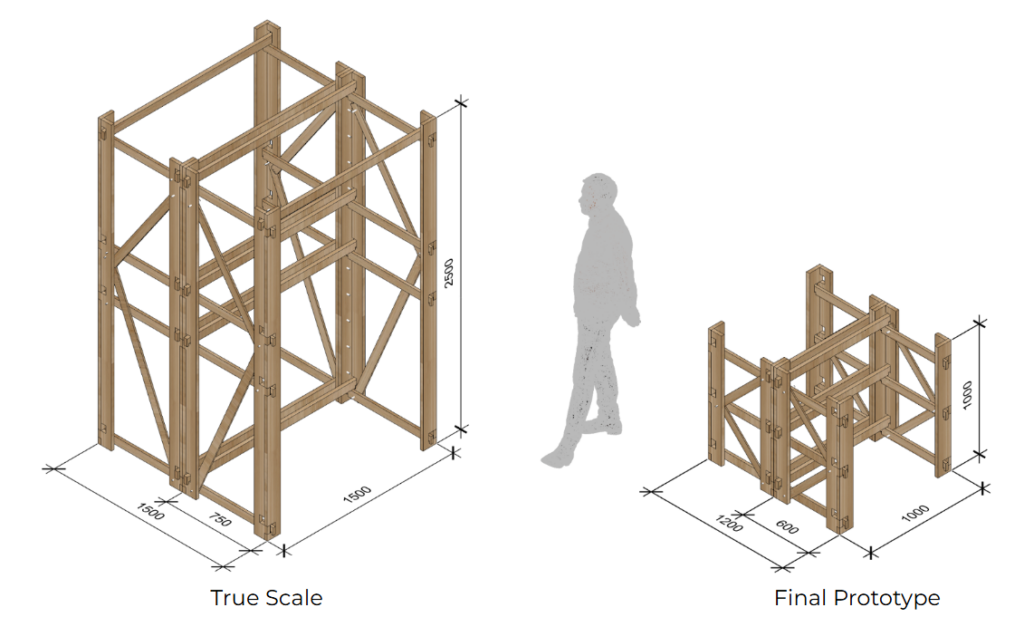

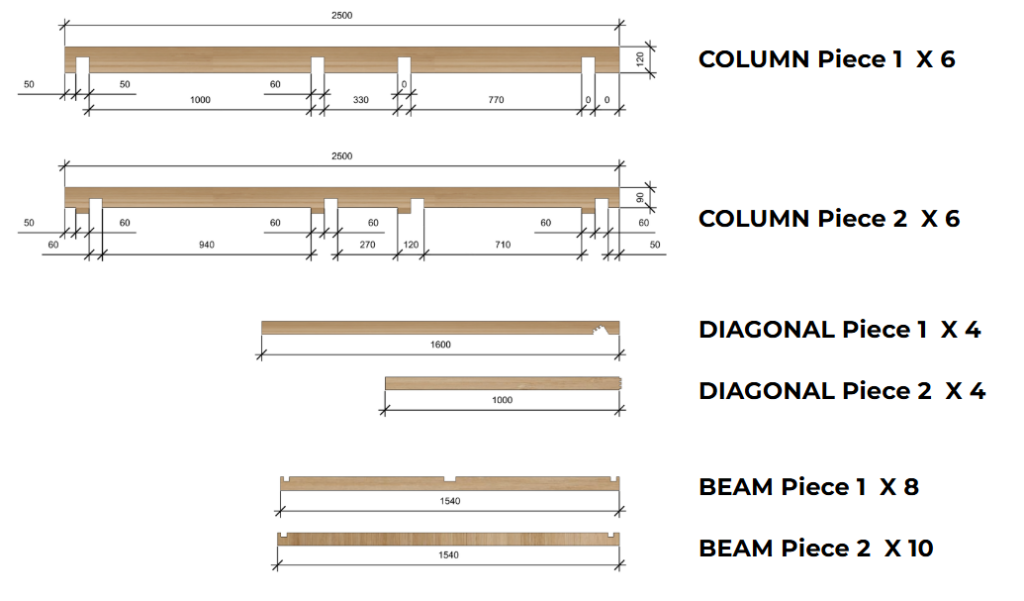

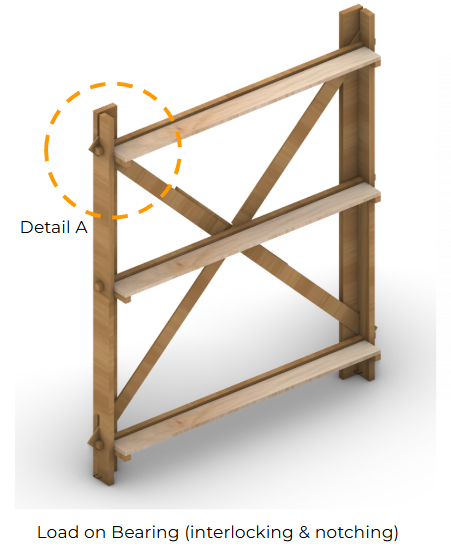

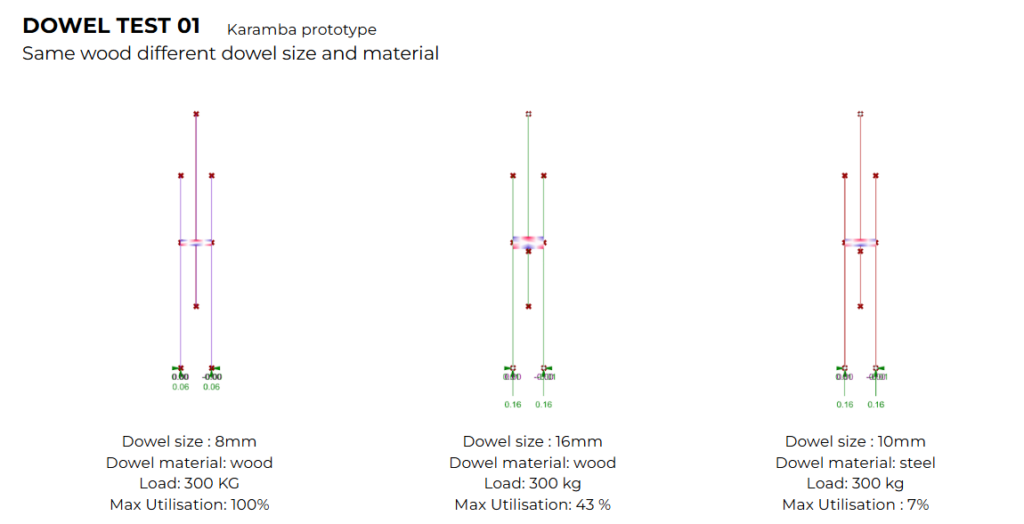

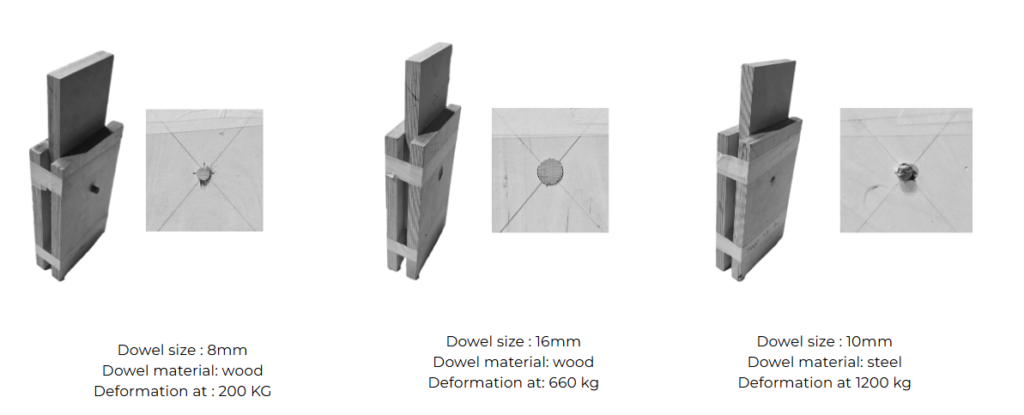

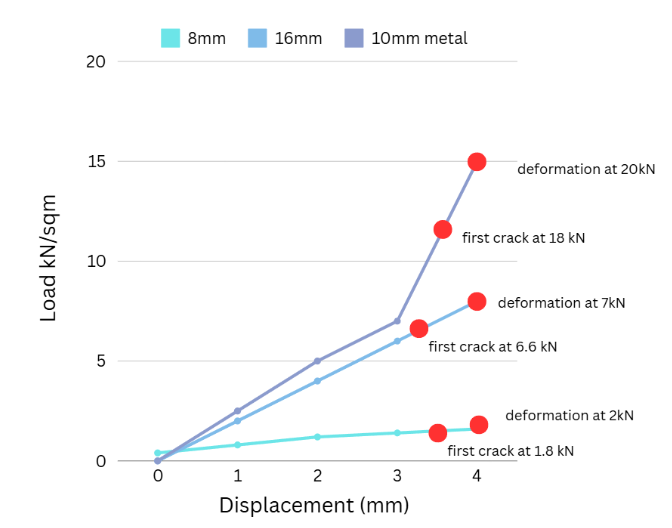

This project explores the structural potential of reused timber in the development of a load-bearing wardrobe system. By adopting a stock-based design approach, we optimize material efficiency, sustainability, and structural performance. Through physical prototyping and computational analysis using Karamba 3D, we assess various connection strategies, including dowel joints, interlocking mechanisms, and bearing-based load transfer.

By reusing discarded wood, we aim to create a structurally efficient, low-carbon system while addressing critical aspects of load distribution, orientation, and material capacity.

Inspiration

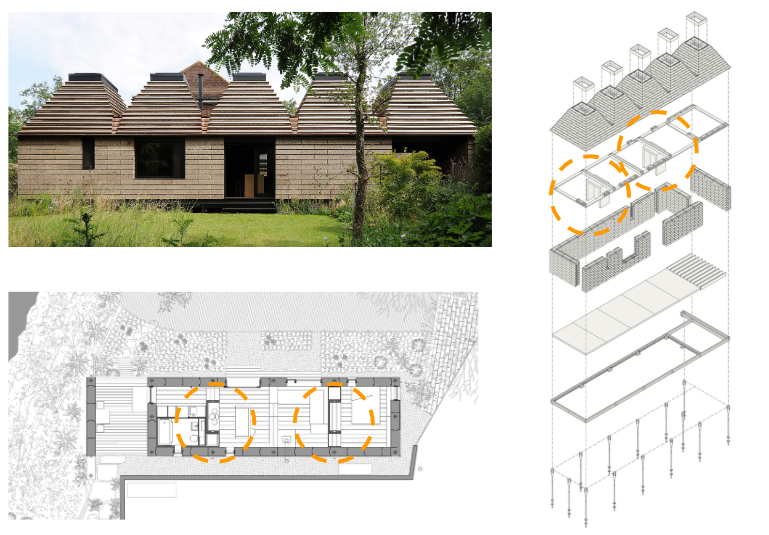

The cork house is an innovative dwelling constructed entirely from cork blocks that interlock without adhesives or mortar. Central to its design is a structural core wardrobe that integrates storage and services, efficiently utilizing space while contributing to the house’s overall stability and contributing to its thermal performance.

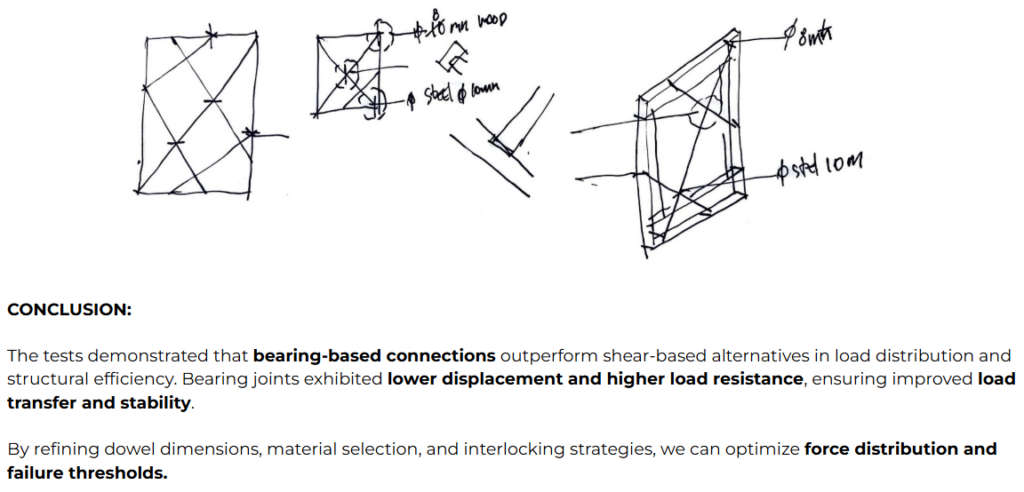

Prototyping the system

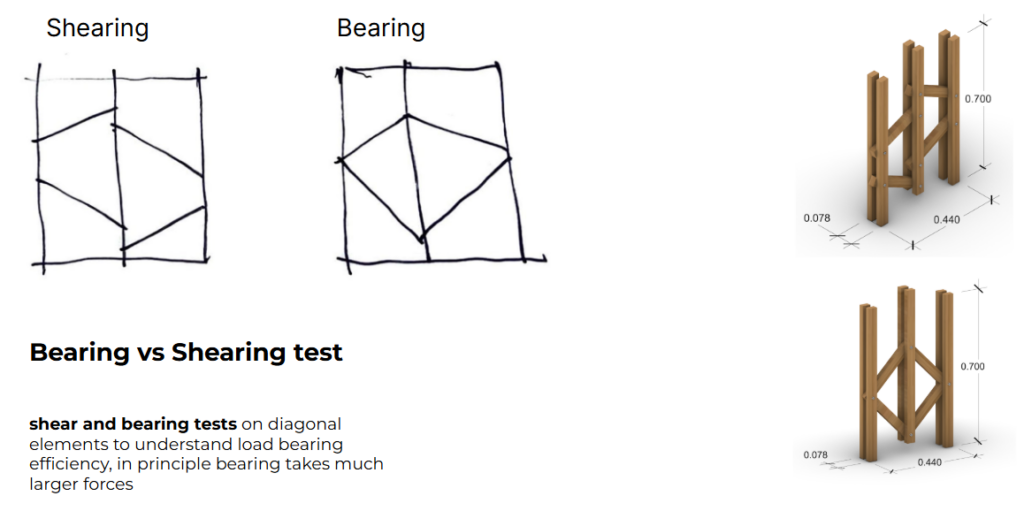

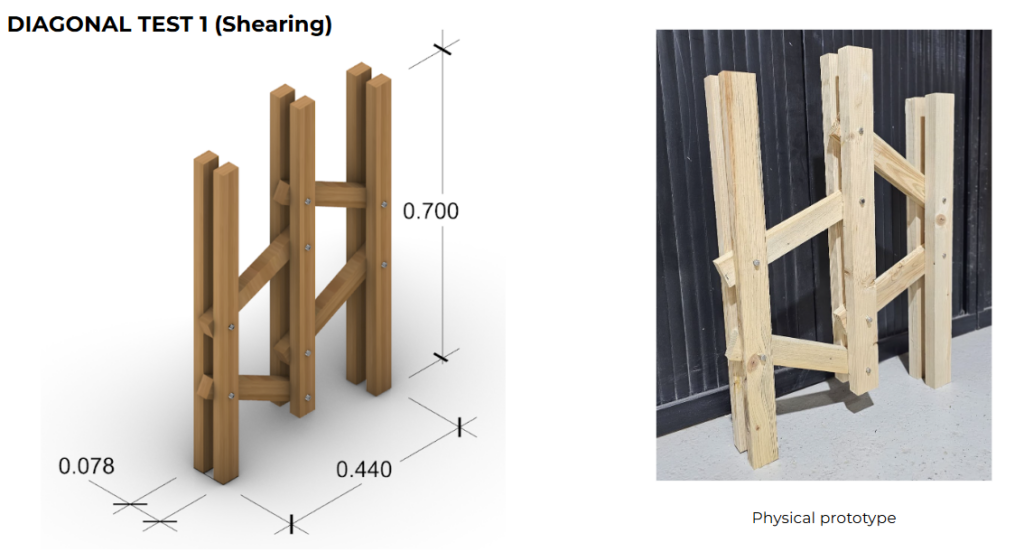

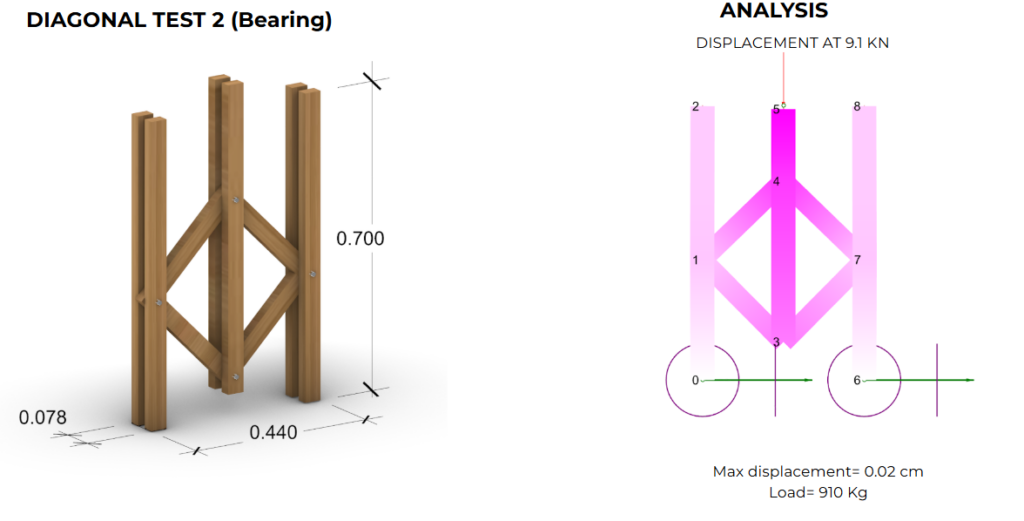

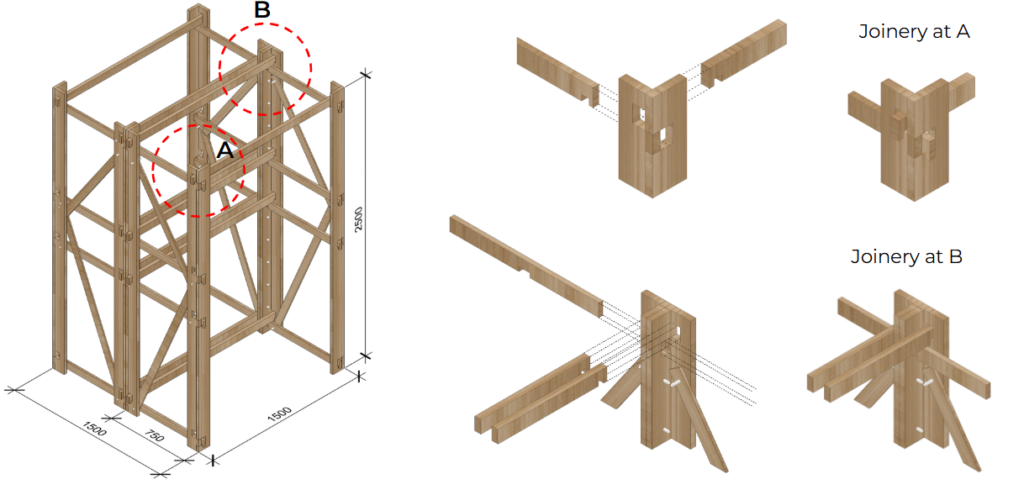

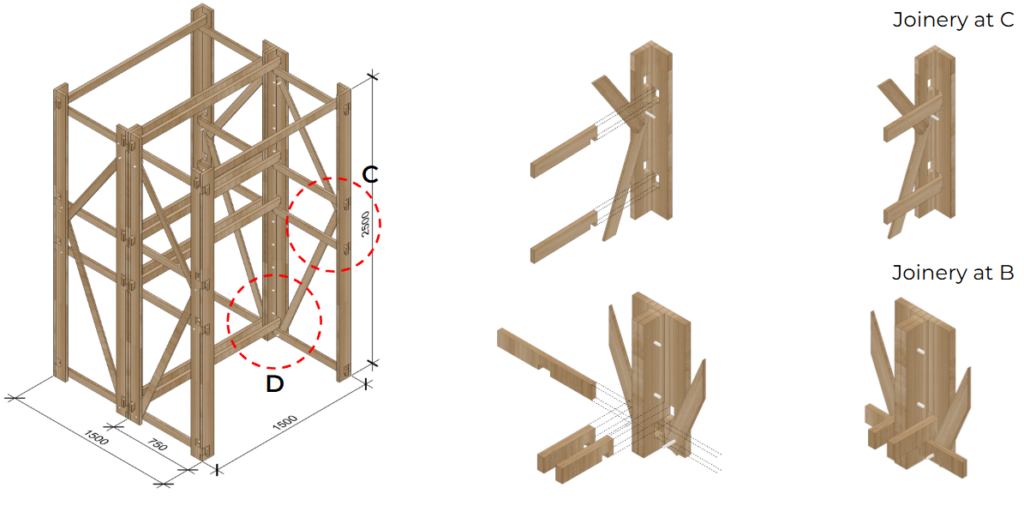

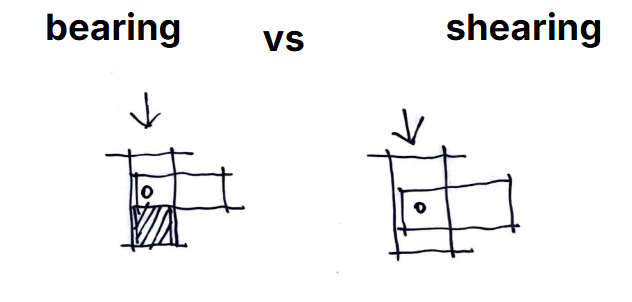

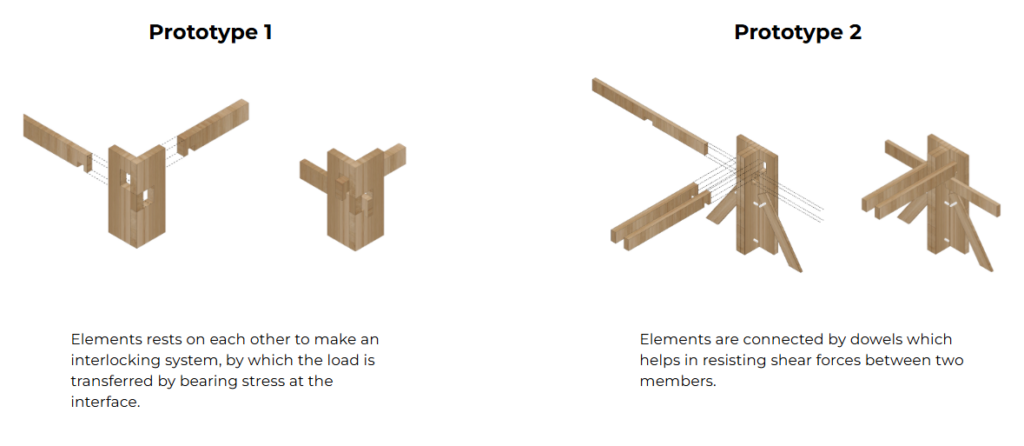

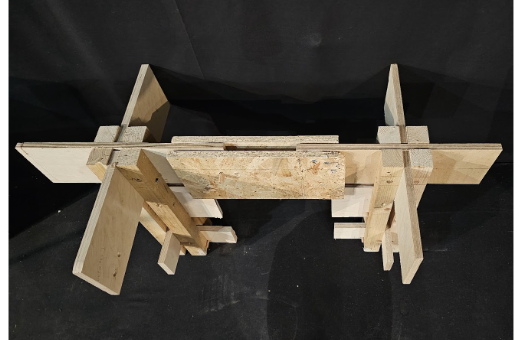

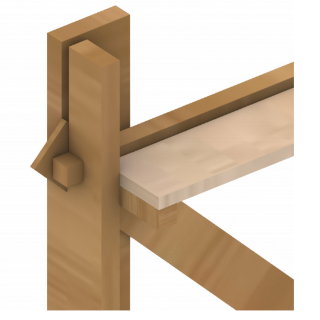

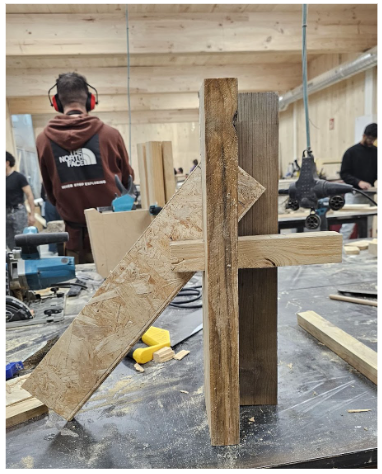

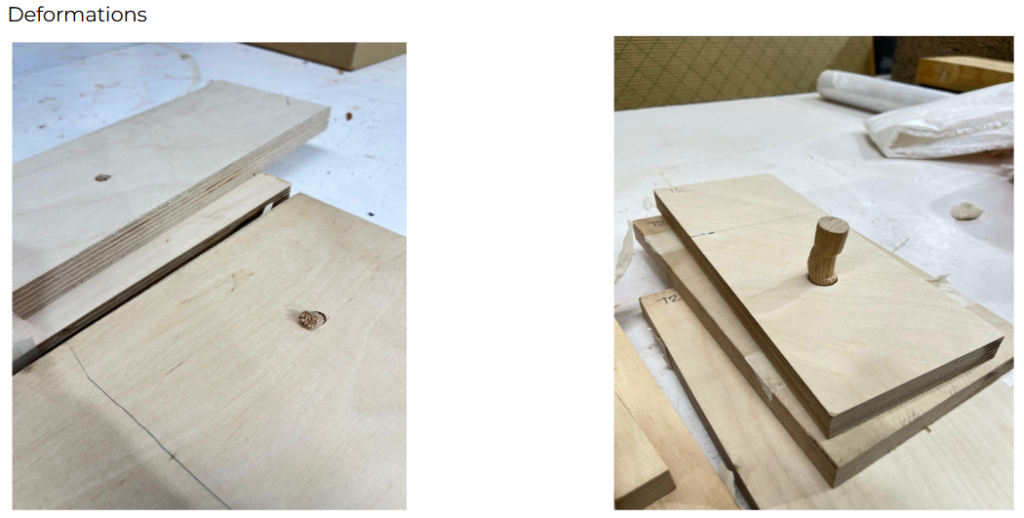

We developed corner joint prototypes to test different connection strategies, focusing on shear, bearing, and interlocking mechanisms. We looked at two different aspects, bearing connections and shearing connections.

Prototype 1

Fabrication

Prototype 2

Fabrication

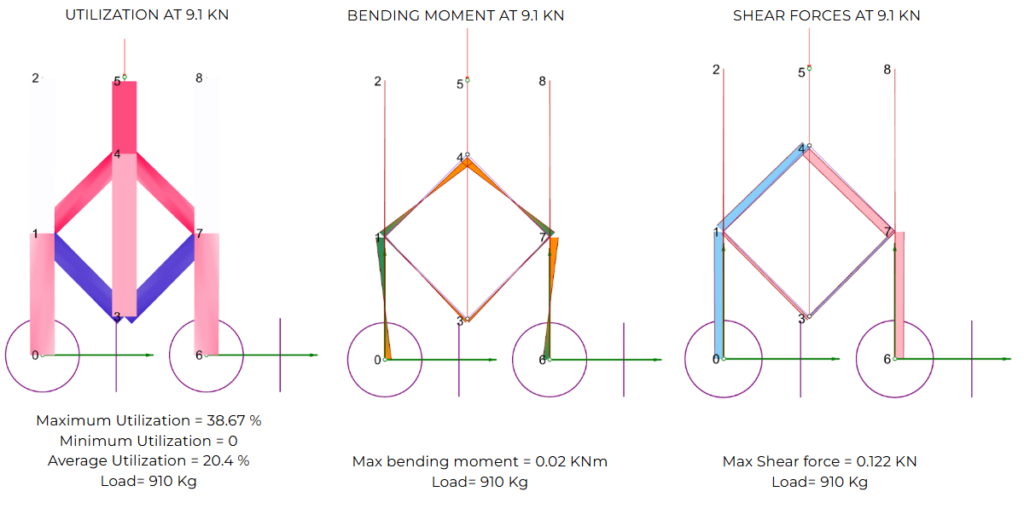

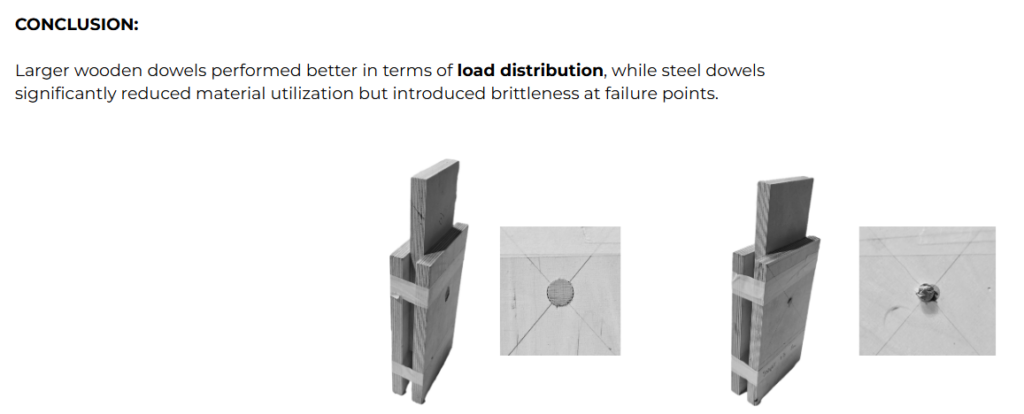

CONCLUSION :

We observed that the interlocking system provided superior structural performance compared to shear and dowel-based connections.

This approach not only optimized material utilization but also simplified assembly, making it a more efficient and structurally reliable solution for the wardrobe system.

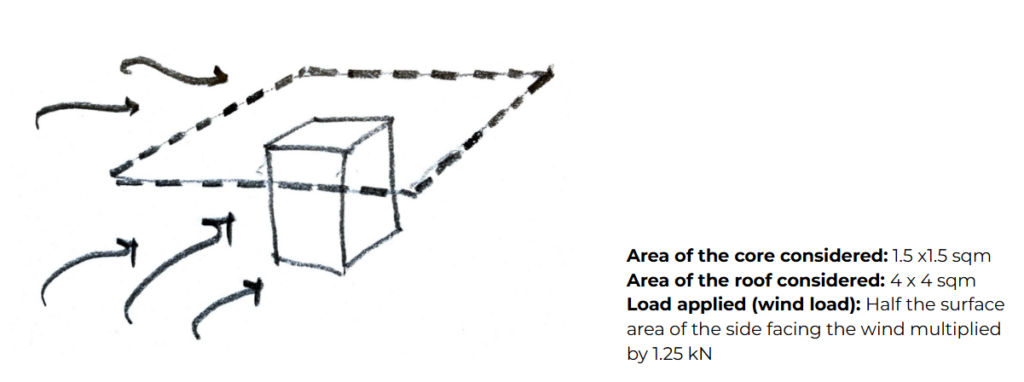

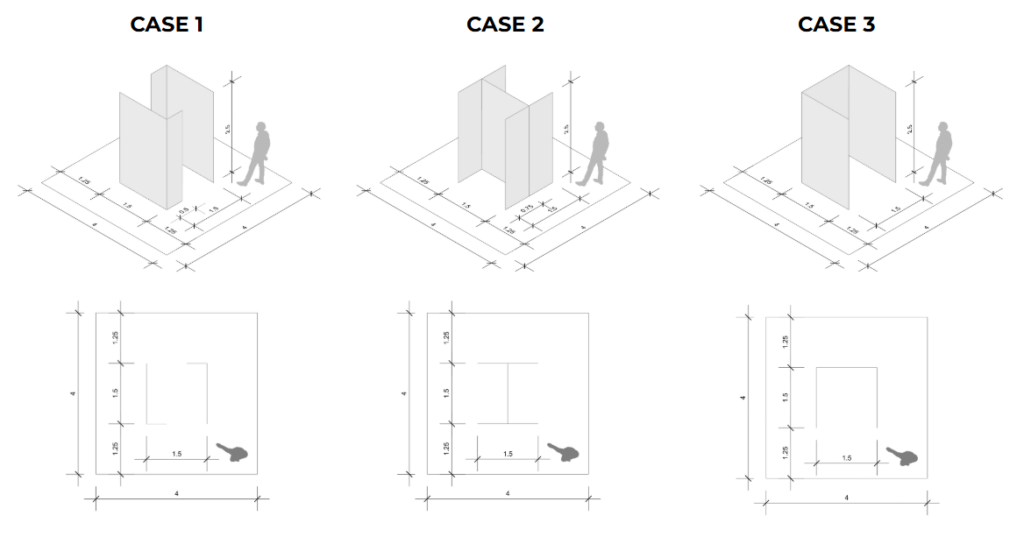

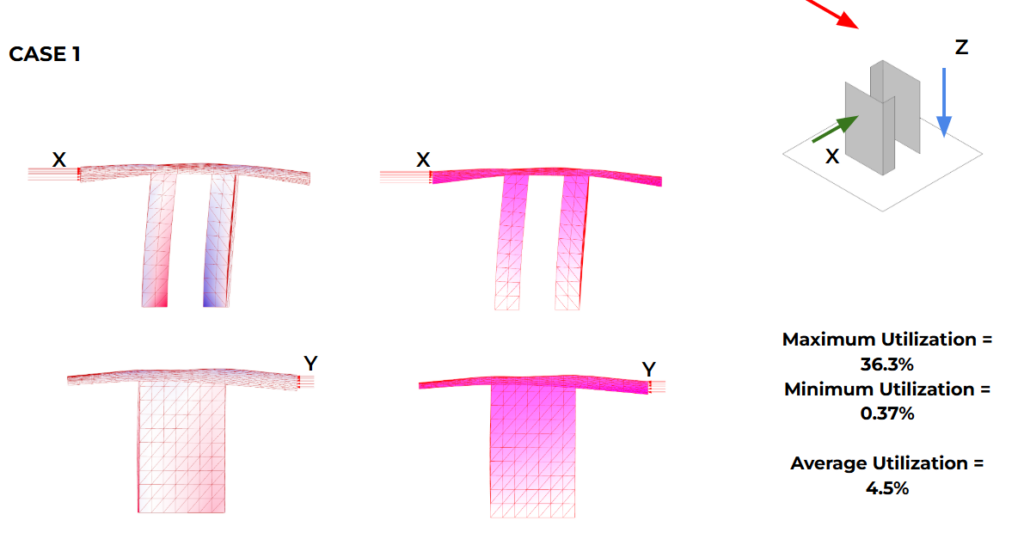

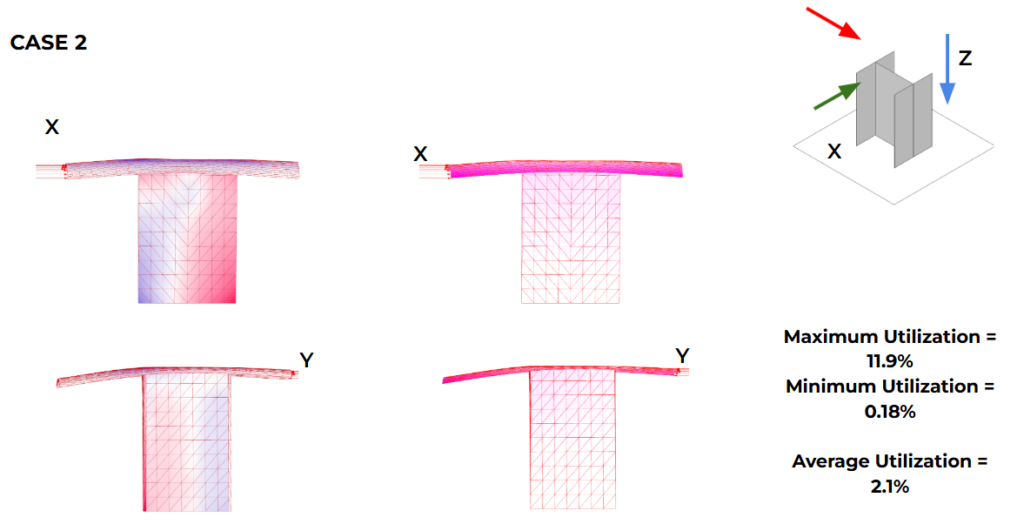

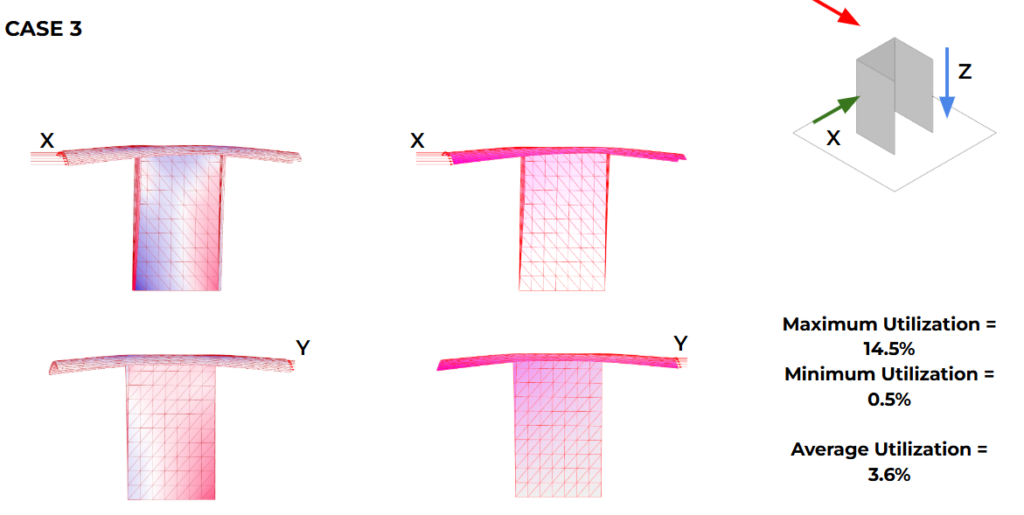

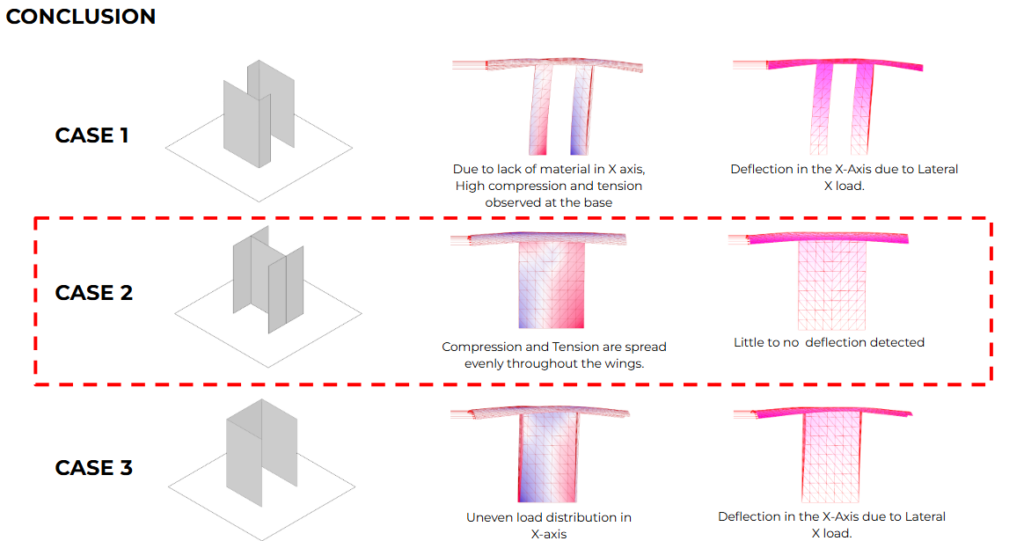

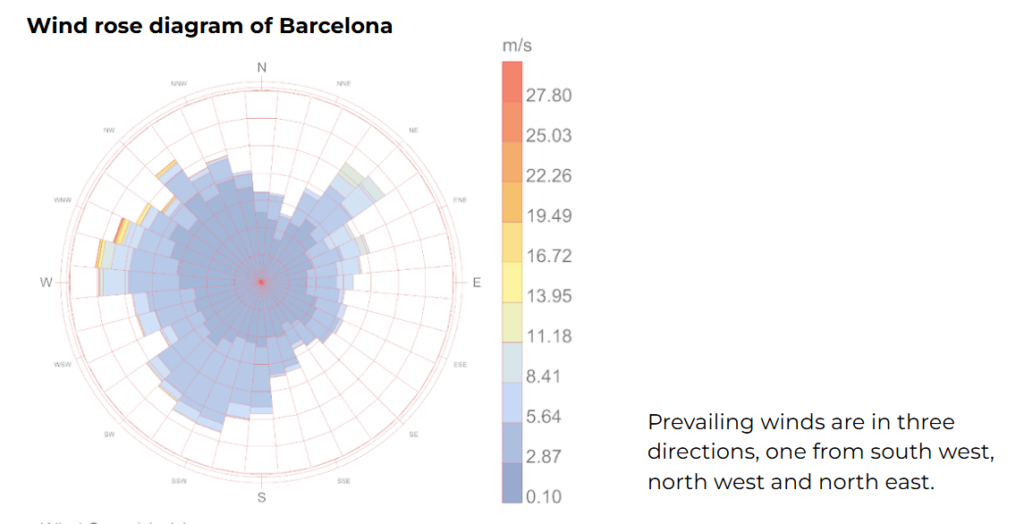

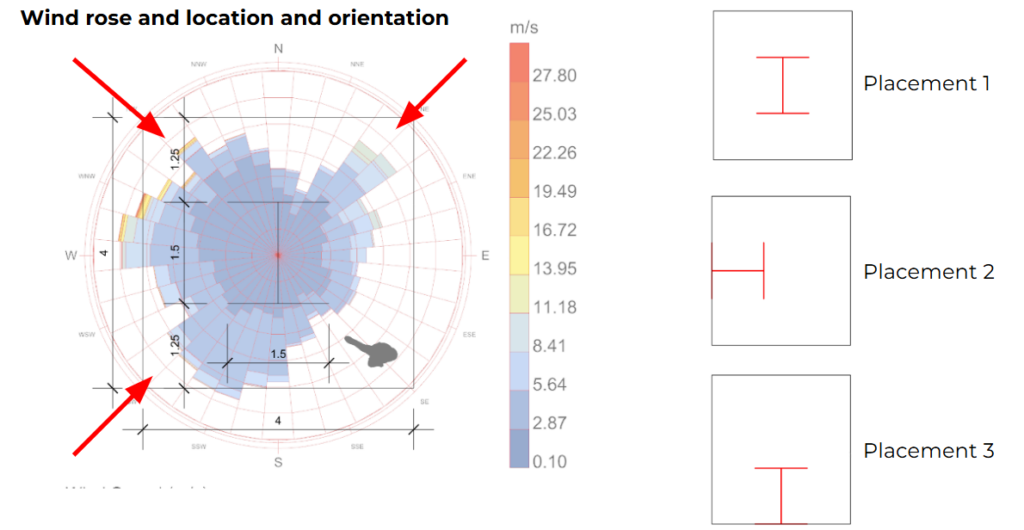

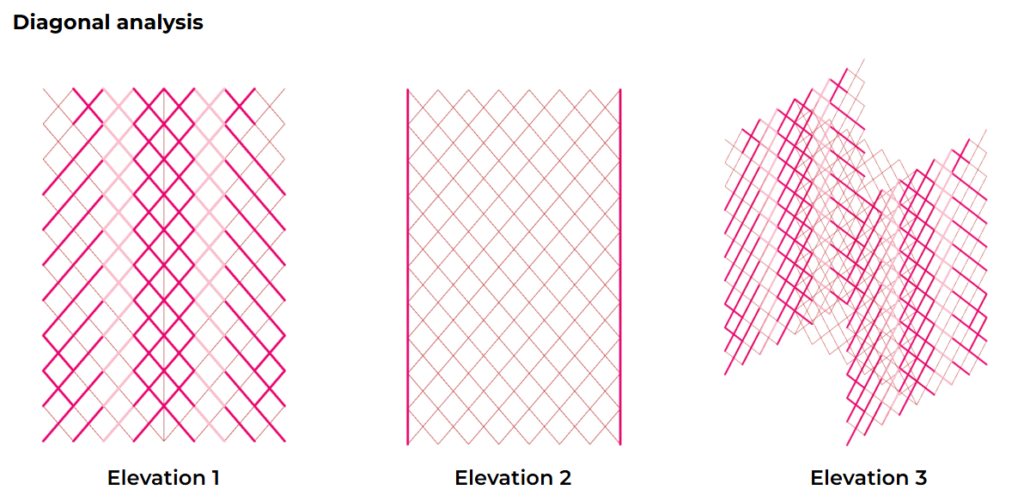

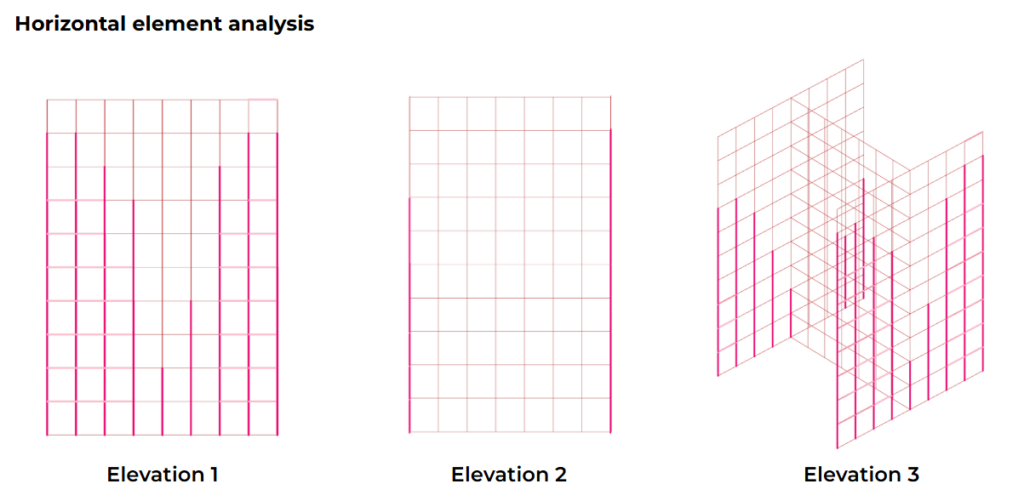

Geometry, location and orientation of the building

Strategy to place elements

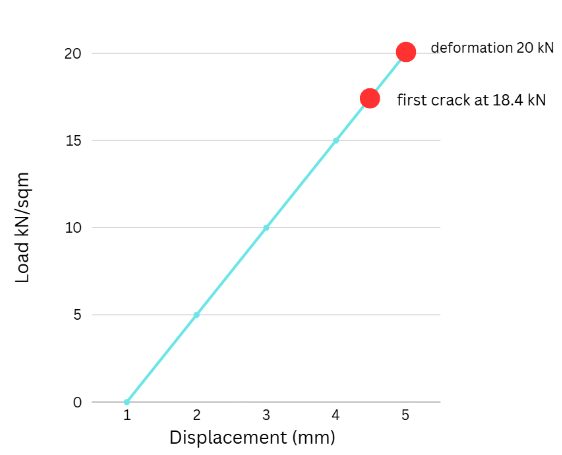

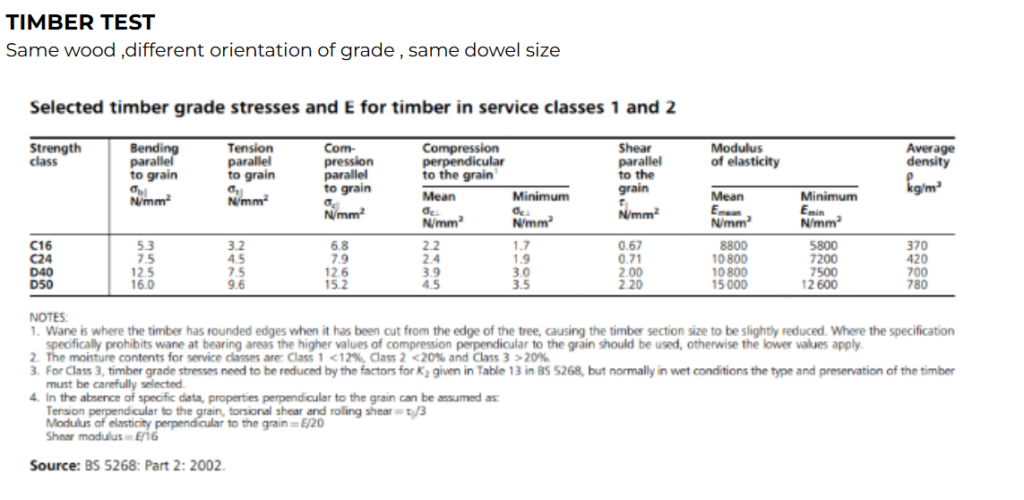

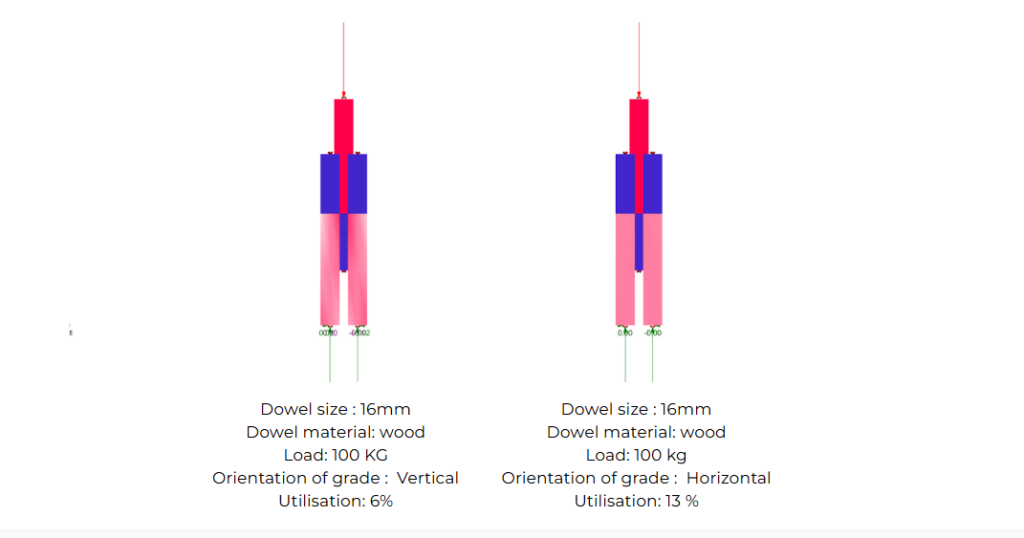

Testing to understand materials

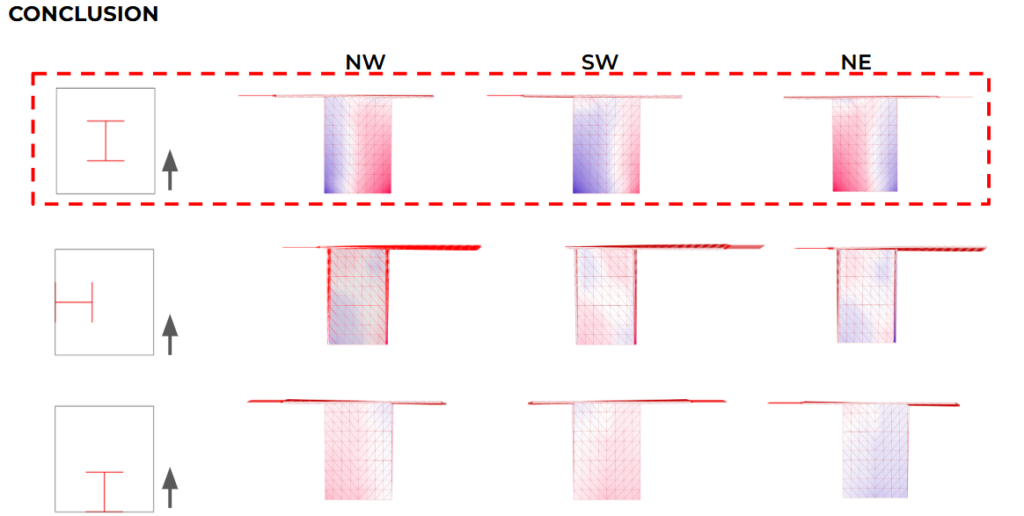

CONCLUSION:

Grain orientation plays a crucial role, vertically oriented grains outperform horizontal configurations in terms of shear resistance.