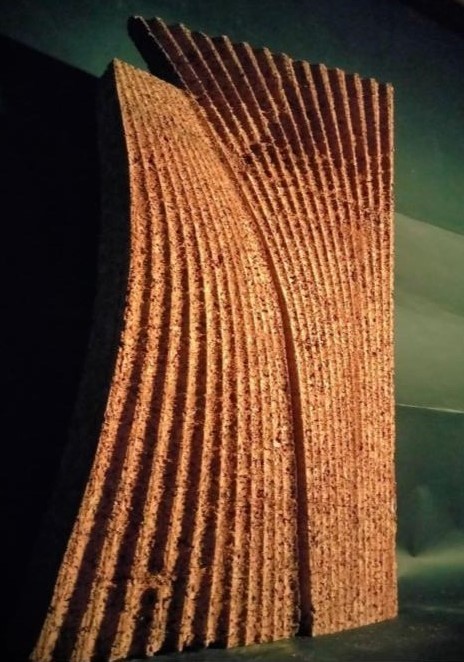

This research study delves into the realm of advanced robotics and semi-automated manufacturing processes that take into account the material properties of cork. Specifically, it explores the design and fabrication of a surface system that is optimized for both aesthetic appeal and functional performance.

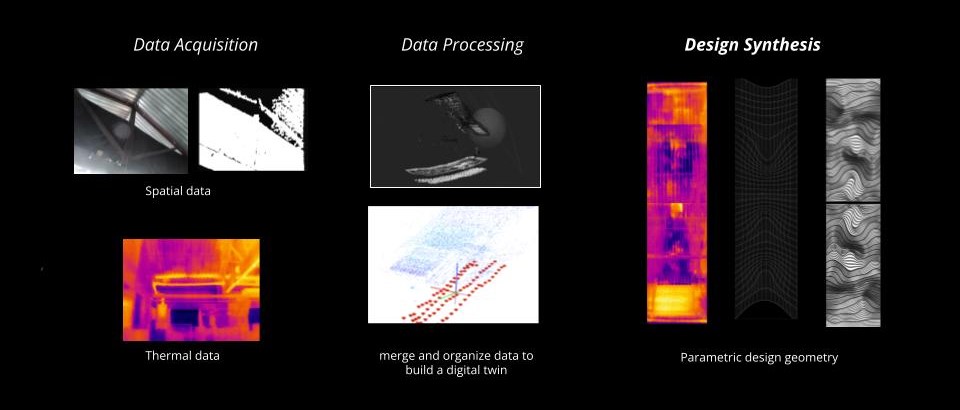

Building on the knowledge gained in a previous term on robotic workflows and the discretization of curve surfaces in cork, this study focuses on the creation of a surface that is customized to the specific design concept. To achieve this, computer vision is employed to generate thermal data that informs the design criteria for reflecting the insulating properties of cork.

Throughout the study, careful consideration is given to the inherent properties of cork, including its thermal performance, suitability as both cladding and insulation layers, and aesthetic appeal. These qualities are harnessed to create a surface system that enhances the material’s natural strengths, while also leveraging the fabrication ideas explored in the previous term.

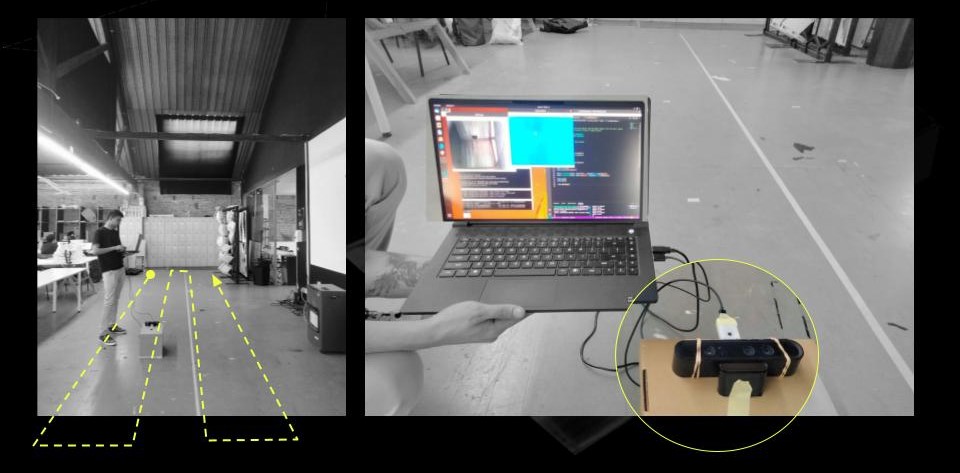

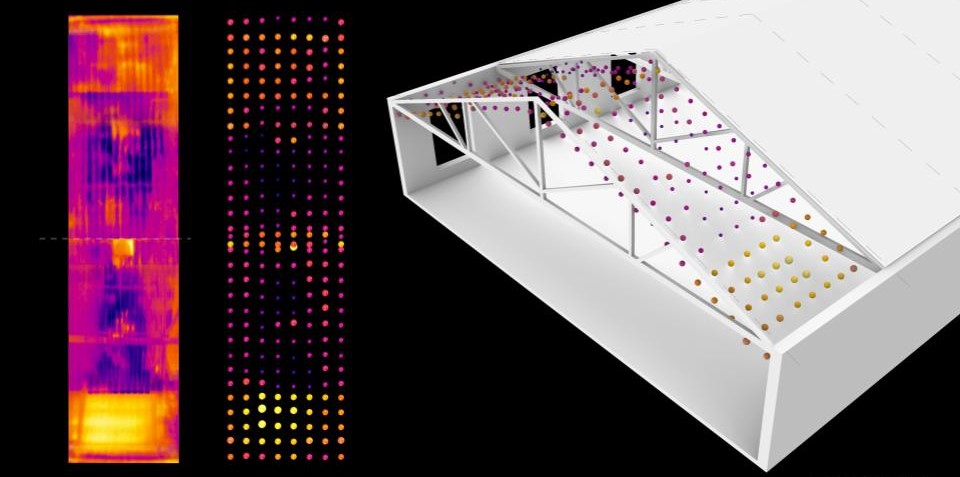

In the context of designing and fabricating a surface system using cork, the roof has been identified as a suitable candidate for cladding due to its ability to exhibit thermal variation on the surface. In order to accurately capture the necessary data to inform the design process, a linear trajectory along the floor was adopted for data acquisition. This approach was chosen to ensure that the camera angle remained constant, as this is critical for building a point cloud from images using photogrammetry.

To facilitate the data acquisition process, two cameras were employed – the Astra Orbec for capturing RGB images, and the Lepton thermal camera for thermal images.

To streamline the data acquisition process, the launch and capture architecture was built using a combination of ROS (Robot Operating System) and OpenCV (open source computer vision library) within python. This powerful and flexible framework allowed for seamless integration of the cameras and other hardware components, ensuring that the data was captured in a timely and efficient manner.

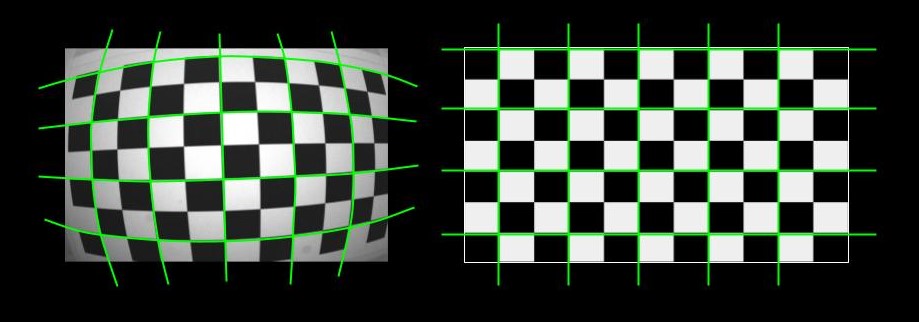

Before capturing images with the cameras, two crucial steps needed to be taken to ensure the accuracy and reliability of the resulting data.

The first step involved calibrating the cameras to obtain their intrinsic values and distortion parameters. This was essential for building the point cloud, as any inaccuracies or distortions in the images would have compromised the accuracy and reliability of the resulting data.

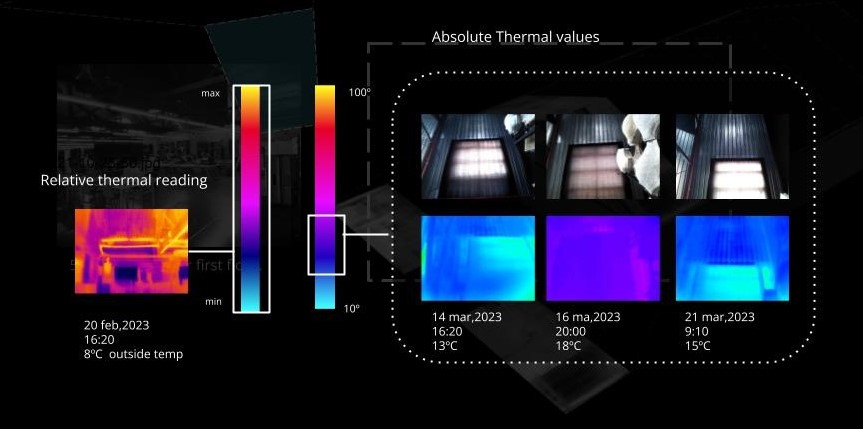

The second important step was remapping the colors of the thermal camera to map absolute temperature values, rather than values that are relative to a particular frame. By mapping absolute temperature values, the resulting data was more precise and could be used to inform the thermal properties of the final surface system.

Once the data had been collected, it was essential to perform feature matching on the images to ensure that the RGB colors could be replaced by thermal values, which was the primary design parameter for this study. This process involved identifying and matching specific features in the images, such as edges, corners, and other distinctive points, and using these features to create correspondences between the RGB and thermal images.

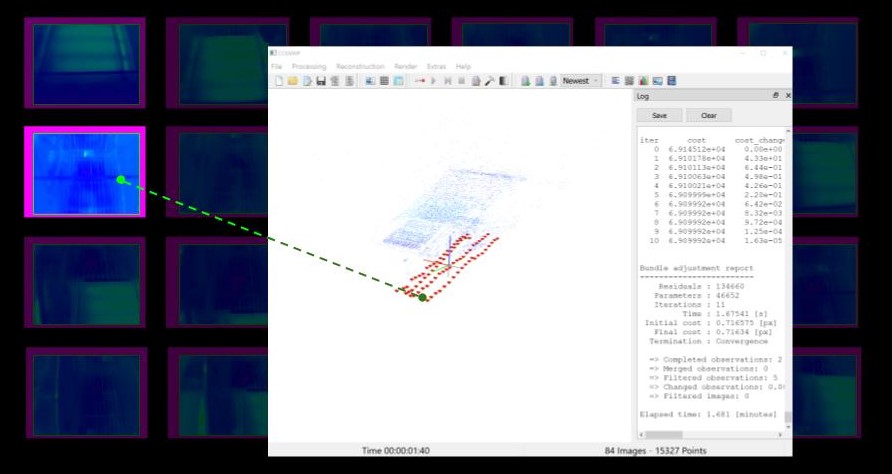

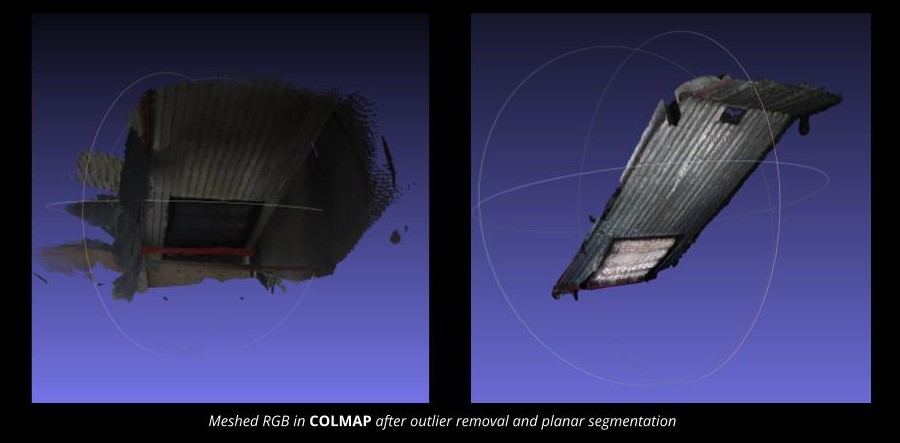

Once feature matching had been completed, a point cloud was built using photogrammetry. This process involved using specialized software to transform the two-dimensional images captured by the cameras into a three-dimensional point cloud.

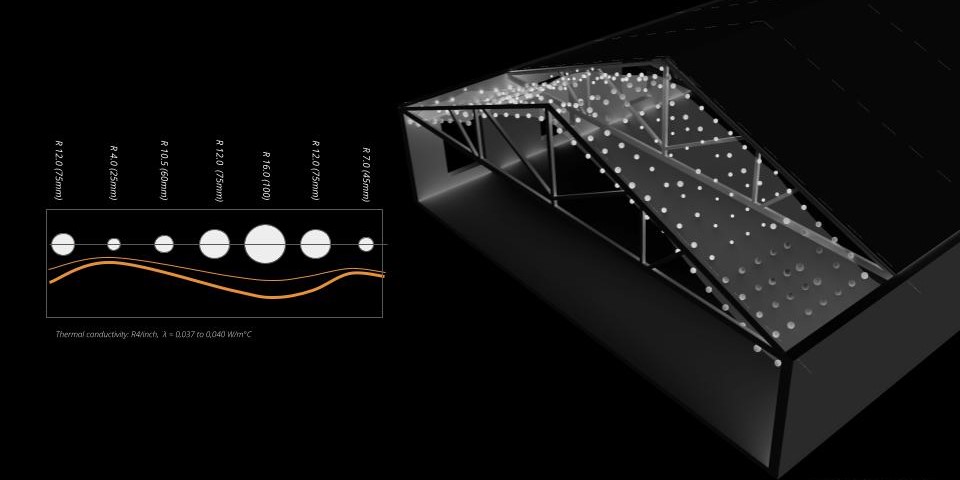

The design strategy for the cork surface system was based on a clear and straightforward approach, which was guided by the thermal data collected during the data acquisition process. The goal was to vary the air gaps in the surface based on the thermal conductivity of the roof, with points of higher thermal conductivity having more gaps and vice versa.

To achieve this, the surface was discretized into panels of sizes that were appropriate for a robotic milling process. This approach ensured that the design could be accurately translated into a physical form, and that the resulting surface system would be structurally sound and aesthetically pleasing.

We will not be talking about the milling strategy as it is similar to our previous term. If interested please refer to: https://blog.iaac.net/robotic-manufacturing-of-cork-surfaces/

Overall, this design strategy was characterized by a careful balance between the thermal properties of the cork material, the capabilities of the robotic milling process, and the desired aesthetic and functional qualities of the final surface system. By leveraging a clear and straightforward design approach, this research study was able to achieve a successful outcome, highlighting the potential of advanced manufacturing techniques to enable new and innovative approaches to material science and design.