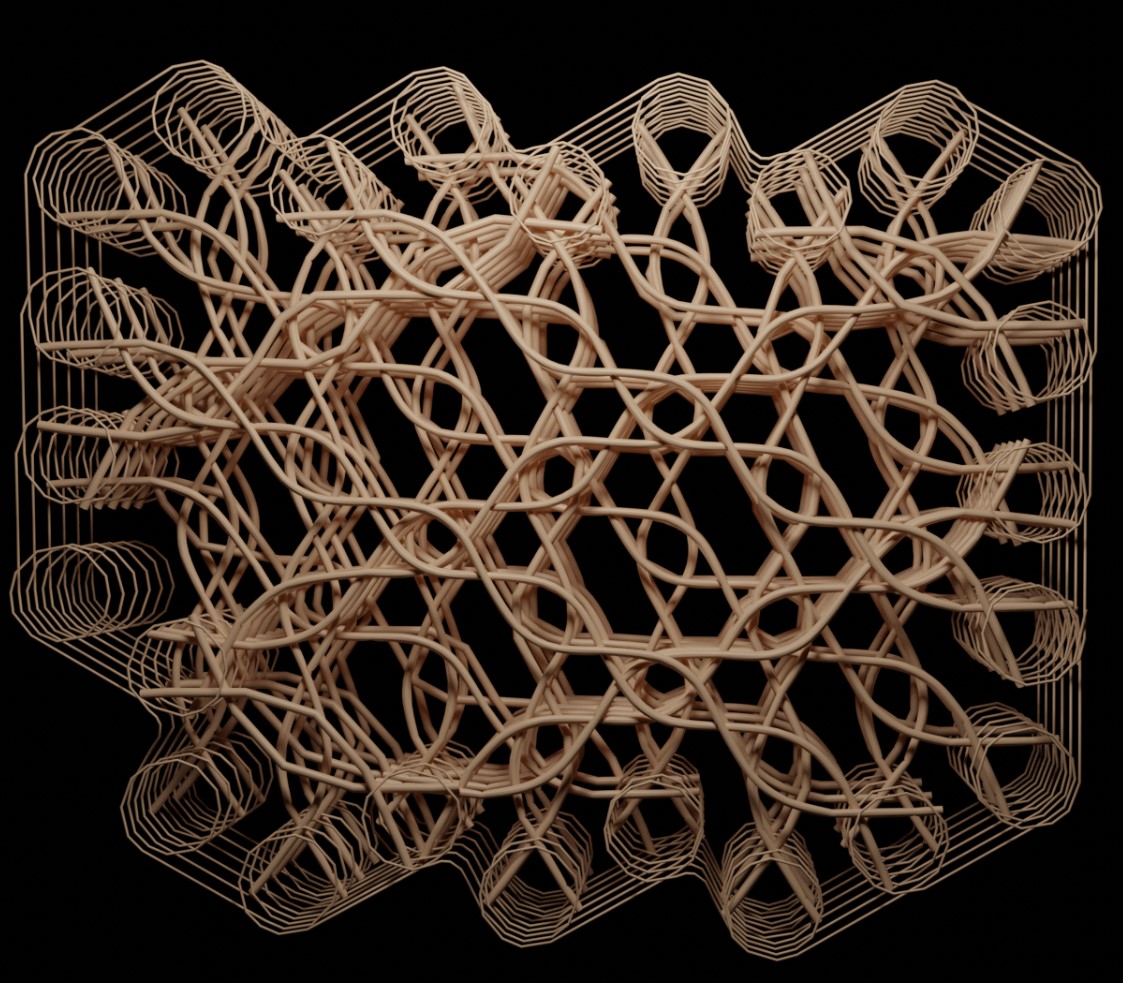

Weaving techniques have been around for thousands of years, used to make a wide range of items from small household goods to large sculptures and furniture. In this workshop, we’ll look at the basics of traditional textile processes such as weaving, knitting, and braiding as a base for their digital reinterpretation through digital design and robotic fabrication technologies. Natural materials such as flax, willow, reed or jute usually present nonuniform characteristics both in physical and geometric terms being a challenge for processing data into digital fabrication processes.

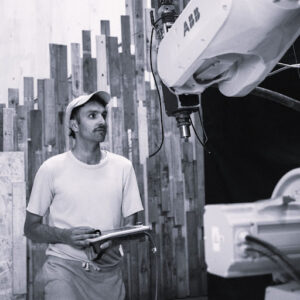

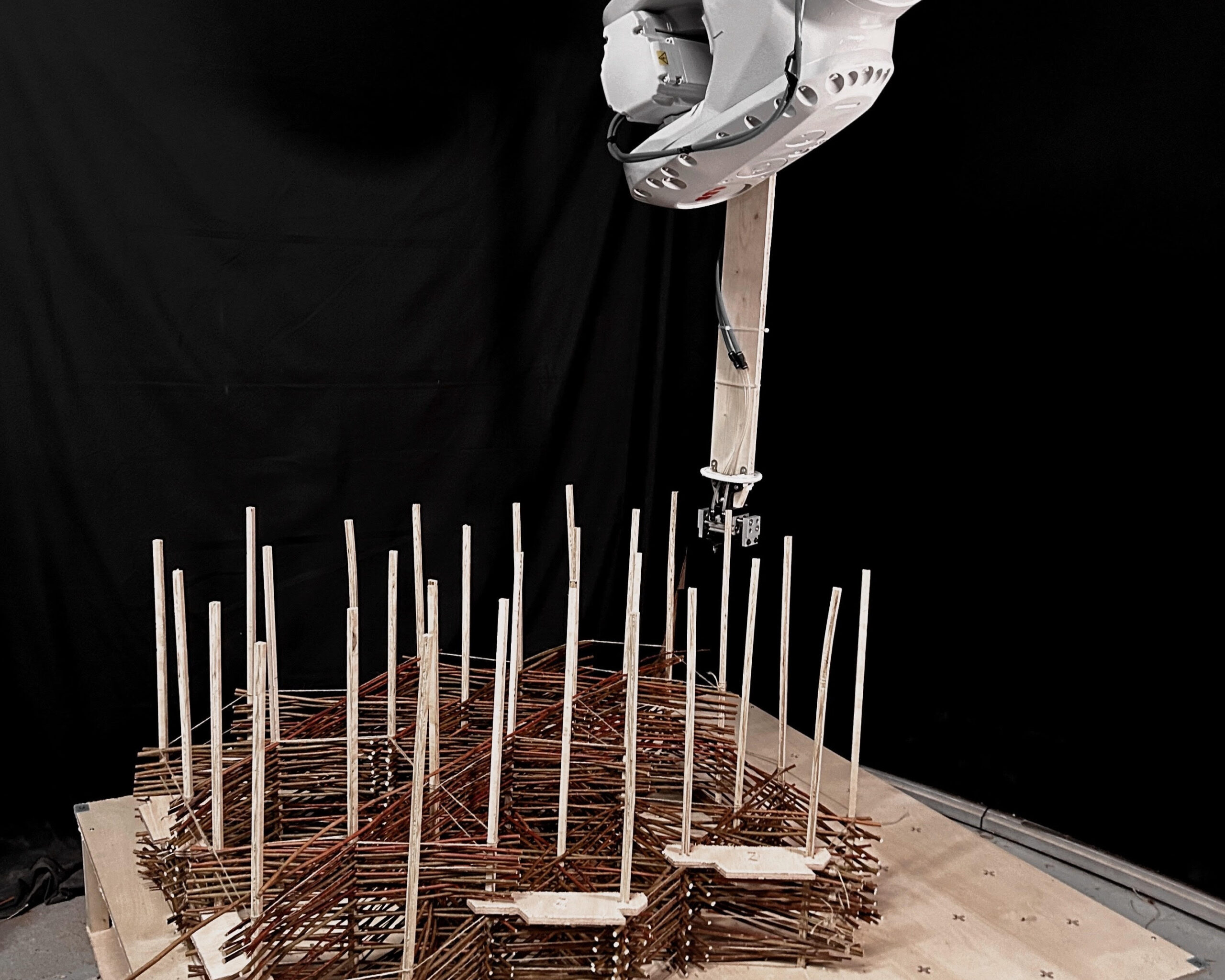

In addition, the complexity of the interaction between natural materials and machines increases as the anisotropy in the different axes of the material grows, creating a complex system that simulates its behaviour in a continuous weaving or deposition process. All those fabrication and material attributes will be translated into a digital fabrication process through an empirical procedure where the digital model will be retrofitted using those constraints as opportunities and potential design features. A small 1:1 prototype will be built guided by a component-oriented logic merging traditional interlacing craftsman techniques with digital construction technologies.

Learning Objectives

- Understand weaving principles & techniques

- Develop a methodology to deal with the heterogeneous characteristics of natural materials.

- Simulate natural material behaviour and characteristics.

- Translate those manual weaving principles & material irregularities into an automated digital fabrication process.

- Inform the design with material characteristics and manufacturing constrains.

- Assembly principles & component-oriented logic.