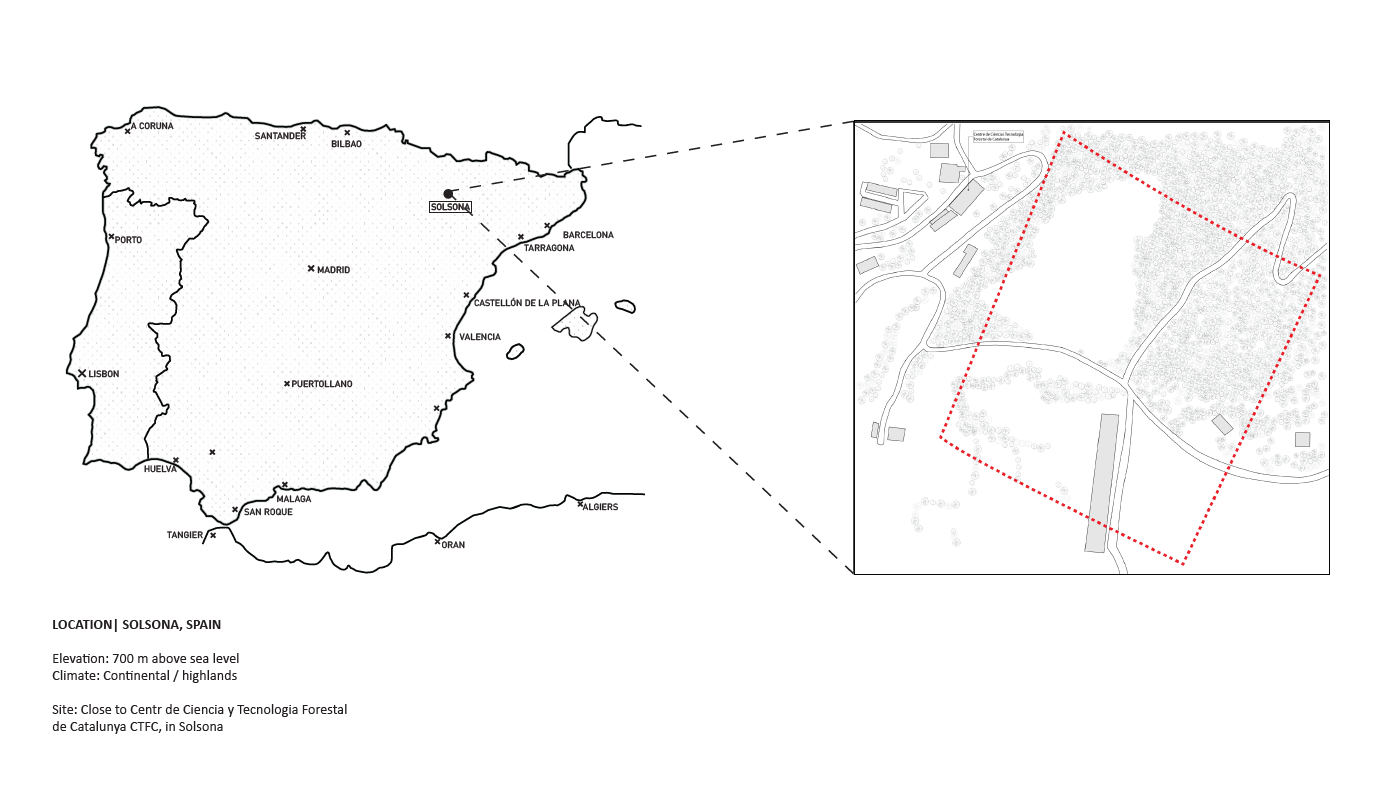

Our project, titled ‘Tree Line’ is a timber saw mill, combining community with industry in the city of Solsona, Spain. The aim of this project is to bridge the gap of knowledge in the public about the milling industry, and bring people closer to the wood that is so often used. It sits within the middle of a chain of processes that bring wood from the Pyrenees mountains to the city of Barcelona.

The initial phase of this project was to design a smaller scale cabin, implementing our thermodynamic strategies for the region, that can be scaled up into a timber saw mill.

Climate Analysis Phase 1

Climate and People Phase 1

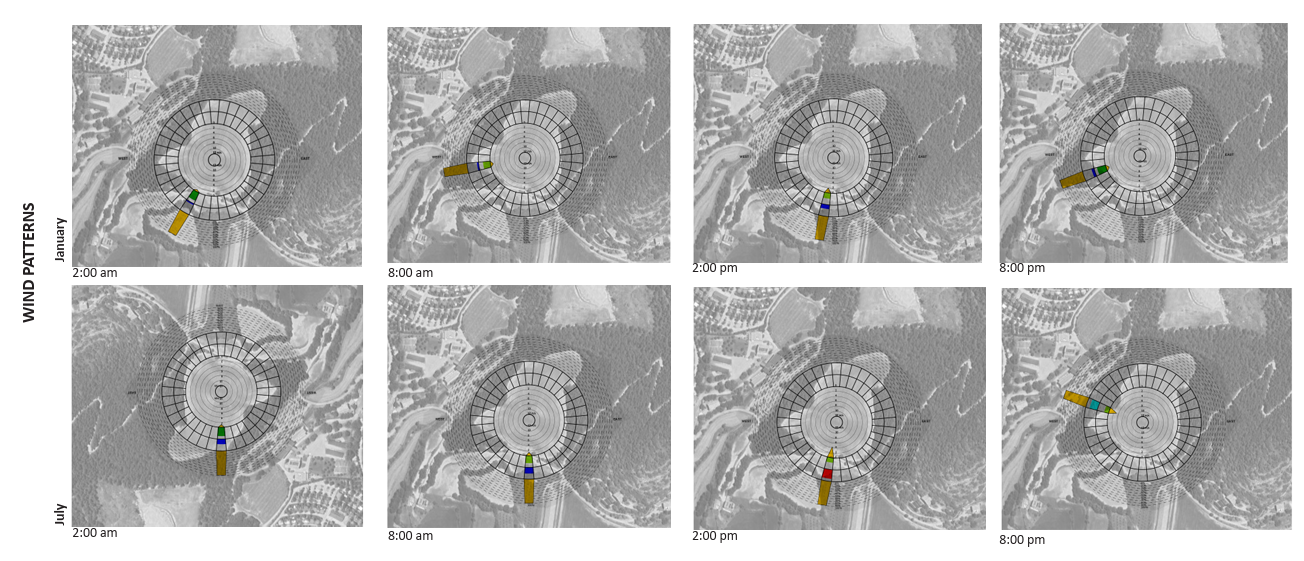

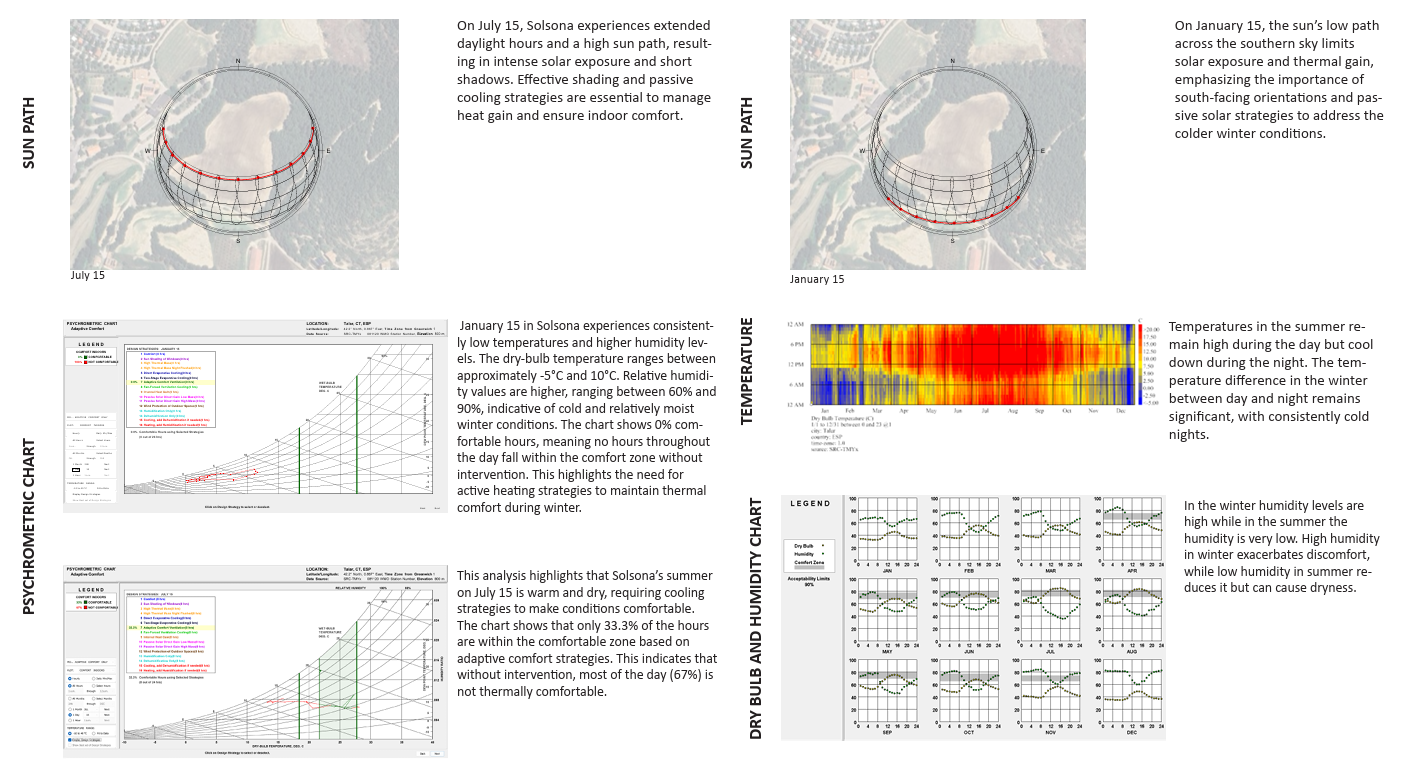

Compiling all of our climate analysis, Solsona is moderate all year round, with only occasional snowfall in the winter. Being halfway towards the Pyrenees, it’s categorized as having Continental climate, and people are able to be outside most of the year comfortably if dressed correctly. The summers are hot and dry and the winters more humid. This leads us to our main challenges of keeping the building warm during the winter months and cooling it during the summer months.

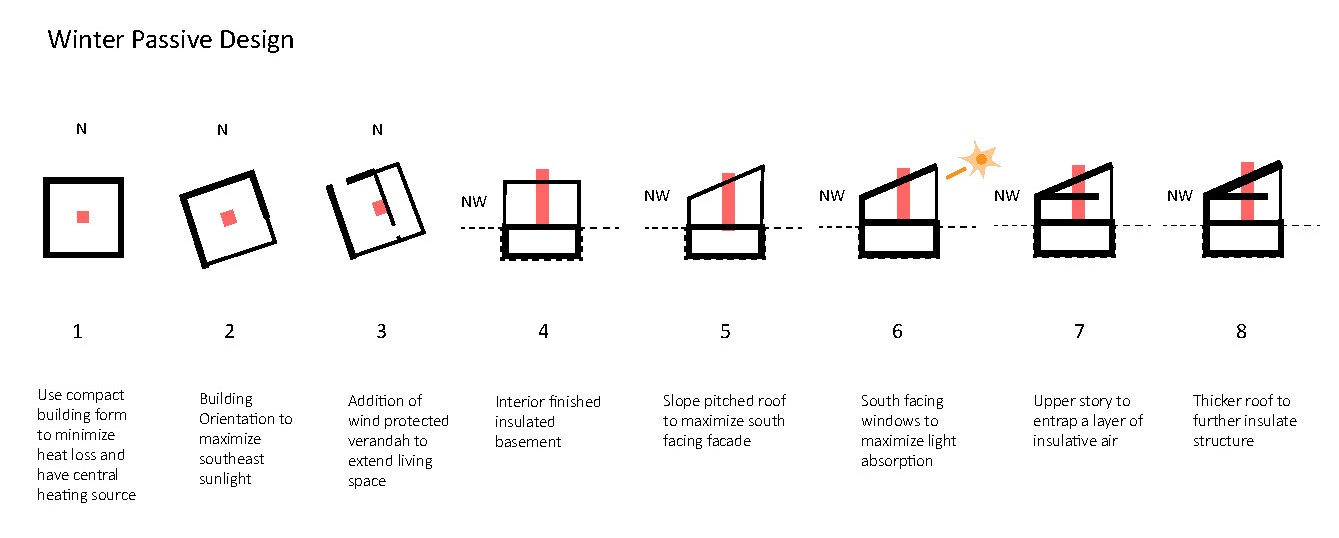

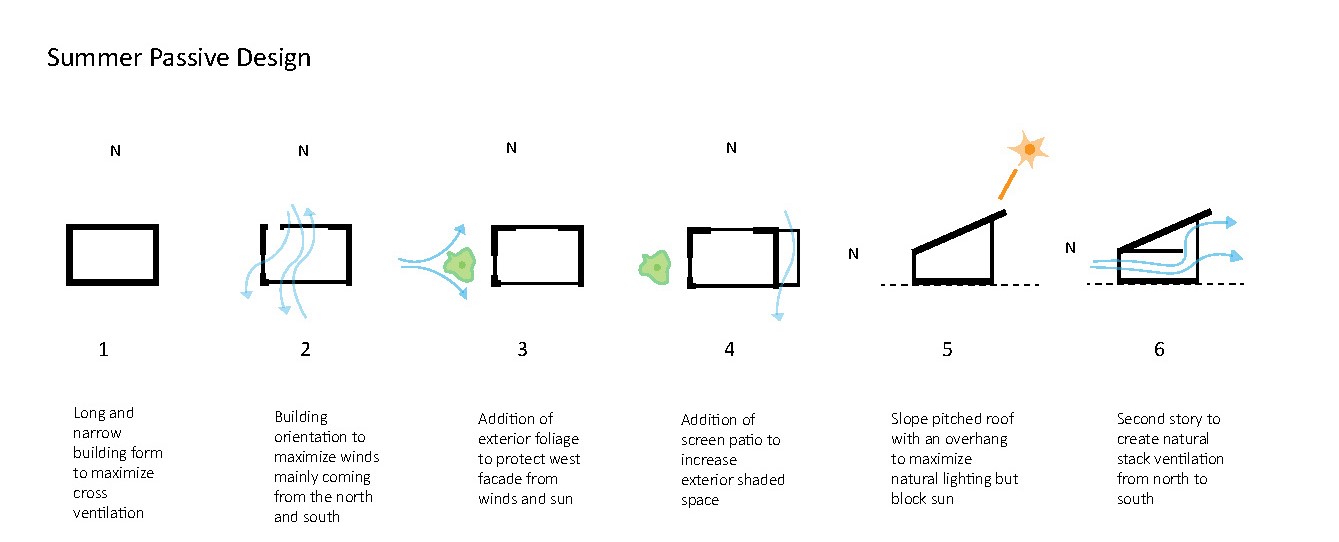

Thermodynamic Strategies Phase 1

For our key strategies we looked into in the beginning, we split the seasons into two, Winter and Summer.

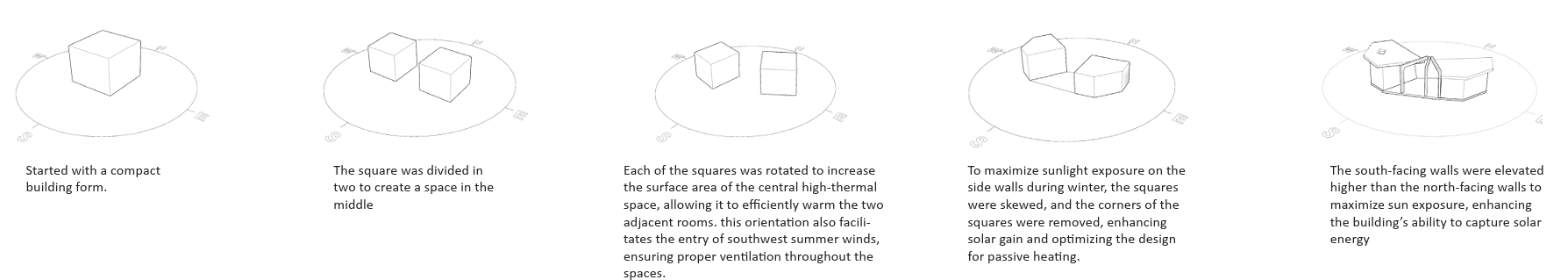

Cabin Design Phase 1

Combining our winter and summer strategies into one cabin began with a general massing exercise, and ultimately led to the final form of our cabin with the main thermal strategies carried through.

———————————————————————————————————————————————————————————————————————

The central space is open in the summer months allowing for ventilation and cool air to enter the rest of the cabin.

Thermal walls are heating up from the winter sun and slowly releasing heat overnight, while the central greenhouse space is closed.

———————————————————————————————————————————————————————————————————————

“Tree Line” A Timber Saw Mill Phase 2

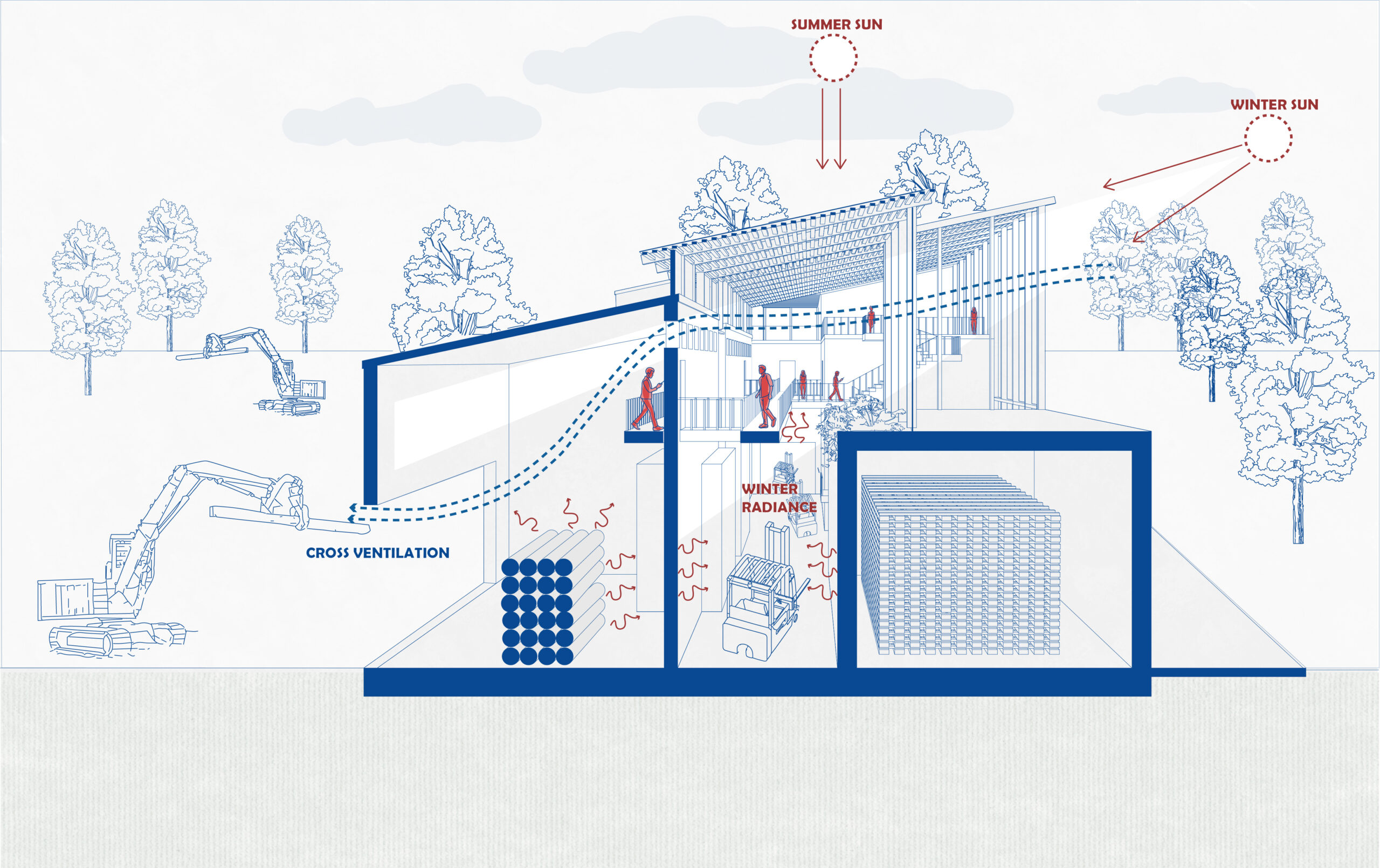

From our cabin to our sawmill, we continues with certain elements, predominantly with the massing of the central indoor/outdoor space between two solid ones. The program is split into several parts, to allow for summer ventilation, and the building is enveloped in a wood glass structure serving as a greenhouse to help insulate in the winter. The implementation of pitched roofs is included as well to allow for winter sun to be absorbed more easily.

The program is organized by the processes that take place when timber is milled, starting in the lumber yard and ending in the shipping loading zone. These main steps decide the organization of main interior spaces, due to the mechanical equipment that would be within them. Many processes, produce byproducts within a sawmill, and one strategy we developed was burning these byproducts to help power the kiln. The kiln is a main energy consumer within the building, and can also be used during the winter months to help heat the building because of the warmth that it gives off. Our thermal walls from our cabin comprise the structure of the kiln and all of those that are south facing in between each program.

Ventilation is able to travel through the entire structure from north to south during the summer months due to the greenhouse structure, while during the winter it will be enclosed and trap heat from all of the equipment and sun. The pitched roofs allow for winter sun to be let in and summer sun to be blocked, and the construction of the kiln is of thicker thermal walls that further entrap heat during the day, while radiating it out at night.

Members of the community can come and see the processes of milling through the circulation of cat walks within the greenhouse, bringing the community of Solsona into the building.