Design Strategy

The Apex project is designed by aligning structure and program into a single tower offering multiple configurations based on environmental optimizations. By approaching the structure as one of the main drivers of the tower, we decided to test what is the effect of the structure’s material on the carbon footprint of the project.

We analyze three types of materials using them as the baselines to understand the effects of their carbon footprint while optimizing for the structural support of the tower.

We looked at understanding how concrete, steel and Glulam can have tradeoffs in their carbon footprint and energy consumption in the production phase A1-A3. These diagrams show the basic System boundaries for each of the materials. We can see how the raw materials are extracted and transported to production. Although they all come from different origins, they still produce waste and consume energy and water for transformation into a usable material for construction.

Analysis of Indicators

Next we looked at the individual metrics for each material. We analyze the common indicators from all of them and broke them down into categories to understand where each material might have its strength and weaknesses.

This bar chart evaluates the End of Life (EOL) Impact of Timber, Steel, and Concrete, focusing on two key aspects.

The EOL impact is measured in kg CO₂-eq/m³, indicating the emissions or carbon sequestration associated with each material during its end-of-life phase.

- Steel excels in end-of-life scenarios with substantial recycling potential and no emissions during waste processing.

- Timber offers moderate recycling benefits but incurs significant emissions during waste processing.

Concrete has minimal recycling advantages and low emissions, making its end-of-life impact less favorable compared to Steel.

This bar chart presents the Global Warming Potential (GWP) by Stage of Timber, Steel, and Concrete across three critical life cycle stages.

The GWP values are measured in kg CO₂-eq/m³, indicating the amount of carbon dioxide equivalent emissions associated with each material during each stage.

- Timber effectively sequesters carbon during the raw materials stage, making it environmentally advantageous.

- Steel demonstrates superior performance in both transport and manufacturing stages with negligible emissions.

Concrete maintains moderate GWP across all stages but doesn’t excel in any single category.

This bar chart compares the Energy Use of Timber, Steel, and Concrete in their production processes.

Energy use is measured in MJ/m³, providing a clear view of the energy sources utilized during production.

- Timber leverages a high proportion of renewable energy, enhancing its sustainability despite significant total energy use.

- Concrete uses less non-renewable energy compared to Steel, making it a more energy-efficient choice.

Steel is highly dependent on non-renewable energy sources, contributing to its high environmental impact.

This bar chart breaks down the Global Warming Potential (GWP) of Timber, Steel, and Concrete into three distinct categories.

The GWP values are measured in kg CO₂-eq/m³, providing insights into the sources of emissions for each material.

- Timber stands out with a negative total and biogenic GWP, making it the most climate-friendly option.

- Steel has the highest total and fossil GWP, primarily due to energy-intensive production.

Concrete offers a balanced GWP but lacks the negative benefits seen in Timber.

Summary of Analysis

- Timber is highly sustainable in terms of carbon sequestration and renewable energy use, making it ideal for minimizing GWP, especially during the raw materials stage. However, its end-of-life emissions need careful management.

- Steel performs exceptionally well in transport, manufacturing, and end-of-life recycling, offering low emissions in these stages. Its primary drawback lies in its high GWP and energy-intensive production, necessitating improvements in production processes.

Concrete serves as a balanced material with moderate GWP and energy use. While it doesn’t lead in any specific category, its low non-renewable energy consumption and durability make it a viable option, though enhancing its recycling potential could further improve its sustainability profile.

Application to our project

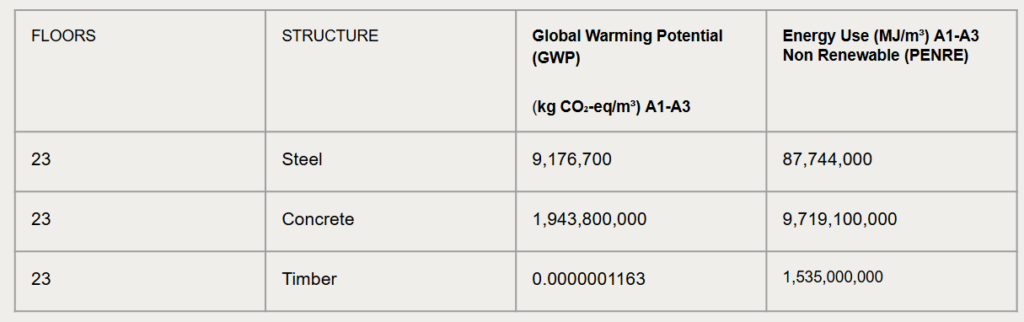

We then looked at the Global Warming Potential and Energy Use of Non Renewable for our project and calculated it for each of the types of structural materials. As expected Timber yields the lowest value for Global Warming Potential but still uses comparable amounts of energy for production. Concrete on the other hand has the most GWP and requires the most energy for production. This provides a guidance of which material will be more impactful on the environment for our structure. We can chose a combination to reduce the carbon footprint.