WEEK 1 : MATTER

This week , Series of experiments were conducted with Secil Afsar and Amanda . Students of 3DPA pre-course were introduced to the physical concepts that relate to the mechanical properties of 3D-printed clay and earthen structures.

The project aims to define and improve the performance of earthen materials used in 3D printing for architectural and construction applications. The main goal is to develop performance benchmarks and guidelines comparable to those of conventional materials, addressing the current lack of standardised regulations for 3D printing with earth.

Field Test

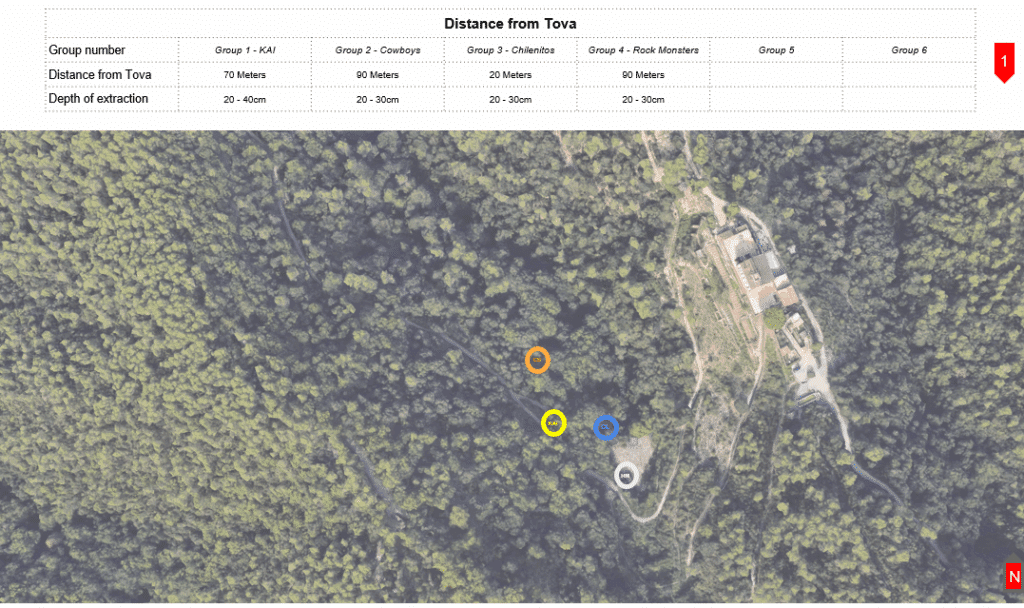

3D Printing Field Test (Soil Collection Special Project) is a special test that focuses on collecting soil samples with high clay content to support the research and development of soil-based 3D printing materials and the application testing of soil printing in construction or art fields, thereby laying a foundation for optimising material formulas and verifying printing processes later.

I. Core Objective

The core objective of this test is to find areas with high clay content (focusing on natural sedimentary areas such as river surroundings and low-lying lake areas, as well as accumulated areas after weathering of shale and mudstone), since clay’s plasticity and cohesiveness are crucial to the quality of soil-based 3D printed products.

II. Significance of the Test

The significance of this test lies in providing real soil samples for 3D printing to solve the problems of difficult material selection and poor adaptability of soil-based printing materials, reducing the cost of subsequent material improvement and improving the quality of printed products; at the same time, the accumulated soil distribution information can provide references for the development of 3D printing soil resources in different regions, facilitating the implementation of 3D printing in more fields.

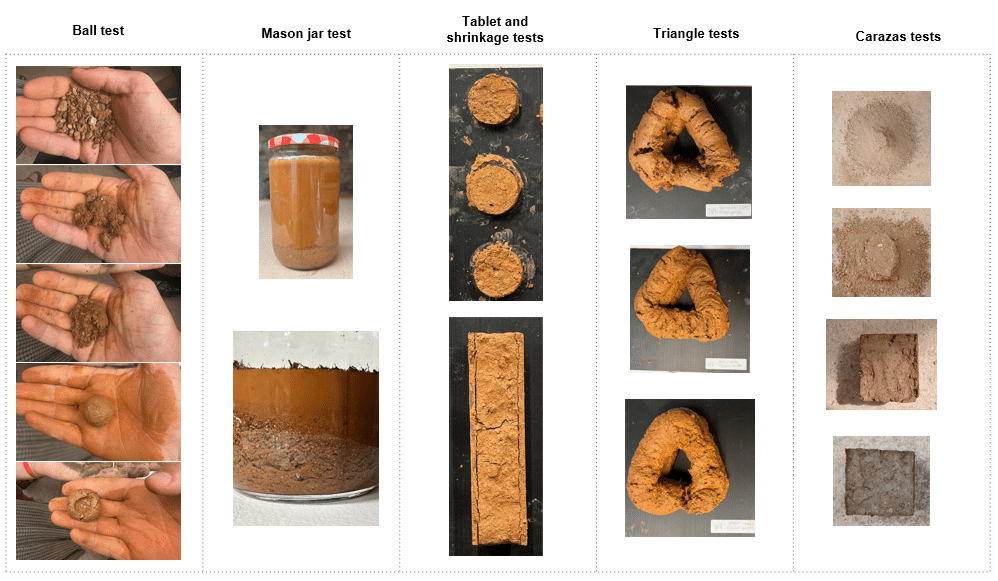

Carazas test

The Carazas Test is a simple on-site geotechnical test that quickly assesses soil’s clay content and plasticity (critical for engineering or soil-based 3D printing) without complex equipment, making it ideal for preliminary field surveys to find high-clay soil.

I. Core Objective

The Carazas Test aims to rapidly screen field soil for areas with high clay potential and quickly judge soil plasticity, helping teams decide if more detailed lab testing is needed for their project.

II. Significance of the Test

The Carazas Test is valuable for its speed and simplicity—it saves time/cost by enabling quick on-site evaluation of multiple locations, helps prioritize areas for further testing, and is accessible to non-specialists for fast soil suitability decisions.

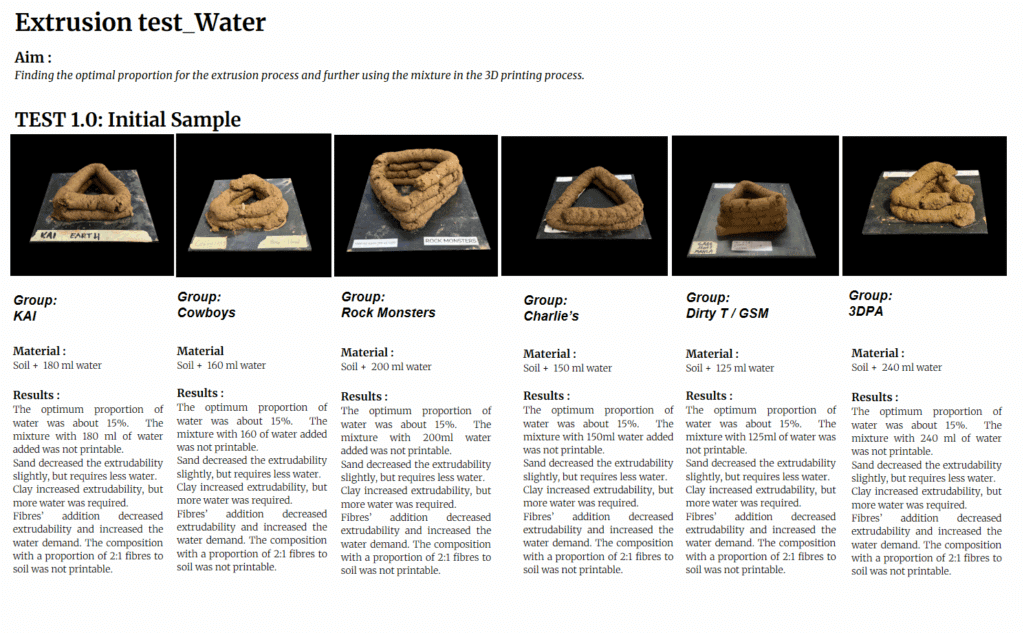

Extrusion test

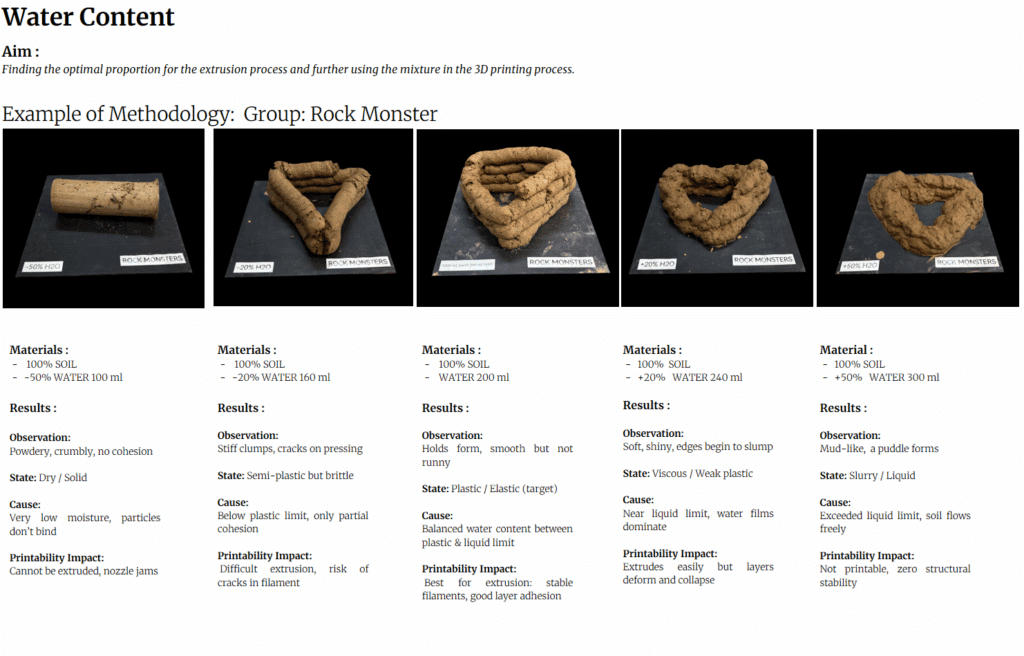

Following the field test, an extrusion test was conducted to evaluate the interaction between the soil material and the chosen manufacturing method, namely additive manufacturing by extrusion.

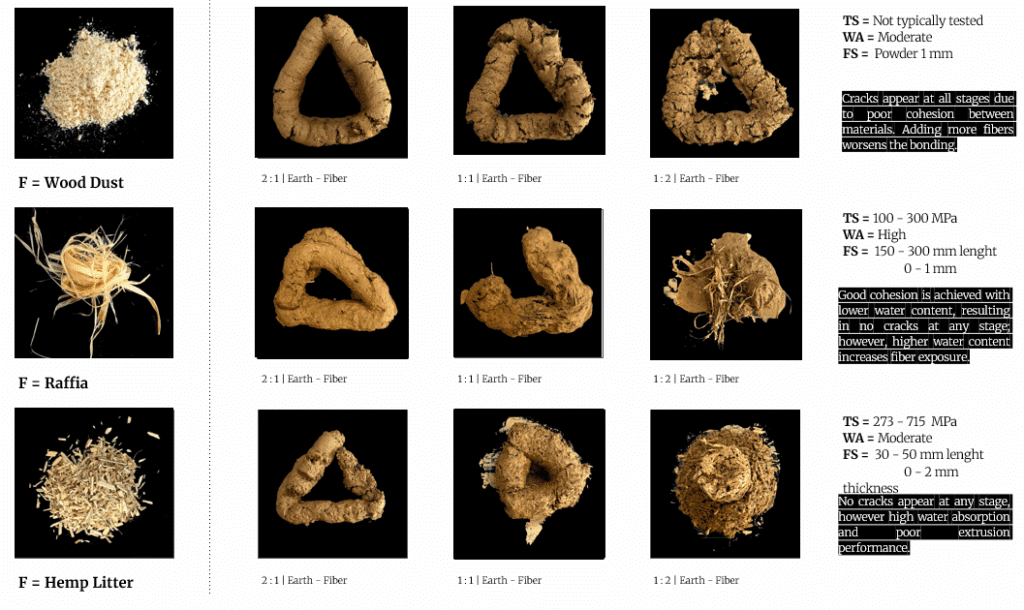

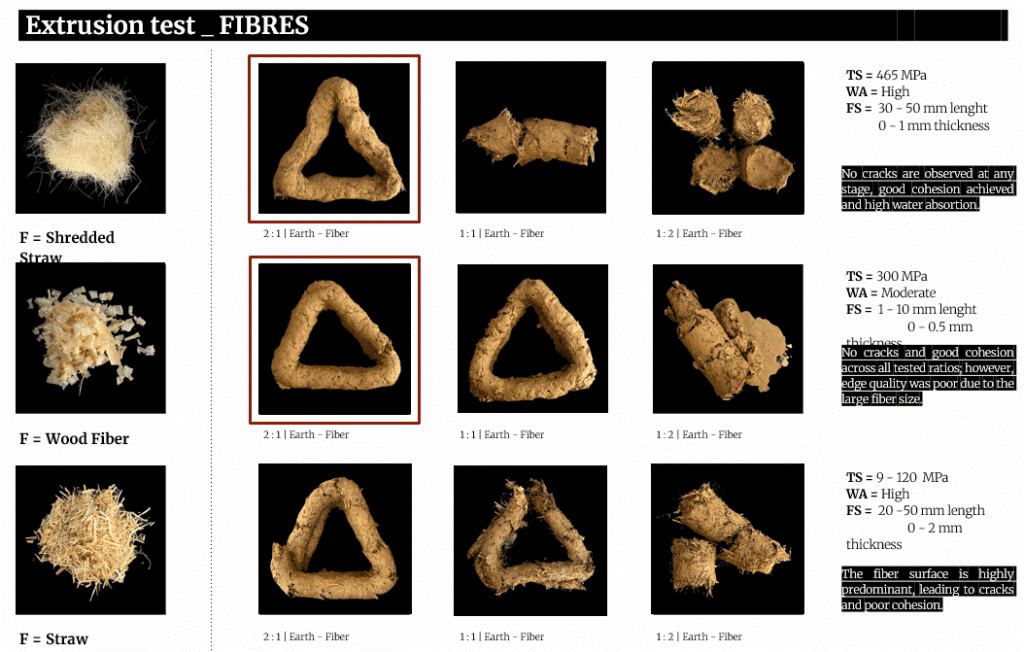

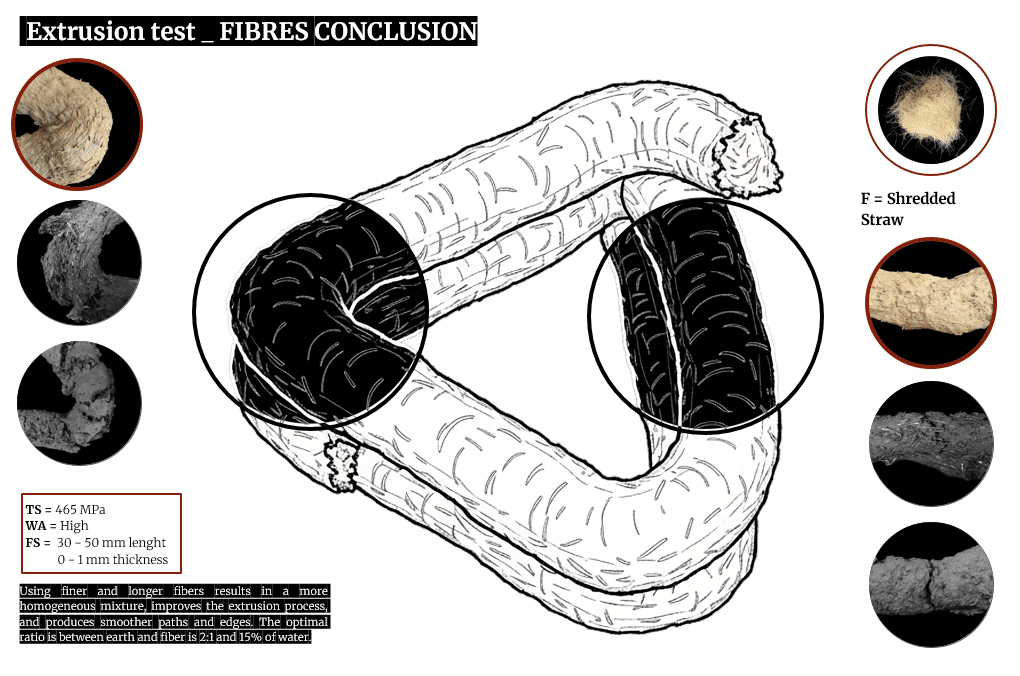

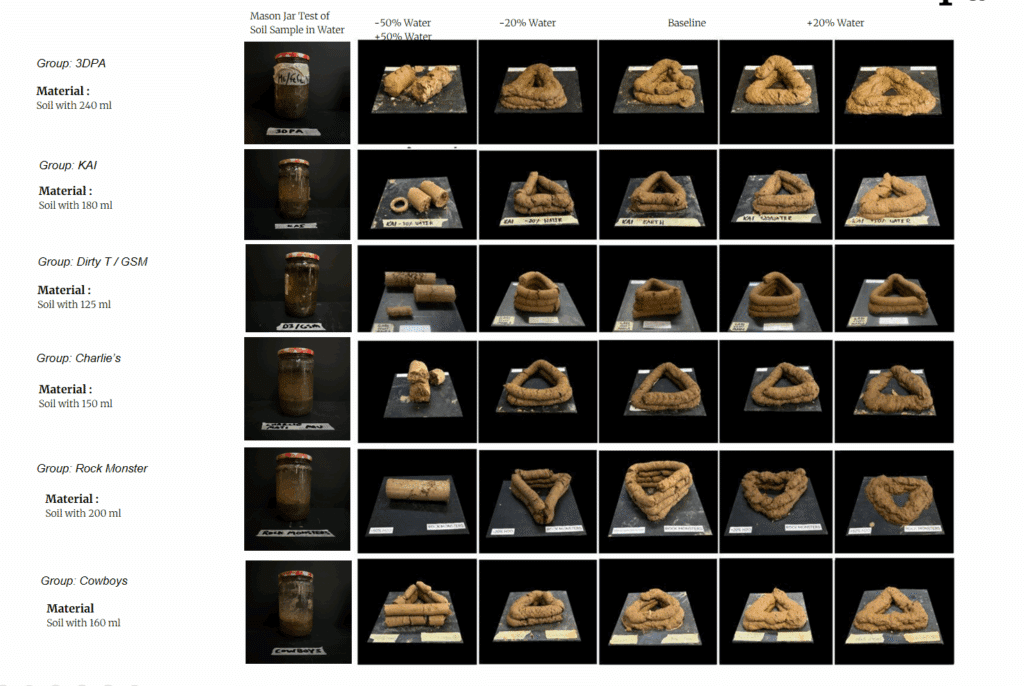

The objective of this test was to determine the optimal viscosity of the soil mixture for extrusion. Several parameters were systematically varied during the evaluation, starting with the water content. The baseline water content was first increased by 20% and 50%, and then reduced by 20% and 50%. A similar stepwise adjustment was applied to the sand-to-clay ratio as well as to the fiber content of the mixture.

Extrusion was performed in two layers following a triangular pattern with 15 cm sides. The sharp corners of the triangle provided a visual assessment of the behavior of the modified soil mixture and the quality of interlayer adhesion. Final evaluation was carried out after drying, with specific attention to shrinkage and dimensional stability for each soil samples.

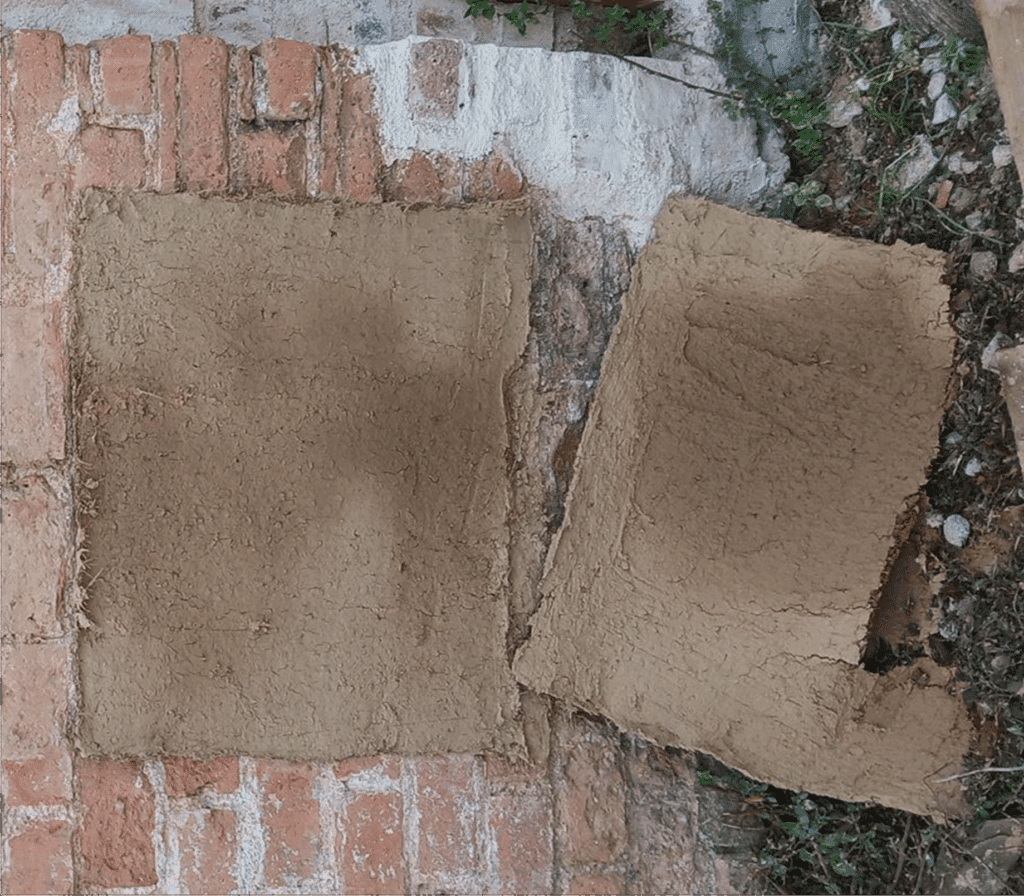

Rendering assessment

The rendering assessment is designed to evaluate the behavior of soil when applied as a render on a vertical surface.

The test consists of a series of square samples measuring 50 × 50 cm, applied at a controlled thickness onto a vertical substrate. Each square receives a reformulated soil mixture, progressively modified by increasing the sand content in one direction and the fiber content in the other, with intermediate samples prepared using combined variations of both.

The objective of this assessment is to determine :

• the degree of shrinkage of each sample,

• the adhesion to the substrate,

• the optimal balance between soil, sand, and fiber,

• and the resistance to surface fragmentation and erosion caused by friction.

This evaluation provides valuable insight into the adhesive properties of clay within the soil mixture and its performance as a rendering material.

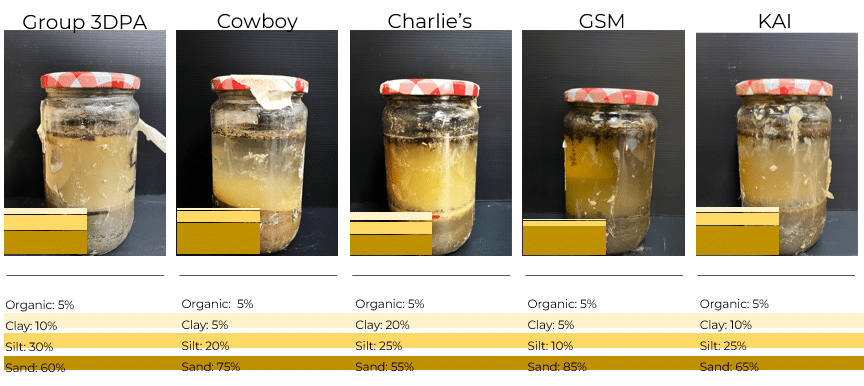

Mason Jar Test

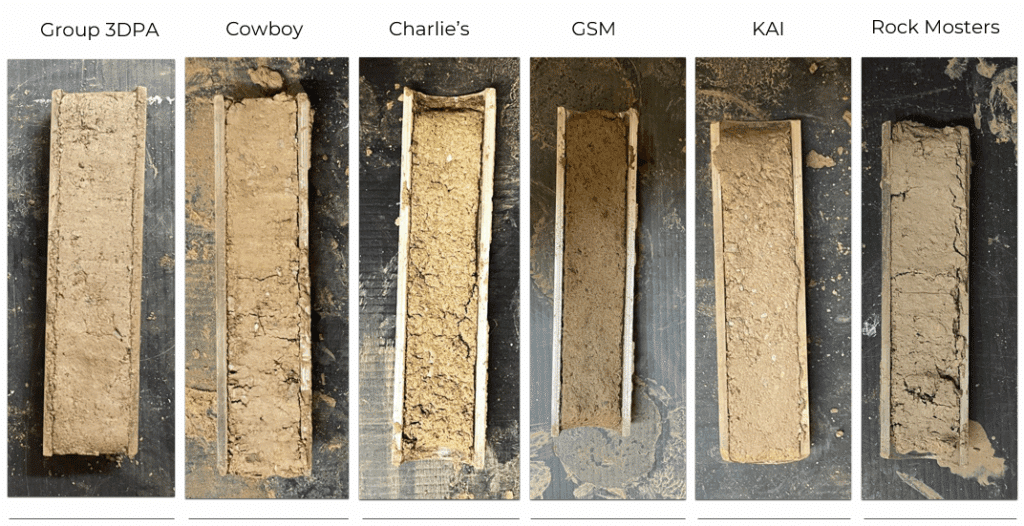

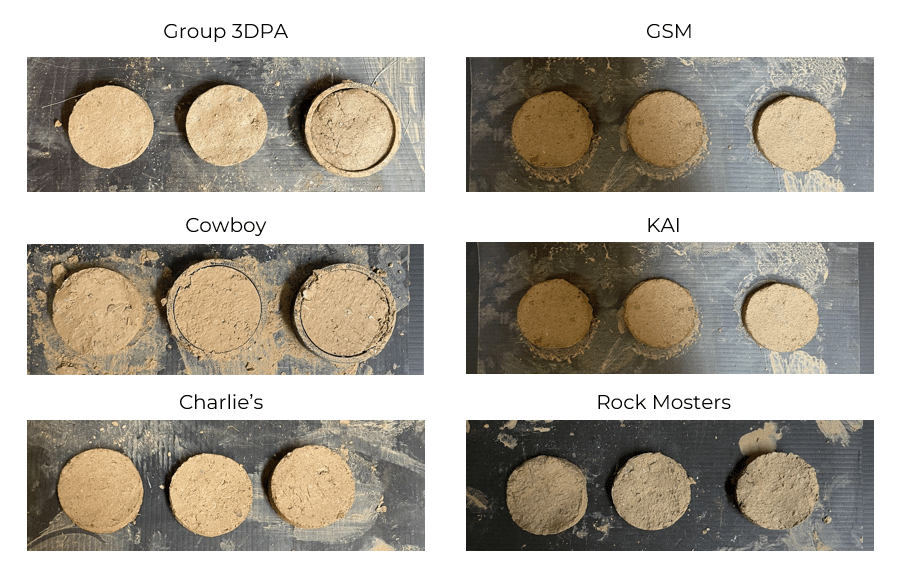

Shrinkage Test

Field Test

Table Test

Soil Assessment

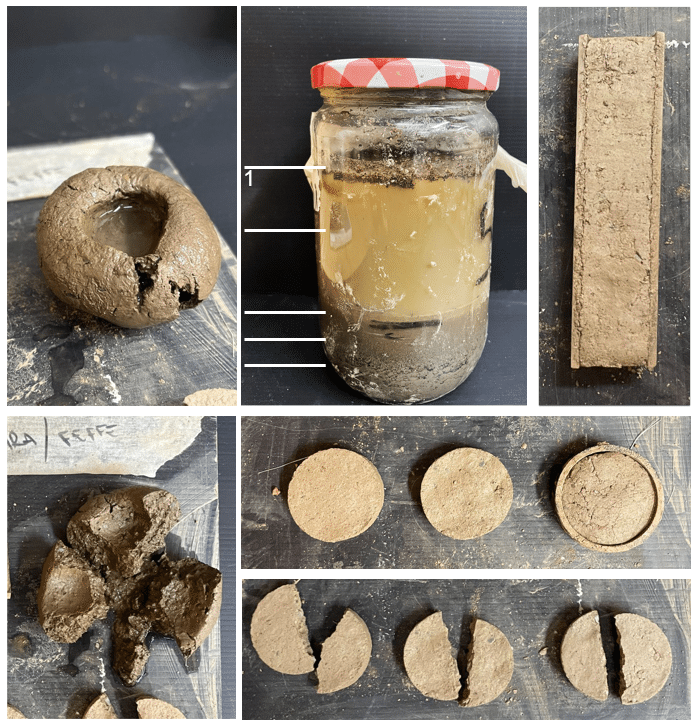

Group -1

Aim:

Preliminary assessment of soil for construction purposes

Material

Soil from 70m above TOVA (see map)

Results

Water permeability – high, (failure happened after around 5 mins)

Sedimentation (jar)

•Layer 1 – organic matter

•Layer 2 – Cloudy water

•Layer 3 – Clay

•Layer 4 – SIlt

•Layer 5 – Sand

Shrinkage

Half-tube – no significant shrinkage after 72 h, which contradicts the high clay content hypothesis, though material is not fully dry.

Rings – a lack of significant shrinkage and a lack of cracks after 72 h, though material is not fully dry

Conclusions

•After three days of sedimentation, the sample shows a clear stratification of soil fractions. A compact layer of sand settled at the bottom, followed by a softer transition zone of silt. The water above remains grey and cloudy, indicating a significant presence of fine clay particles still in suspension. This composition suggests that the soil is clay-rich, which provides good cohesion and binding properties but may also lead to shrinkage and cracking if not stabilised.

•Lack of shrinkage and cracks which is beneficial for construction purposes.

•Low permeability is beneficial, but rapid cracking towards end of drying process can cause material failure.

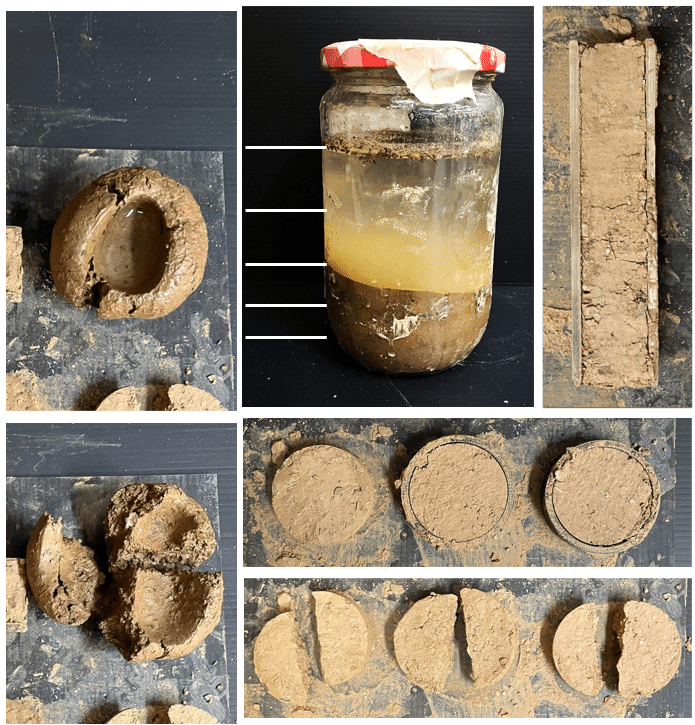

Aim:

Preliminary assessment of soil for construction purposes

Material

Soil from 70m above TOVA (see map)

Results

Water permeability – high, (failure happened after around 5 mins)

Sedimentation (jar)

•Layer 1 – Organic matter

•Layer 2 – Clay still in suspension, giving the water a turbid appearance.

•Middle yellowish-brown zone: Mostly silt — medium-sized particles

•Lower layer – Sand and heavier particles.

Shrinkage

Half-tube – no significant shrinkage after 72 h, tbut cracks occur

Rings – a lack of significant shrinkage and a lack of cracks after 72 h, though material is not fully dry

Conclusions

•The soil shows all main fractions (sand, silt, and clay) with a high clay content.

•The presence of floating particles suggests possible organic matter or contaminants.

•Test samples developed shrinkage cracks after drying, confirming clay-rich behaviour and limited strength.

•Overall, the soil requires stabilisation or treatment to improve durability for construction use.

•Low permeability is beneficial, but rapid cracking towards end of drying process can cause material failure.

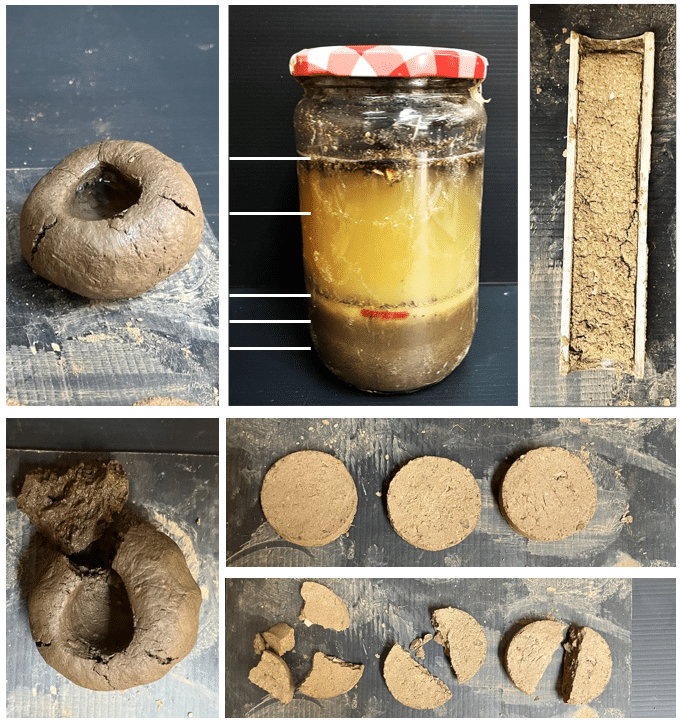

Aim:

Preliminary assessment of soil for construction purposes

Material

Soil from 70m above TOVA (see map)

Results

Water permeability – high, (failure happened after around 5 mins)

Sedimentation (jar)

•Upper layer – Organic matter

•Upper cloudy/whitish water: Clay still in suspension, giving the water a turbid appearance.

•Middle yellowish-brown zone: Mostly silt — medium-sized particles

•Lower layer – Sand and heavier particles.

Shrinkage

Half-tube – no significant shrinkage after 72 h, tbut cracks occur

Rings – a lack of significant shrinkage and a lack of cracks after 72 h, though material is not fully dry

Conclusions

•The soil shows all main fractions (sand, silt, and clay) with a high clay content.

•The presence of floating particles suggests possible organic matter or contaminants.

•Test samples developed shrinkage cracks after drying, confirming clay-rich behaviour and limited strength.

•Overall, the soil requires stabilisation or treatment to improve durability for construction use.

•Low permeability is beneficial, but rapid cracking towards end of drying process can cause material failure.

Extrution test – Fibers

Valldaura Soil Map

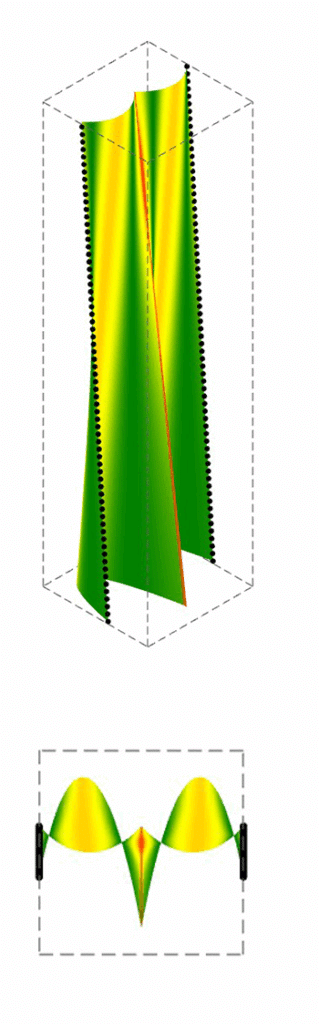

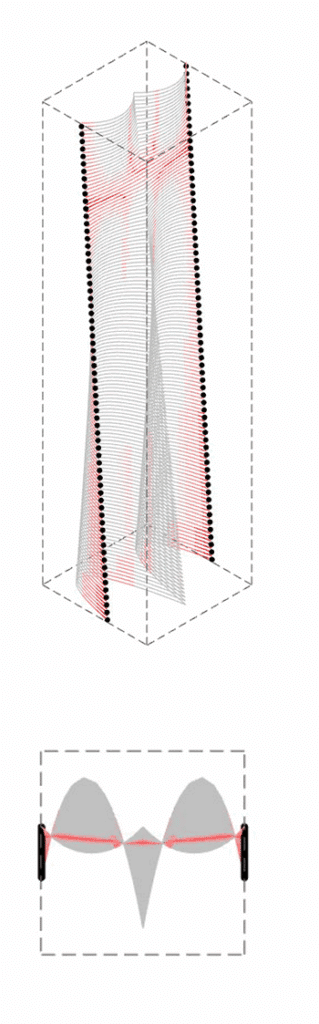

WEEK 3 : STRUCTURE

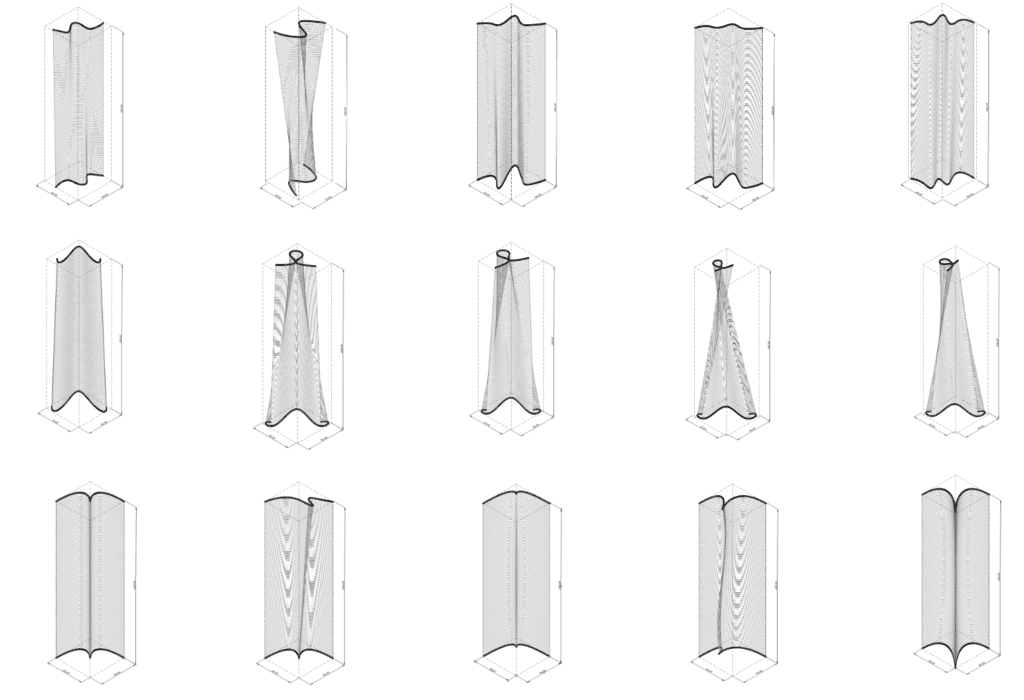

This week, through a series of lectures by Alicia Huguet, students of the 3DPA pre-course were introduced to the physical concepts that relate to the mechanical properties of 3D-printed clay and earthen structures. Earthen materials perform well under compression but are weak in tension. Proper geometry has a critical influence on structural stability, allowing better control of compressive strength within the designed elements. The distribution of geometry has a greater impact on compressive strength than the total amount of material used. Through simulations, digital analyses and iterative testing, we were able to minimise tensile stress in our structural designs by identifying high-risk regions before printing, as well as developing an intuition for what geometries are likely to be successful.

The process unfolded as follows:

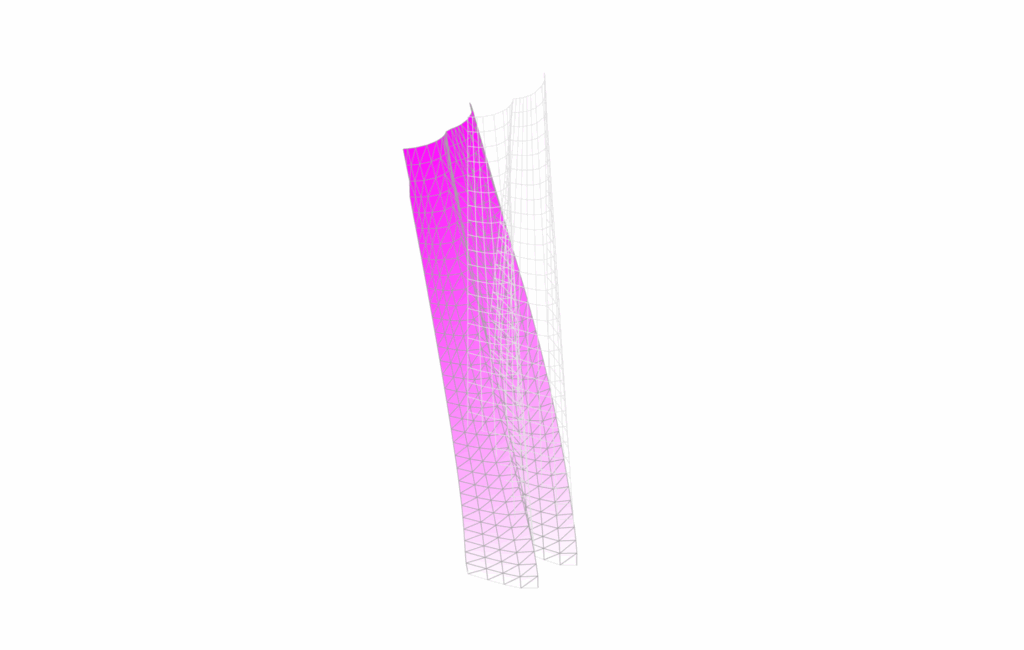

Each team developed a diverse catalogue of concepts and intuitive optimisations for achieving structural stability. Twisting, tapering, and widening profiles were selected for their variety of structural approaches.

Digital Analysis:

Once geometries were selected, they were analysed in Karamba layer by layer to simulate the printing process and identify potential weaknesses. Those with the fewest weaknesses were further studied using Grasshopper scripts to examine inertia and inclination. These tools enabled us to determine the most structurally viable geometries among all iterations.

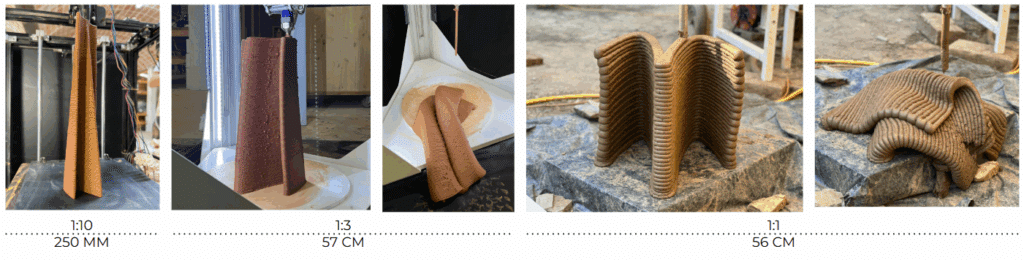

Marianne Weber, Mohammed Aboeloyoon and Nacer-Eddine Azzoug

Testing and Optimisation:

We began with single curves defined by a maximum of seven control points to understand the basics. As the week progressed, we gradually introduced double-curve geometries to analyse how increased complexity influences stability. The selected single-curve, plus additional double-curve forms, were printed and compared with the simulation results. This step helped us interpret how varying geometric complexity affects structural stability and the success rate of smaller-scale prints. Finally, the optimised single-curve geometries were tested at 1:3 scale, still using clay material, to evaluate potential risks for full-scale (1:1) printing. Lastly, 1:1 scale print with earth was tested.

From this research, we learned the following:

Utilizing digital simulation tools

- Digital analysis tools like those used in this exercise, are helpful for learning and initial analysis, but they should be used with a critical eye, as they are merely simulations and therefore the printed structure may behave differently.

- It is crucial to thoroughly understand the simulation tools, as they can be misleading if not set up correctly.

Wider base sections increase the moment of inertia, improving resistance to buckling.

- Slender or irregular upper sections are more prone to twisting and local failures.

- Circular cross-sections perform best under vertical loads, while edge areas often initiate failures due to distance from the centre of gravity.

Printing and Scale Optimisation

- The printing scale strongly influences mechanical performance and stability. On a 1:1 scale, the local material material mass is greater, so local failures are more likely than global failure, as was mostly observed in 1:10 scale.

- Environmental factors (e.g., moisture) and equipment issues (e.g., nozzle force) can compromise build integrity.

- Double-curved geometries exhibit a larger moment of inertia, reducing the chance of centre of gravity drift and structural failure.

Failure Modes and Risks

- Collapse: Occurs when applied stresses exceed material strength.

- Stability failure: Caused by the centre of gravity movement beyond the moment of inertia limit.

- Overhang failure: Results from unsupported angles producing localised slumping.

- Machine-induced failure: Nozzle contact generates lateral shear stresses, which can increase with larger print scales.

- Small deviations or buckling in early layers often propagate, leading to larger positional errors and eventual collapse.

In conclusion

Theoretical background knowledge together with digital simulation tools and hands-on printing, proved to be an effective way to develop an intuition on how to optimise printed structures and identify potential points of failure before printing. This intuition is important to have when working with other aspects of 3D printing with earth to avoid possible problems down the road.