The project envisions a thermal and data hub in Barcelona’s 22@ district, transforming IT infrastructure into a sustainable heat source. Inspired by Roman baths, the design uses underground server racks as modern-day “columns” in a hypocaust system. Waste heat from servers is collected through metallic pipes, directing it to heat floors and supplement the Llevant heating network, extending its reach to older buildings. To ensure optimal server performance, Peltier modules are strategically placed: the cold side cools the servers, while the hot side enhances heat transfer to the second layer for heating. Temperature sensors regulate efficiency, and fans dissipate excess heat, creating a seamless integration of data processing and heating. This innovative fusion of ancient architecture and technology exemplifies a sustainable future.

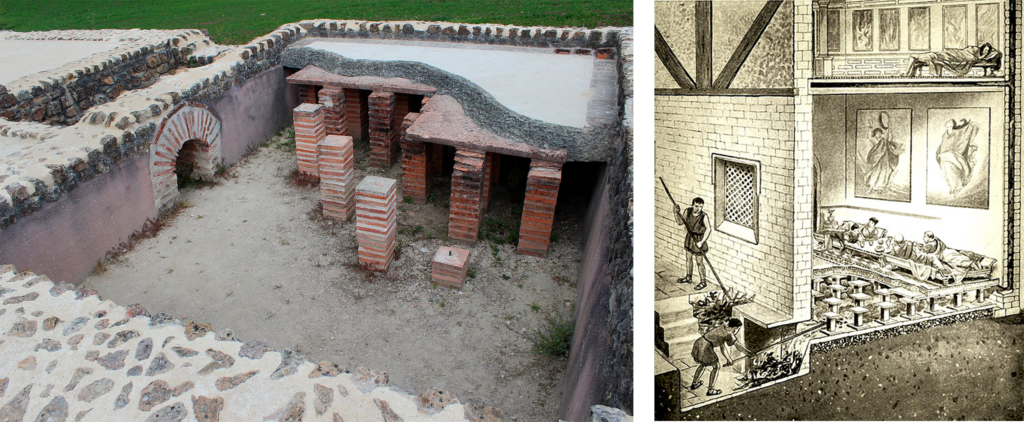

The hypocaust was an ancient Roman central heating system that used a network of hollow spaces and flues to circulate warm air beneath floors and within walls. Heat was generated in a furnace (praefurnium) and channeled through these spaces, which were supported by small columns (pilae stacks). The floors, often topped with tiles or mosaics, absorbed and radiated the heat to warm rooms like the caldarium (hot baths). This innovative system provided efficient heating for large buildings and baths while demonstrating sophisticated thermal engineering for its time.

Concept

Inspired by Roman hypocausts, underground server racks act as columns generating heat, which is captured via metallic pipes to warm floors and extend the Llevant heating network to older buildings. Key to this system, Peltier modules enhance efficiency by cooling the servers with their cold side and boosting heat transfer to the second layer with their hot side. Temperature sensors dynamically monitor system performance, while fans dissipate excess heat, ensuring consistent server functionality and optimized heating.

This dual-layer system integrates advanced cooling and heating solutions while maintaining efficiency through proper insulation and component alignment.

Cooling Layer Specifications (First Layer)

The cooling layer is designed to keep servers at optimal temperatures for maximum performance and longevity. Servers are arranged as columns, with key heat-generating components (CPUs, GPUs, and power supplies) prioritized for heat management. The cold side of each Peltier module faces the GPUs base, using thermally conductive adhesive to maintain full contact. The hot side is coupled with high-efficiency aluminum supported by an active cooling mechanism, fans to dissipate excess heat.

Heating Layer Specifications (Second Layer)

The heating layer efficiently transfers waste heat from the servers to warm floors and surrounding spaces. Heat is carried upward via a network of stainless steel pipes, which connect directly to the server heat sinks. On the floor-heating side, Peltier modules are used with their hot side in contact with these pipes, ensuring enhanced thermal transfer. For even heat distribution, a thermal diffuser plate is placed above the modules, followed by a layer of floor insulation to minimize downward heat loss. Finally, thermally conductive flooring material, ceramic tiles, support effective dispersion of heat into the living spaces above.

System

ARDUINO CODE

T Sensor

Assemblage

- Peltier Module

- H bridge Motor Driver

- DC Motor (Fan)

- 9v Battery

- DHT11 Sensor

- Arduino Board

CLIMATECH combines cooling and heating functions in two distinct layers, optimizing energy use and sustainability. In the cooling layer, the cold side of the Peltier module directly cools the servers’ heat-generating components, such as CPUs and GPUs, maintaining their performance at optimal levels. Excess heat from the hot side is dissipated through heat sinks and fans, ensuring the Peltier module operates effectively. In the heating layer, the hot side of the Peltier modules transfers heat to metallic pipes, which channel it upward to warm floors and extend the Llevant heating network to nearby buildings. Temperature sensors dynamically regulate the modules, ensuring precise control of heating and cooling, while fans improve efficiency by managing airflow and dissipating residual heat. This innovative integration creates a seamless system, transforming waste heat from data processing into a valuable resource for urban heating, inspired by the ancient Roman hypocaust system.