Overview

Building with earth is one of the oldest construction techniques and can be dated back to 7000BC due to the abundance of raw earth all around us. Around the globe different building techniques emerged depending on the composition of the available soil. Understanding its properties is vital for the success of a construction project. To gain an insight into the properties of the available soil, different field tests can be performed. To build up an intuition of the soil properties we collected 6 samples around Valldaura Labs.

Carazas Test

To have an intuitive overview of the behavior of different types of soil mixtures a compacting test in cube form was performed on six different soil samples, ranging from pure red clay to pure sand. A two-parameter grid was created where along one axis the water content of the sample was increased from dry to liquid. On the other axis the compacting pressure was increased from pouring, to compacting with hands, to ramming with wooden block. In the dry state only the soil samples consisting of finer particles and clay could be somewhat compacted in the form. After adding some water, the compressibility of the samples increased dramatically. By further increasing the amount of water added to the samples they could be poured into the form. In the samples rich in clay the samples were still very viscous and could keep their shape, however in most other cases the water drained from the samples leaving a puddle of material.

Analyzing with all senses

When searching for a suitable source of construction earthen material an all-senses analysis can be performed to evaluate the available soil. Using our sense of touch the grain sizes such as pebbles, gravel, sand, and finer particles of the dry soil sample can be felt. By adding a few drops of water to the sample and smelling we can evaluate the presence of organic matter giving off a humus smell. Crushing some of the hydrated soil between the fingers near one’s ear, the cracking of sand particles can be heard and thus the sand proportion can be evaluated. By feeling a small sample of the soil with our tongues we can evaluate the presence of fine sand and silt. By further adding water to the mix, it can be moved into its plastic state whereby molding its we can feel if it holds its shape. We then mold the mixture into a ball and make a thumb imprint into it. In this indent we pour a few drops of water and observe how quickly the water drains. A stagnation of the water would indicate a high amount of clay content. Further a washing of the hand is performed to find out if the soil is rich in clays. If the hands are hard to clean this indicates a lot of clays in the mixture. Performing this analysis on the 6 samples collected at Valldaura Lab is an area of we could find a wide spectrum of soils from clayey soils with small slate stones to silty soils with almost no clay.

Tablet Test

The collected soil samples are tested for shrinkage using the tablet test. A small part of the sample is mixed with water until it reaches its plastic state. The mixture is then pressed into a circular mold and left to dry. After drying the sample is evaluated for shrinkage by placing it back in the mold and observing any gaps. The adhesion of the sample is tested by trying to break the edges of the tablet and then trying to break the tablet in two. The wide range of soil samples could be observed here too – the samples poor in clays could be broken in two without much pressure and the ones rich in clays needed support and much more weight applied to break them. Further a dull sound was heard when breaking the samples poor in clay, while a sharp sound was heard when breaking the ones rich in clay.

Cigar test

Using the collected soil samples a cigar test can be performed to evaluate the tensile strength of the plastic state of the soils. For this purpose, three cylinders with a diameter of 3 cm and length of around 20 cm can be rolled. The rolls are then slid over an edge to test when the roll breaks under its own weight. Performing this test, we also observed a wide range of tensile properties of the collected soils. The observed breaking length ranged between 10 cm for the clayey soils and 3 cm for the clay poor soils. The tensile strength of extruded earth is of importance considering cracking and stability during extrusion and layering.

Sedimentation Test

By dissolving the soil samples into water, the different grain sizes can be separated, and their proportions can be visibly observed. The range of the obtained samples was also clear in this test. The bottle test was also performed on a pure sand and pure clay sample. The samples poor in clays separated in the first 10 minutes, whereby the control sand sample separated first. The clayey samples needed more time to settle, while the pure clay sample didn’t settle at all even after 24 hours.

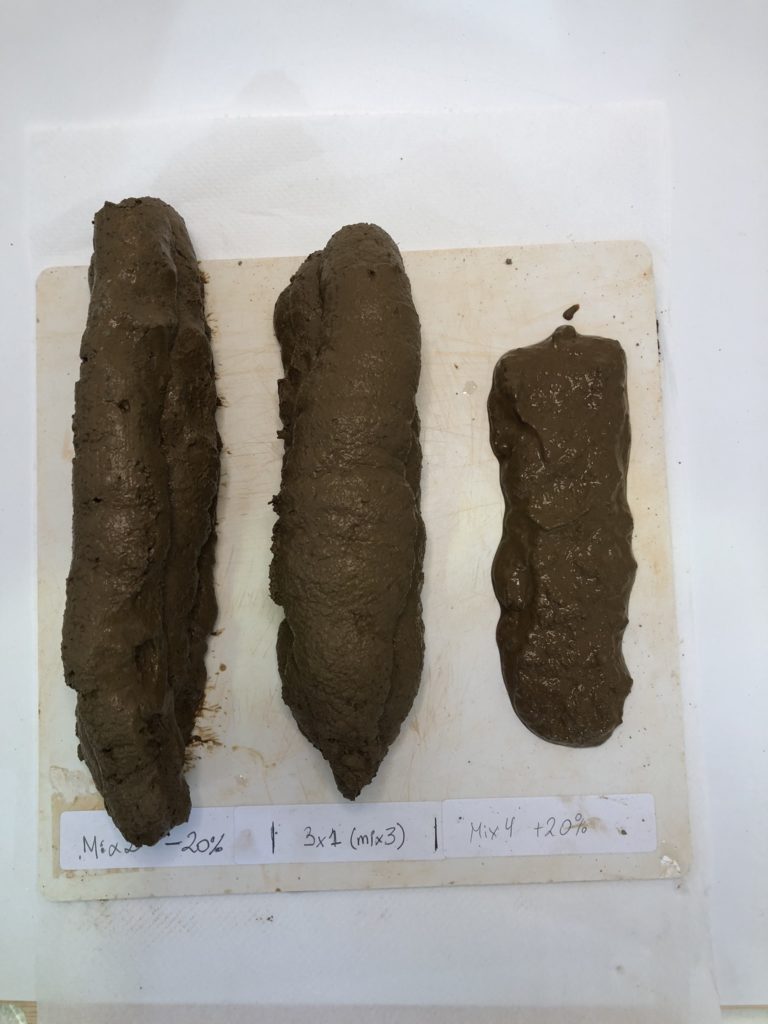

Influence of water content on extrudability, cracking and shrinkage

The collected samples were mixed with enough water to reach an extrudable plastic state. Then 20% and 50% of water were subtracted or added to the mixture to observe the effects of water on the mixtures. For most samples a reduction of 50% of water meant that the mixture would not pass over the plastic limit and an increase of 50% lead to the mixture passing the liquid limit. For most groups an improved mix from the initial plastic state mix was achieved when adding 10% more water, based on the extrudability.

Influence of sand and clay on extrudability, cracking and shrinkage

Like the addition or subtraction of water, changing the matrix of the earthen material by changing the proportion of clay or sand has a huge influence on extrudability. By keeping the amount of water of an easy to extrude earthen mixture, but substituting 1/3 of the total volume with sand, we observed a rapid change in the viscosity of the mixture. The sandy mixture was very runny, and it could be concluded that it had passed the liquid limit. By substituting the same volume with clay, the mixture kept its original viscosity, but reduced its volume. By controlling the amount of sand in the mixture we can control its fluidity, without having to add additional water, which would lead to shrinkage.

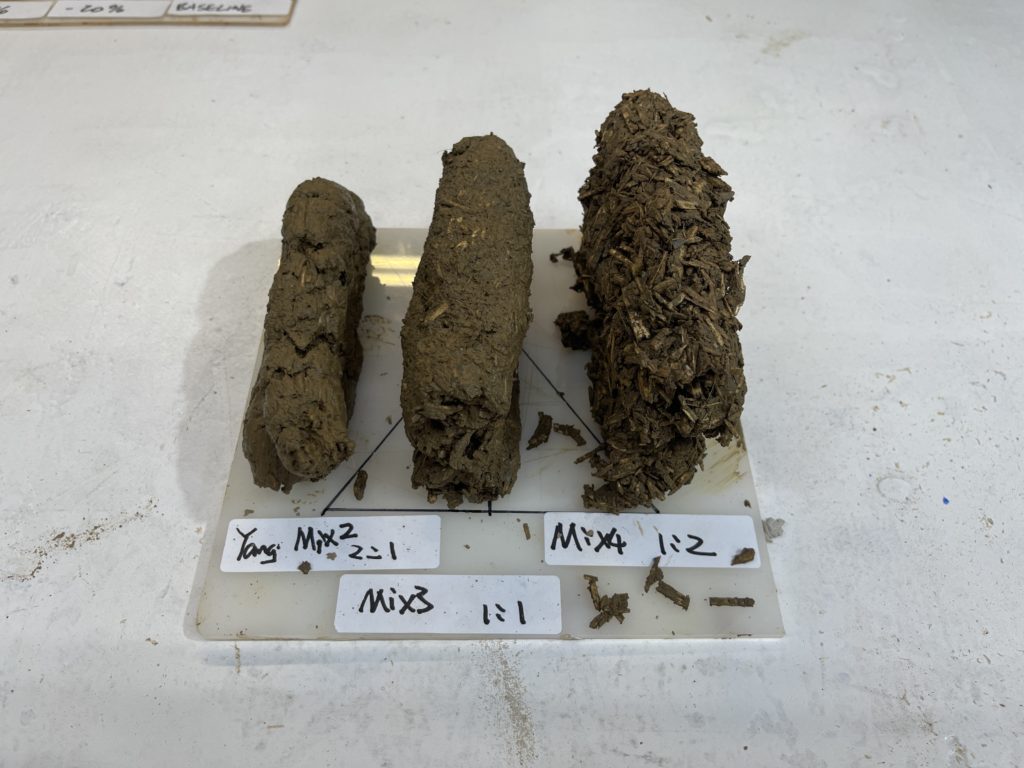

Influence of fibers on extrudability, cracking and shrinkage

Fibers can be added to an earthen mixture to reduce shrinkage and cracking. Six types of natural fibers were tested – hemp, saw dust, sisal fibers, straw, wood chips and wood wool. The best extrudability was provided by the hemp, sisal fibers and wood wool, due to their longitudinal proportions, which led to the alignment of the fibers during extrusion. A 3-point bend test will provide further insight into which of the three best performing fibers leads to better tension strength of the extruded samples.

Influence of additives and coating on durability of earthen mixtures

As soils are dissolvable in water, earthen constructions are susceptible to direct contact with water. To protect them against the elements, natural stabilizers can be incorporated into the mixture or applied as a finish. Black soap, casein (sour cream), egg whites, linseed oil and tannin (manure) were incorporated into a clay plaster mixture or were applied as a finishing on top of a molded clay plaster plate. The dried plates were then positioned under a water dispenser, that produced water drops at regular intervals, for two hours. Egg white and tannin (manure) visibly improved the erosion resistance of the samples compared to the other admixtures and finishes.