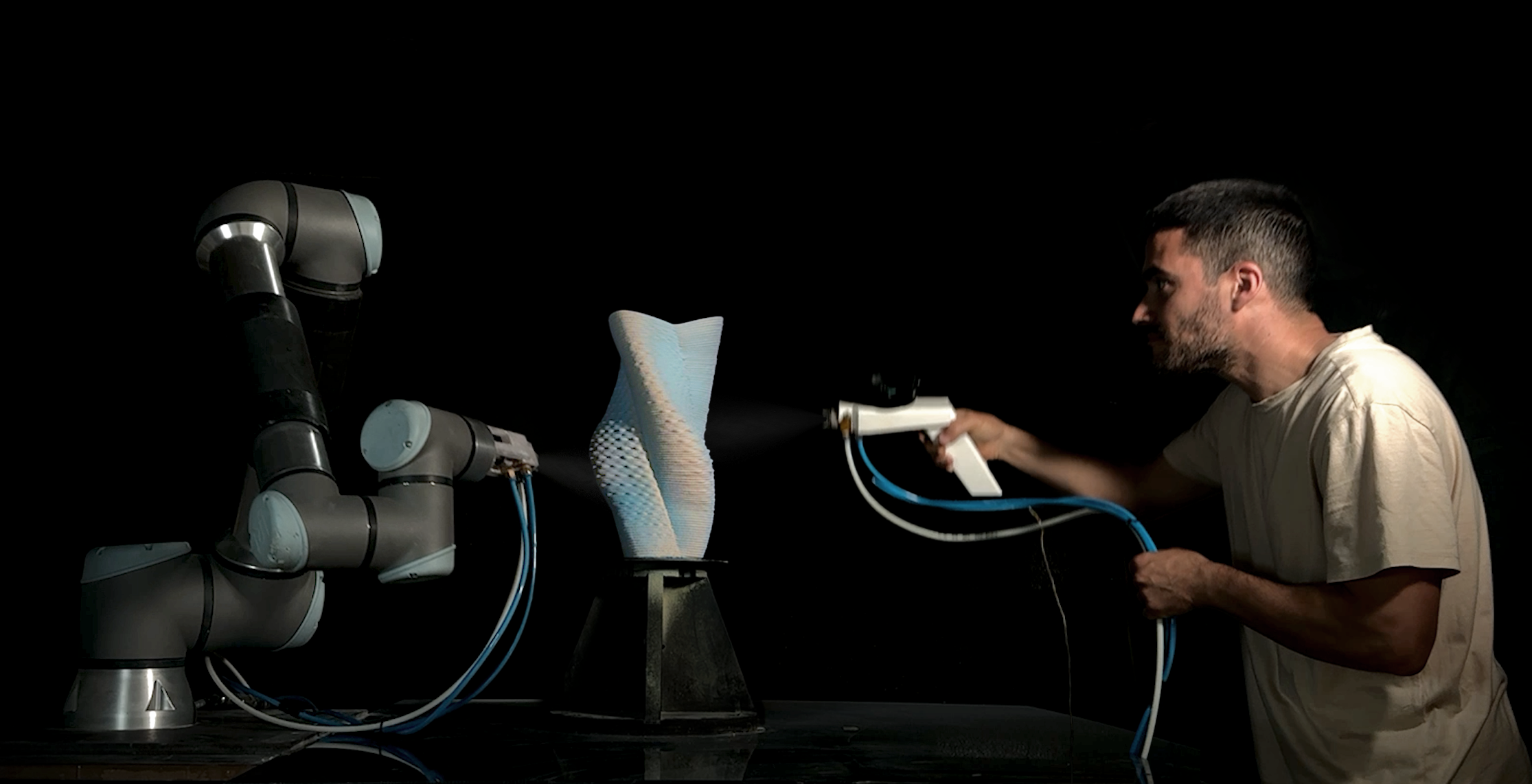

Photo credit: Alex Dubor

Description

As our society evolves to lower our ecological impact on the planet, the construction industry needs to reduce its energy consumption, material extraction and waste generation, while improving productivity and affordability. Shifting to natural and recycled resources is a challenge for large industrial processes that are tuned for mass production of standard material and struggle with unpredictable / heterogeneity in the material input. In this context, sensor, robotics and algorithmic design offer the opportunity to create new products that can adapt to this stream of sustainable material, keeping high productivity and low cost production, yet offering new possibilities in design optimization and final performance. Inspired by the craftsmanship capacity to creatively adapt to materials and demands, a new robotic craft is envisioned as a possible response.

How will we design architecture in this new robotic craft paradox between the precision of the technique, a new sensitivity for our environment, and the singular creativity of craftsmanship ? How do digital design and fabrication processes negotiate with the unpredictability of natural and recycled materials ?

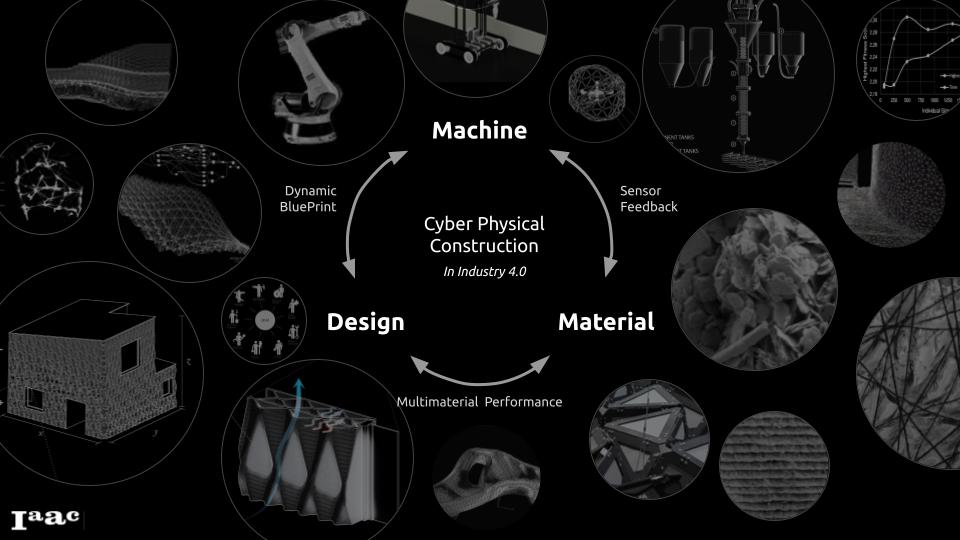

This research studio will allow students to continue their studio project and brings together learnings acquired over the three terms of the 1st year of the master program, possibly using computational design, robotic fabrication, sensor, robotic control, machine learning and machine interaction into a coherent solution for the construction industry. Studio III will start from re-assessing the work achieve in term 1 and 2 to redefine the goal and targets of the research. Within the 10 weeks of development in the third term, the focus will be in closing the interaction loop between design, material, machine and humans. The studio intends to conclude with a large-scale prototype, and a vision about the future application, both architectural and technological, capable of convincing the AEC industry.

Learning Objectives

While the seminars and workshop of the MRAC third term allow students to gain knowledge into Human Machine interaction and Machine learning, the Studio class will frame students works toward their 1st year “Final project”, that should be understood as the synthesis of all three terms of the master, combining knowledge and topics of previous seminar(s) and/or workshop(s) into one clear proposal for a better AEC industry. Students can expect to learn to :

- Frame a research, defining achievable objectives, organising a timely calendar, clear deliverable.

- Drive the research process, adapt to the unknown,

- Combine technological and conceptual investigation into a prototype.

- Develop workflow from design to fabrication, including feedback loops.

- Explore possible interaction between design, machine, material & human.

- Design with a bottom up approach / emergence concepts / with unknown material geometry and properties.

- Propose and defend the project relevance in our socio-economic and ambiental context.