Context

Architecture, in general, is the least optimized industry. This results in more workload and less output. Hence the productivity rate is negative 1.4. In the furniture industry, even loose or modular furniture, typically expected to have quicker turnaround times faces significant delays due to the manual nature of customization and the complexity of matching specific design requirements.

Problem

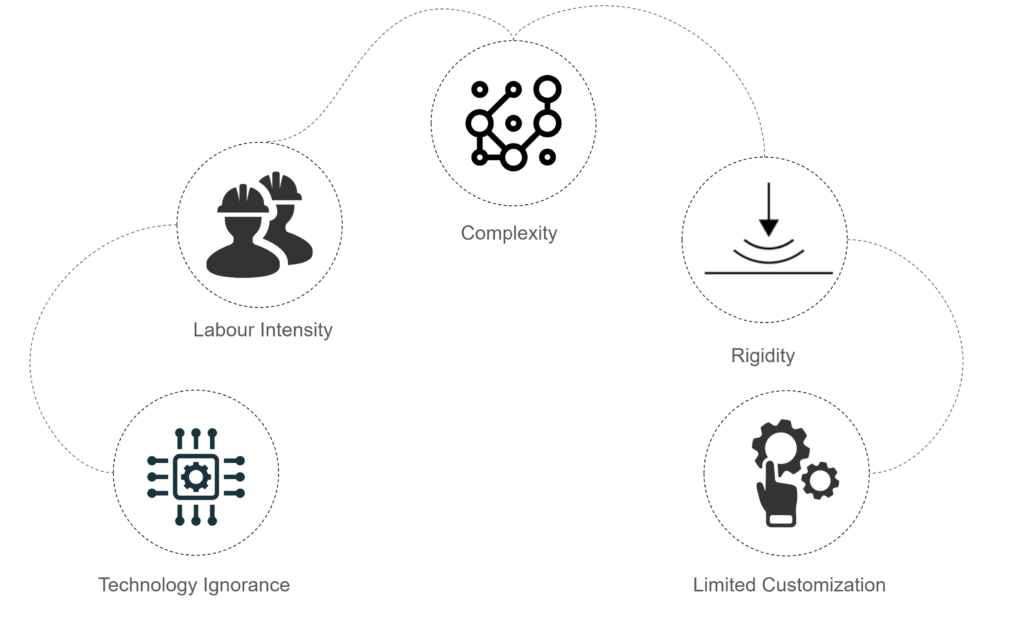

The furniture industry faces significant labor intensity and time delays due to manual craftsmanship, particularly for custom or large-scale projects. Design iterations often require extensive back-and-forth between clients and manufacturers, lengthening lead times. The rigidity of traditional methods and slow adaptation to specific spatial requirements create inefficiencies, hindering fast, tailored solutions.

Market Gap

The furniture industry lacks efficient, customizable solutions for large-scale, non-standard spaces. Current methods are time-intensive, relying on manual craftsmanship, leading to delays in delivery. High-end sectors like hospitality and healthcare demand adaptable, generative designs that traditional furniture makers cannot efficiently produce, creating a market gap for automation-driven, parametric solutions

Solution

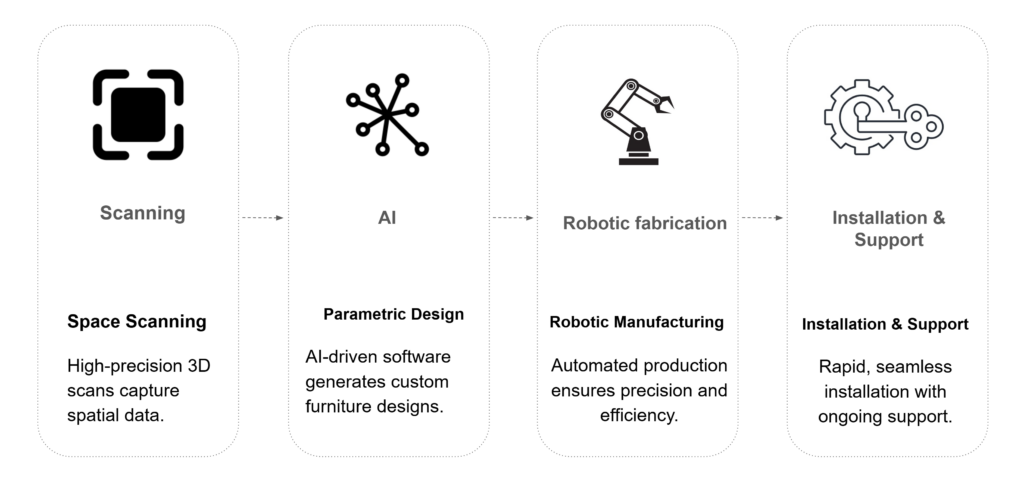

Our business model revolves around delivering generative furniture solutions tailored to architectural spaces. We use parametric design tools to create highly customizable, innovative furniture that adapts seamlessly to any space. Clients can visualize designs in real time through a digital platform, ensuring precision and aesthetic harmony. Fabrication is outsourced to specialized manufacturers, leveraging advanced technologies like robotic production for efficiency and scalability

How it works

Customer Acquisition

Our business utilizes generative design powered by machine learning (ML) to create adaptive, customizable furniture solutions. By leveraging ML algorithms, we optimize design parameters like material usage, spatial fit, and structural integrity, allowing for highly personalized furniture that meets specific client needs. The process involves scanning the space and using data-driven insights to generate designs that evolve and adapt in real-time. This approach significantly reduces time and labor intensity, addressing the inefficiencies of traditional design methods while enabling faster, more accurate customization. Outsourced fabrication partners then produce the designs, ensuring a seamless end-to-end solution