Hypothesis:

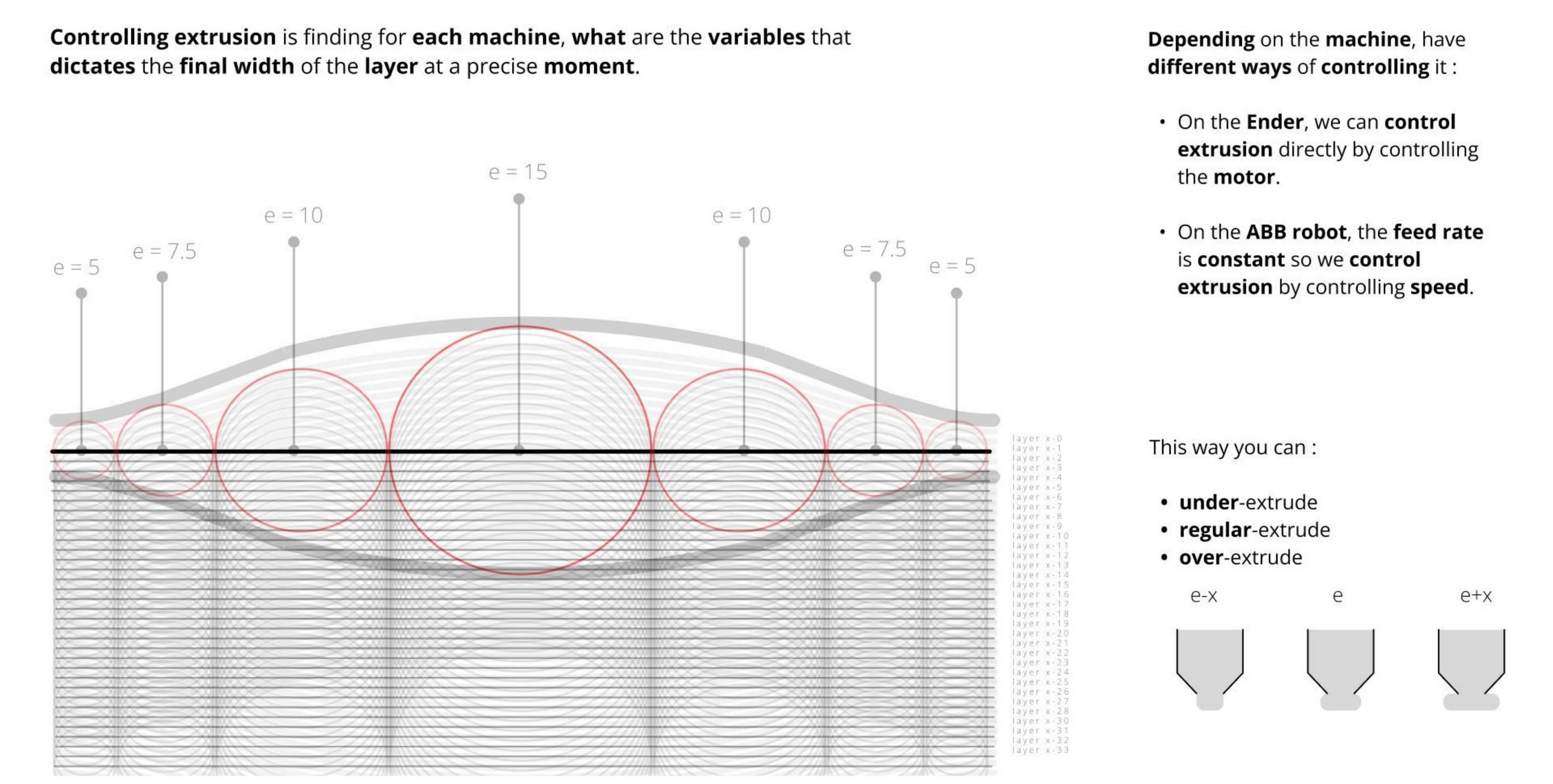

By integrating controlled extrusion and topological optimization into 3D printing processes, it is possible to significantly enhance structural efficiency, reduce material usage, and simplify toolpaths. By drawing insights from nature and leveraging data-driven design and analysis, this method enables the creation of structures that are lighter, stronger, and more resource-efficient. When applied to architecture, such as wall systems, this strategy has the potential to redefine construction practices. By using earth-based materials and optimizing deposition, we can conceptualize sustainable, self-evolving designs that are not only structurally sound but also aesthetically organic. Ultimately, this vision could yield a comprehensive toolkit that can control the amount of extrusion required at specific areas by increasing or decreasing speed.

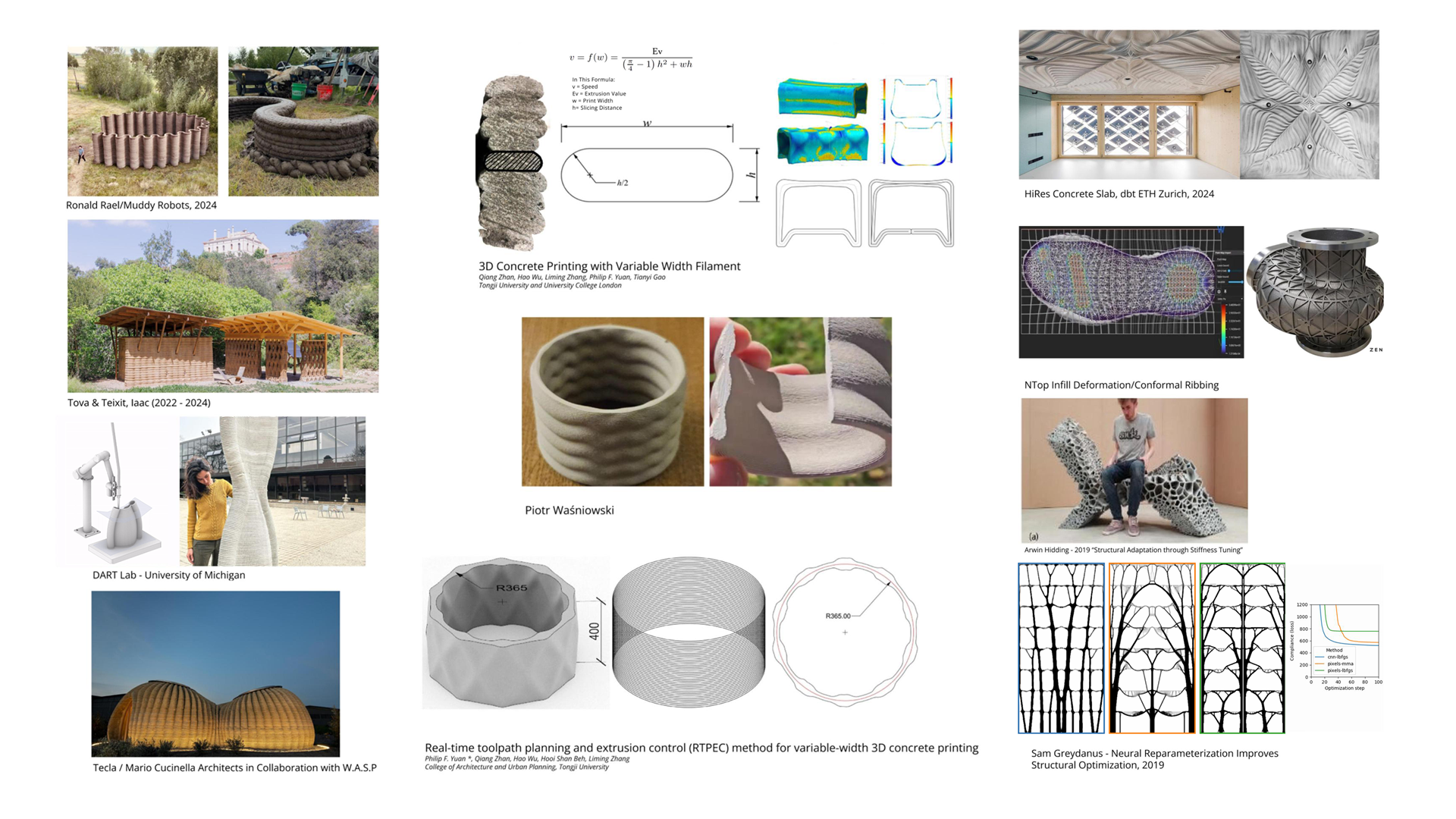

State of the Art – Machine, Geometry, Topological Optimization:

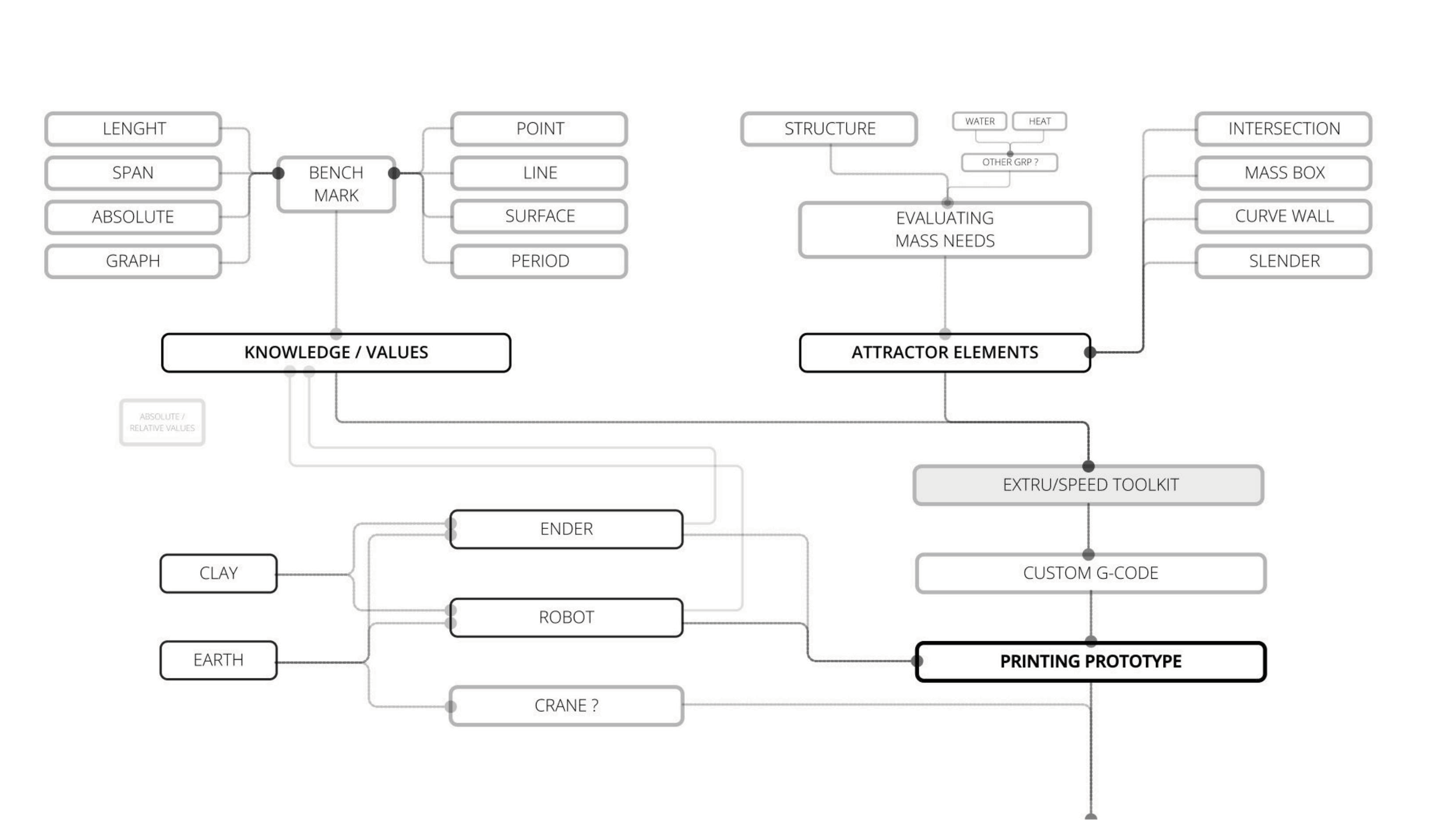

Methodology:

Workflow:

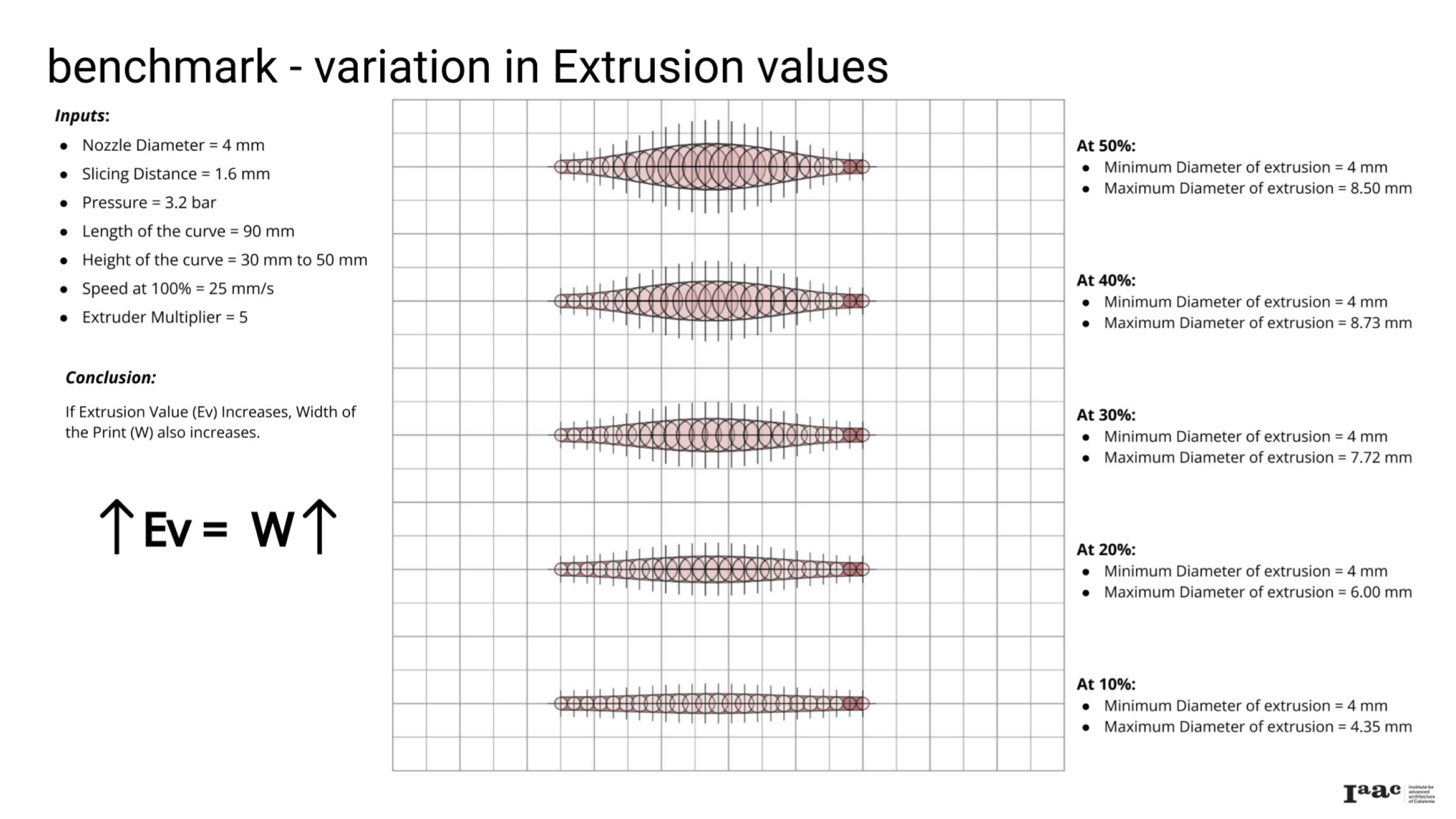

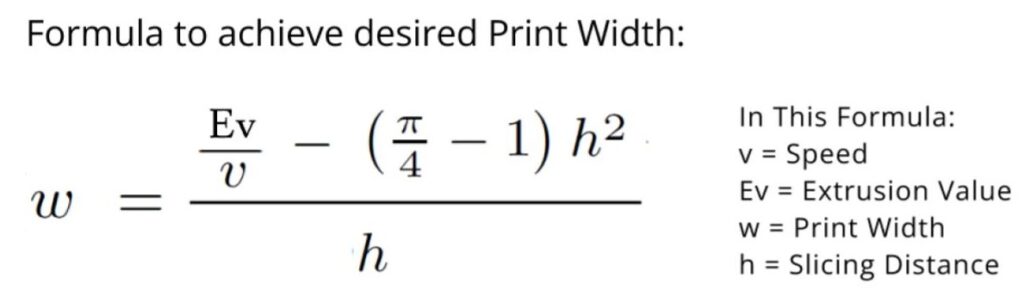

Extrusion Multiplier:

Strategies:

Proof of concept:

To prove the hypothesis, a quick script was developed where the E value and speed were modified along a straight line, The Image provided above was the result. Although it was a happy accident, it proved multiple concepts can occur on GCODE without topological modifications or complex modeling. Time to reverse engineer every parameter.

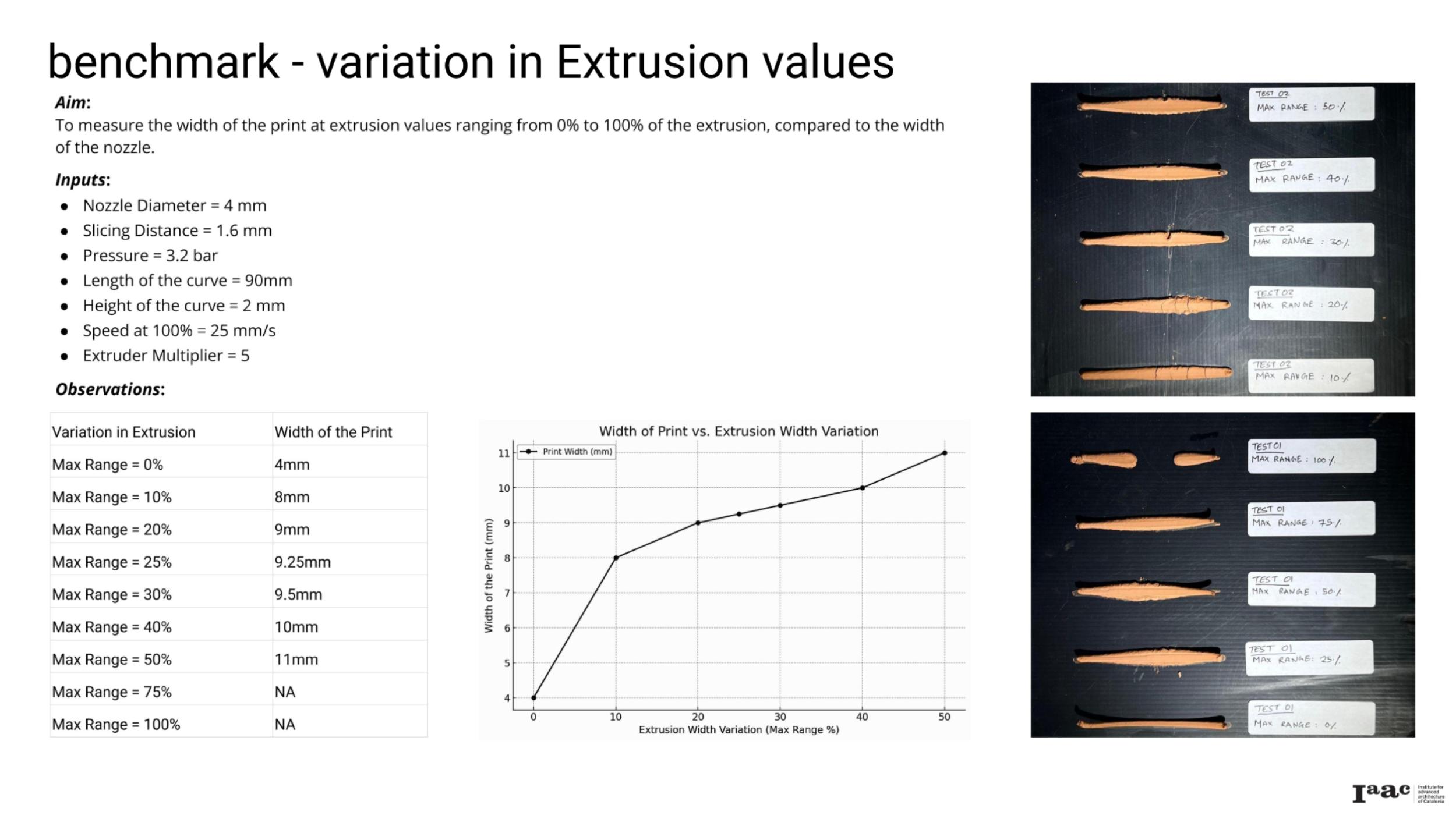

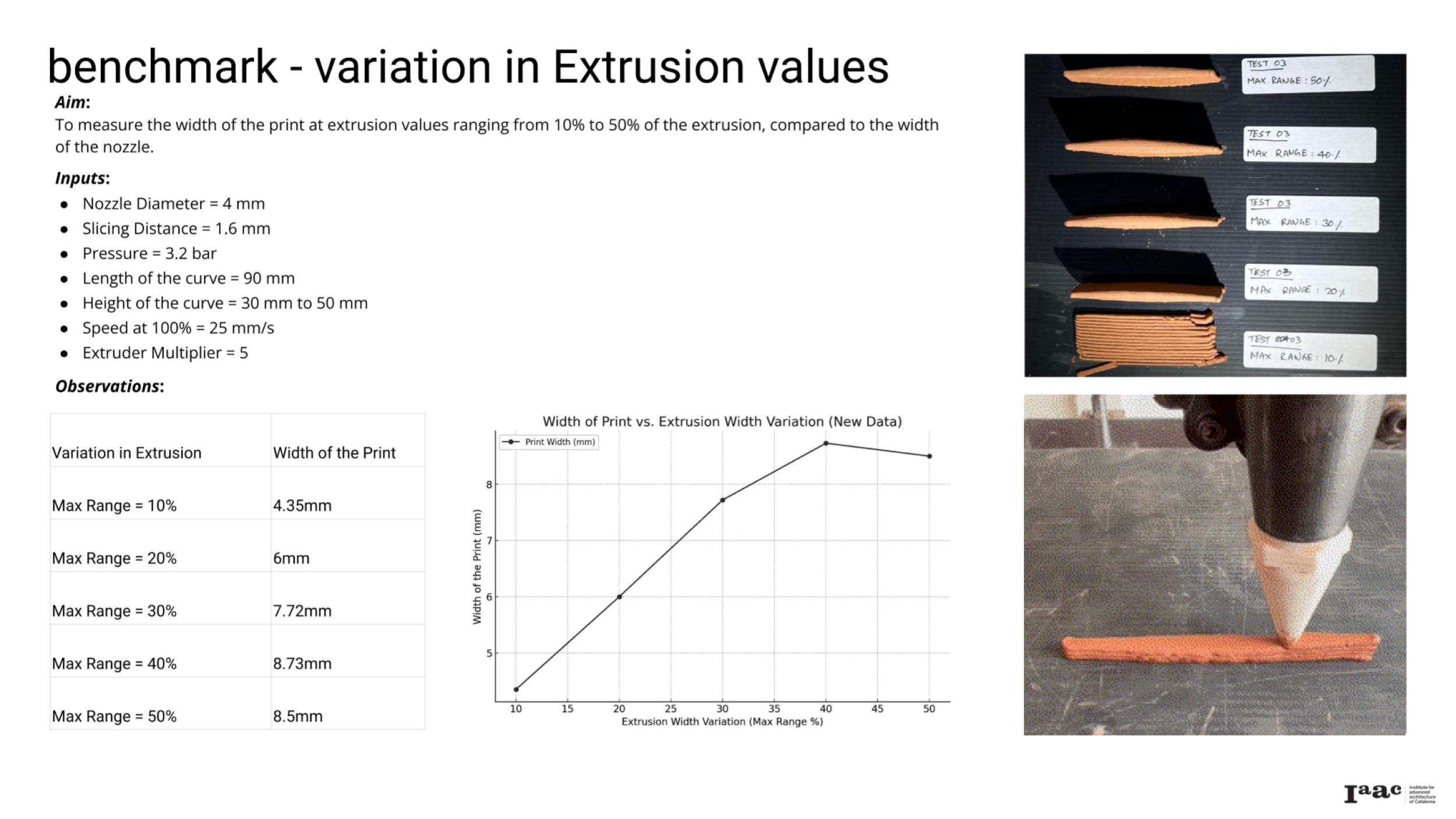

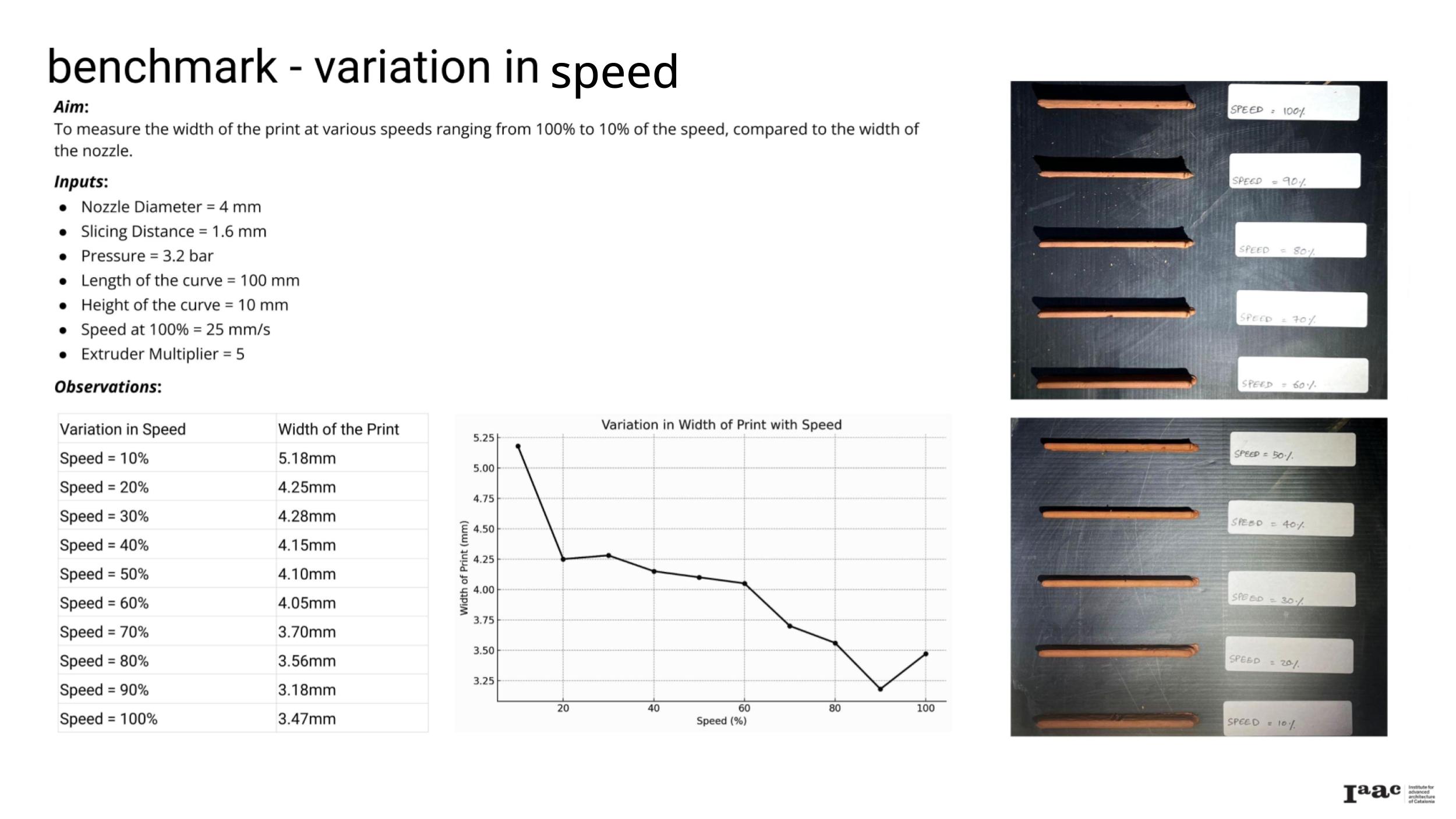

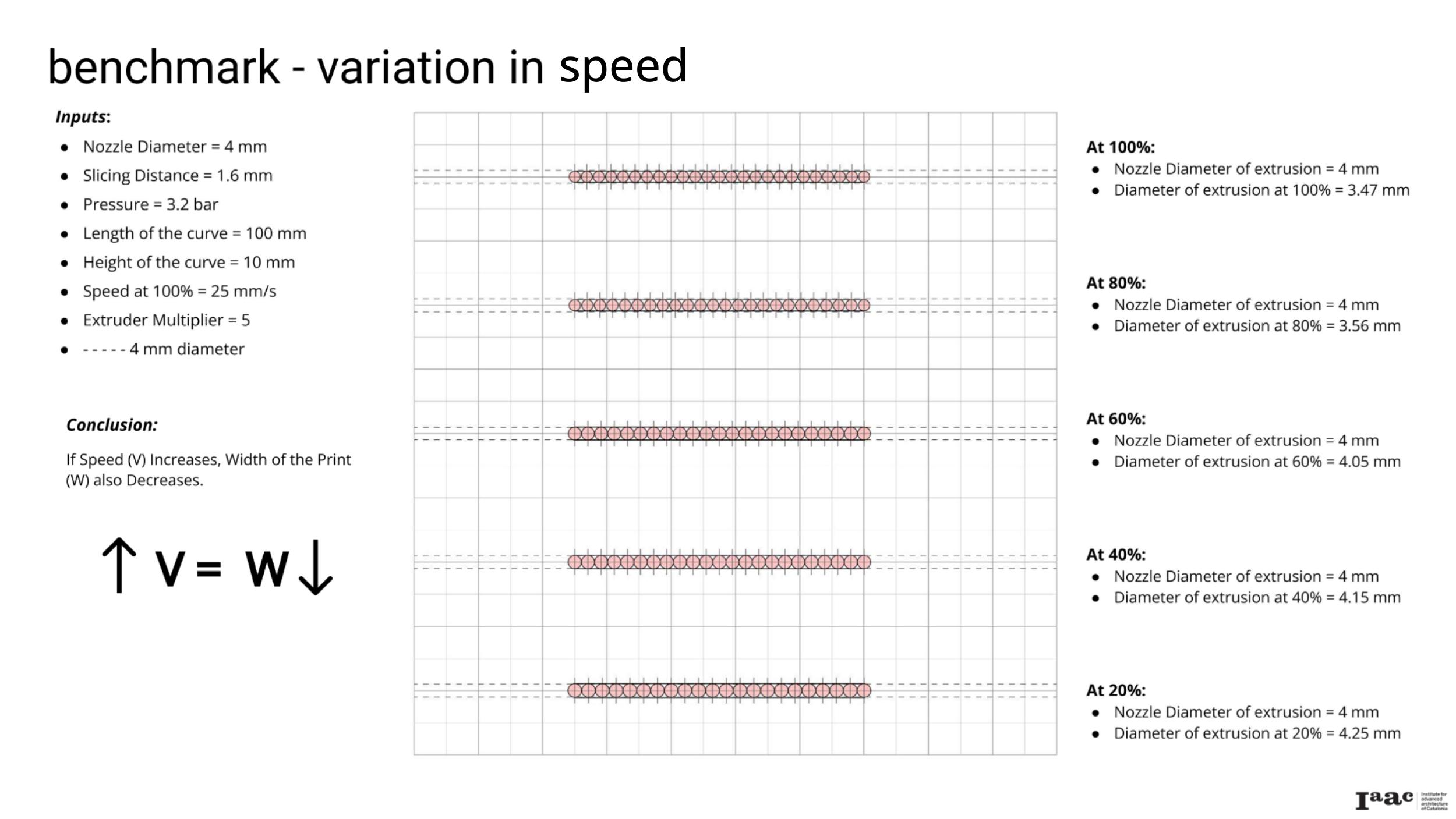

Benchmarks (Scale 1:10, Desktop printer and Clay) :

Strategies (Scale 1:10, Desktop printer and Clay) :

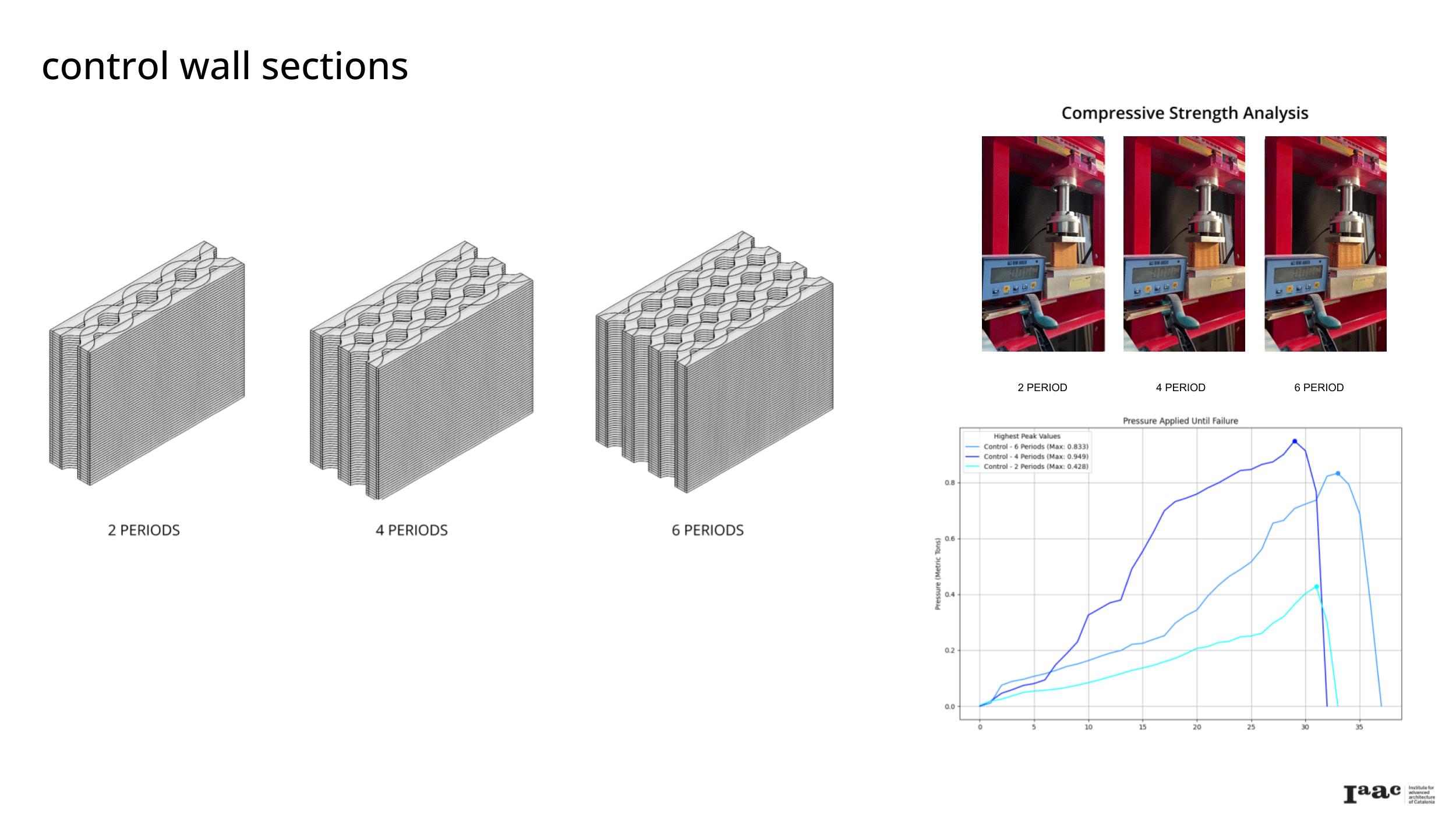

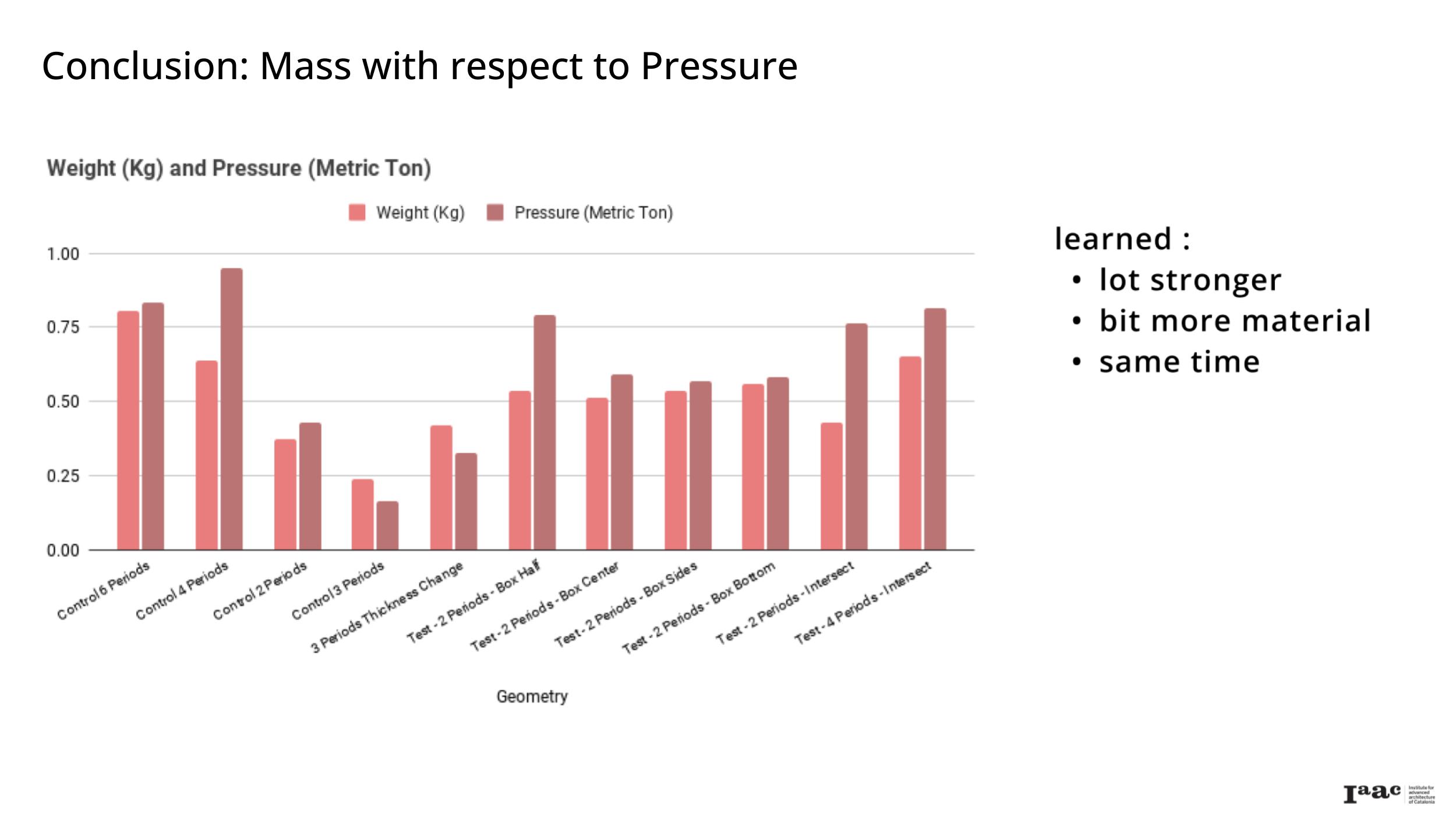

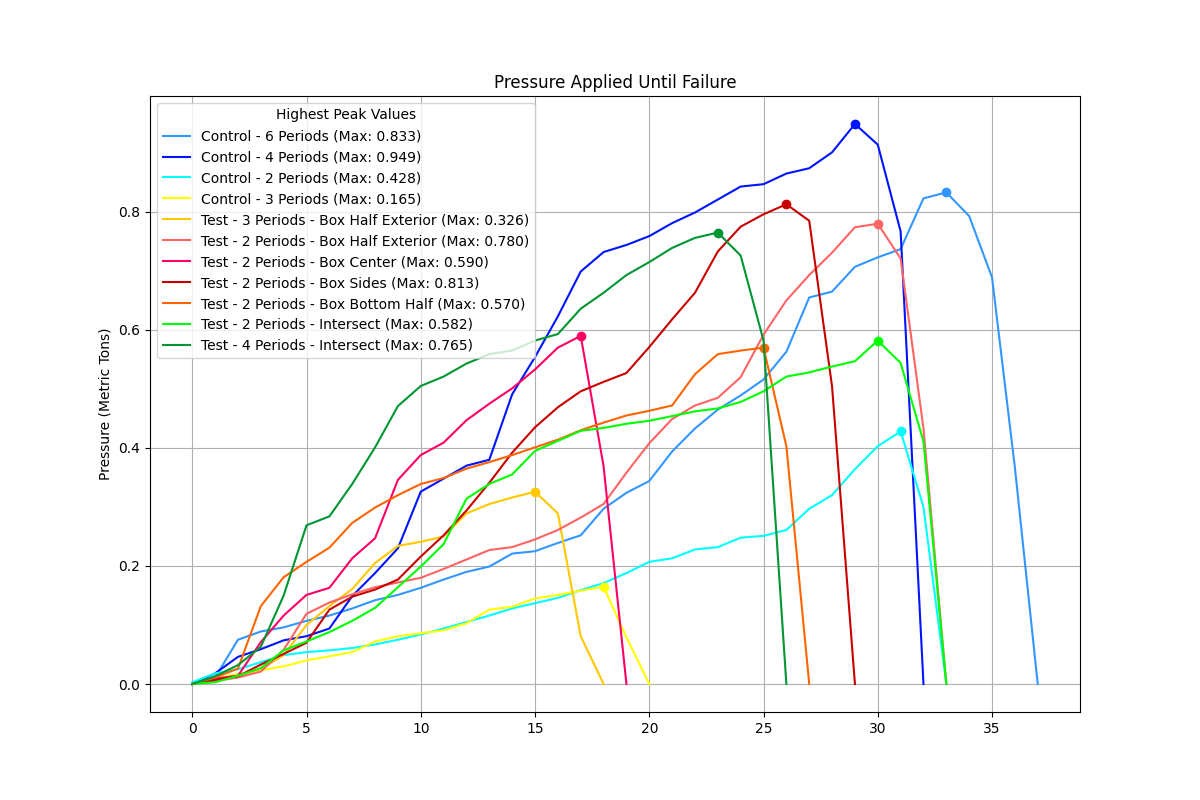

1. Controlled samples: Of various thickness of the wall (2 period = 200mm, 4 period = 400mm, 6 period = 600mm) without any modification were tested under compressive strength analysis.

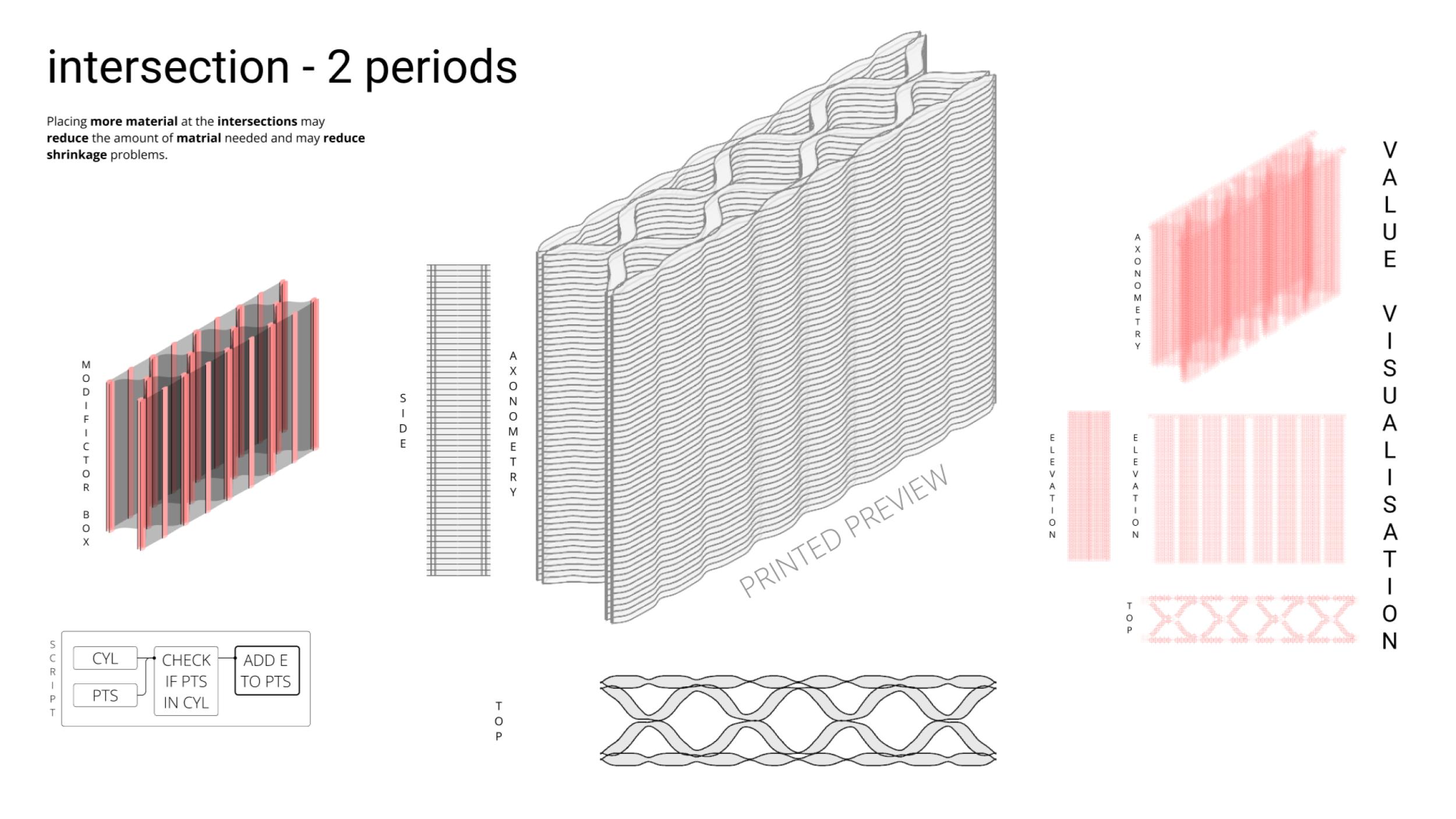

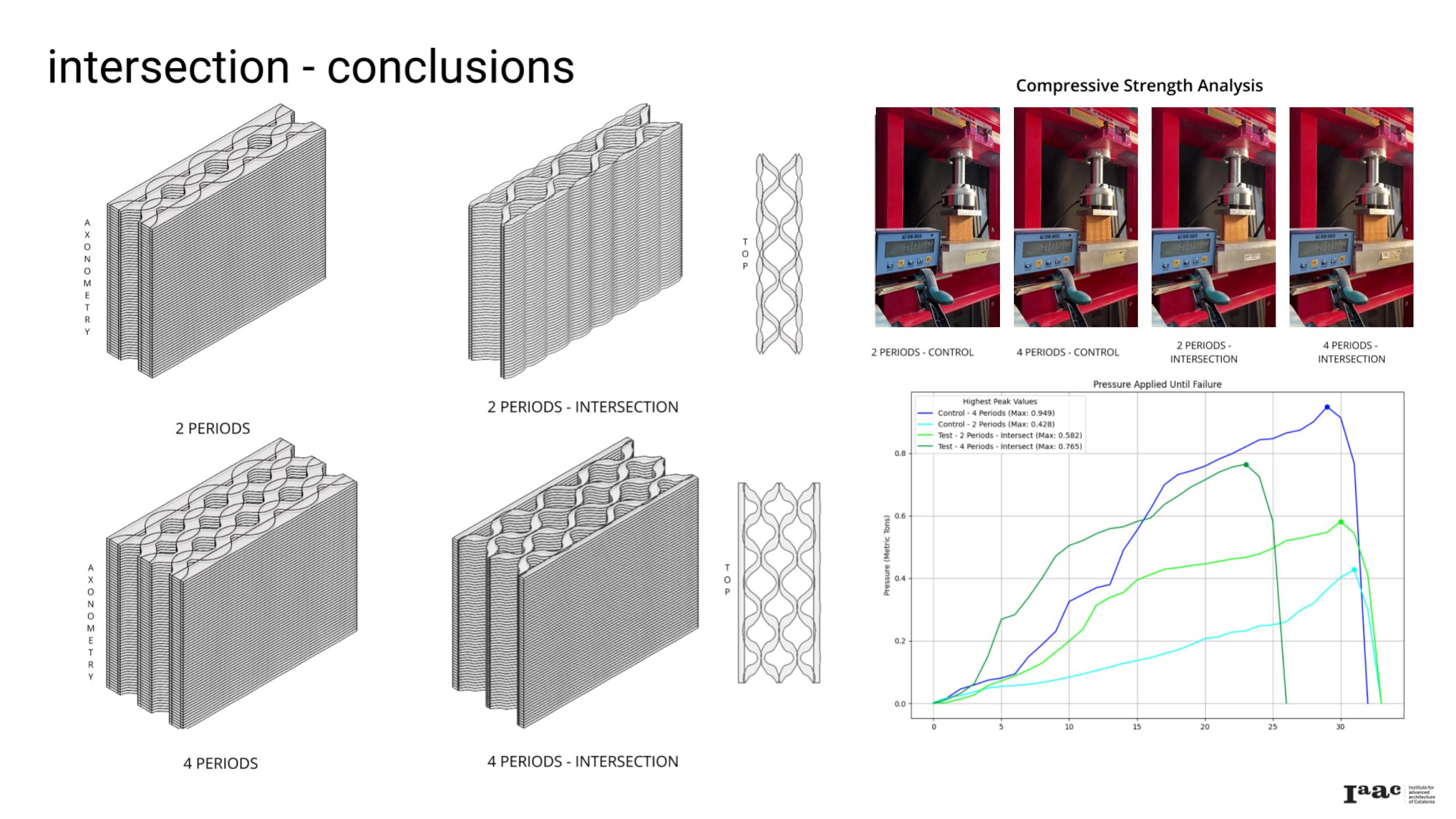

2. Intersection strategy: Under this strategy, modification of Extrusion value is done at intersecting points of the wall and were tested under compressive strength analysis.

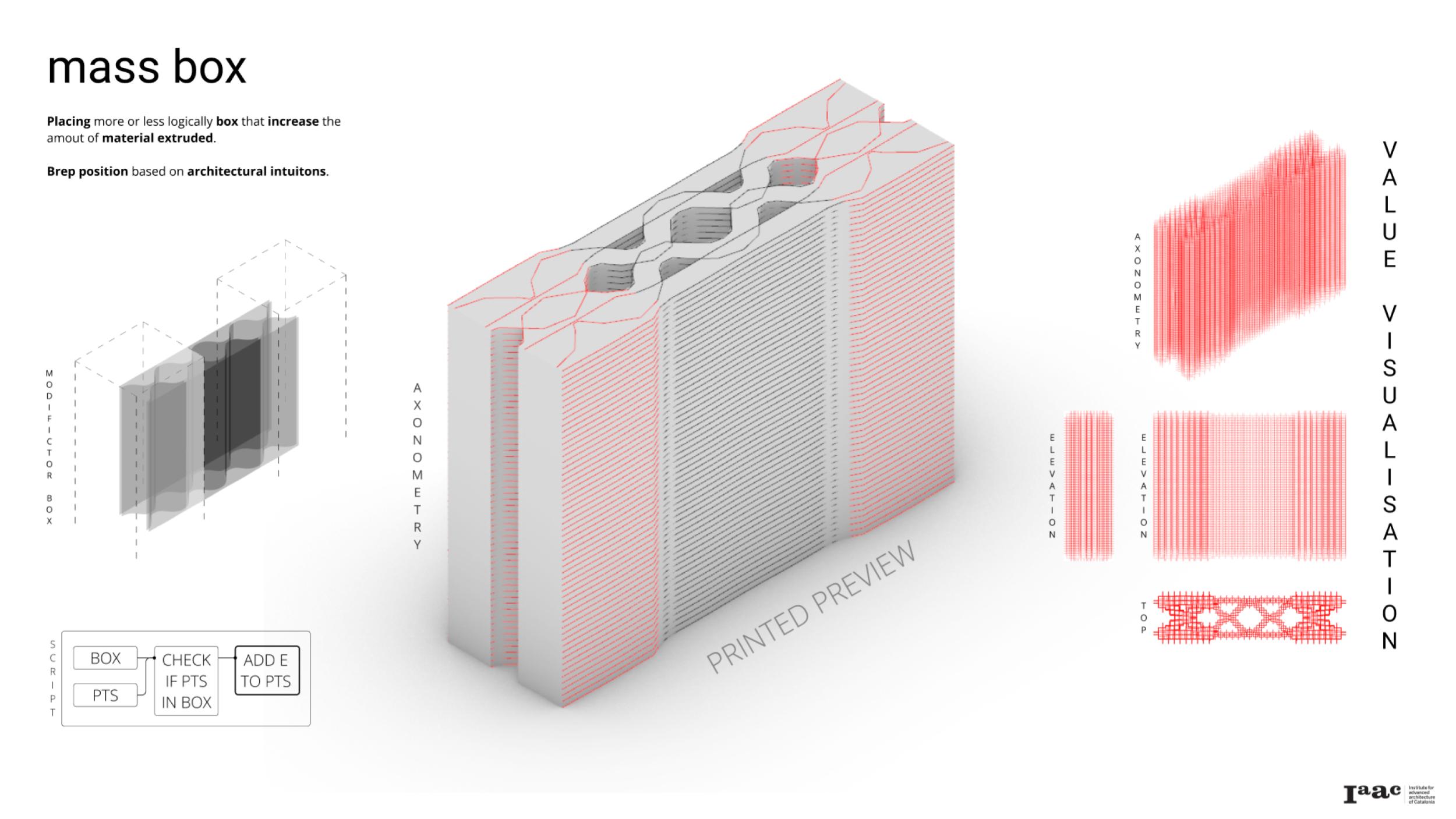

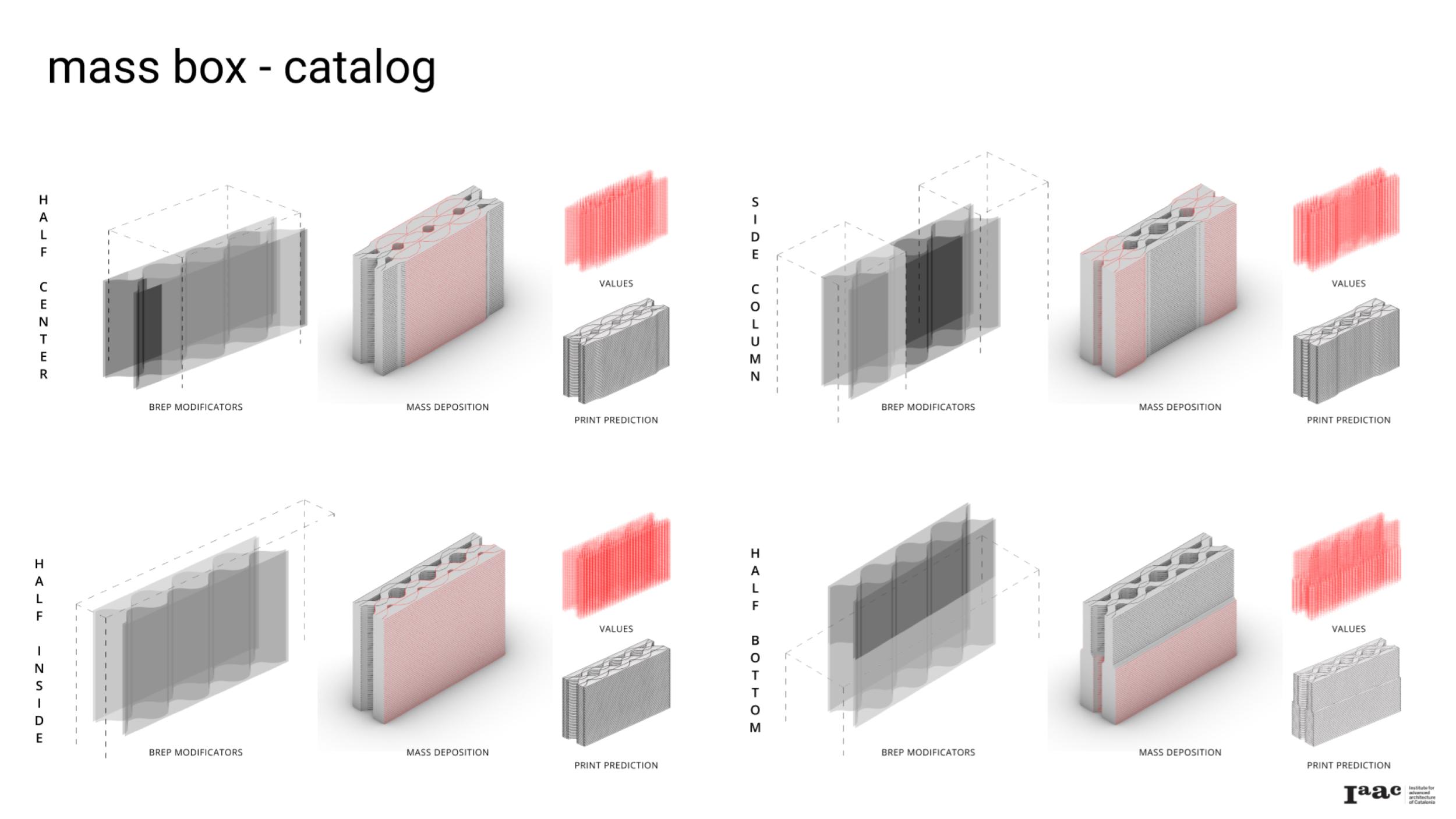

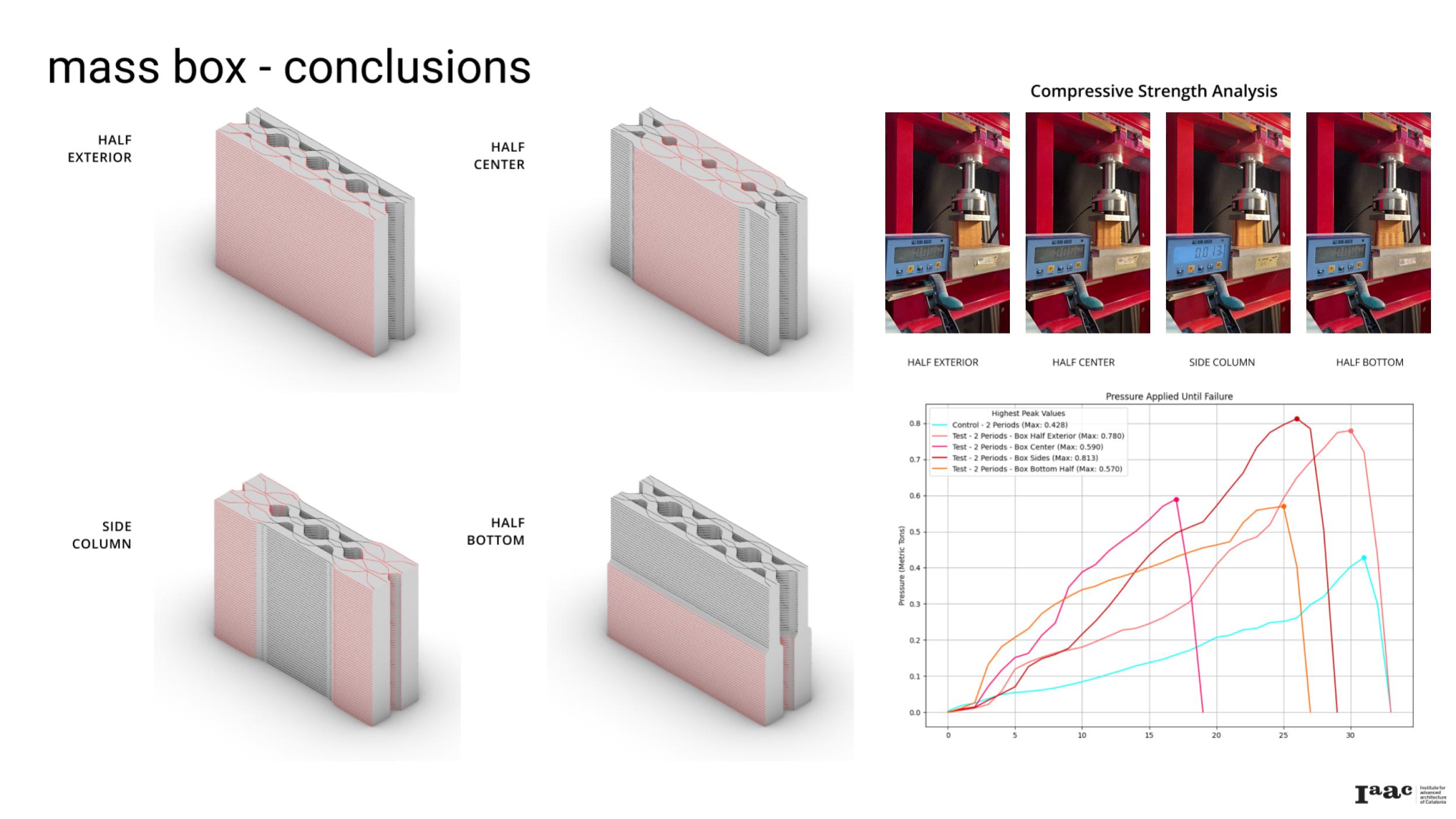

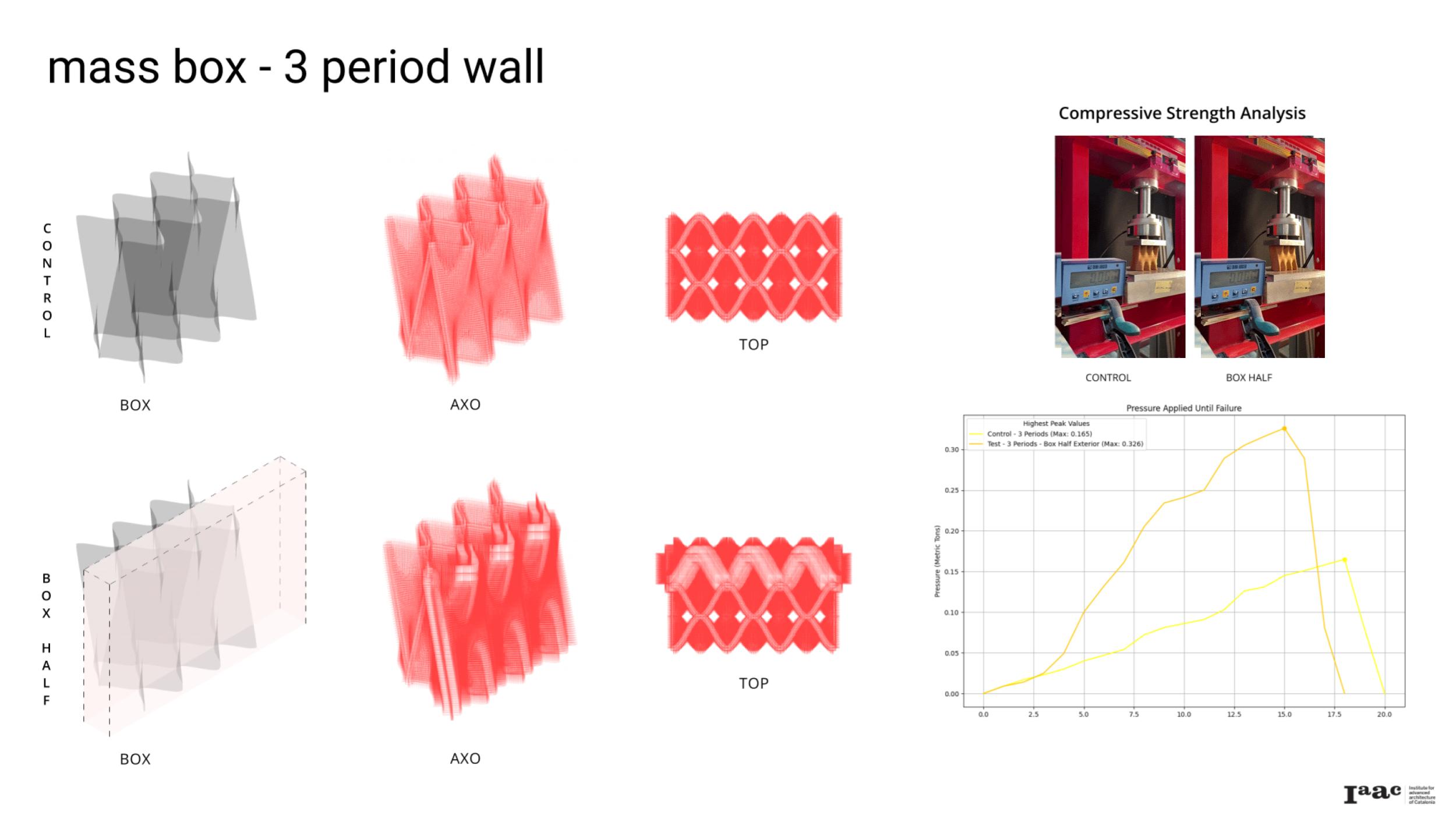

3. Mass box strategy: Under this strategy, modification of Extrusion value is done at Various Breps (Mass box) that account an area of the wall and were tested under compressive strength analysis.

Conclusion: After the above showed results of the compressive strength analysis, walls with less thickness but with more mass deposition ( Extrusion Value) at various strategies have better compressive strength than the others.

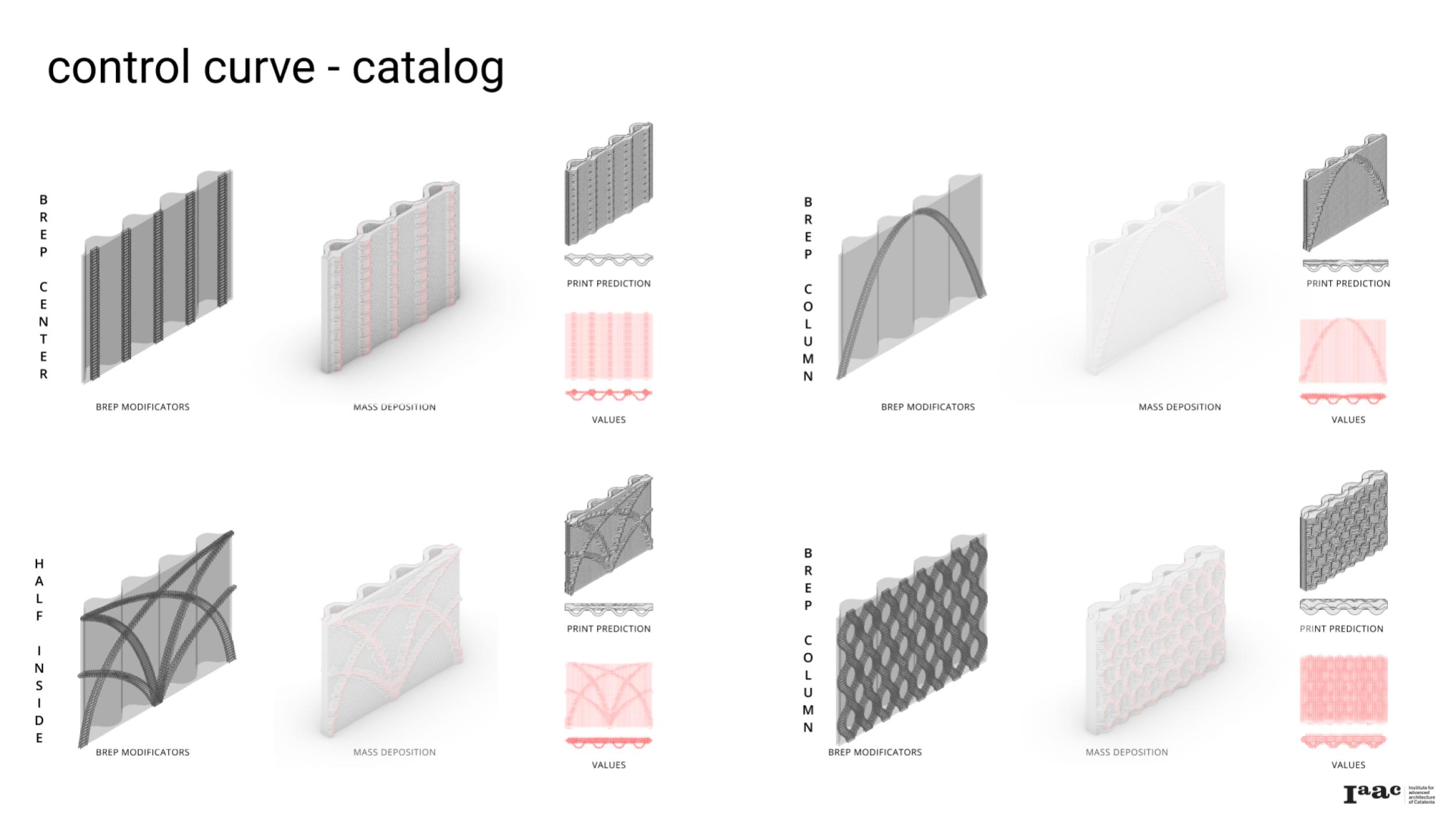

4. Control curve strategy: Under this strategy, modification of Extrusion value is done at Various curves that account an area of the wall and were tested under compressive strength analysis.

Conclusion – Control curve:

– It prevents buckling of the print.

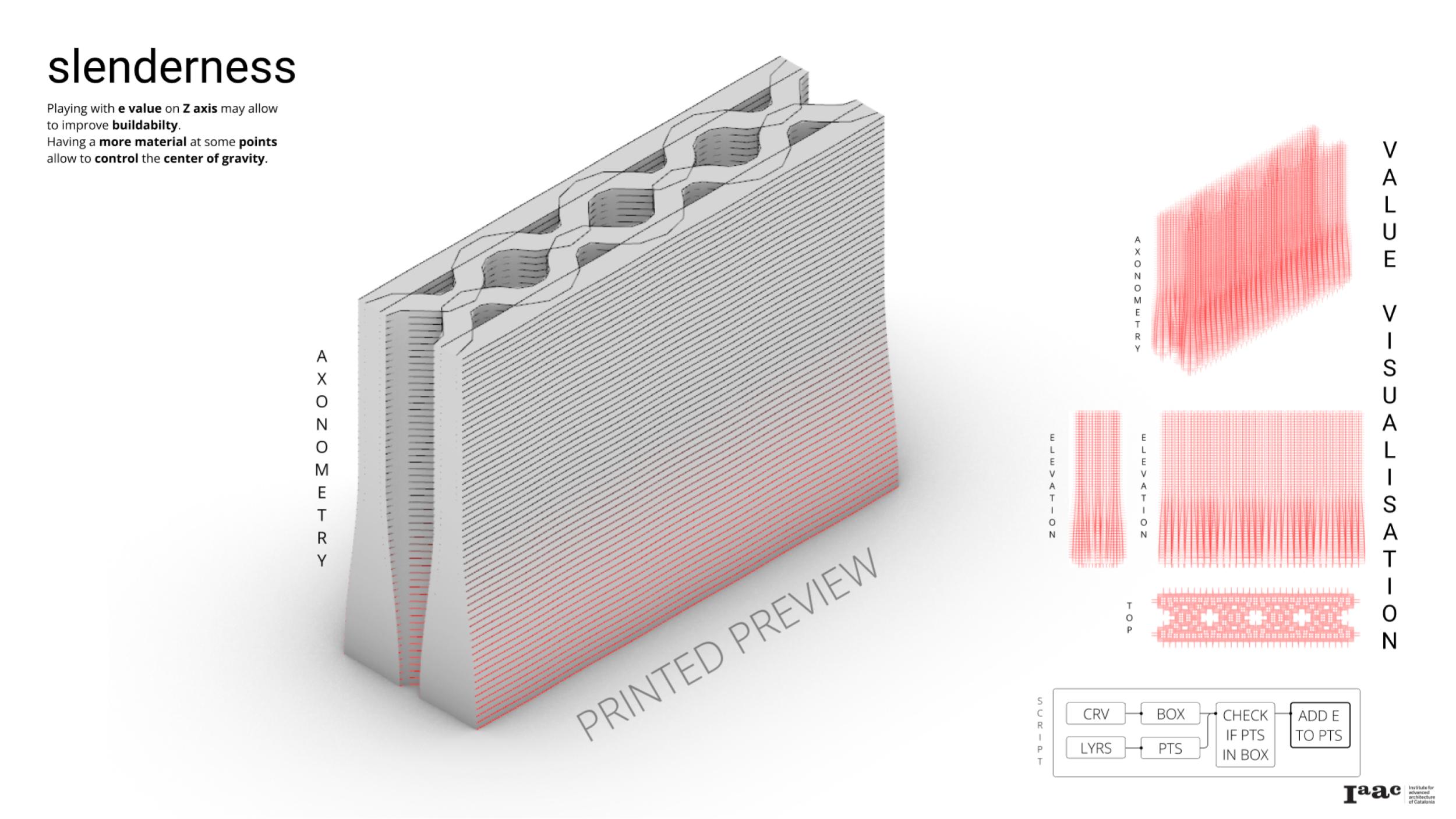

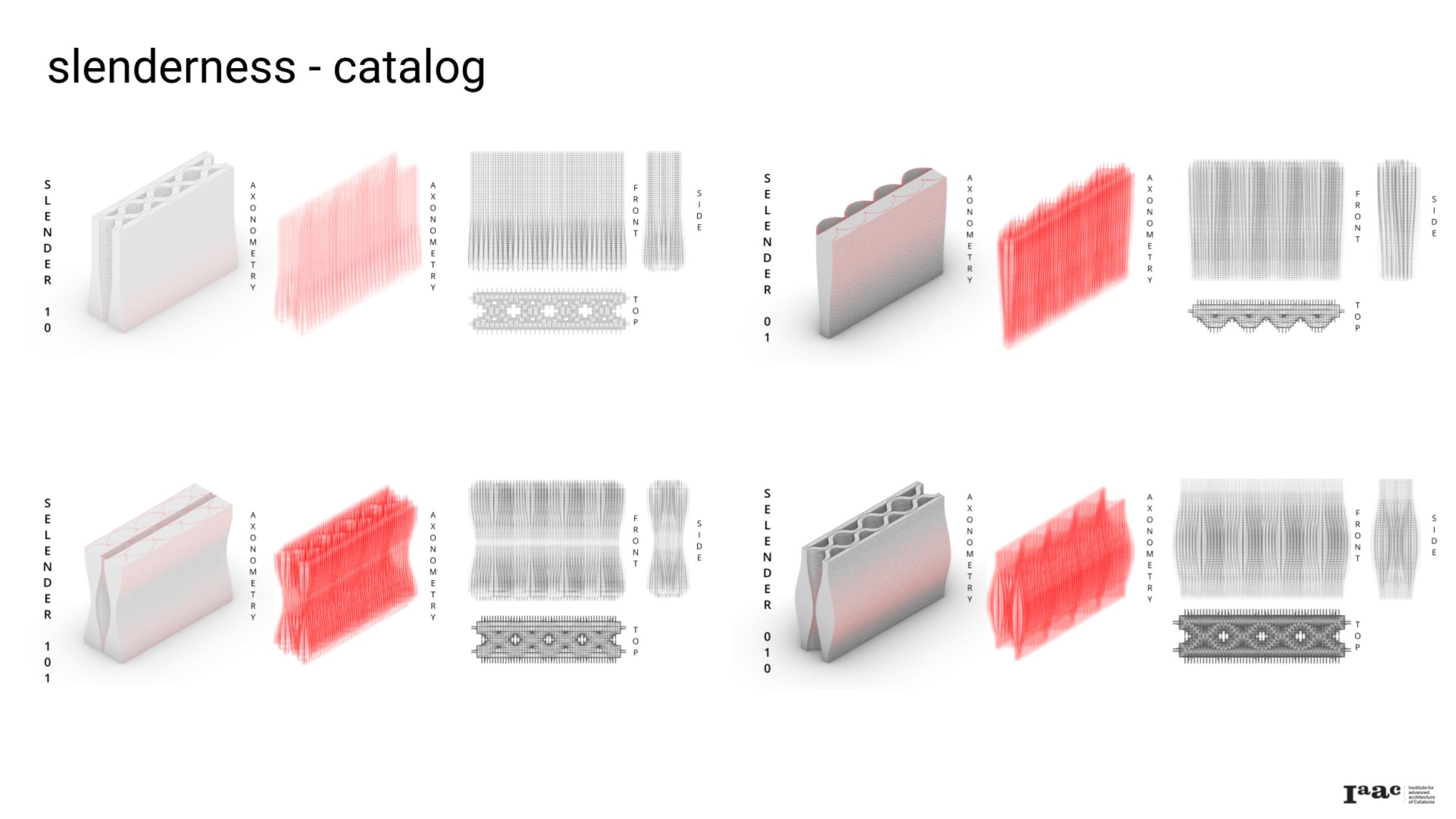

5. Slenderness strategy: Under this strategy, modification of Extrusion value is done at the Z axis of the wall and were tested under compressive strength analysis.

Conclusion – Slenderness:

– It improves buildability of the print.

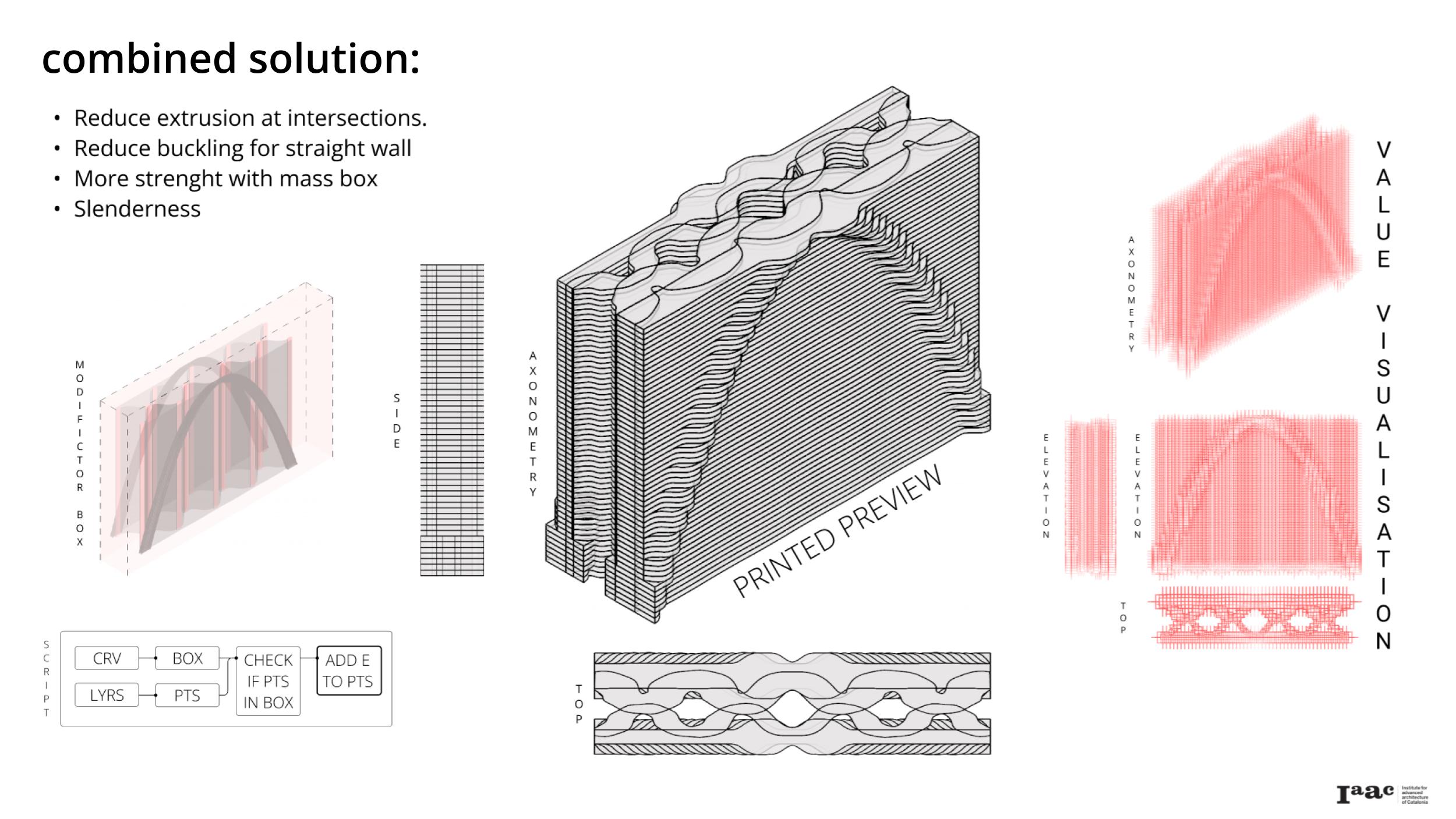

Combined Solution: Under this geometry of the wall, al the above strategies were implemented in order to print a wall with maximum compressive strength.

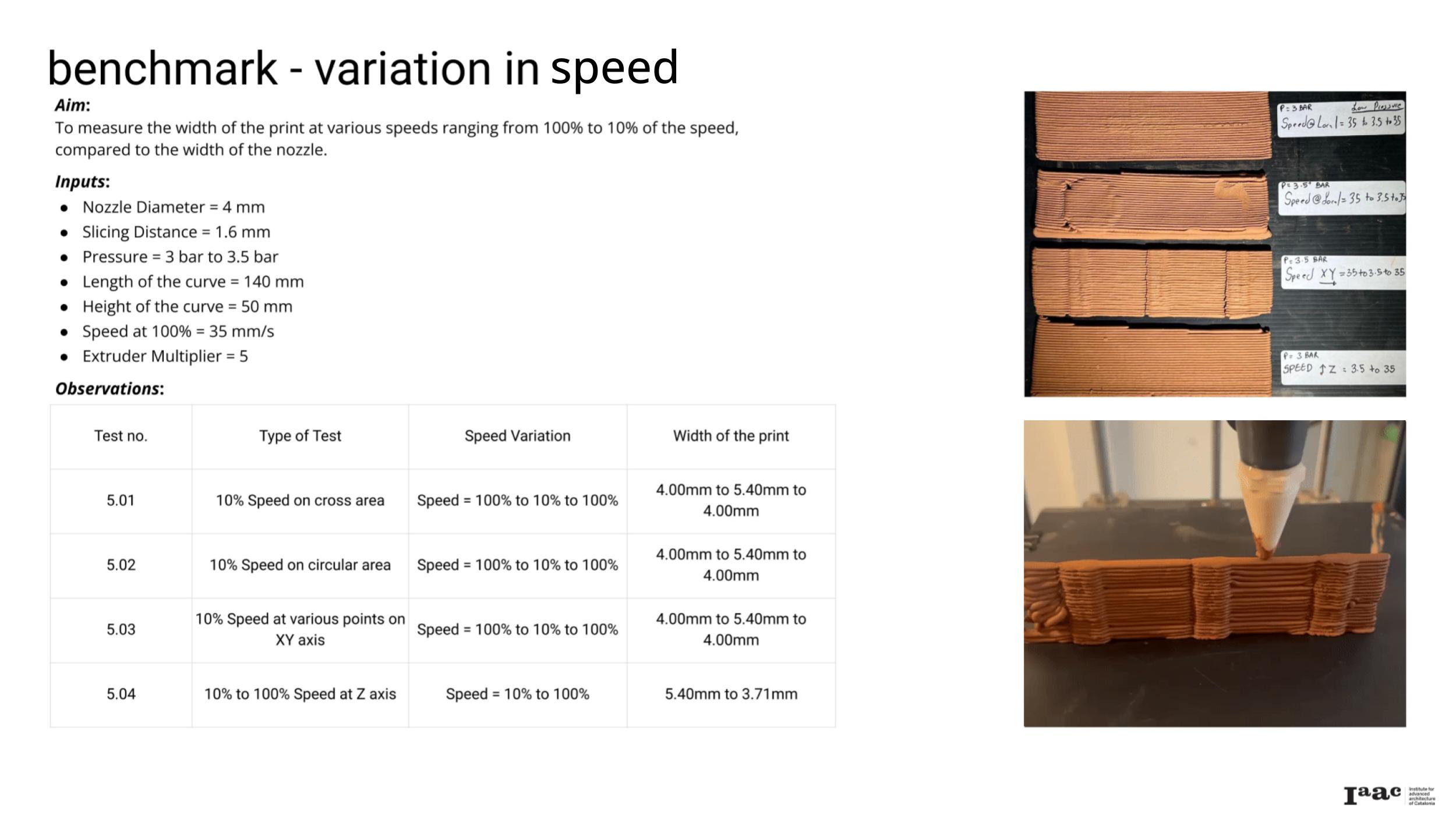

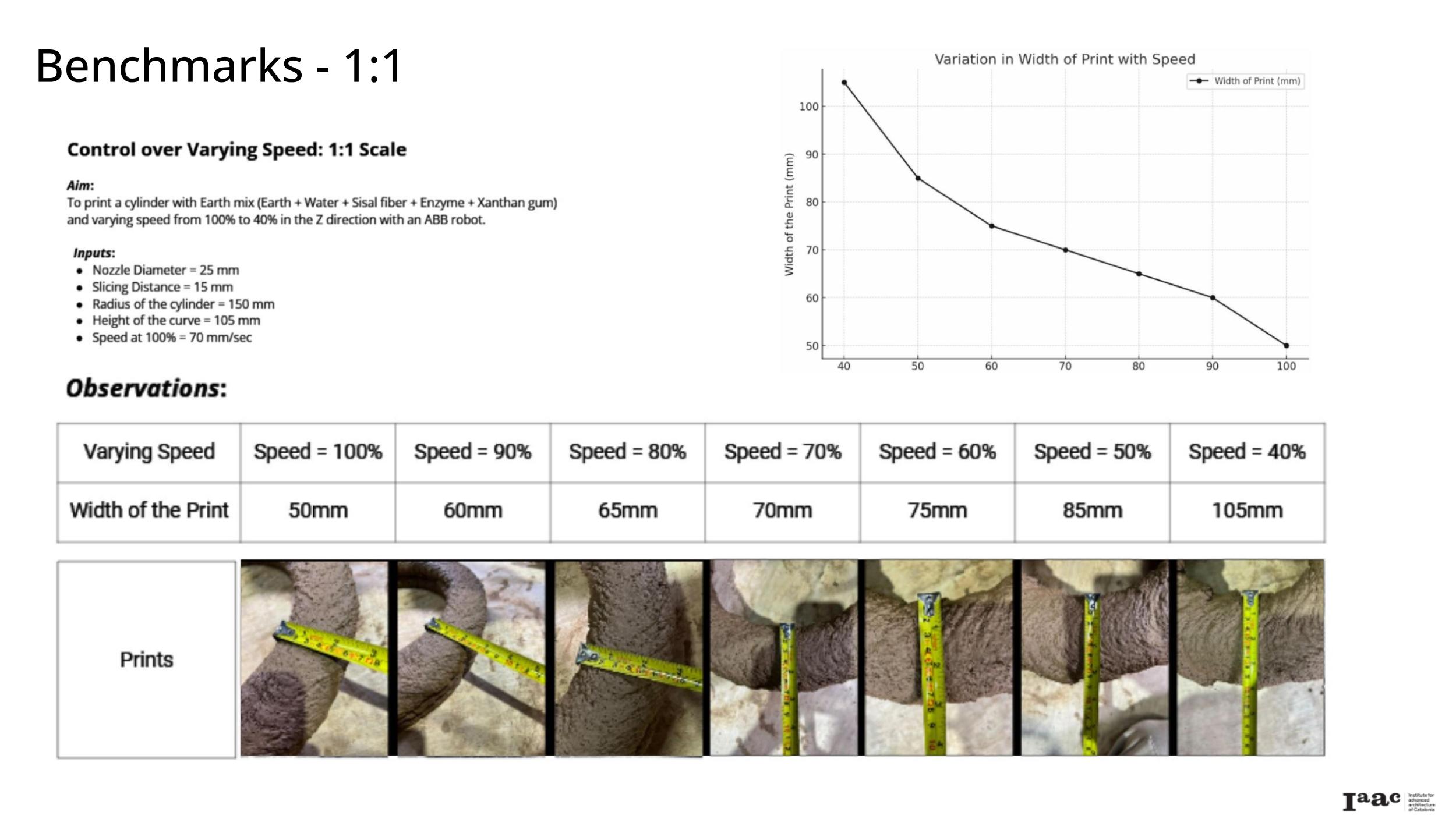

Benchmarks (Scale 1:1, Robot and Earth) :

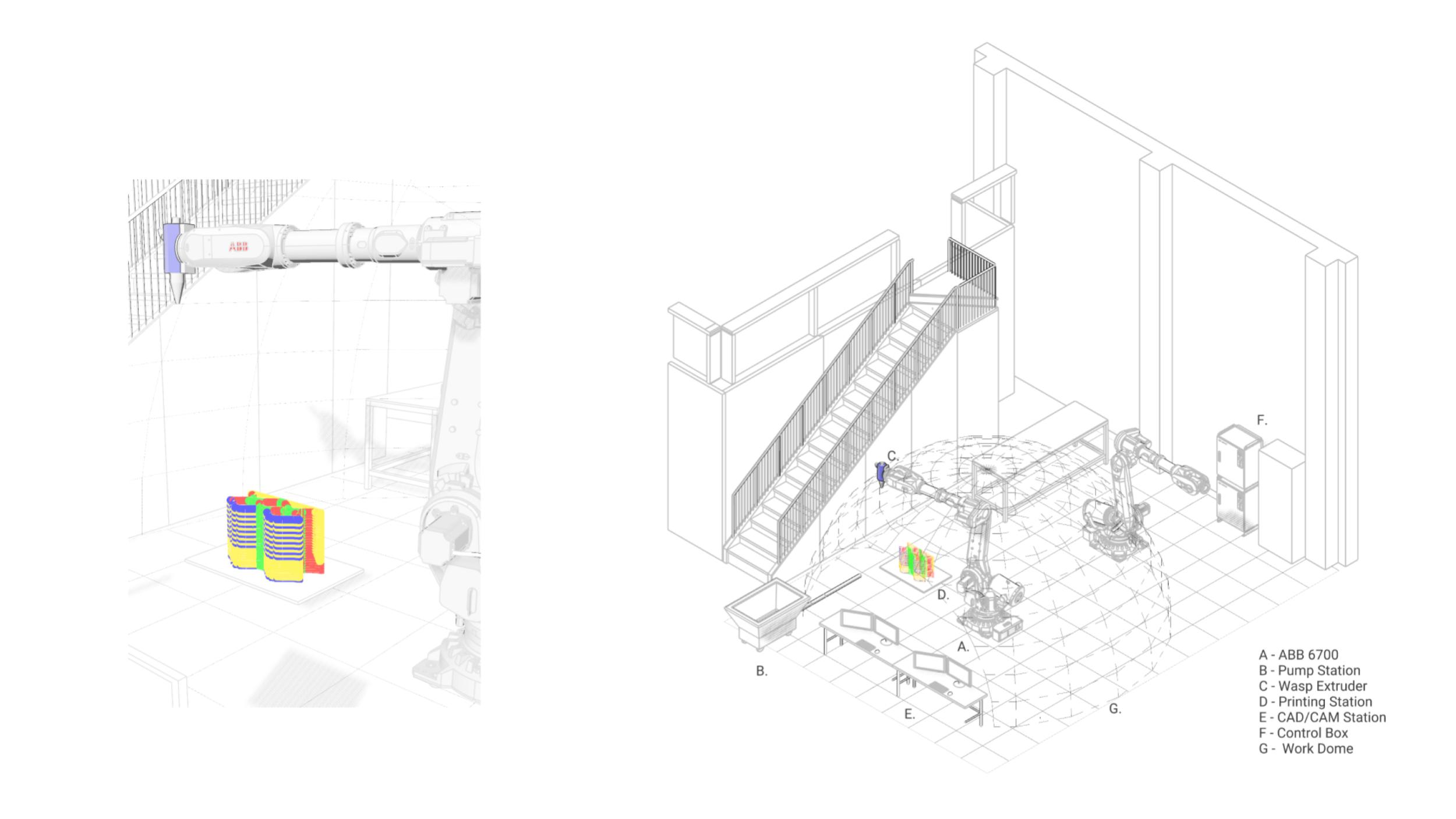

Robotic cell :

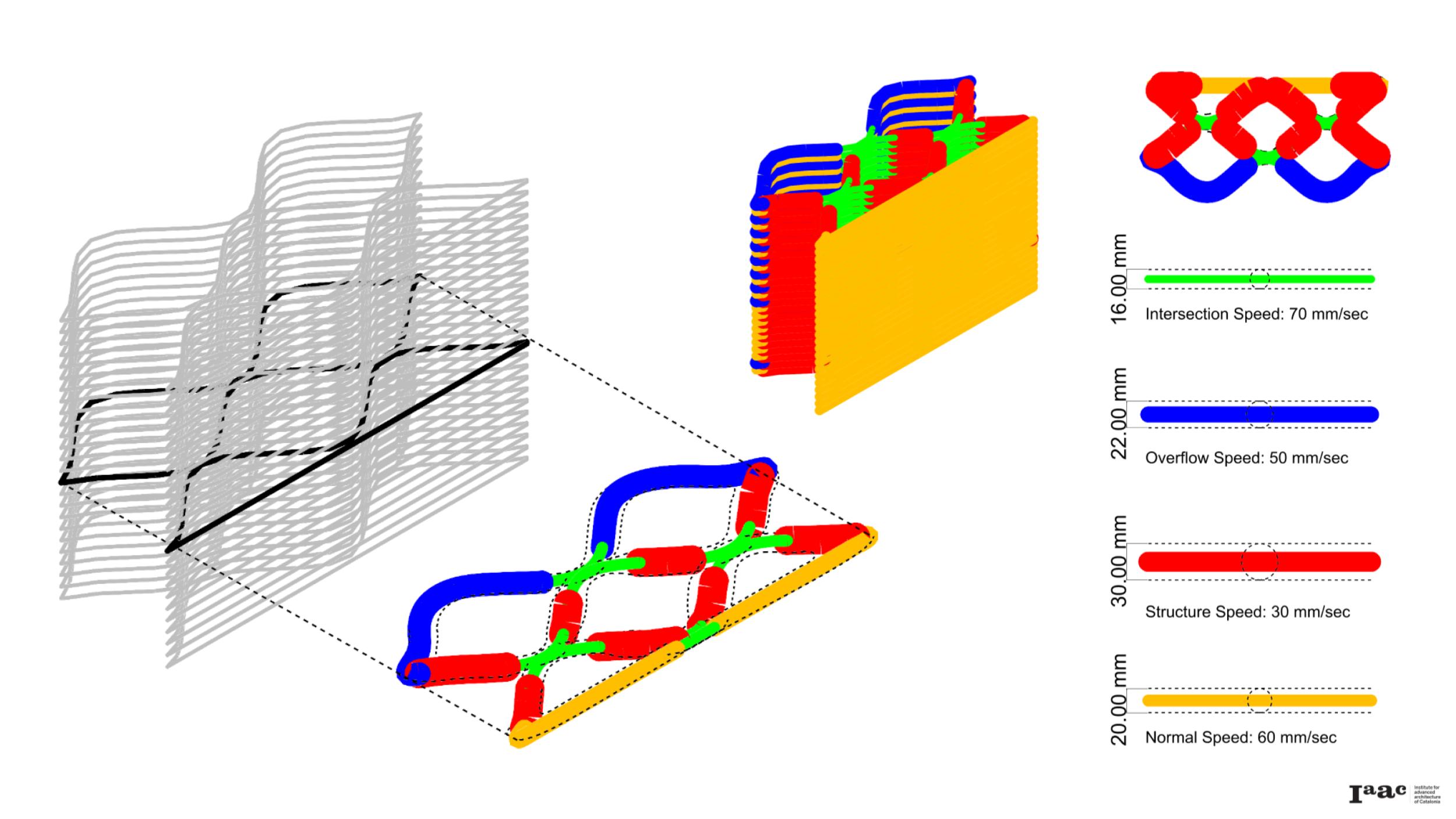

Test Print 1: The section of the wall was printed with various speeds to have various print widths.

Observation: While printing, buckling was observed on the straight section of the wall and also print widths were narrow resulting to cracks.

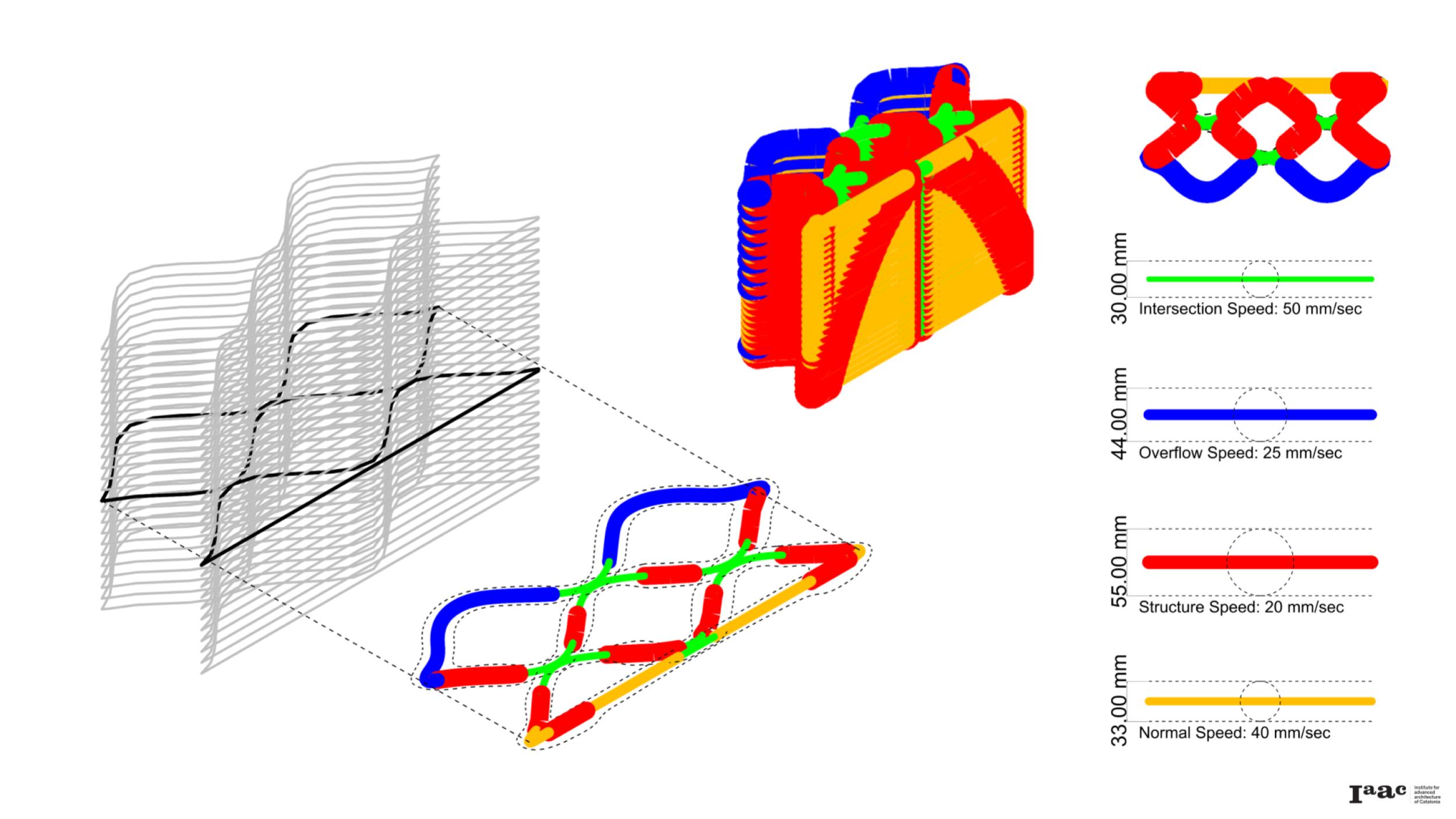

Test Print 2: After Test Print 1, various speeds were changed to print thicker layers and also curve strategy was applied in order to avoid buckling in the straight section of the wall.

Observation: Best print quality with various print widths resulting in no buckling and stable structure.

Conclusion:

- Whenever Extrusion Multiplier increases, Print width increases.

- Whenever Speed increase, Print width decrease.

- Buckling can be avoided by applying curve strategy.

- Slenderness strategy improves buildability of the print.

- More extrusion at various parts of the print can be used as strategy to tackle rainfall.

- Walls with less thickness but with more mass deposition (Extrusion Value) at various strategies have better compressive strength than the others.

Future Outlook:

- To explore strategies that can solve overhanging, column, corners and openings in a wall.

- To implement various climatic factors such as thermal mass and water retention through strategical mass depositions.

- To use OpenCV as a optimization tool to detect development of cracks under compressive straight analysis.

- To utilize Karamba as a benchmark digital tool to simulate printability of the wall.

- To Print 1:1 on WASP crane.