The seminar explores a series of methodologies, that incorporate advanced design thinking, generative algorithms and mass customized fabrication in existing industrial processes.

This development is accompanied with novel interfaces for robotic programming and large-scale automated construction.

Syllabus

Credits: Design for robotics, IAAC Global Summer School 2020

Robotics has opened up new avenues of designing, making, assembling and indeed the whole spectrum of architectural production. Although robots, particularly industrial robots, have been around since the 1960s, have not yet been directly linked to the design process.

The construction sector has not yet taken full advantage of the digital revolution that is happening in other manufacturing sectors, such as in the automobile and aerospatial engineering industries. While studies predict that Automation, Robotics, and AI will possibly increase productivity by 60% in the construction sector, they also open new opportunities for design and for increased building performance.

In this context, today we find ourselves looking at the midst of a significant transformation regarding the way we produce products thanks to the digitization of manufacturing. This brings us to the emergence of a community of research and education centres including IAAC exploring new fabrication methods that can be more efficient, sustainable, and customisable thanks to the use of robotic fabrication within its educational programs, consolidating an emerging paradigm within the current production system.

To quote Richard Sennett, “Making is thinking”, this seminar will focus on a manufacturing driven design approach towards conceiving spaces. Students are offered the opportunity to learn and explore robotic fabrication within IAAC’s particularly open environment for direct manipulation and testing. In parallel, students are encouraged to develop a design protocol suitable for robotic fabrication that could serve to envision an application at architectural scale.

In this connection, with Robotic fabrication, tackling architecture details becomes an exciting new field of exploration for designers. The seminar invites students to explore joints and additive manufacturing through robotic systems in architecture facade design. Therefore, the seminar will conclude with a robotically fabricated prototype fabrication, together with a video of the design process, the prototype fabrication and the envisioned architecture.

Learning Objectives

At course completion the student will:

- Have an overview of the possible robotic fabrication processes available for architects and designers;

- Understand the basics of robotic kinematics, robotic simulation and robotic control;

- Be capable of generating the robotic simulation and production files to produce a prototype;

- Be capable of integrating the limitations and opportunities of a specific robotics process into a final architecture design.

Faculty

Projects from this course

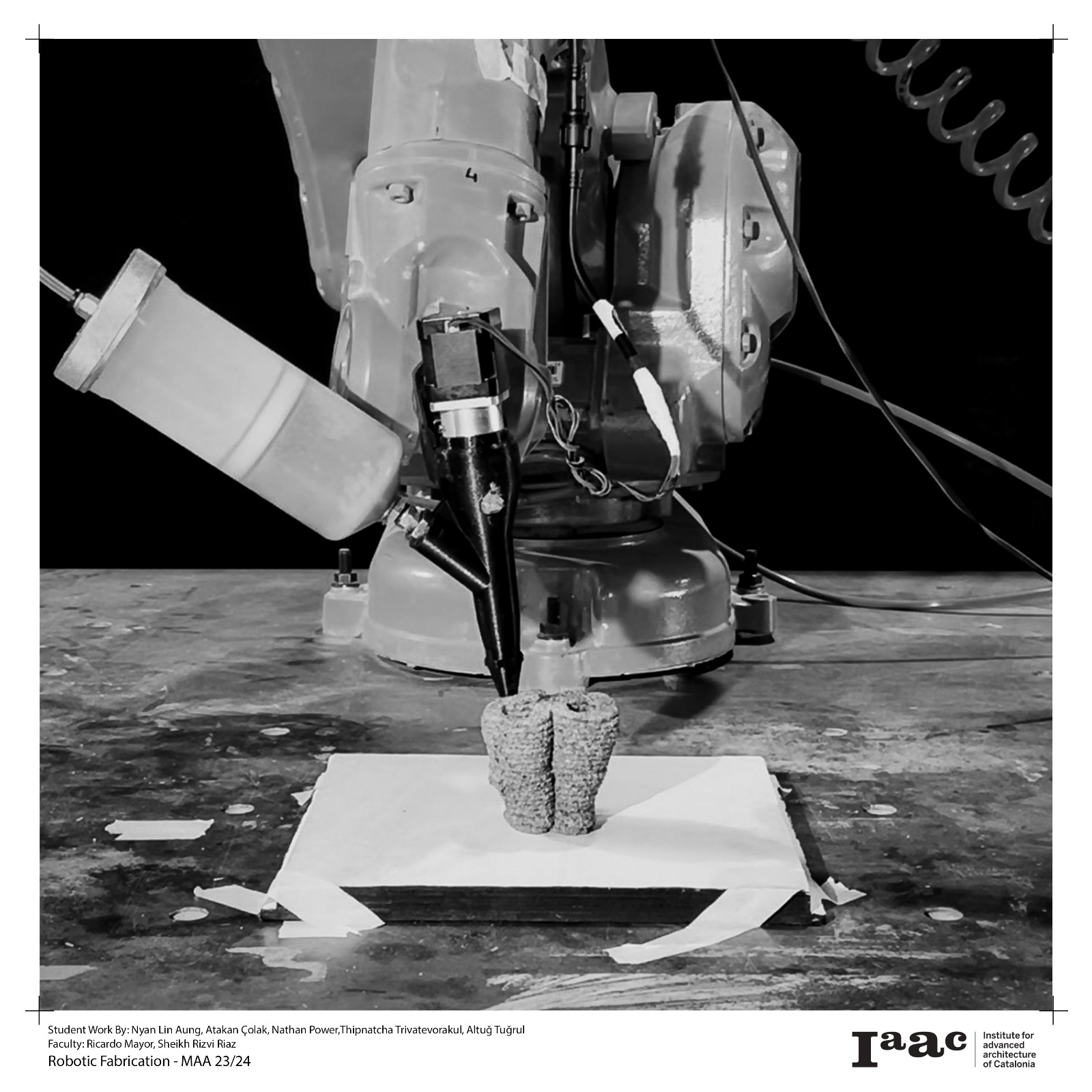

CORK.CATENATION

Non planar 3D printing cork based biomaterial CORK.CATENATION employs the novel methodology of non-planar 3d printing using Cork as the bio-material. The final outcome is a connection of interconnected lattice structures- broken down into modules that can be assembled to form a building skin that can morph according to the surface topology and solar radiation results.

The Spaces in Between

The objective of this project was to investigate the potential of the pick and place technique in producing a compelling vertical element that showcases the precision of robotic fabrication. Our column boasts an intricate design of oscillating, twisting triangles that expand and contract throughout the height of the structure. The purpose of this design is … Read more

Timber Zipper

The goal of this project is to comprehend the pick-and-place robotic fabrication process using timber members and how to optimize the process using design choices. By experimenting with various twist, rotate, shift, mirror, and scale actions, column typologies that eventually took the form of a zipper-like column were created. The exercise helps us to understand … Read more

BALANCED STRUCTURES

Balances Structures uses the ABB robot to develop a column through a pick-and-place strategy. Pushing robotic precision to its limits and minimizing human error, this project showcases how a structure in a state of delicate balance can be produced. The balance of the column was showcased not only through the placement of the structure on … Read more

TOWER TWIST

Concept Catalogue Main Catalogue Weekly Catalogue Catalogue of the digital exploration Parameters Digital input and ABB Fabrication Physical Limitation of fabrication Design Analysis Rules of the Proposed Geometry Layers: 30N. of Sticks: 120Pivot angle Increment: y = sin (x)Total Rotation: 160* Rotation’s Logic Column Making: The 3 modules Comparison Physics Simulation | Robot Simulation | … Read more

IN_(TERLOCK) CHAOS

Abstract This project will focus on using the pick & place operations to develop column geometries stacked out of timber elements. Below we present the development of a parametric system capable of integrating fabrication constraints and architectural goals. The aim was to create a natural geometry with a simple linear element, a catalog of multiple … Read more