As businesses evolve in the 21st century, success is no longer measured by profit alone. Today, organizations are expected to create meaningful value for people, the planet, and the broader economy. The Sustainable Business Canvas is a strategic tool that helps businesses embed sustainability at the core of their operations by assessing not just economic outcomes, but also social and environmental impact.

This canvas builds upon the foundations of the traditional business model canvas, expanding it to include a comprehensive analysis of Value Captured, Value Missed, and Value Opportunities across key stakeholder groups:

- Society

- Employees

- Founding Team

- Other Stakeholders (e.g., governments, NGOs)

- Suppliers and Partners

- Shareholders

- Customers

- The Environment

Through this lens, companies can identify areas where they are already creating positive impact, where opportunities for improvement exist, and where new initiatives can drive sustainable innovation.

Importantly, the Sustainable Business Canvas is a practical framework for aligning business strategy with the United Nations Sustainable Development Goals (UN SDGs). In this case, it specifically connects with:

- Goal 8: Decent Work and Economic Growth—ensuring fair employment, fostering entrepreneurship, and promoting inclusive growth.

- Goal 9: Industry, Innovation and Infrastructure—supporting sustainable industrialization and driving forward innovation.

- Goal 11: Sustainable Cities and Communities—creating products, services, and systems that contribute to resilient and inclusive urban environments.

- Goal 12: Responsible Consumption and Production—encouraging efficient use of resources, circularity, and reducing waste through sustainable production processes.

By integrating these global priorities into their business model, organizations not only future-proof their operations but also contribute to building a more inclusive, innovative, and sustainable world.

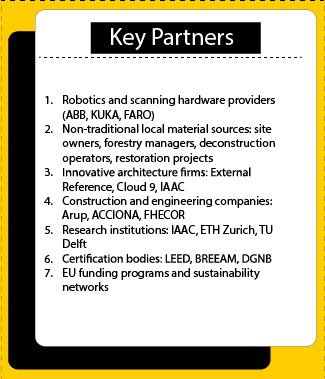

Our key partners include local craftspeople, material suppliers specializing in sustainably sourced timber and stone, academic research institutions, and technology providers focused on robotic systems. Collaborating with these partners allows us to integrate traditional knowledge with cutting-edge fabrication, ensuring material authenticity and precision in our processes. Partnerships with NGOs and municipal bodies also help us support community-driven initiatives, aligning our work with regional development goals and sustainable urban strategies.

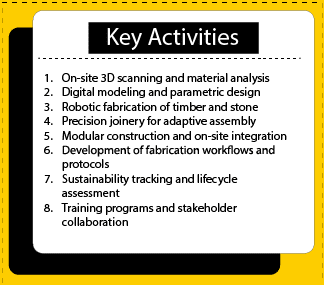

Our key activities center around the design and robotic fabrication of sustainable architectural components. This includes scanning and processing local materials, developing customized toolpaths based on craft techniques, and prototyping advanced joinery and assembly methods. We also conduct ongoing research and development to refine robotic operations and material efficiency while engaging in community outreach programs to share knowledge and promote sustainable construction practices.

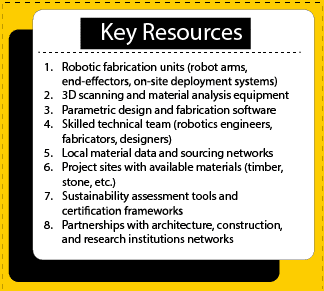

The core resources driving our project include advanced robotic fabrication equipment, local natural materials (such as timber and stone), and a multidisciplinary team combining expertise in architecture, robotics, and traditional crafts. Our partnerships with universities and technology providers enhance our access to data, software, and cutting-edge hardware, while our network of skilled artisans ensures cultural continuity and craftsmanship quality in each project.

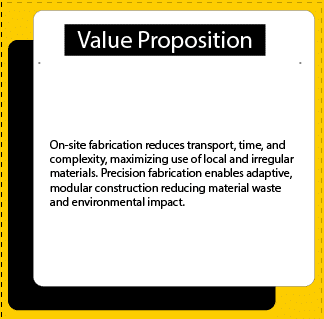

We offer a unique fusion of traditional craftsmanship and modern robotic fabrication to create sustainable, high-quality architectural solutions. Our approach emphasizes the use of locally sourced materials, reducing environmental impact and supporting regional economies. By reinterpreting traditional techniques through technology, we deliver bespoke, durable, and resource-efficient components that contribute to responsible production (SDG 12), innovative industry (SDG 9), and resilient communities (SDG 11).

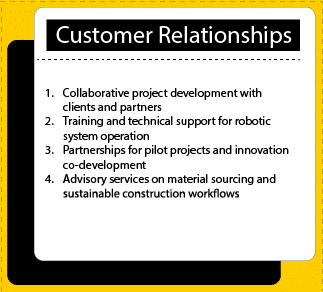

We foster long-term, collaborative relationships with architects, developers, and communities who value sustainability and craftsmanship. Through co-design processes, workshops, and transparent communication, we engage clients directly in the material and design decisions, ensuring each project aligns with their values while contributing to broader sustainability goals. This participatory approach builds trust and positions us as partners in innovation rather than just suppliers.

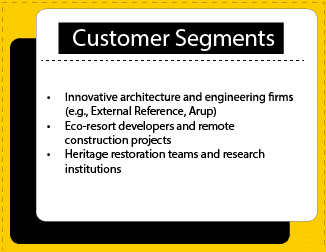

Our key customers are forward-thinking architects, developers, and municipalities committed to sustainable design and construction. We also collaborate with cultural institutions and educational organizations interested in preserving and advancing craft through modern technologies. Our clients value innovation, environmental responsibility, and the integration of traditional craftsmanship in contemporary architecture.

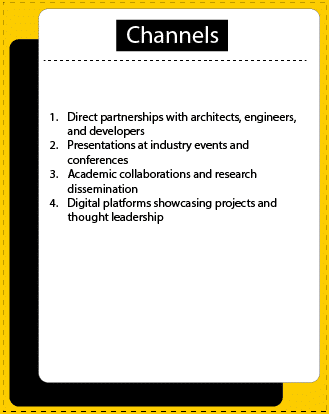

Our primary channels include direct partnerships with architecture and construction firms, presentations at industry conferences, and publications in sustainability and design journals. We also engage with the local community through exhibitions and workshops that showcase our methods and outcomes. Digital platforms, such as our website and social media, amplify our reach and share our commitment to sustainable and responsible building practices.

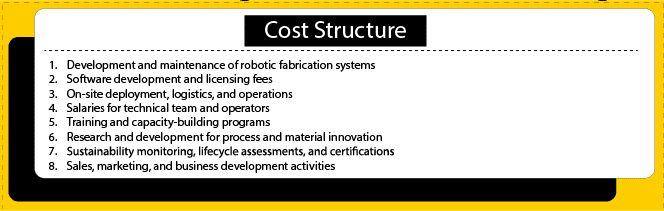

Our main costs stem from acquiring high-quality, sustainably sourced raw materials, operating and maintaining robotic systems, and investing in skilled labor—both in digital fabrication and traditional craftsmanship. Additional expenses include R&D for developing new fabrication techniques, energy consumption (with a focus on renewable sources), and community engagement initiatives that ensure inclusive project development.

Our primary costs are centered on the upfront investment required to establish the robotic fabrication workflow and infrastructure. This includes:

- Robotic equipment and end-effector development: €150,000

- Workshop setup, tools, and safety systems: €50,000

- Software licenses and development for digital workflows: €20,000

- Training and team development (craftspeople + engineers): €30,000

- Ongoing operational costs (energy, maintenance, materials): €5,000/month

The total initial investment is approximately €250,000, excluding monthly operating costs. We also allocate a percentage of project budgets for continuous R&D, material sourcing, and partnerships with local artisans to ensure ethical and sustainable practices.

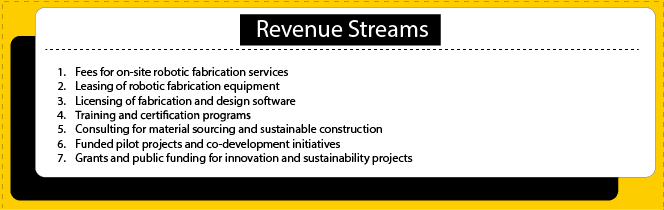

Revenue is generated through custom fabrication services, design-build contracts, and consultancy for sustainable construction and digital craftsmanship integration. We also offer workshops and training programs that create additional income streams while promoting knowledge-sharing. Long-term, we plan to expand into licensing proprietary fabrication methods and digital toolkits to broaden our impact and scalability.

Our income is primarily generated through:

- Design fees: Custom architectural design services, typically charged at 10% of total construction costs.

- Fabrication and construction fees: Digital fabrication and assembly services, averaging €1,500–€2,500 per m² of built space, depending on complexity and material selection.

- Workshops and training programs: Generating €1,000–€5,000 per session, depending on scale and audience (professionals, students, or communities).

- Consulting services for sustainability and digital craft integration: €100–€150/hour, or fixed packages for municipalities and developers.

Break-even Analysis

Assuming a standard project size of 200 m², with an average construction value of €2,000 per m², each project represents approximately €400,000 in construction costs. If we charge:

- 10% design fees = €40,000

- Fabrication and construction services = €2,000 per m² × 200 m² = €400,000

This results in €440,000 gross revenue per project.

Subtracting project-specific costs (materials, labor, energy, etc.), estimated at 40% of revenue, leaves us with €264,000 net per project.

Breakeven Point

With an initial €250,000 investment, we can anticipate breaking even after one full-scale project of 200 m², provided the margins hold. More conservatively, if projects are smaller or margins are tighter, two mid-sized projects (100–150 m² each) would likely cover the upfront investment.

Return Timeline

Depending on the project pipeline:

- Completing one 200 m² project per year would recover the initial investment within 1–1.5 years.

- With two to three projects per year, break-even could occur within the first year, followed by profitability and funds for reinvestment in scaling operations or expanding services.

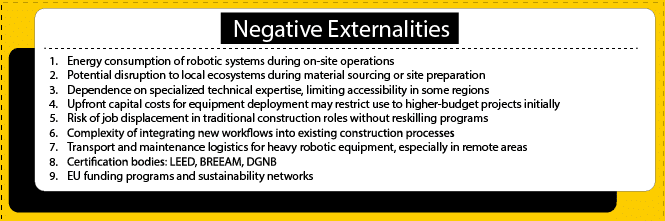

Despite our efforts, some negative externalities are inherent in our operations. The energy consumption of robotic fabrication processes can be significant, particularly if renewable energy sources are not consistently available. There’s also a potential risk of displacing traditional labor if automation is not thoughtfully integrated alongside craftspeople. Sourcing natural materials like stone and timber, if not carefully managed, can contribute to environmental degradation or resource depletion. Additionally, the use of high-tech equipment and systems can inadvertently widen the digital divide, limiting access for communities without the resources or skills to engage with advanced technologies.

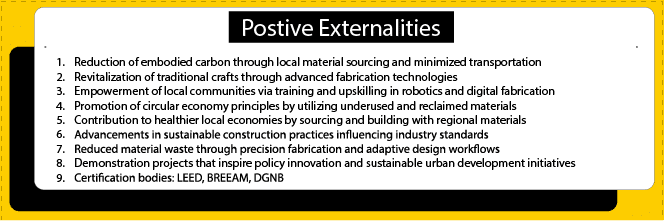

Our work generates several positive externalities that extend beyond our immediate stakeholders. By sourcing and processing local timber and stone, we stimulate regional economies and support traditional craft industries, contributing to local job creation (SDG 8). Our integration of robotic fabrication increases efficiency and reduces material waste, promoting responsible production practices (SDG 12). Additionally, our projects demonstrate how advanced technology and heritage craftsmanship can coexist, encouraging innovation in sustainable industry and infrastructure (SDG 9). The use of renewable and locally sourced materials also reduces the carbon footprint of construction projects, fostering more sustainable cities and communities (SDG 11). Through workshops and knowledge-sharing initiatives, we inspire a broader cultural appreciation for craftsmanship and sustainability in design.