A series of four fabrication exercises completed over eight weeks, each using a different digital manufacturing method at IAAC: CNC milling, 3D printing, laser cutting and robotic clay extrusion. Although each piece explores a distinct workflow, we maintained a consistent design logic by referencing coral ecologies and seabed morphologies.

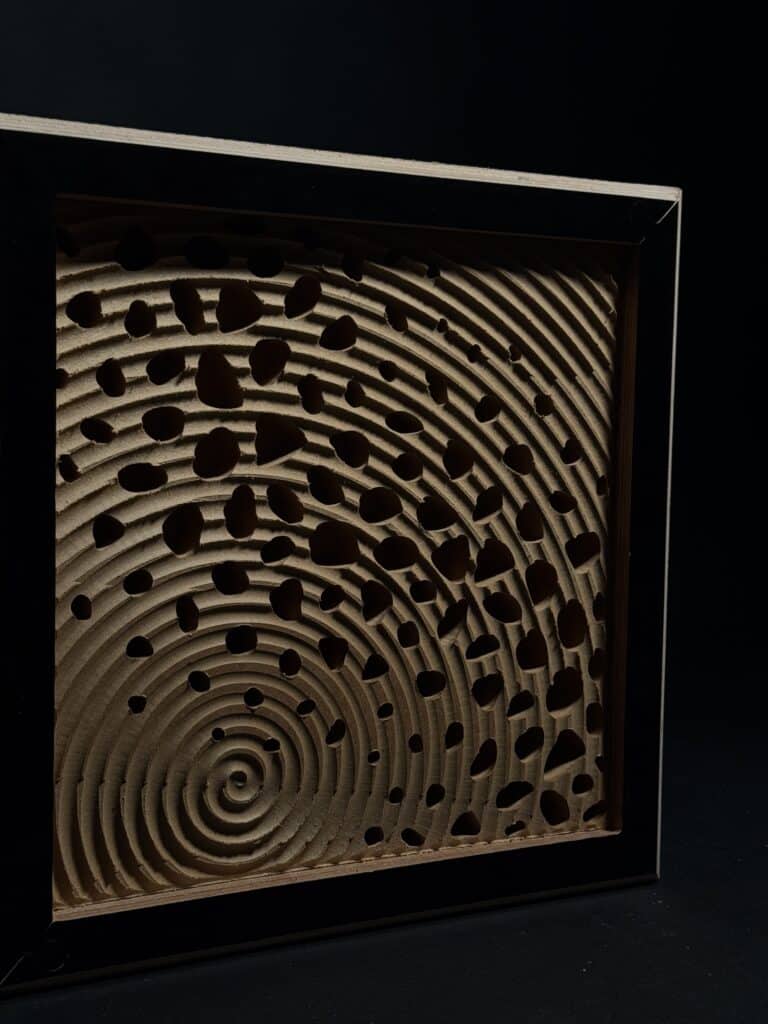

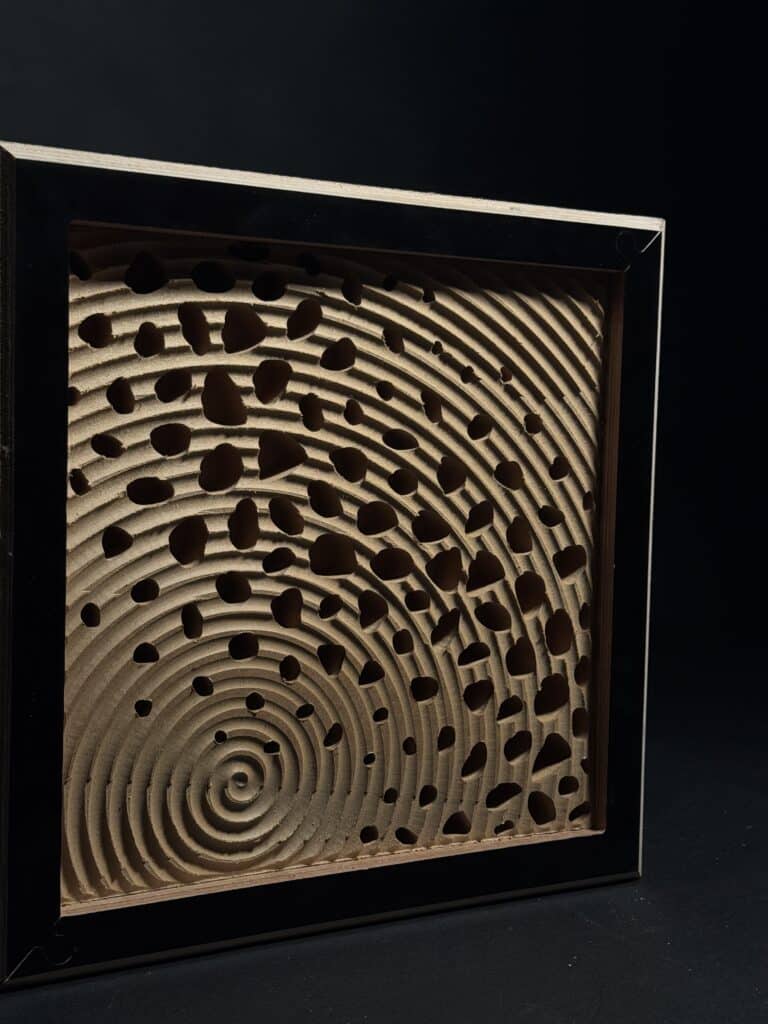

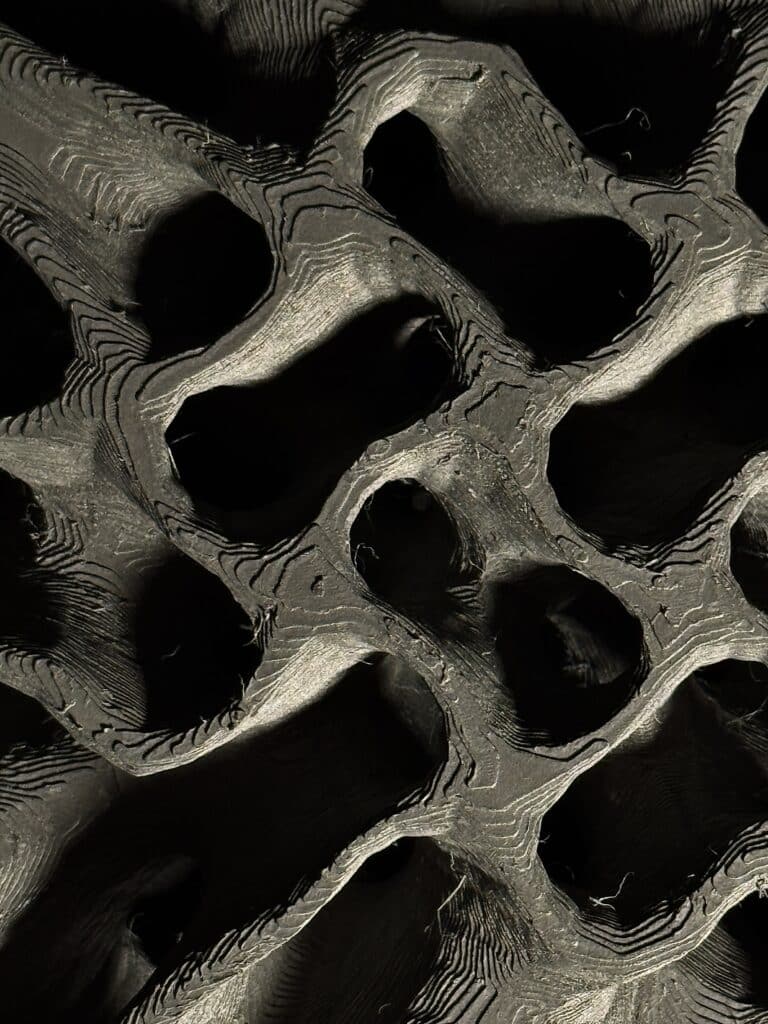

CNC Milling – Coral Veil

Coral Veil began as an exploration of how a flat, rigid sheet could take on the softness and movement of the sea floor. By carving out clusters of organic openings that fade toward the edges, we aimed to mimic the way coral surfaces shift from dense to porous. The CNC milling process became a way to translate this natural flow into a precise but expressive surface.. part veil, part landscape.

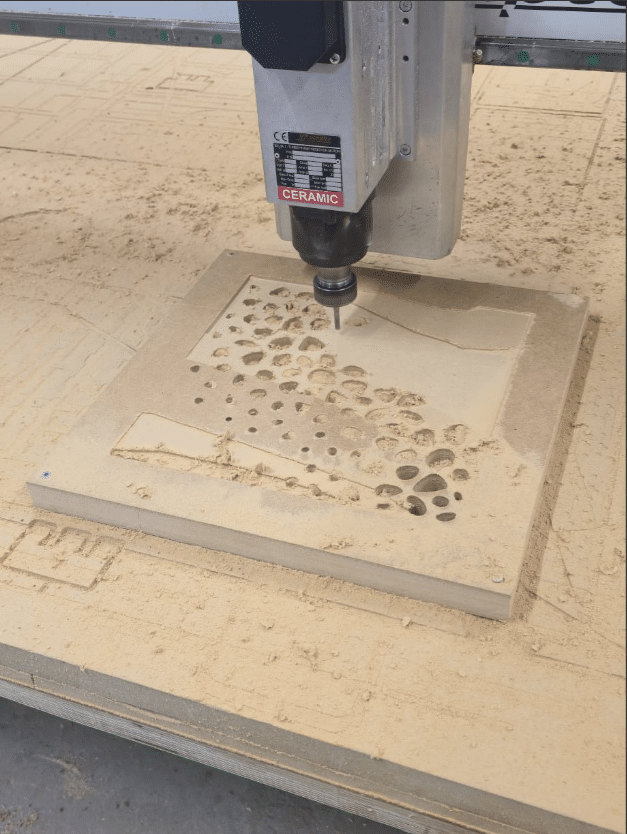

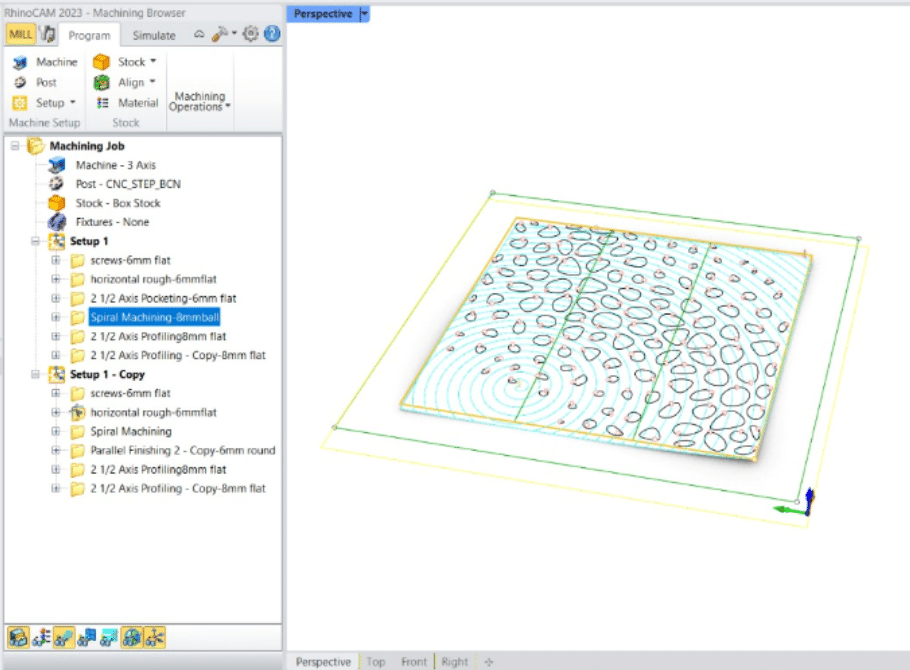

Fabrication Overview

- Material: MDF

- Machine: Raptor X-SL

- Workpiece: 400 × 400 × 30 mm

- Workflow: Roughing → Pocketing → Spiral finishing → Profiling

Toolpaths

- Horizontal Roughing:

- Flat mill, Ø6 mm, 2-flute, 12,000 rpm, downcut

- Stepdown 75%, stepover 70%

- Time: 22 min

- Pocketing:

- Flat mill, Ø6 mm

- Same spindle speed and geometry settings

- Time: 44 min

- Spiral Finishing:

- Ball mill, Ø12 mm

- 12,000 rpm

- Time: 12 min

- Profiling ×2:

- Flat mill, Ø8 mm

- 12,000 rpm

- Time: 4 min

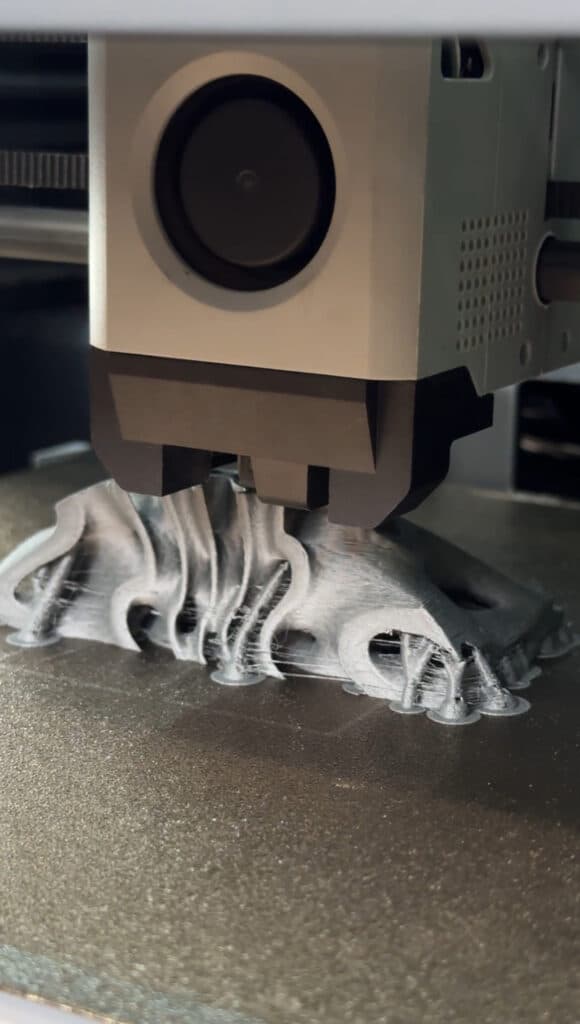

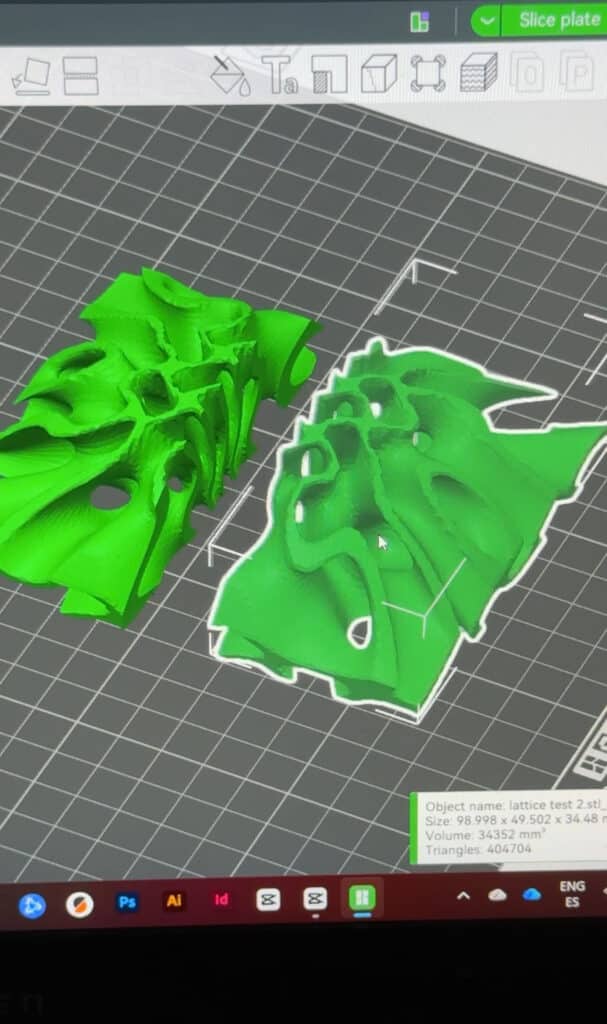

3D Printing – Coral Bloom

We wanted to capture the sense of growth and erosion that defines natural coral formations. Instead of designing a fixed shape, we experimented with a form that feels like it’s still in the process of becoming. Full of cavities, textures, tunneling and unexpected transitions. 3D printing allowed us to freeze this moment, turning digital experimentation into a physical piece that invites light and shadow to move through it.

Fabrication Overview

- Material: PLA

- Machine: Bambu Lab P1S

- Workpiece volume: 200 × 200 × 35 mm

- Supports: Tree (auto), 30° threshold

- Layer height: 0.16 mm

- Total print time: 17 hours

Laser Cutting – Coral Spine

We reimagine the internal logic of coral skeletons as a layered and almost architectural assembly. The idea was to reveal how repetition and variation work together in natural systems. Our first prototype didn’t quite come together physically, but the process pushed us to rethink the structure, refine the joints, and pursue a form that better expresses the rhythm and delicacy of coral growth.

Fabrication Overview

- Material: 4 mm plywood

- Machine: Rayjet

- Engraving: Power 7.5, Speed 12.5

- Cutting: Speed 1.80, Power 55.0

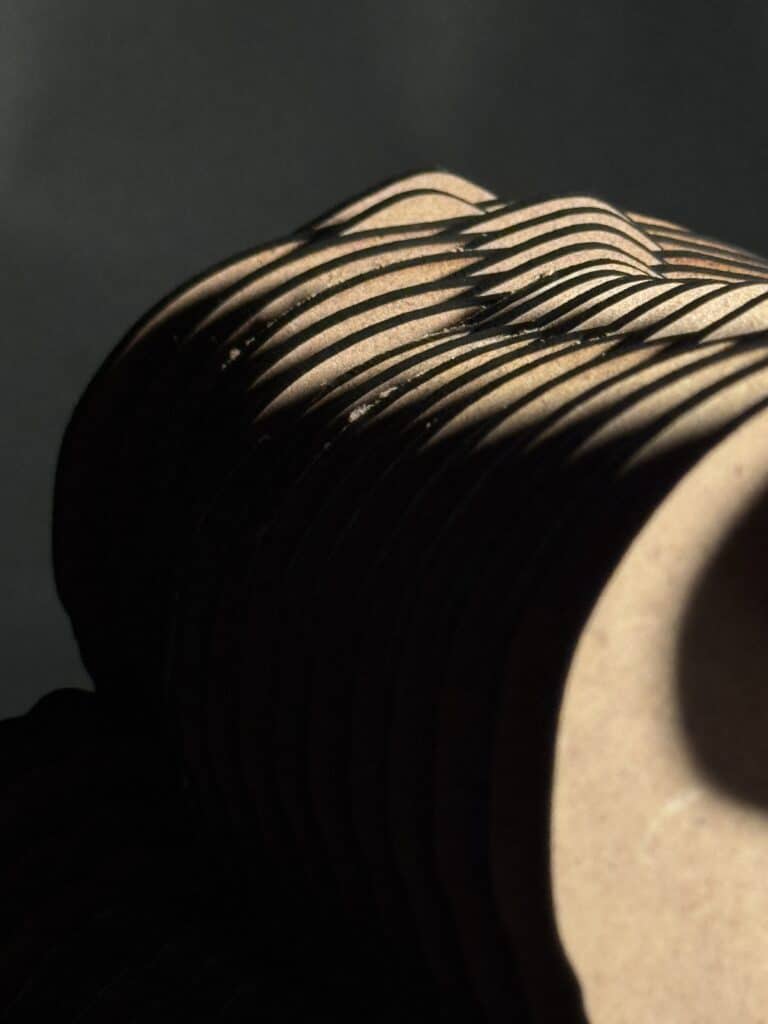

Robotics Clay Printing – Waterdrop cup

Our final piece uses a custom clay extrusion toolpoint with an ABB 140 robotic arm. The form is a 90x90x90 mm vessel defined by a water-drop base shape based off three attractor points around its perimeter. These attractors modulate the layer paths, pulling and compressing the printed contours to generate a subtle, seafloor-like deformation.

Course Conclusion

This collection of projects reflects eight weeks of experimenting, mistakes and unexpected discoveries. We had many failed prototypes, broken joints, messy prints and surprises, but each setback pushed us to better understand the machines and design decisions behind digital fabrication.

Although we still have a lot to learn, these classes gave us a clearer sense of how organic ideas can be shaped simply through digital processes. In the end, the work is not just a set of final pieces but an exploration of errors and adaptation, much like the coral forms that inspired us.