Laser Cutting | Folded Flakes

Laser cutting, a precision-focused technique, revolutionizes the art of crafting by using a high-powered laser to precisely slice through various materials with immaculate accuracy. Whether it’s intricate designs on wood, metal, acrylic, or fabric, laser cutting brings imagination to life with clean, sharp edges and detailed patterns. This technology merges innovation with craftsmanship, allowing for the creation of customized designs, prototypes, and functional objects with unparalleled intricacy and finesse. Embrace the power of laser cutting and unlock a world of limitless creative possibilities.

Concept

Creation of hexagonal shapes, complemented by openings, are making different designs and shapes depending on the position of the sun. This little modules can be used as pattern, or structure of a Pavilion. Most of all, we can play with these shadows, thanks to the different shapes that a pavilion can represent.

References

Biocomposites Experimental Pavilion

3D Model +Technical Drawing

To transform this vision into a tangible reality, we employ powerful design tools such as Grasshopper and Rhino. These software platforms become our artistic canvases, where we weave intricate forms and structures. These hexagonal shapes, complemented by these openings, create different designs and shapes depending on the position of the sun. This little modules can be used as pattern, or structure of a Pavilion. Most of all, we can play with these shadows, thanks to the different shapes that a pavilion can represent.

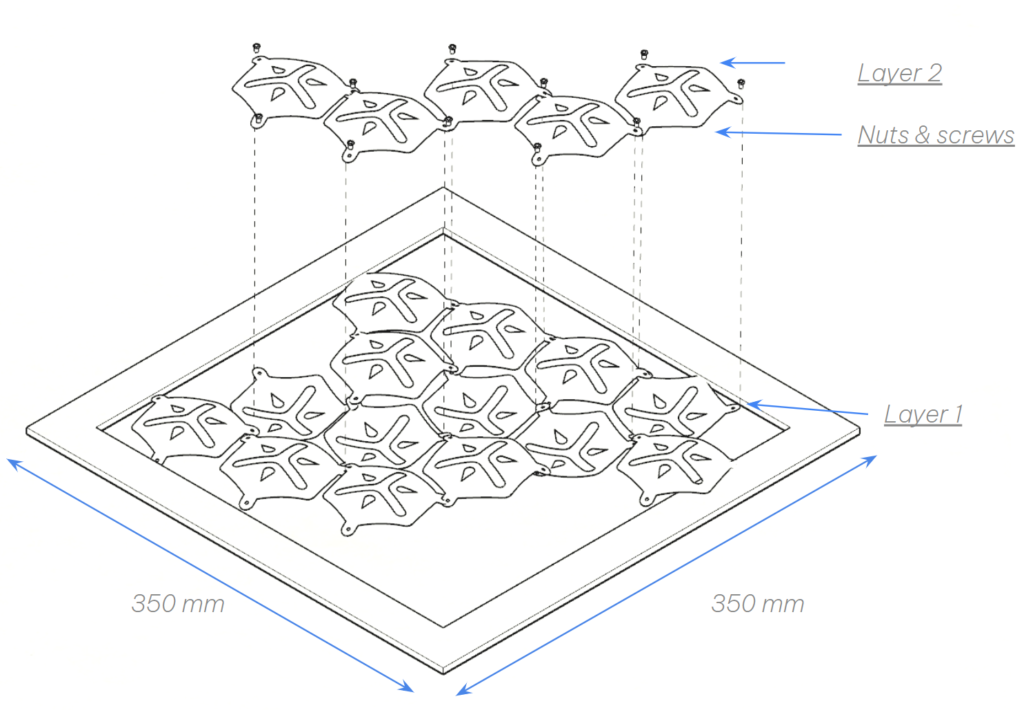

Production Calculation

TRANSPARENT & BLACK POLYPROPYLENE

- Machine : Epilog

- Technique : Folding & Interlocking

- Thickness : 0.5MM

- Time : 7 mins 38 sec

- Cutting

- Power : 45

- Speed : 45

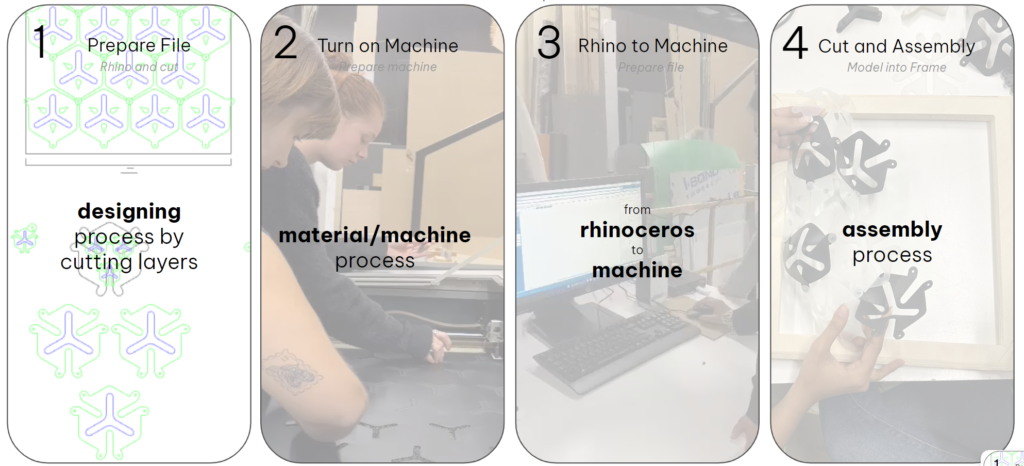

Prototyping and Fabrication Process

Final Geometry

3D Printing | Tesseract Morphology

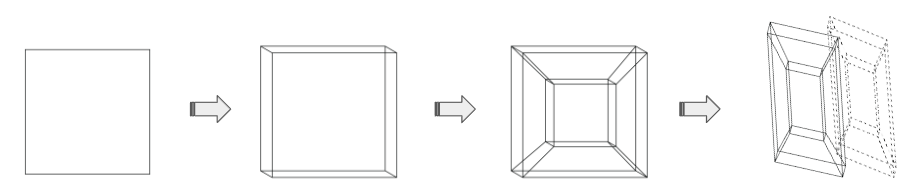

Exploring the fascinating realm of 3D printing concepts. Through tesseracts we tried to unlock the potential of intricate geometries and mind-bending shapes. We tried to blend technology and craftsmanship, by creation of facades using mortise and tenon joints for easy interlocking .

Concept

SQUARE CUBE TESSERACT TESSERACT MORPHOLOGY

Using the concept of tesseracts with the fluid folds reminiscent of Zaha Hadid’s iconic designs. This model seamlessly integrates the ordered complexity of tesseract-inspired bone-like structures with the organic fluidity of Zaha Hadid’s architectural language. The tesseract forms the structural backbone, creating a lattice that echoes the intricacy of bone formations. The aim was to create a visually captivating, inviting observers to appreciate the synthesis of nature-inspired rigidity and fluid architectural expression. A canvas for light’s dance, transforms into a living element, casting an ethereal ambiance. This intentional play with light and shadow adds visual intrigue, emphasizing the concept’s commitment to an immersive architectural experience.

References

Louvre Abu Dhabi Wooden Waves Dragon

Jean Nouvel, Abu Dhabi, 2007. Mamou-Mani, Paris, 2021. Joris Laarmans, Oregon, 2014.

Technical Details

- Printer – Zortax M200 Plus

- Material- Z-ULTRAT (ABS)

- Estimated print time –8h 13m // 9h 21m

- Nozzle diameter – 0.4 mm

- Infill – 30%

Prototyping and Fabrication Process

Final Geometry

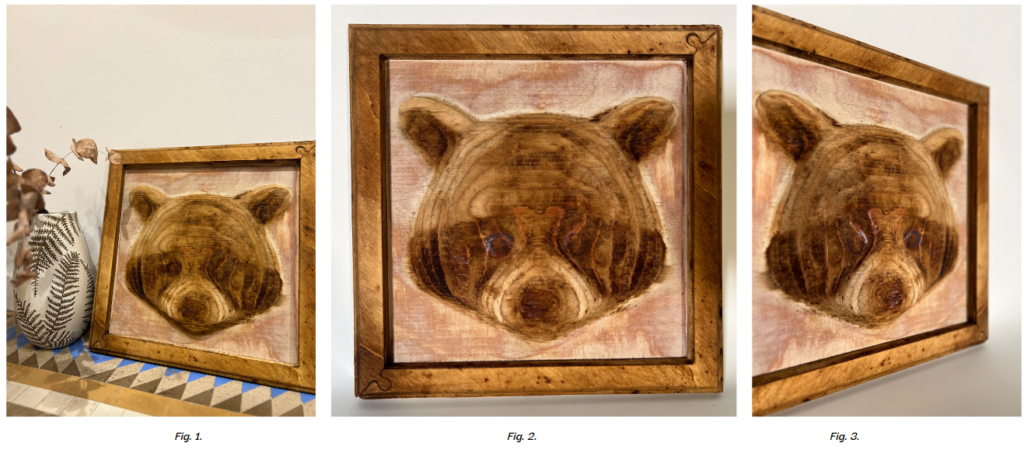

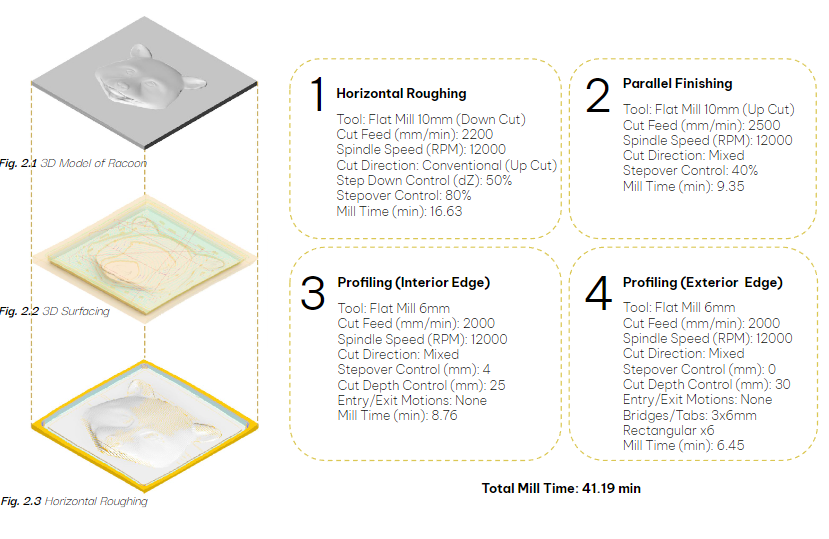

CNC | Rustic Racoon

CNC milling stands as a cornerstone in modern manufacturing, employing precision machinery to sculpt raw materials into bespoke designs and functional parts. This computer-controlled process utilizes rotating cutting tools to carve, shape, and refine materials with unmatched accuracy and consistency. From metals to plastics and wood, CNC milling unlocks the potential for intricate detailing, complex geometries, and prototypes that bridge imagination and reality. Embrace the precision of CNC milling to craft exceptional components and bring innovation to the forefront of creation.

Concept

Our first intention of making this project, was to incorporate animal-inspired geometry into an architectural element at our spaces: Our first step was to establish a strong foundation, providing a stable starting point, then we observed that curves can impart a sense of dynamic motion and finally, we integrated animal-inspired geometry into the curves formed through cutting and material.

stable starting point curves that create motion integration of animal inspired geometry

Technical Drawing

Prototyping & Fabrication Process

Final Geometry