DIGITAL FABRICATION

3D Printing | CNC Milling | Laser Cutting

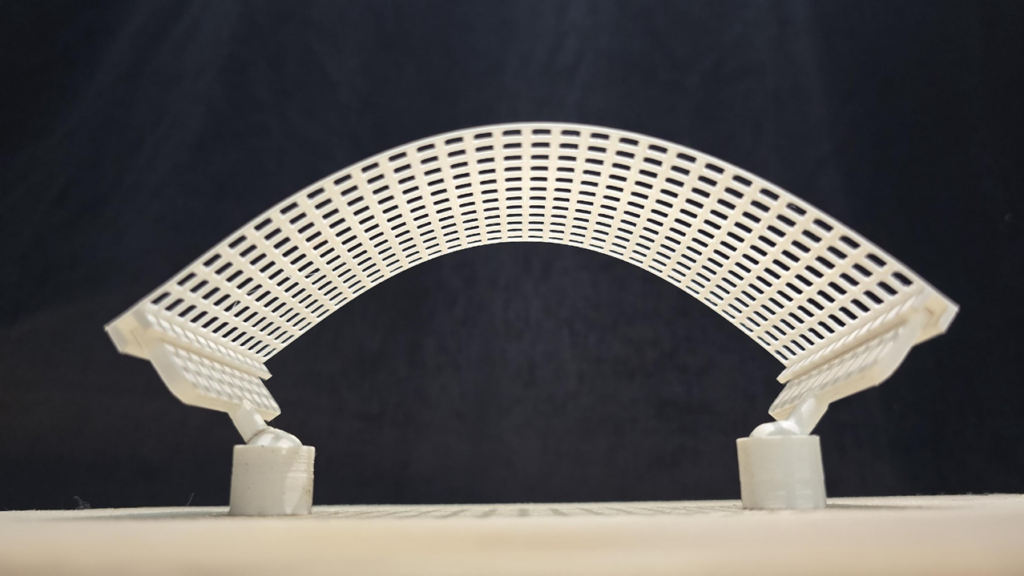

3D PRINTING

As we embarked on this three-week journey of digital fabrication, we began with 3D printing in the first week. Our goal was to create something that could be integrated with our other techniques in the weeks to come.

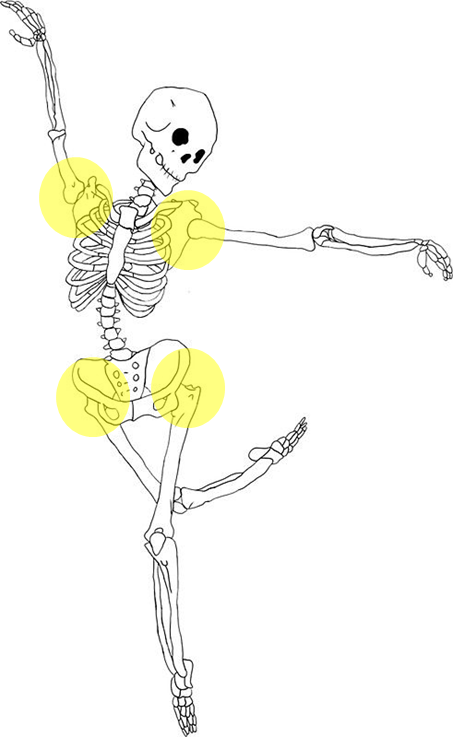

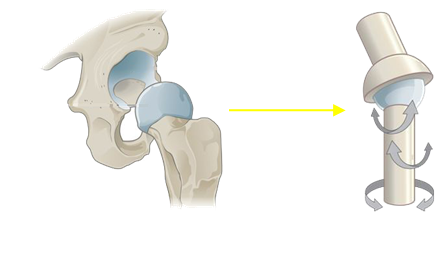

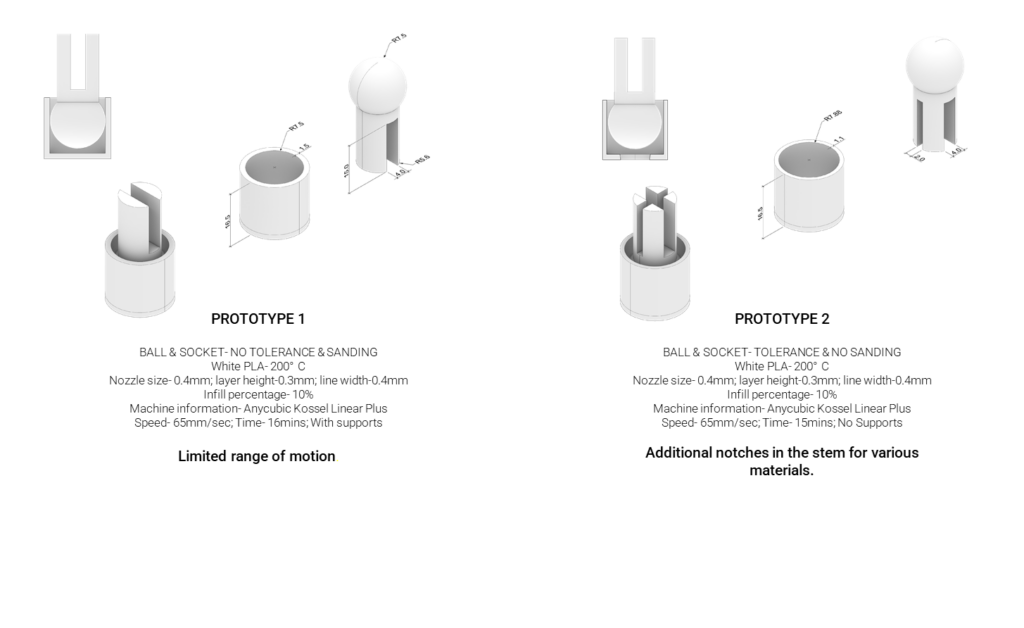

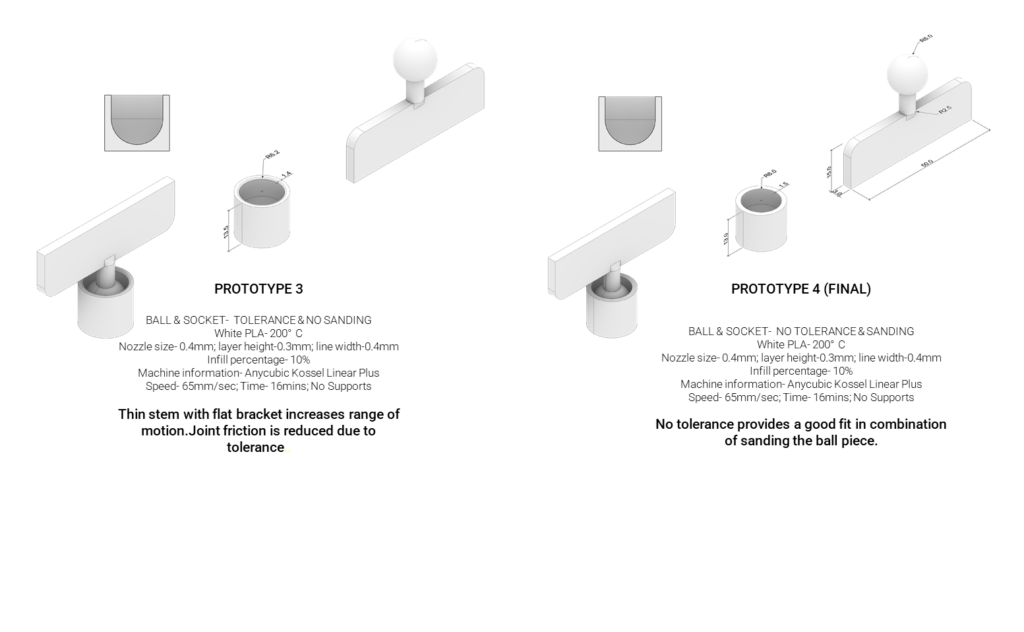

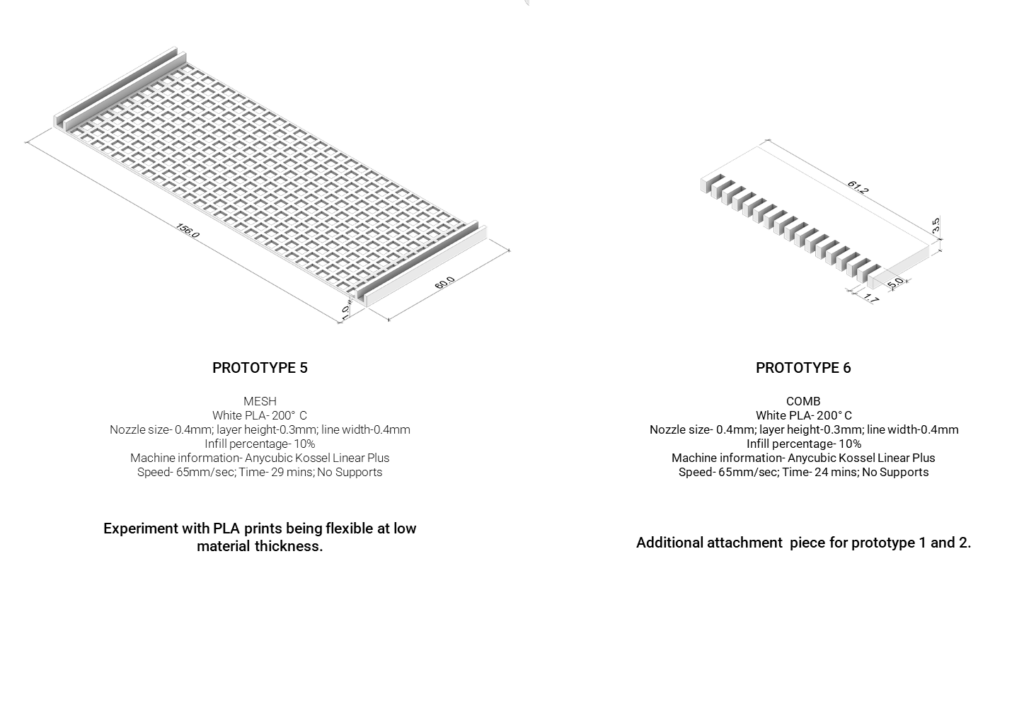

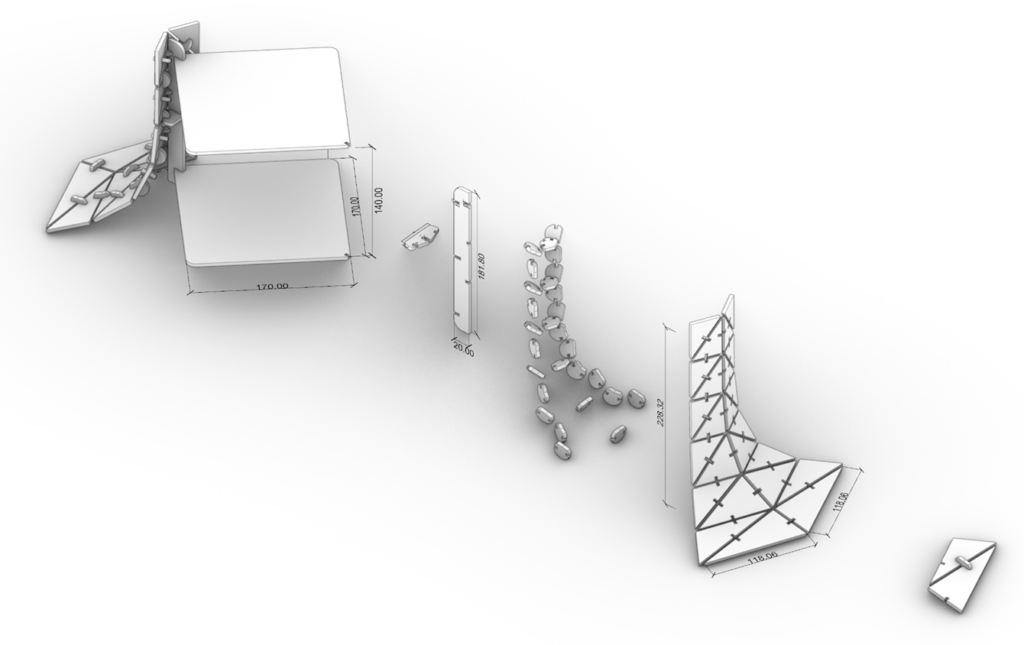

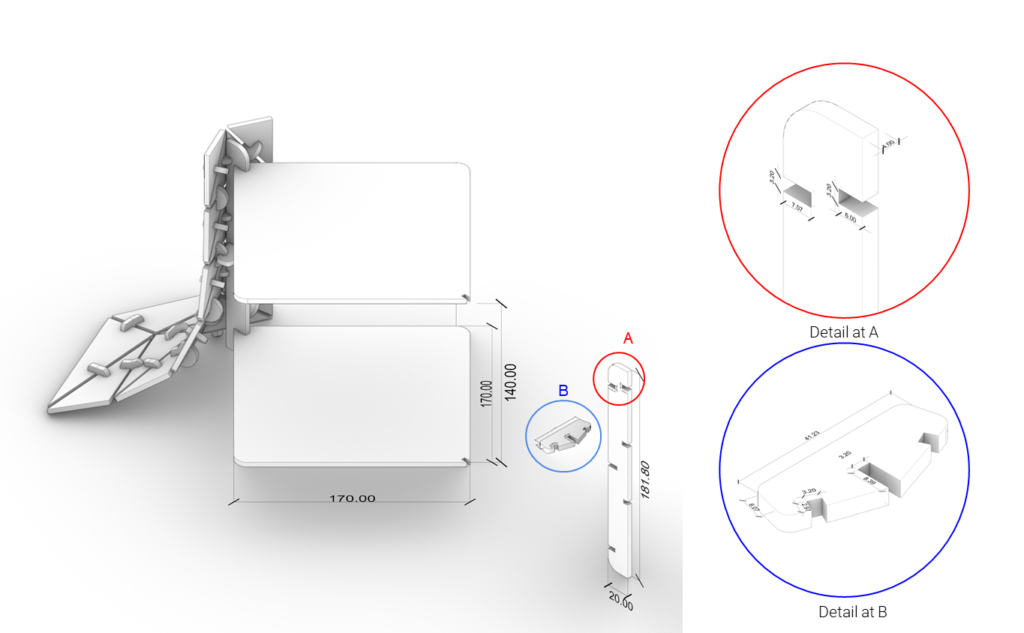

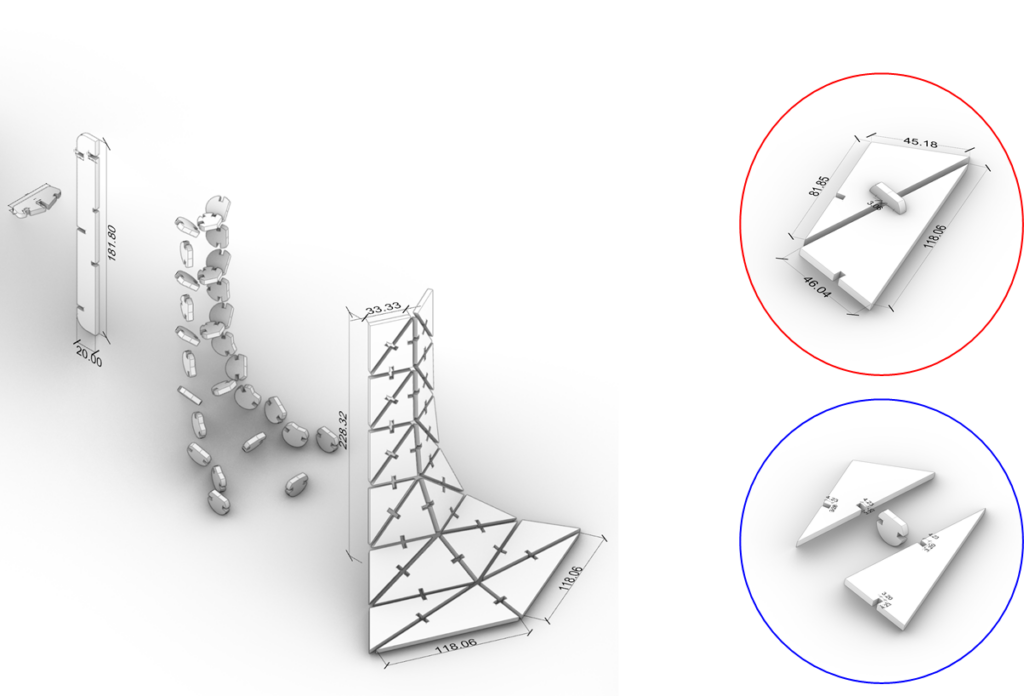

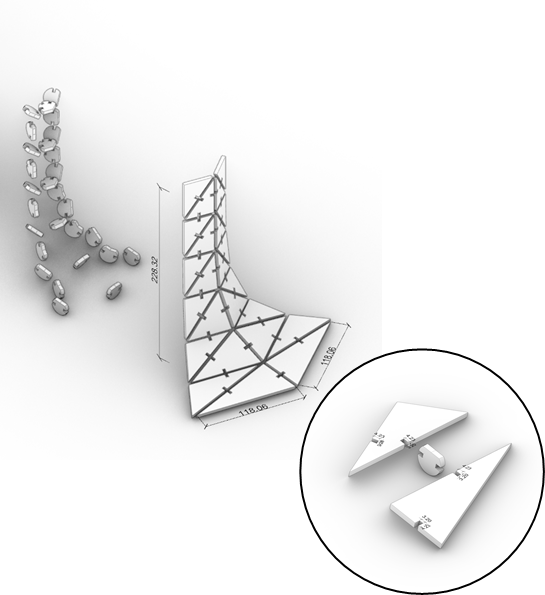

To maintain flexibility and openness in our design possibilities, we chose to create a joinery for our cabin using 3D printing. Inspired by anatomy, the concept of “Pitch and Roll” led us to reference the ball-and-socket joint in designing our 3D printed components.

The ball and socket joint is commonly used in everyday objects such as cranes and toys. The idea here is to apply this joint to introduce movement into architectural design itself.

CNC MILLING

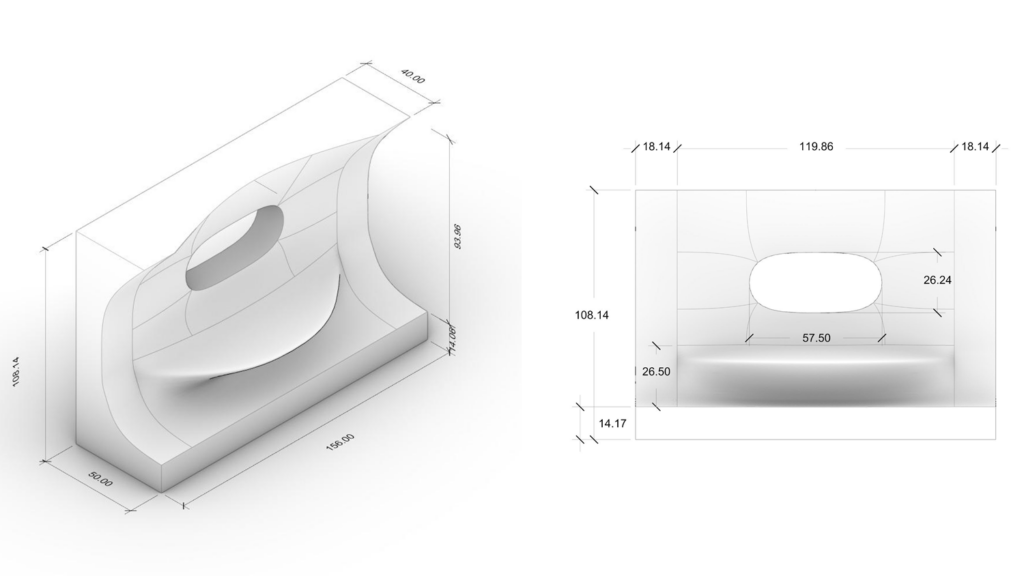

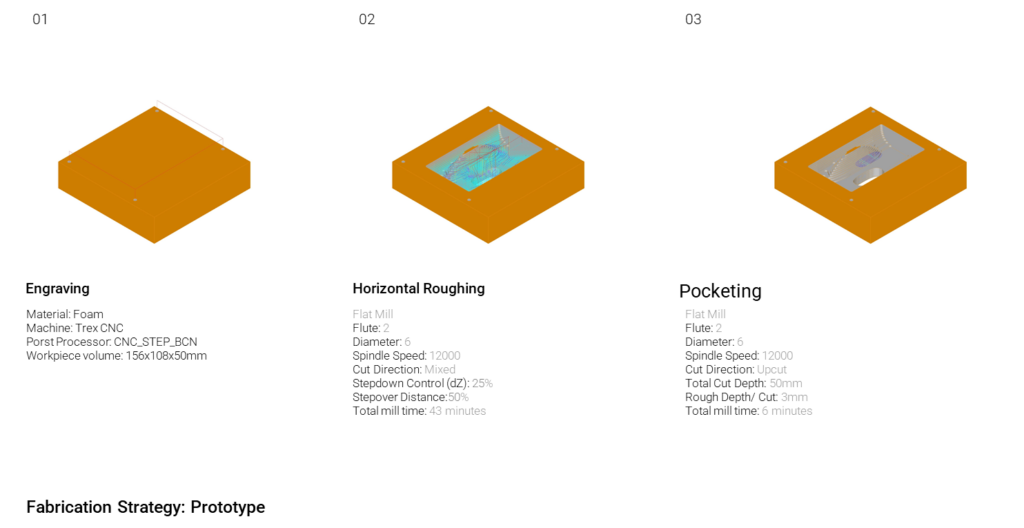

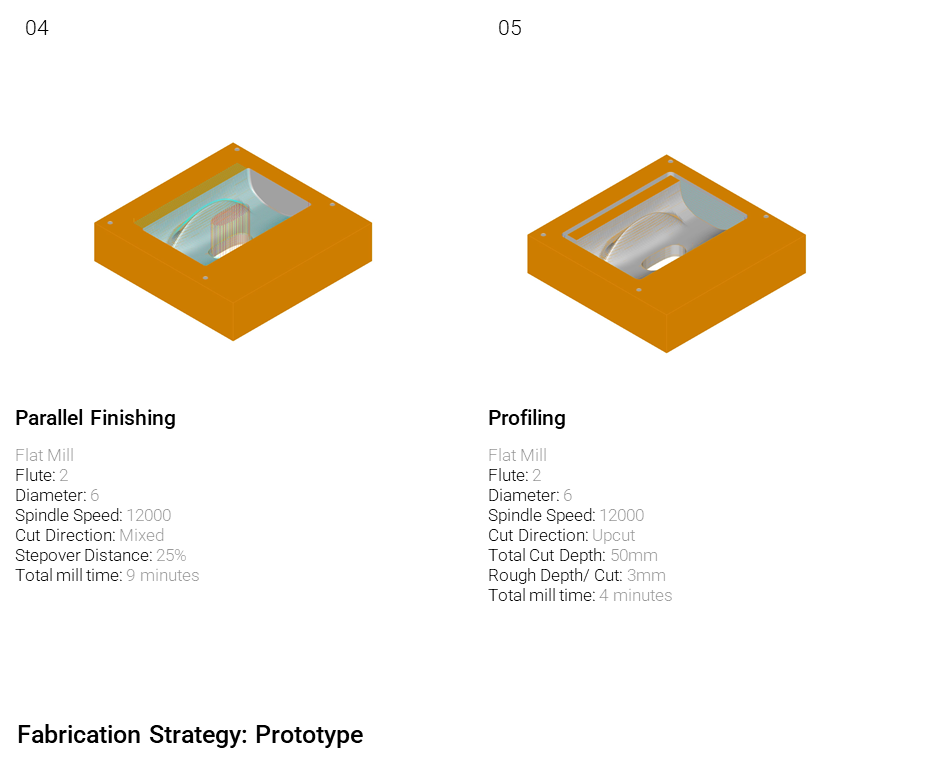

As we entered the second week of digital fabrication focused on CNC cutting, our aim was to explore various CNC milling techniques by testing different operations on several prototypes.

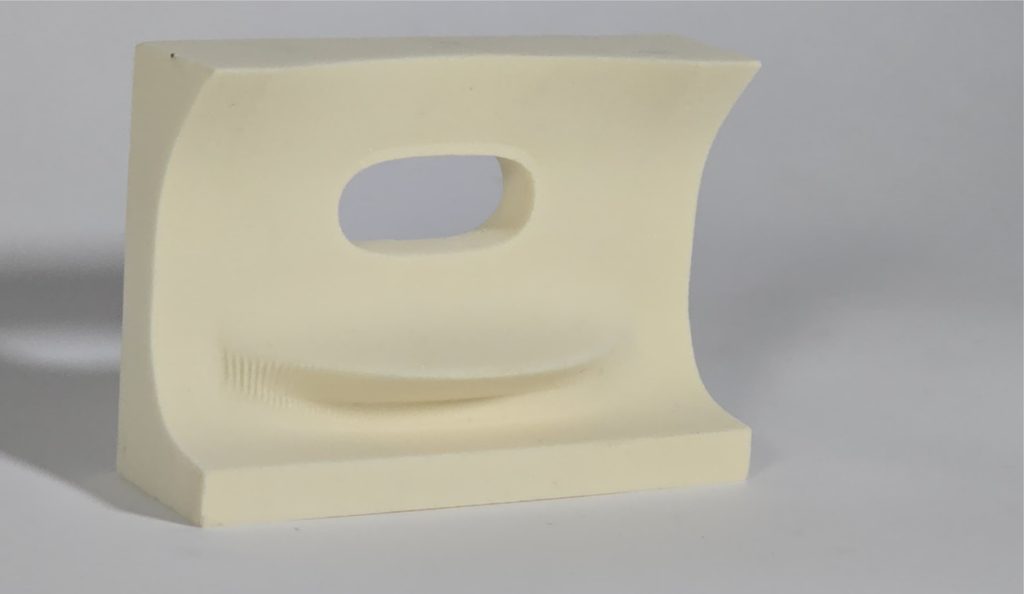

Prototype

For the organic wall, we utilized engraving, roughening, pocketing, parallel finishing, and profiling techniques.

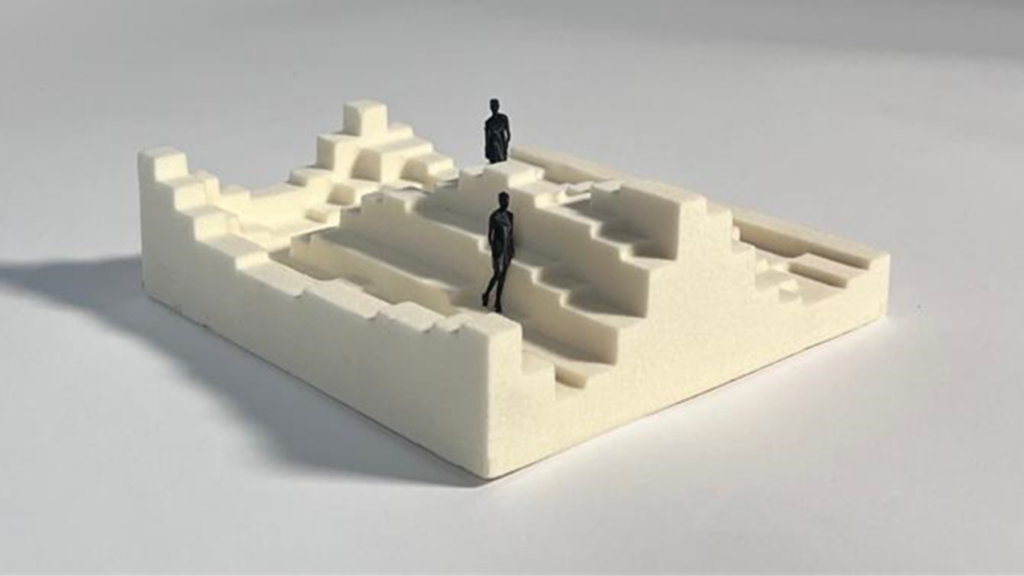

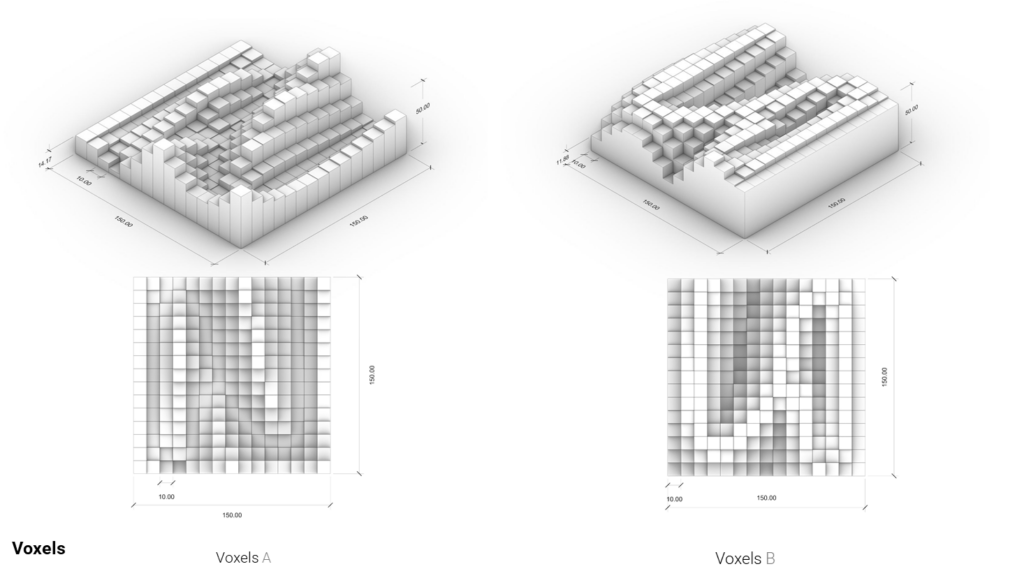

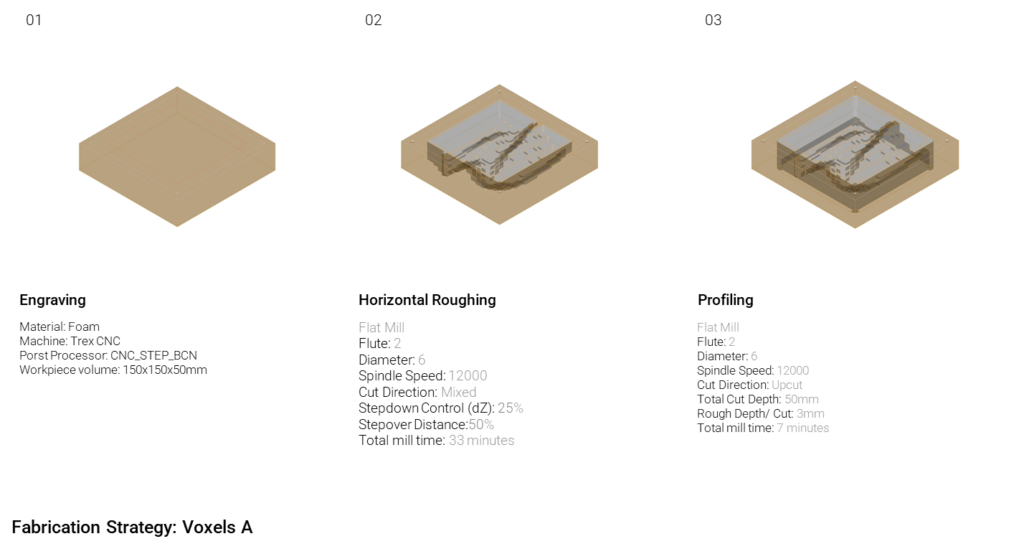

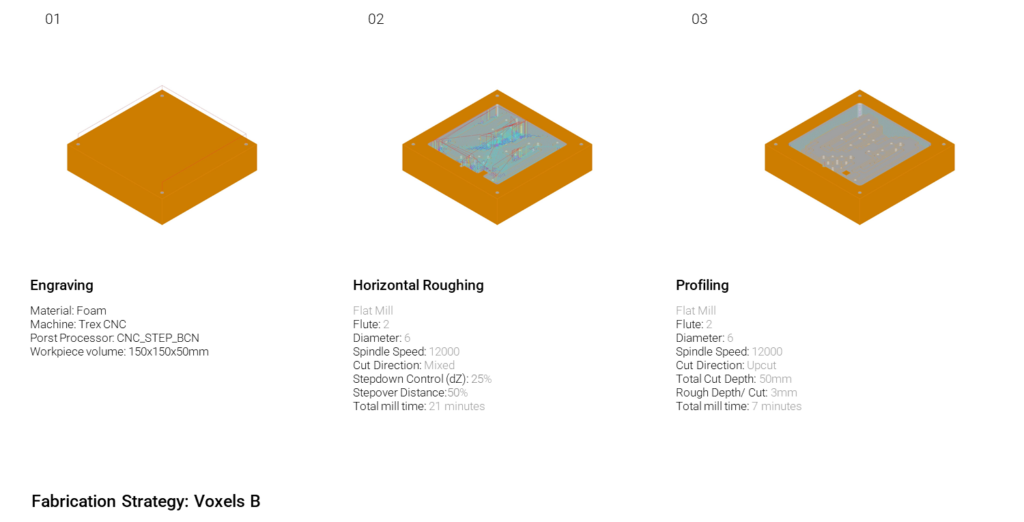

VOXELS

For the Voxels, we started with engraving, followed by roughening and profiling.

LASER CUTTING

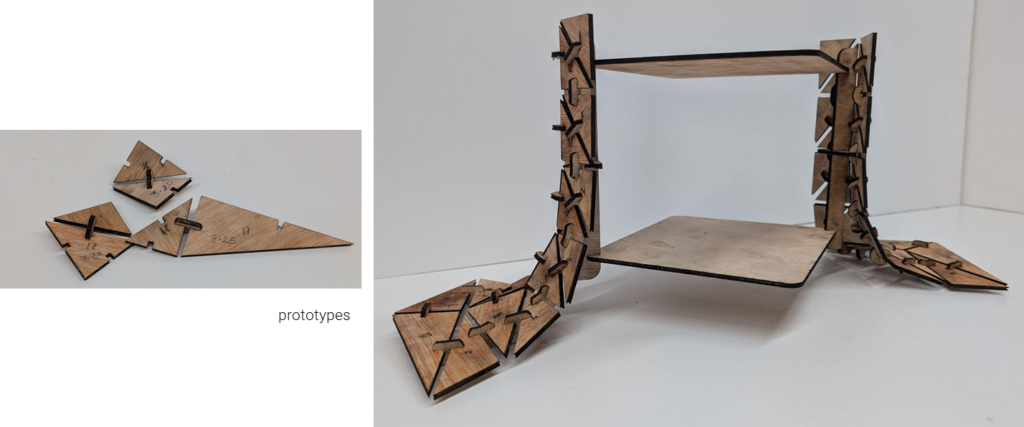

The goal was to explore interlocking techniques with plywood, discovering its potential and ways it could enhance our cabin design. We began with interlocking links, but this approach proved challenging as the links began to break due to their narrow width.Then, we moved on to a basic interlocking method, aligning the pieces at specific angles to achieve the desired structure for our design.

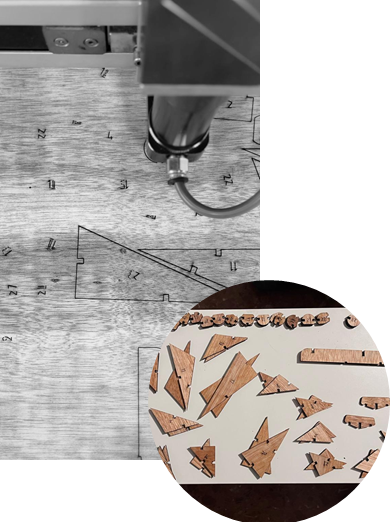

1. Designing

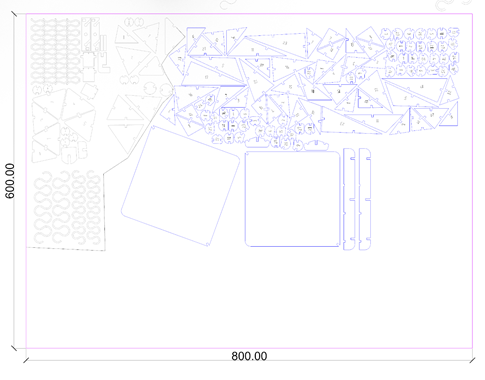

Using Grasshopper and our target curve shape, we generated the triangular and button pieces with cuts for interlocking positioned and angled precisely as needed.

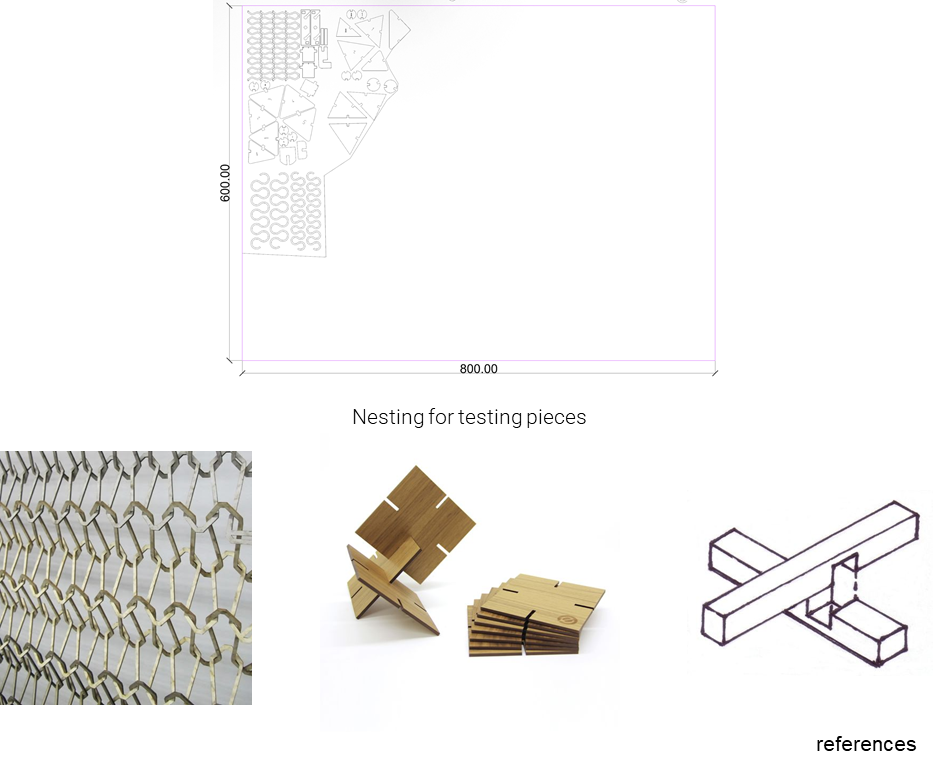

2. Nesting

Once we had the desired pieces, we nested them efficiently. We carefully considered color coding, settings like the speed and power for cutting and engraving.

3. Cutting

After making the necessary adjustments, we set up the machine with attention to the origin, laser position, and gas outlet knob. The laser cutting operation took 26 minutes to complete.