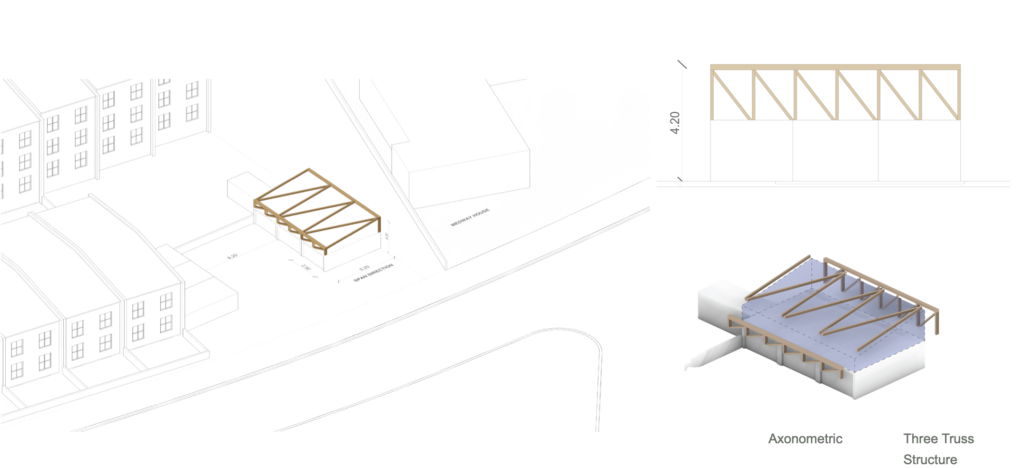

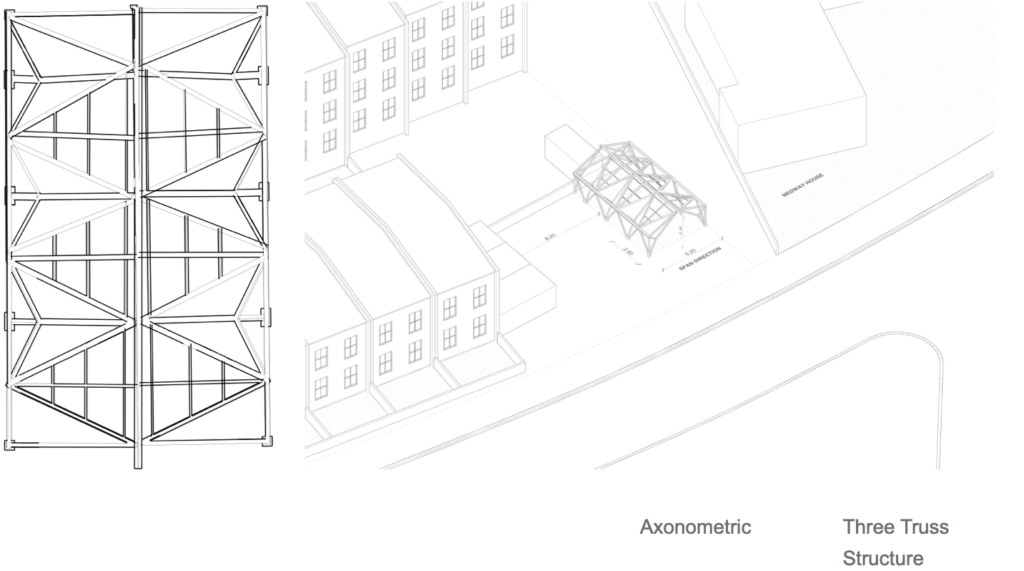

Our journey to craft a thoughtfully designed structure for the STORE x STORE garage transformation began with two distinct timber frameworks, each built around a trio of trusses. Structure A started as a straightforward, three-truss framework, embodying simplicity. In contrast, Structure B ventured into more complex territory, presenting a three-dimensional, intricate timber assembly. Throughout this course, we’ve dived deep into modeling, fabricating, and testing various designs. This hands-on exploration allowed us to experiment with different elements, pushing the boundaries of design and structural concepts. Our aim has been clear from the start: to evolve these initial ideas into a refined and informed final proposal that stands out not just for its aesthetic appeal but also for its structural ingenuity.

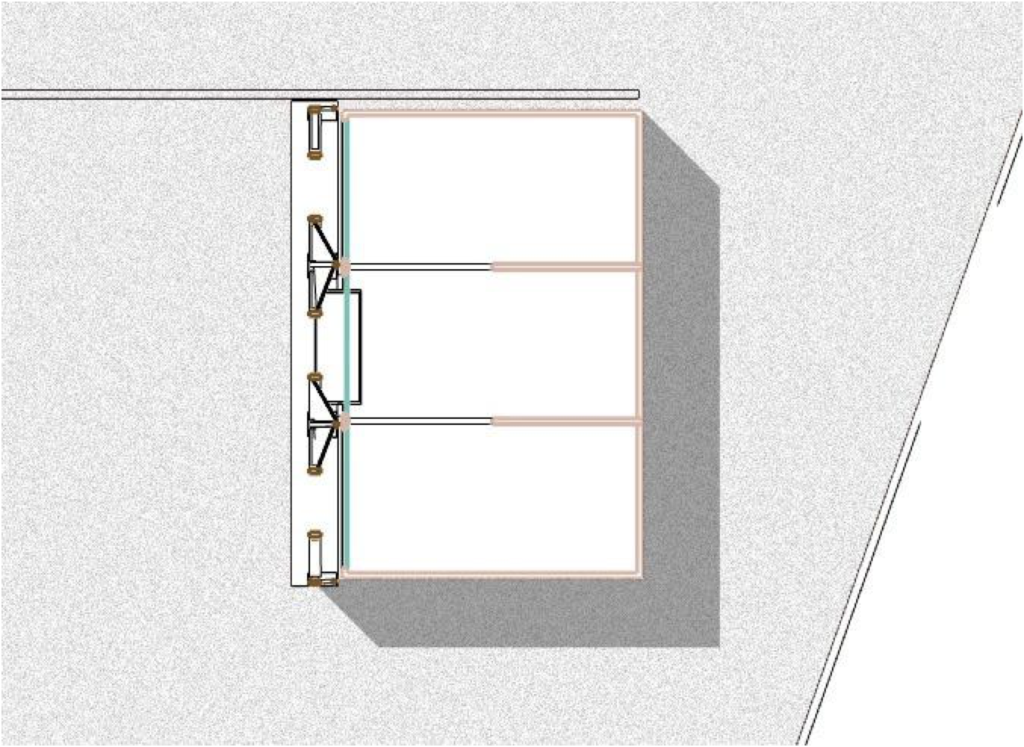

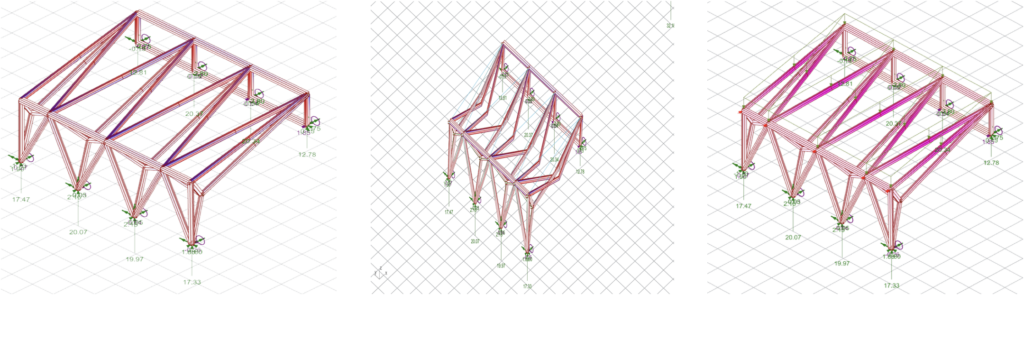

Structure A

Structure A was created as a basic three truss structure that sits on top of the existing structure. it was created as a first trial to compare to available compression and tension diagrams and to understand force flows

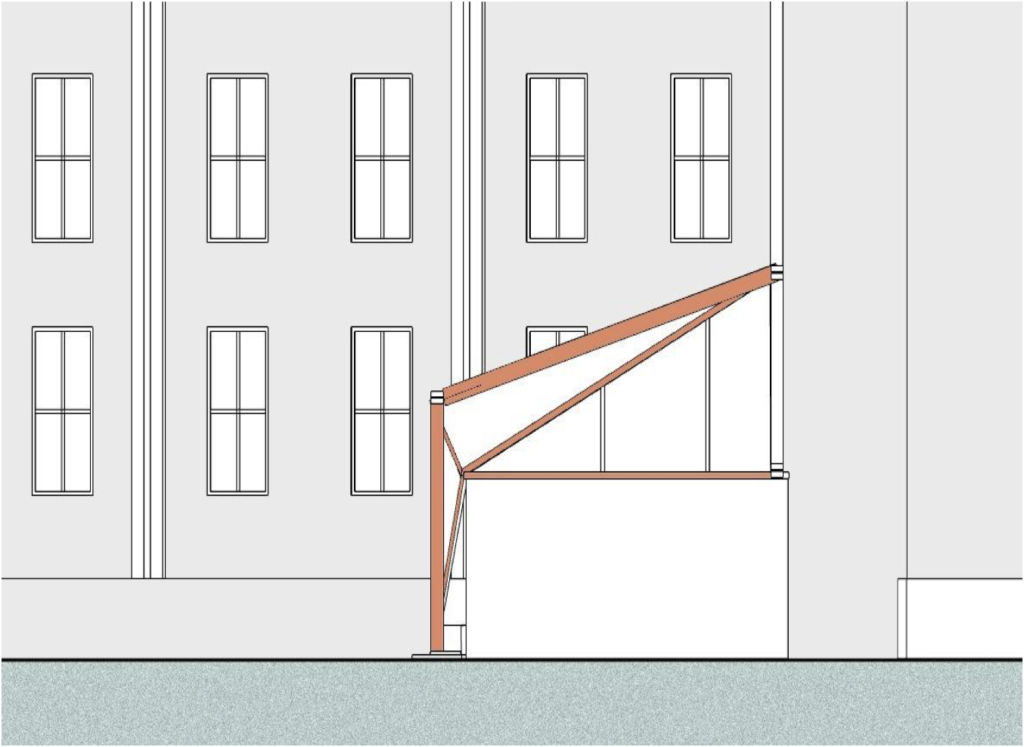

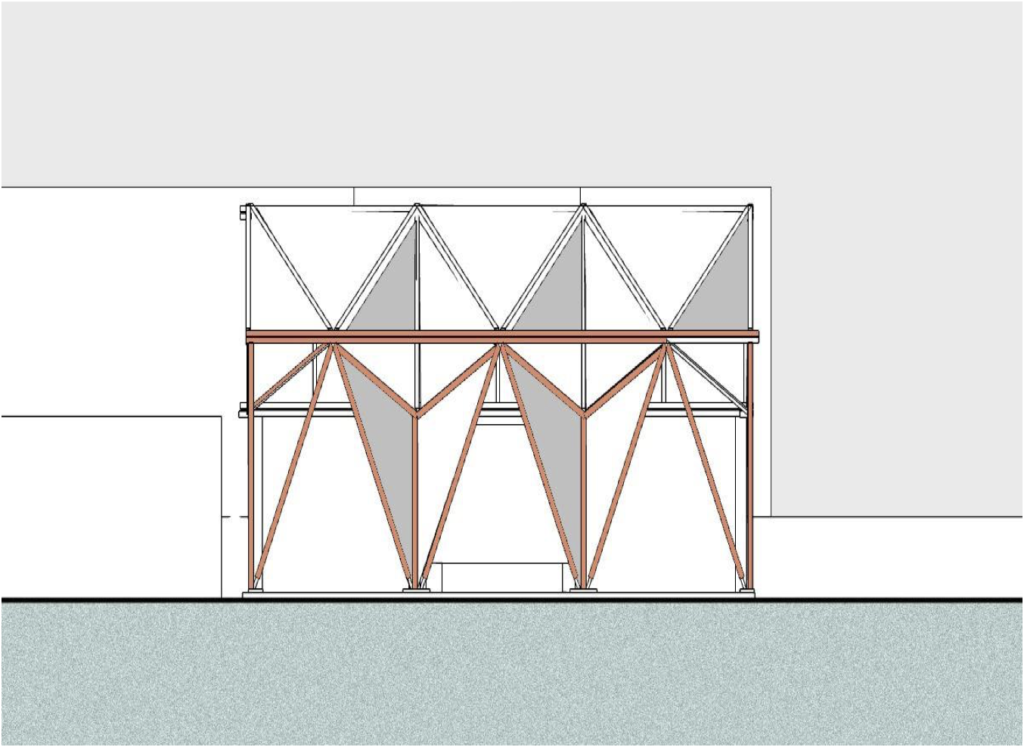

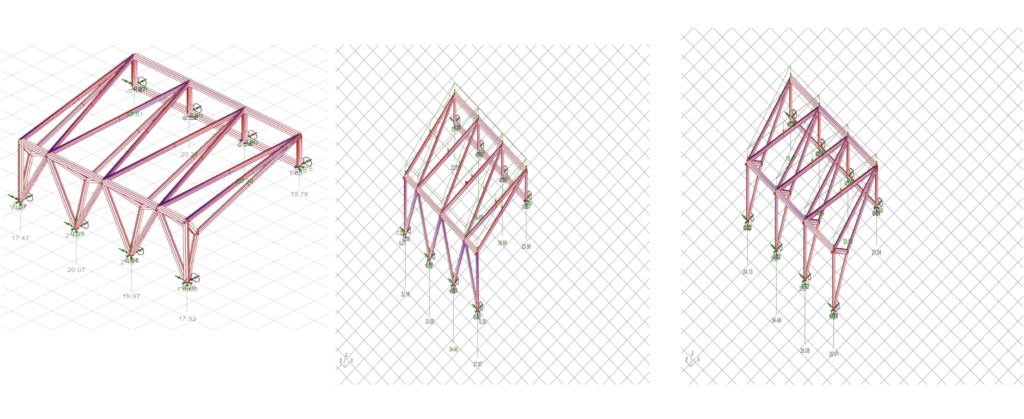

Structure B

Structure B was created as an ambitious exploration for timber structures to create an interesting and open space that combines different types of timber trusses to shape an area for contemplation and work for art residents.

STRUCTURE B SINGLE MODULE

The single module from the garage structure is shaped like a bow tie with two symmetrical sides that lean on to each other to create a stable structure.

The single module was fabricated using cardboard in an attempt to understand design challenges and constraints, as well as to explore opportunities for creating modular connections that can be prefabricated to cut construction time on site

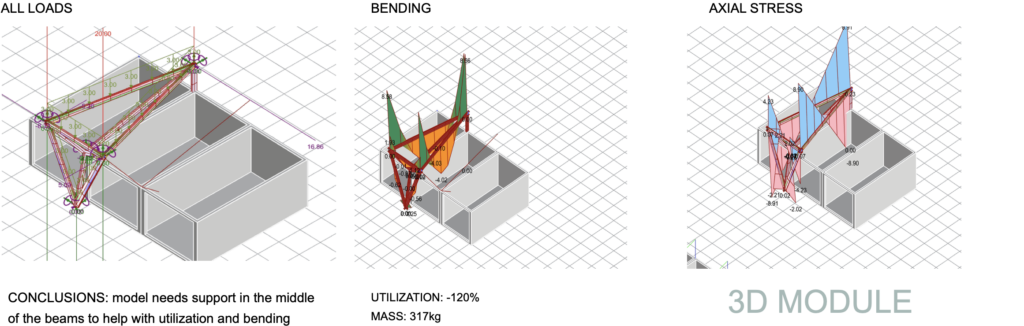

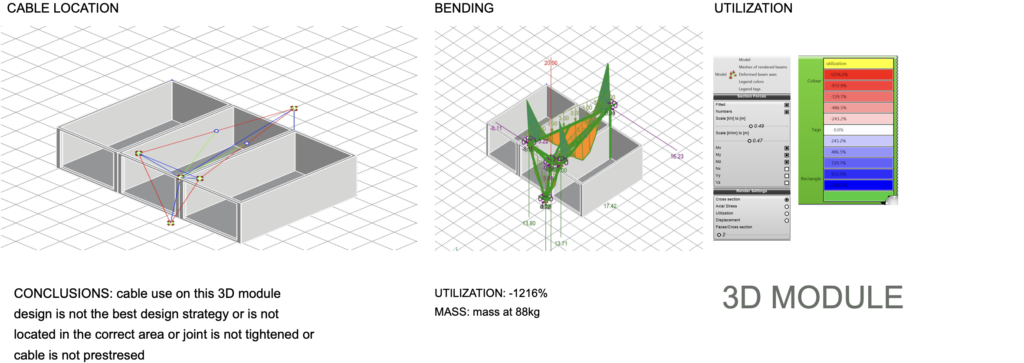

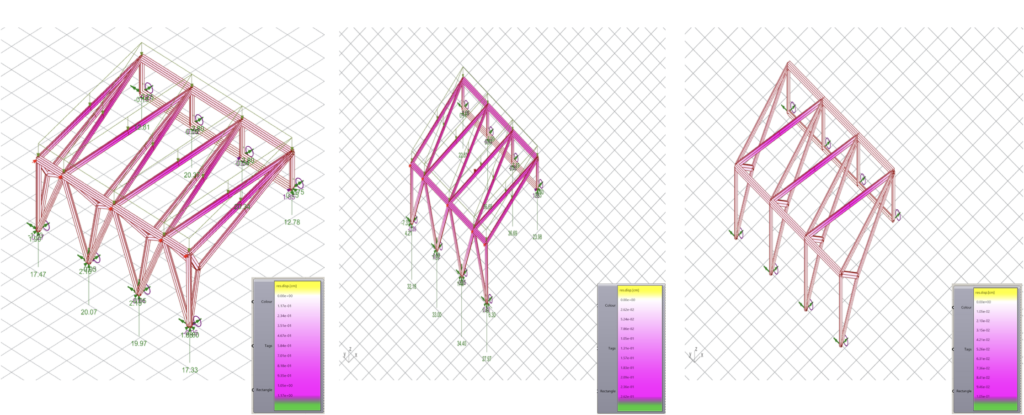

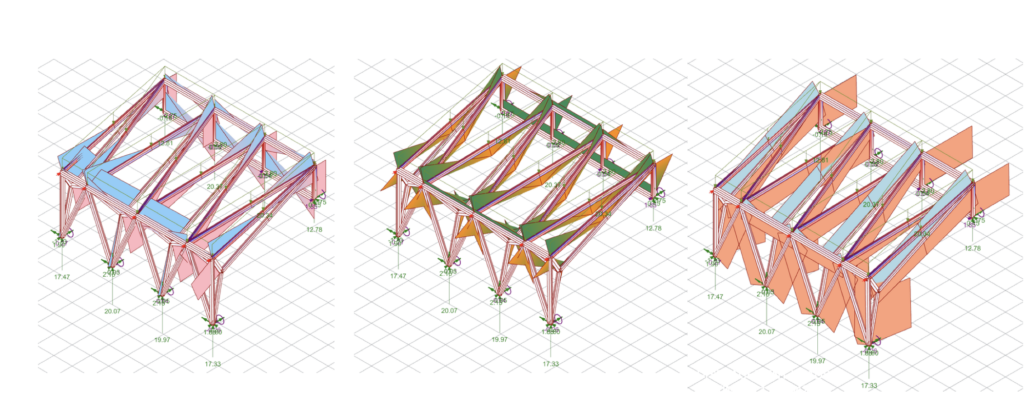

KARAMBA SIMULATION

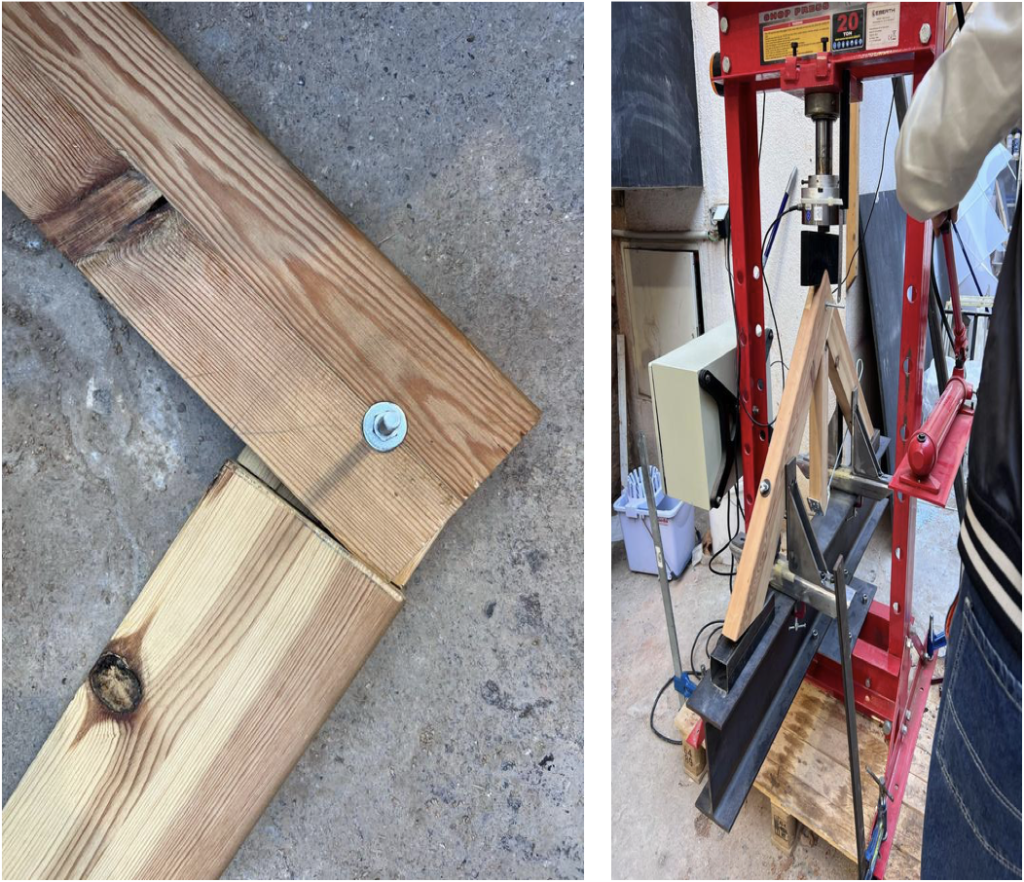

JOINT FABRICATION

PRESSURE TEST

- Joint was fabricated manually to try to test out the two prim ( beams and single strut module, cables were introduced in attempt to balance forces.

- joint took over 100kG before experiencing any deformation

- deformation experienced when pressure point was shifted from the center.

- this caused the wood to rotate out of focal points.

KARAMBA SIMULATION

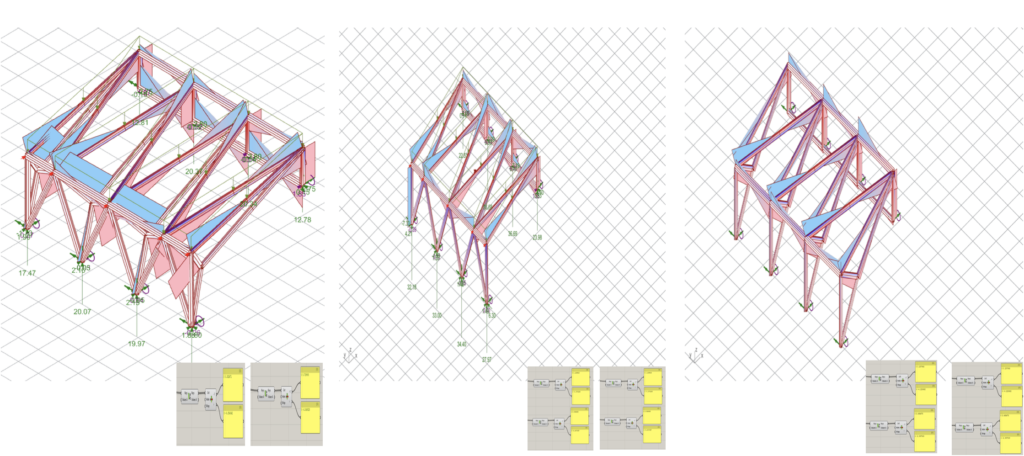

PROPOSED DESIGN STRUCTURE

This iteration takes the foundational concept of Structure B and expands it into a three-dimensional form, incorporating horizontal beams to integrate all modules and utilizing struts to apply compression against an existing brick wall. The total mass of this configuration is 6460 kg, indicating a substantial structure designed to accommodate various loads and stresses.

PROPOSED DESIGN STRUCTURE VARIATIONS

DISPLACEMENT VARIATIONS

VZ

CASE 1 DEV

PROPOSED DESIGN

Design proposal for store x store london, designed to open up space for visitors and create a productive and wellness oriented work zone.

- wall for flow throughout space on lower side

- space for plantation in the middle

- light transfer throughout space