[ 1 ] FIRST QUESTIONS :

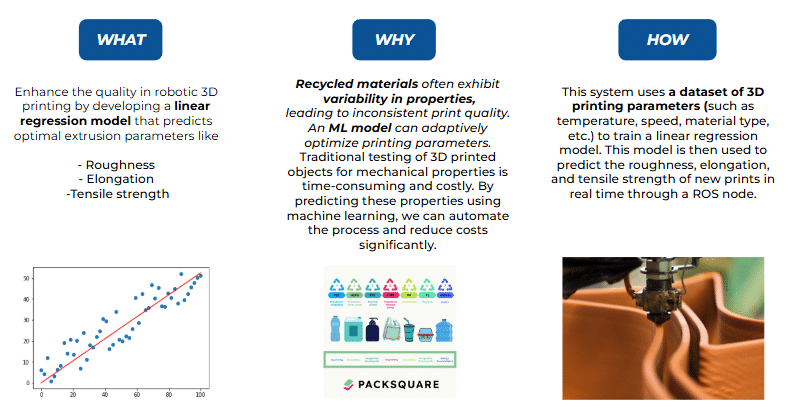

The application of Machine Learning (ML) to the prediction of 3D printing parameters presents a challenge that necessitates a structured approach and raises many questions on how to approach this combination. To effectively explore this integration, it is essential to address three core questions: What are the process and the ML model to be employed? Why is ML an appropriate and valuable tool for enhancing this fabrication process? And how can ML techniques be implemented to accurately predict the parameters that govern the quality and efficiency of 3D printing? Addressing these questions provides a foundational framework for systematically investigating the synergy between ML and additive manufacturing.

DATASET :

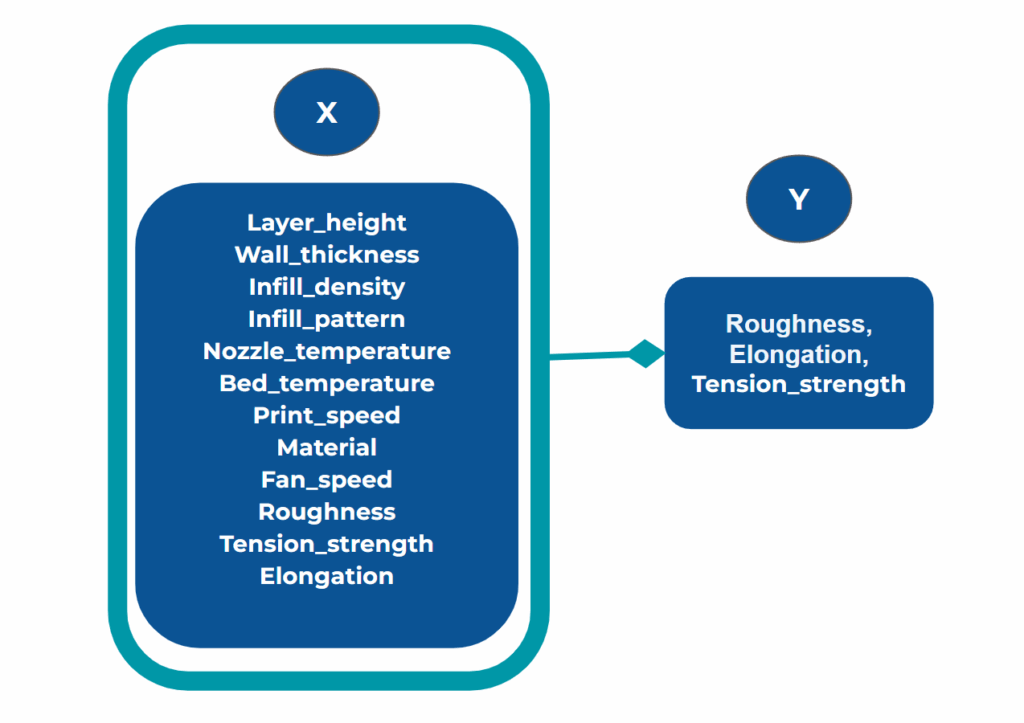

To train and validate the Machine Learning (ML) model, a comprehensive and structured dataset is essential. In this study, we utilize the publicly available 3D Printer Dataset for Mechanical Engineers provided on Kaggle (https://www.kaggle.com/datasets/afumetto/3dprinter?resource=download). This dataset includes key printing parameters and corresponding mechanical performance indicators such as surface roughness, tensile strength, and elongation at break. By leveraging this dataset, the model could possibly learn the underlying relationships between input parameters and desired output properties, thus enabling accurate prediction and optimization in the robotic 3D printing process.

3D Printer Dataset for Mechanical Engineers:

https://www.kaggle.com/datasets/afumetto/3dprinter?resource=download

[ 2 ] CONCEPT OF OPERATIONS :

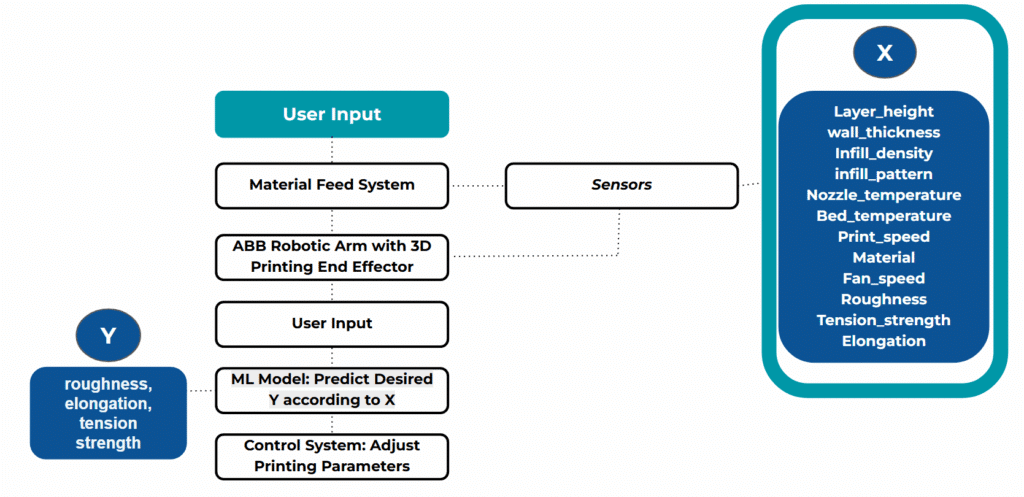

An ABB industrial robotic arm, equipped with a 3D printing end effector, is utilized to fabricate large-scale panels from recycled polymers. Machine Learning (ML) is integrated into the system to predict and optimize key printing parameters in order to achieve desired mechanical and surface properties, namely surface roughness, elongation and tension strength.

Selected Process:

Robotic 3D printing using recycled plastic materials.

Concept :

Utilize an ABB robotic arm equipped with a 3D printing end effector to fabricate panels.

The ML model predicts optimal printing parameters to achieve desired

roughness, elongation, tension strength.

1. Surface Roughness (Ra)

- Definition: Measures how smooth or rough the printed surface is.

- Why it matters: Rough surfaces can weaken mechanical properties and reduce print quality.

Evaluation: Unit: Micrometers (µm) 0.1-6

2. Elongation at Break (%)

- Definition: How much a material stretches before it breaks.

- Why it matters: Shows flexibility and ductility of the printed part.

Evaluation: Unit: Percentage (%)

3. Tension Strength (MPa)

- Definition:

The maximum tensile stress a material can endure under pulling (tensile) load before failure. It reflects the material’s resistance to breaking when stretched. - Why it matters:

Shows how much pulling (tension) a material can resist before it fractures — essential for designing parts that carry loads, suspend weight, or stretch under force. - Evaluation:

Unit: Megapascals (MPa)

[ 3 ] ML CONTRIBUTION :

[ 4 ] TECHNOLOGY :

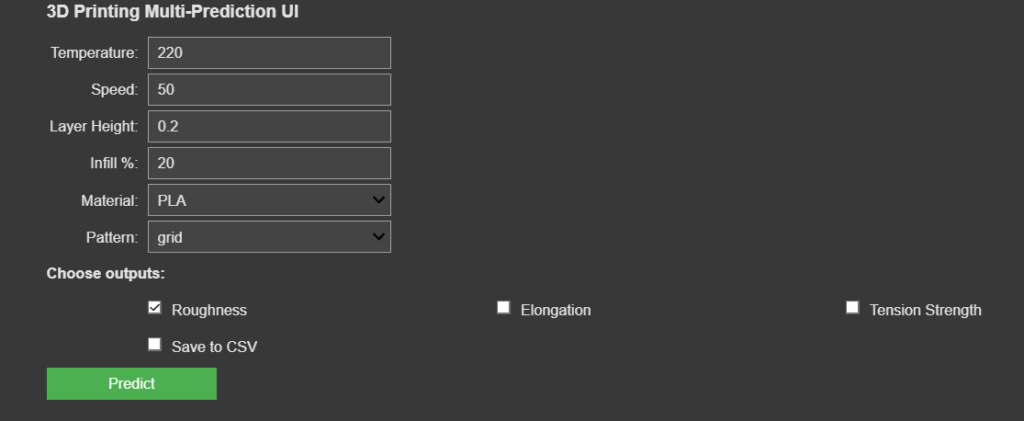

Technological Framework

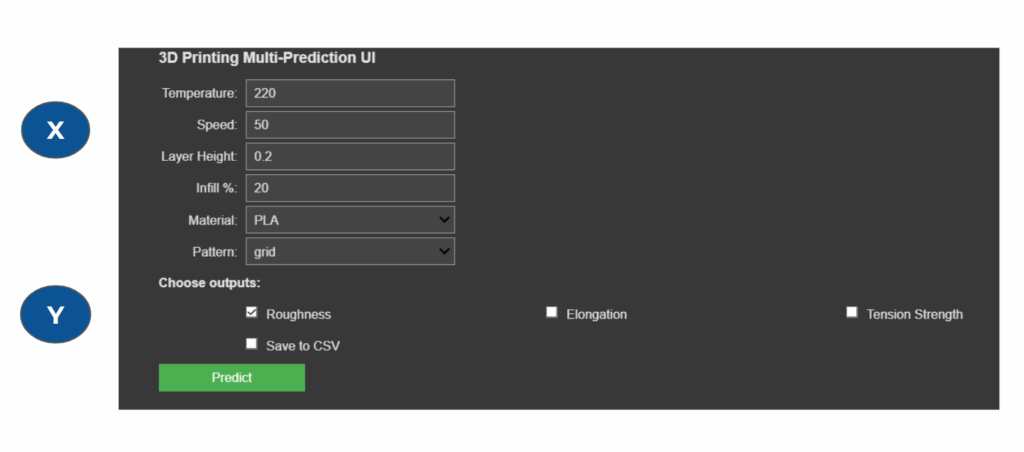

- Programming Language: Python

- ML Framework: scikit-learn, implementing linear regression to model relationships between input parameters and target properties

- Robotics Middleware: Robot Operating System (ROS), enabling real-time communication between sensors, actuators, and ML modules

Current and Future Data Acquisition

- Current: Parameter input via user interface

- Future: Integration of environmental and process sensors (e.g., for temperature, extrusion speed) for automated real-time data acquisition

Hardware Components

- ABB IRB 140 or 6700 robotic arm

- 3D printing end effector compatible with recycled filament

- High-resolution camera for visual inspection

- Embedded sensors for monitoring temperature and extrusion dynamics

[ 5 ] EXPECTATIONS :

The primary objective of the model is to predict optimal parameters; however, this project is fundamentally an exploration of the potential applications of Machine Learning (ML) in the context of 3D printing. It serves more as an opportunity to gain insights and develop a deeper understanding of ML methodologies rather than as an attempt to deliver a finalized, production-ready model. This work emphasizes learning and observation, with the intent to assess the feasibility and limitations of ML in predicting 3D printing parameters.

[ 6 ] QUESTIONS [ 7 ] :

- Experimental Data:

Conduct a series of test prints varying temperature and extrusion speed, recording the resulting layer adhesion quality.

- Data Logging:

Use ROS to log sensor data and camera assessments, storing them in CSV format for model training.

- Physical Testing:

Implementation of the ML model on the actual robotic system, performing test prints to validate model predictions.

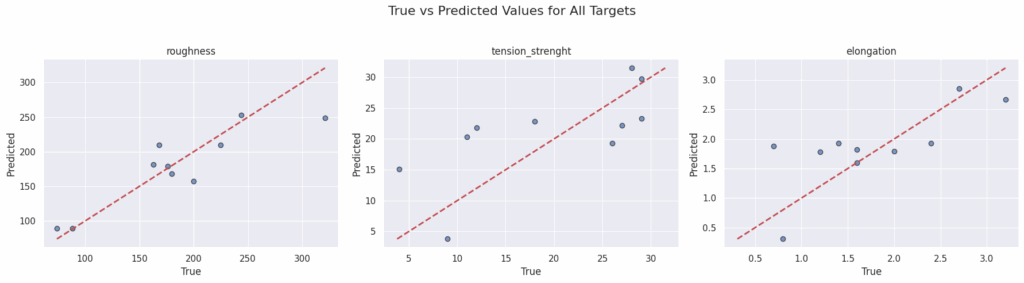

[ 8 ] INTERPET RESULTS :

Given that the linear model may not adequately capture the complexities observed in the data, particularly in light of visible biases, it may be beneficial to explore alternative modeling approaches. A polynomial model, for instance, could offer a more flexible fit to the data, potentially addressing non-linear relationships that a linear model fails to represent. This exploration of different models will help to assess their suitability in minimizing bias and improving the accuracy of predictions, providing a more robust framework for model optimization.

ALL TARGETS RESULTS :

[ 9 ] FUTURE STEPS & IMPROVEMENTS :

Model Possible Enhancements:

We could incorporate additional parameters, such as

- ambient temperature

- humidity

Advanced ML Techniques:

We could explore a Polynomial regression model or more complex models, like neural networks, to capture nonlinear relationships between parameters.

Scalability:

We could adapt the system for different materials and printing processes, broadening its applicability in sustainable construction.

Adaptability:

Capable of adjusting to variations in recycled material properties by continuously learning from new data.

Efficiency:

Reduce the need for manual parameter tuning, thereby saving time and resources during the fabrication process.

GITHUB REPO:

https://github.com/VasiliMav/3D-Printing-Prediction-System-with-ML-