Abstract

Over the last decade, the surf industry has been rapidly expanding, as an increasing number of people worldwide are embracing the sport. However, despite the rising demand, traditional surfboard design approaches have yet to fully embrace the potential of tailored equipment that takes into account the unique needs and preferences of individual surfers. As a consequence, many surfers find it challenging to locate the perfect surfboard that matches their particular physical attributes and environmental surroundings, which can detract from the overall surfing experience.

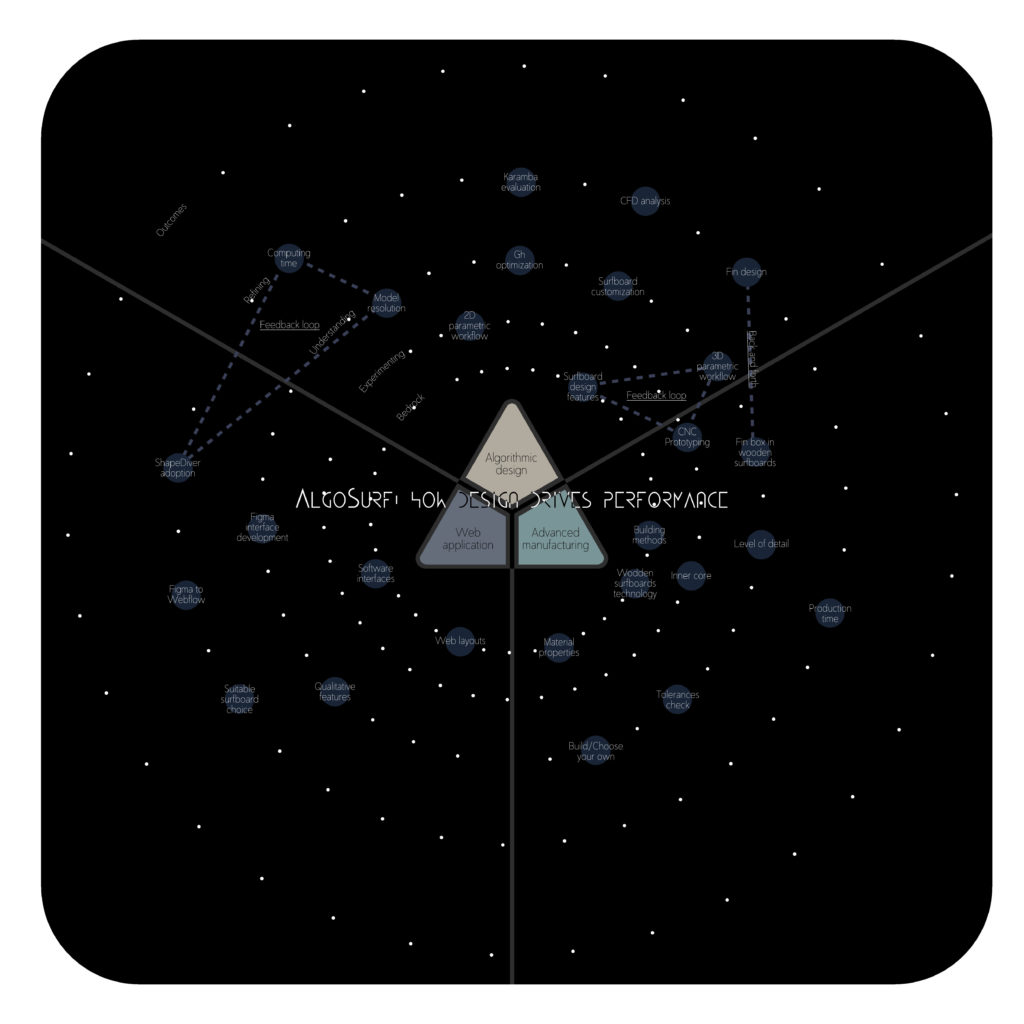

AlgoSurfboards involves leveraging computational tools, such as computational fluid dynamics and structural optimization, to create custom-tailored surfboards that match the unique physical attributes and environmental features of individual surfers. Using the latest knowledge and understanding of surfboard design principles and techniques, the web-based platform allows surfers to input data and generate personalized surfboard designs that are optimized to enhance performance. Thereafter the personalized designs are actualized through a meticulous crafting process that utilizes cutting-edge manufacturing tools, resulting in a high-performance surfing experience.

The making of high-accuracy surfboards takes advantage of sustainably-sourced wood as a material that has traditionally relied on manual crafting methods. By employing state-of-the-art manufacturing tools was possible to achieve greater precision and efficiency in the production process, while still maintaining the unique characteristics and aesthetics of the wooden surfboard. The results demonstrate the potential for sustainable materials and advanced manufacturing technologies to revolutionize the surfboard industry and provide surfers with an exceptional surfing experience. Alongside this, the online platform serves as a mediator between the shaper and the user, providing a user-friendly interface that streamlines the design process. Through the platform, users input their individual specifications and receive personalized design recommendations from the algorithm.

With the use of sustainable materials and advanced manufacturing technologies, it is possible to shape high-performance surfboards that are not only tailored to the physical attributes and environmental conditions of the individual surfer but also offer an augmented surfing experience. Likewise, the online platform that acts as a mediator between the shaper and the user streamlines the design process and provides real-time feedback, enhancing the accuracy and efficiency of the design process. Ultimately, the integration of emerging technologies such as machine learning and artificial intelligence holds possibilities to further improve the personalization and precision of surfboard design, providing surfers with even more tailored and unique experiences.

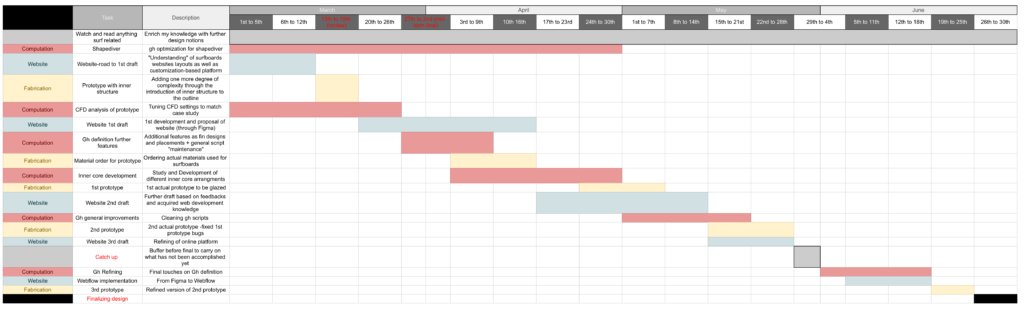

Framework

Scientific interest

(Structural) Optimization is an active field that recently saw major changes alongside the development of manufacturing processes and machine learning algorithms.

The surfboard industry is slowly absorbing these computational features within the design. ProjectName enriches surfboard design with optimization features which

ultimately deliver a bespoke product – meeting individual needs.

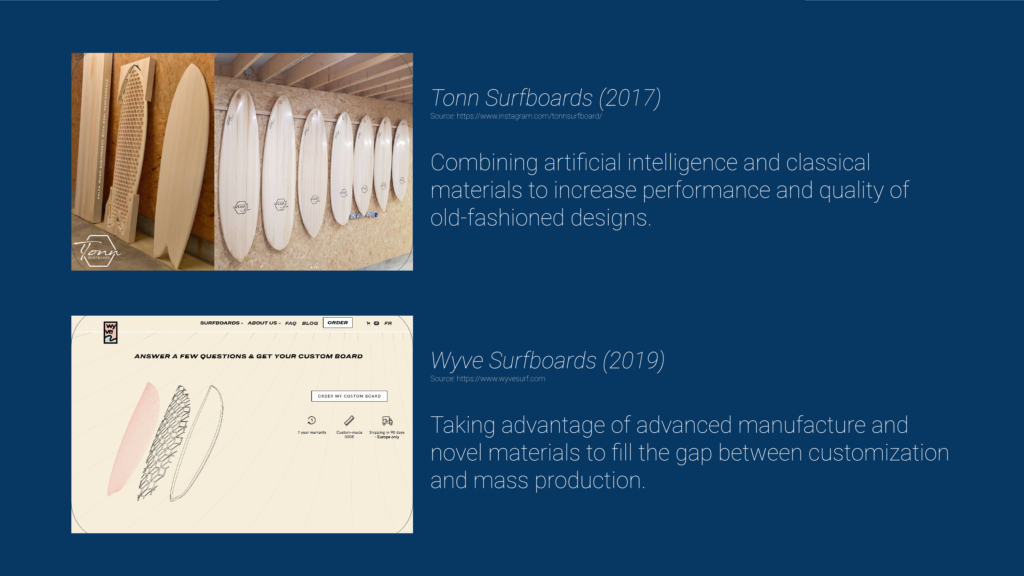

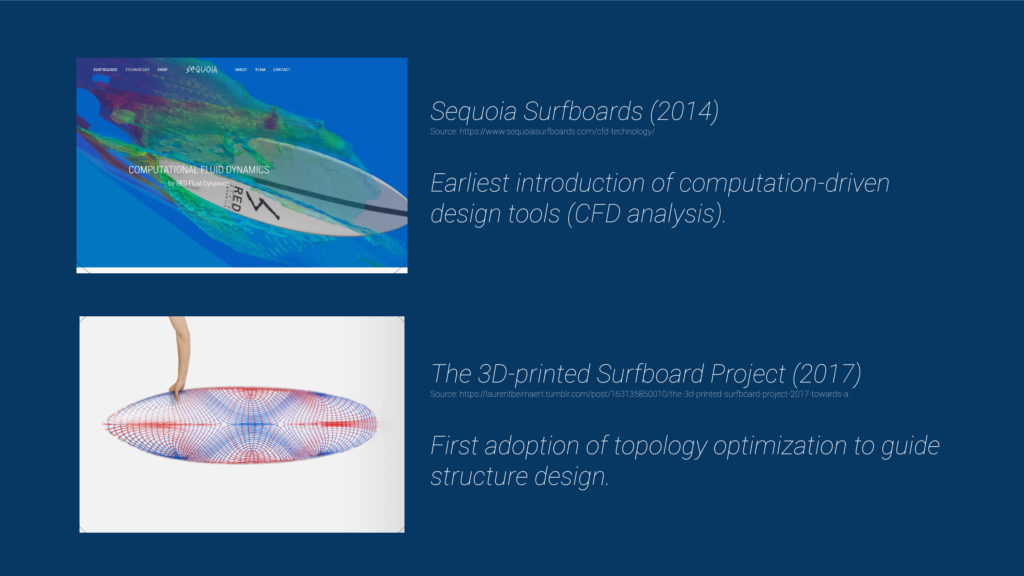

State of art

Although digital tools are taking place in the surfboard industry, structural optimization strategies, i.e. the application of recursive patterns, have not fully being based on machine learning algorithms yet.

1st Thesis statement

The widespread development of parametric design for structural modeling and analysis has increased new possibilities such as the capability of assessing a wide variety of design options avoiding time-consuming operations. This aspect supports the creative process and greatly increases design flexibility. ProjectName delves into structural optimization taking advantage of computational tools to ultimately enhance product performances: custom-tailored surfboard as a case study.

2nd Thesis statement

The widespread development of parametric design for structural modeling and advanced manufacturing has opened new possibilities such as the capability of assessing a wide variety of design options, supporting the creative process and greatly impacting architectonic. This bespoke approach has gained particular attention in relation to sports equipment optimization; it provides customizable products whose ultimate purpose is to enhance individual(s) performance. In the watersport framework, surfboard design is undergoing design changes through the introduction of artificial intelligence tools. ProjectName, takes advantage of machine learning operations, delving into structural optimization and digital fabrication to explore a novel framework from custom-tailored surfboard design.

3rd Thesis statement

The Surfboard Industry is currently employing advanced manufacturing and parametric design tools in the boards making process in order to ultimately enhance the overall ride experience. These novel implementations have opened new possibilities such as the capability of assessing a wide variety of design options, supporting the creative process, and greatly impacting customization. This bespoke approach accommodates user individual needs and skills through a set of ever-growing computational means ProjectName aims to enrich the contemporary computational spectrum, delving into structural optimization and digital fabrication to create a framework for custom-tailored surfboard design.

ALGOSurfboards: how design drives performance is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Architecture02 2022/23 by Student: Federico Caldi and Faculty: Mathilde Marengo, Nikol Kirova and Fiona Demeur.