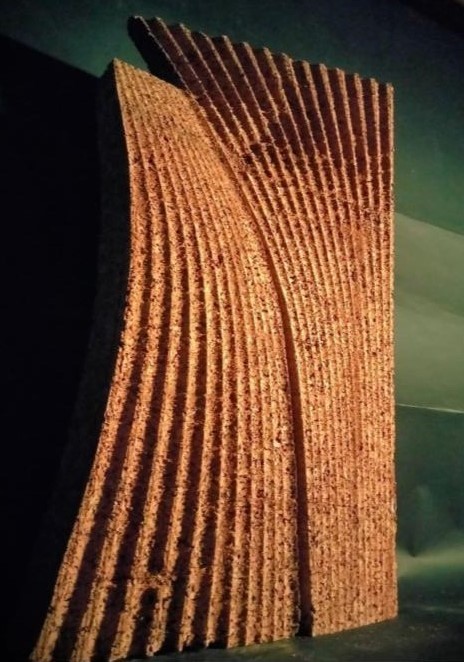

Photo Credits: ROBOTIC MOSAIC // MRAC WORKSHOP 2.1, IAAC 2021

* The focus of this intense workshop was to navigate the use of computer vision to repurposing ceramic waste. A workflow was designed that uses as an input of a set of random ceramic pieces and outputs a strategic design. OpenCV is used for feature recognition like tile contours and colours

The objective of this design studio is to explore the opportunities of image analytics and computer vision for improving manufacturing processes and informing design decisions. Specifically, students will be asked to expand upon their design proposals from MRAC Studio I and integrate computer vision techniques for data collection and analysis of important parameters that affect the execution quality of their designs.

Students are asked to conduct a literature review on the integration of sensing in robotics for manufacturing, with a focus on computer vision and image processing. A scanning setup will be created that allows for object inspection. The hardware, and software requirements for data generation and analysis will be defined in the first sessions. Using this information, students will generate a digital twin of their proposed object. This provides the canvas for data mapping which in turn will facilitate the association of this data with relevant manufacturing parameters. the design and manufacturing systems of each group will be further developed by incorporating data-driven decision making.

Students will be assessed on their research, data collection, digital twin creation, data processing and association to the realities of fabrication. Design development and presentation skills are also key evaluation parameters, as well as the ability to effectively use computer vision tools to inform manufacturing and design decisions.

Learning Objectives

Key learning outcomes of this studio are:

- Understand the principles and applications of image analytics and computer vision in the context of robotics and architecture.

- Develop skills in collecting, processing, and analysing data for use in manufacturing and design processes.

- Understand the potential of creating digital twins, and incorporating data-driven decision making into design proposals.

- Develop the ability to effectively communicate the results of such processes

KEYWORDS

Robotic manufacturing, Computer vision, Data processing, Digital twin