Insights from LCA, Materials, Energy, Circuitry, and Transport

Modular design is increasingly becoming a cornerstone of sustainable construction, offering innovative ways to balance environmental responsibility with functional efficiency. Our recent exploration through five interconnected sessions—ranging from Life-Cycle Assessment (LCA) to energy use, advanced manufacturing, and transport—has provided profound insights into how we can optimize modular projects for sustainability. This blog post summarizes key learnings and personal reflections on how these concepts shaped our understanding and approach to modular design.

Session 01: Introduction to Life-Cycle Assessment (LCA)

The journey began with an introduction to Life-Cycle Assessment (LCA), a critical tool for evaluating the environmental impact of products and processes. LCA allows designers to assess trade-offs across a product’s life cycle by considering factors such as raw material extraction, manufacturing, usage, and disposal.

Key Takeaways:

- LCA helps identify environmental hotspots and provides a framework for informed material selection.

- Designers face challenges in aligning LCA practices with varying regulations and system boundaries.

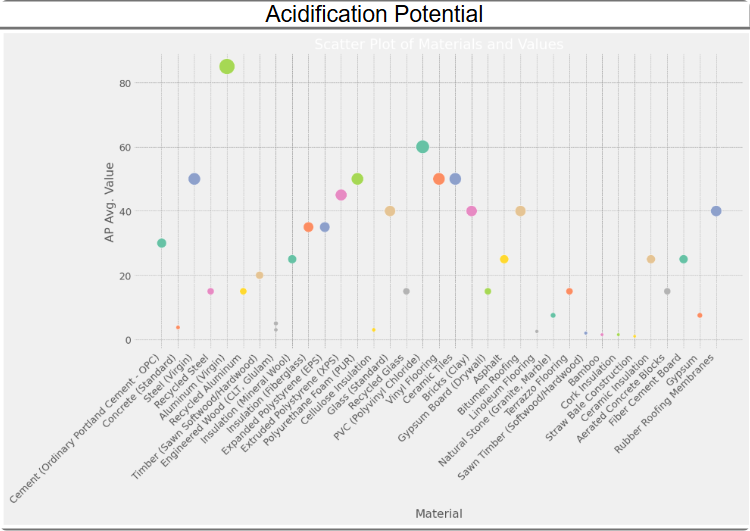

Session 02: Materials

This session focused on how material choices influence a project’s sustainability. It delved into the environmental trade-offs of materials like Portland cement and introduced advanced manufacturing techniques and alternative materials, such as biopolymers.

Key Takeaways:

- Material life cycles reveal their environmental trade-offs, helping designers choose more sustainable options.

- Advanced technologies and alternative materials offer solutions to mitigate environmental impacts.

Session 03: Energy

The energy-focused session explored the fundamentals of energy use, including the concept of Energy Return on Investment (EROI). It also examined scenarios like green growth and degrowth, emphasizing the trade-offs in energy decisions.

Key Takeaways:

- Clean energy solutions are context-specific and often require small-scale implementation.

- Evaluating energy trade-offs helps balance advantages and disadvantages across systems.

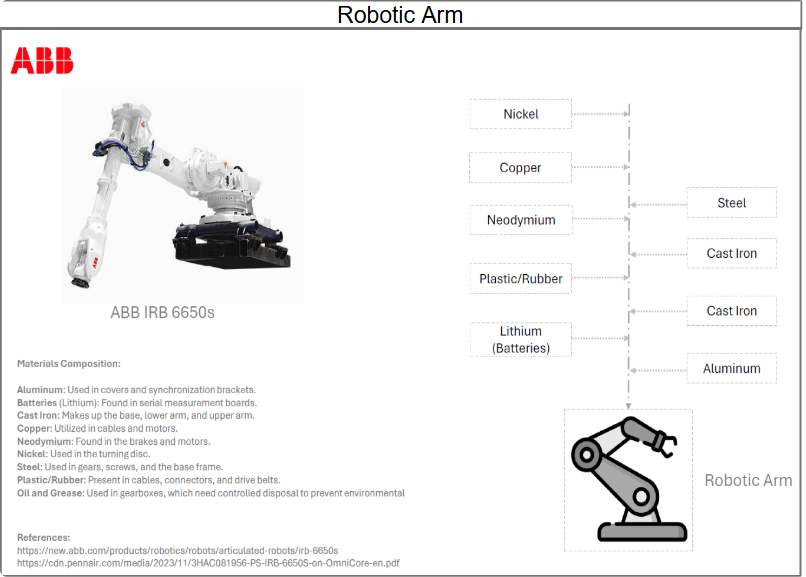

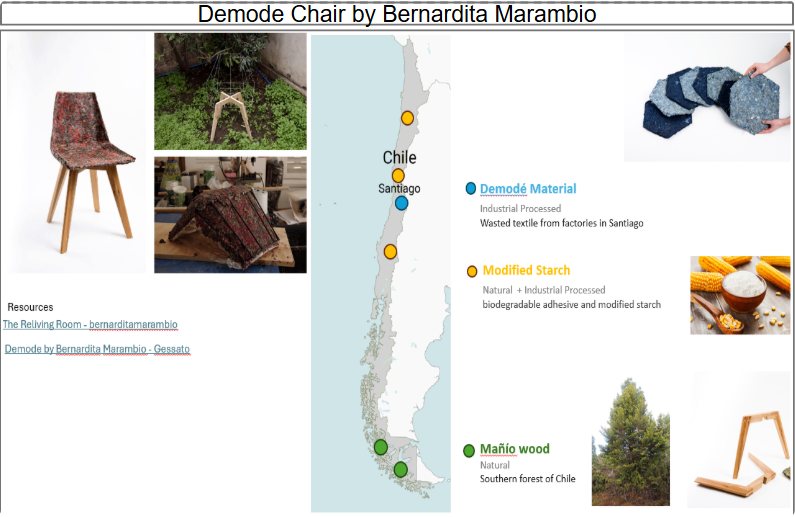

Session 04: Circuitry

This session introduced 3D Concrete Printing (3DCP) and its implications for sustainable manufacturing. The discussion highlighted the role of advanced technologies in reducing waste and maximizing resource efficiency. Real-world examples, such as the Demode Chair, demonstrated the potential of locally sourced and recycled materials.

Key Takeaways:

- Technologies like 3DCP can minimize waste and improve resource management.

- Biodegradable and recycled materials align with circular economy principles.

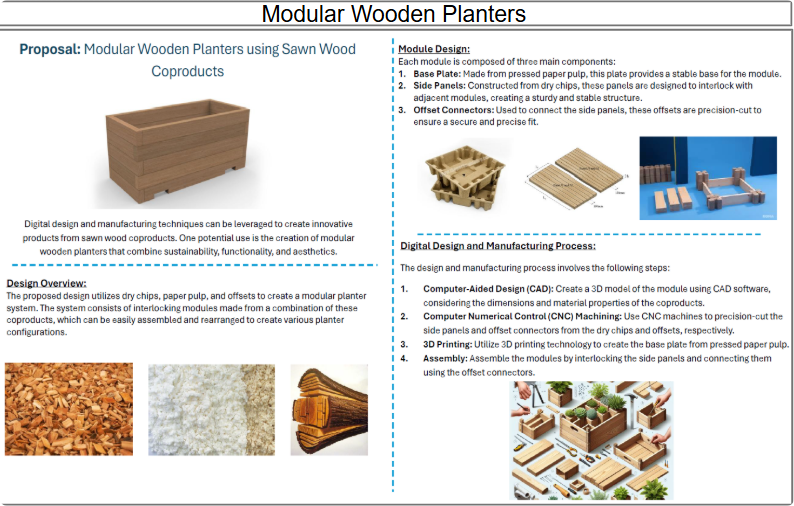

Session 05: Transport

The final session explored Bio-Local Advanced Manufacturing (BLAM) and the benefits of using local material streams like eelgrass and miscanthus. The concept of modular wooden planters served as a practical example of how waste streams can be transformed into valuable resources.

Key Takeaways:

- Localized production reduces transportation emissions and supports environmental sustainability.

- Modular systems using interlocking components enhance efficiency and minimize waste.

Our Vision for Modular Design

These sessions have deepened our understanding of how to integrate sustainability into modular design. By leveraging tools like LCA, embracing advanced manufacturing, and prioritizing local materials, we can create modular projects that are not only functional and efficient but also environmentally responsible.

Whether it’s rethinking material life cycles, adopting clean energy solutions, or utilizing waste streams, each step brings us closer to a modular design approach that aligns with the principles of sustainability and circularity.

As we move forward, these insights will continue to guide our approach, ensuring that every modular design we create is optimized for environmental, economic, and social impact.