This project seeks to transform La Fira, an industrial zone in Barcelonès, into a sustainable insect farming hub. By embedding insect farming within the existing infrastructure, it will leverage local resources to efficiently produce high-protein insect products. Traditional agriculture faces growing pressures including water scarcity and limited space, especially in urban areas like Barcelona. Insect farming requires far less water, space, and resources, offering a sustainable solution to rising protein demands.

The project will implement advanced farming technology and foster resource-sharing with neighboring industries, creating a symbiotic model. Public spaces will promote community engagement and education on sustainable food systems, merging industrial efficiency with ecological responsibility for broad-reaching impact.

At the beginning of this course, we were introduced to these picture which were really impactful. As you maybe know, this is the reservoir of sau. The picture on the right is now and the other is 10 years ago, the constrast between the 2 pictures shows one of the main problems Catalonia is dealing with, the water gesture. Our project is developed around this problematic and try to bring an answer to it. In catalonia 70% of the water usage comes from traditional agriculture, That’s why, today, we offer the alternativ of insect farming.

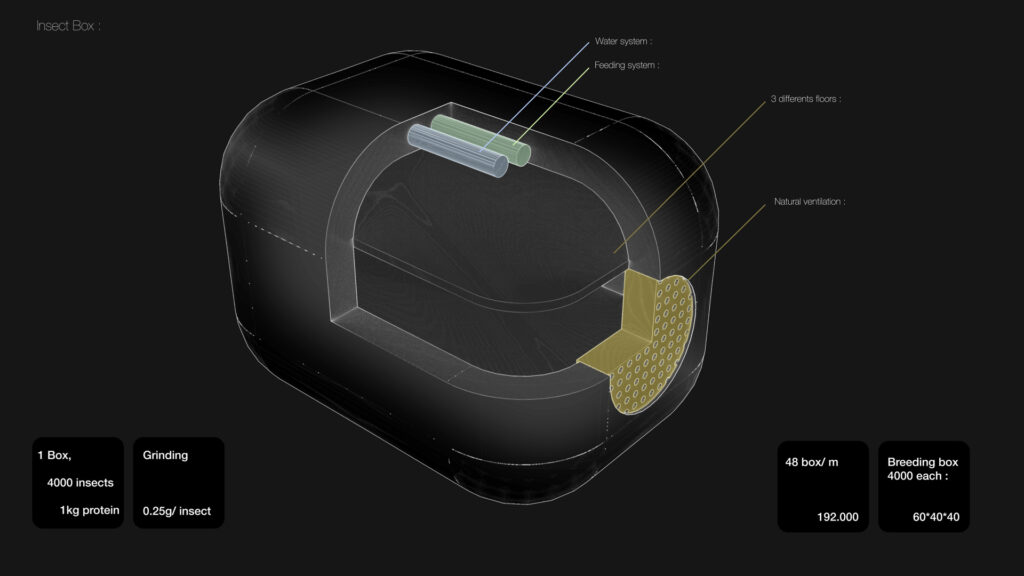

Technology :

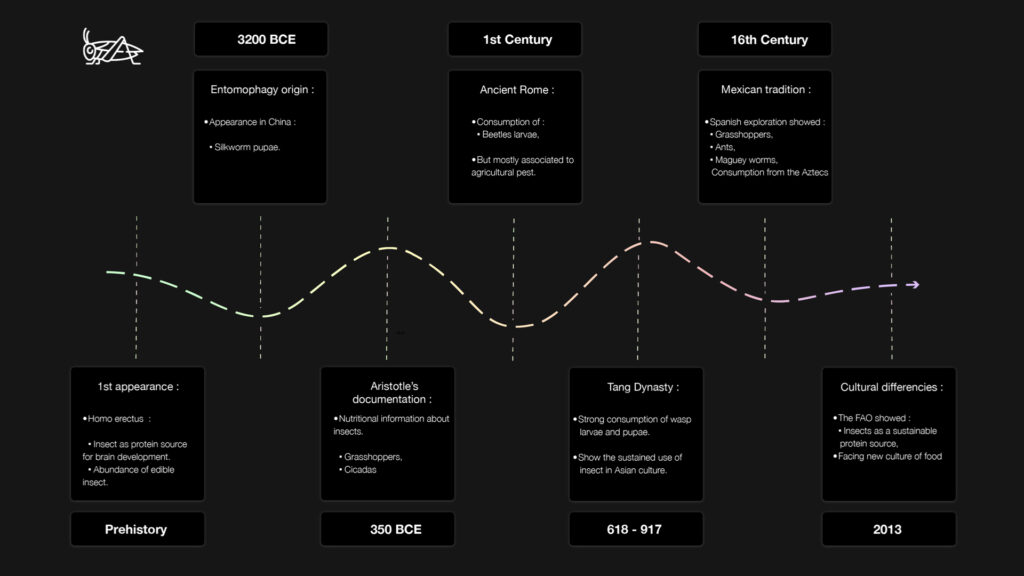

Let’s make a jump into the history of insect farming. The first statement we had in our research was that, this is a type of food that was more popular before than now or at least in Europe. So, the first apparition of insect farming was around 3200 BCE in china, but it started to be more concrete in 350 BCE when Aristotle made research about the nutritional aspect of insect. However it appeared a long time ago, today our approach is different, we no longer eat insect on their formal shape.

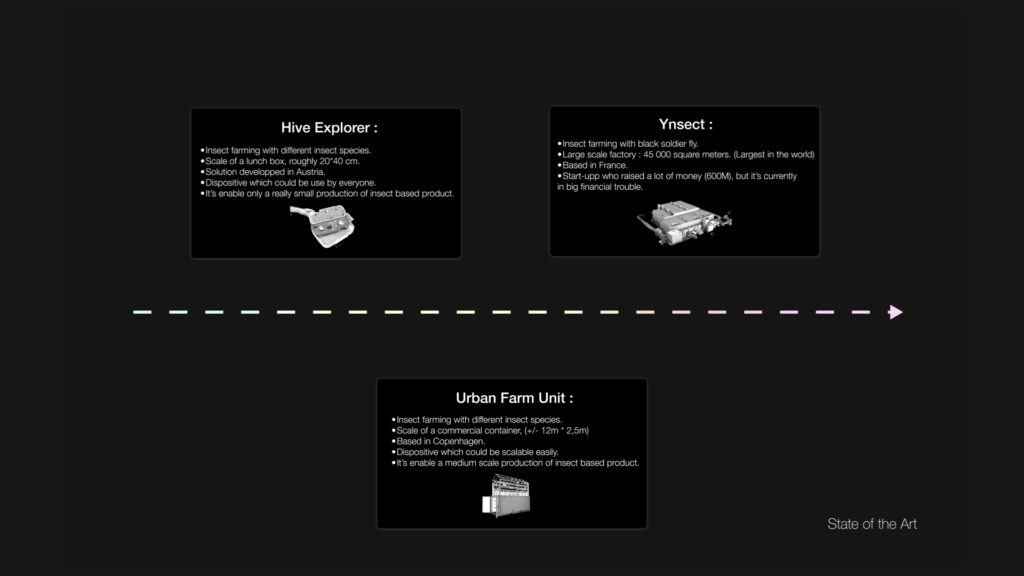

Regarding, the state of the art, we noticed that the size of the production around Europe varies a lot, going for example from the hive explorer which is designed for single family, as a lunchbox to bigger factory as Ynsect, which is based in France and has a factory of 45000 sqm.

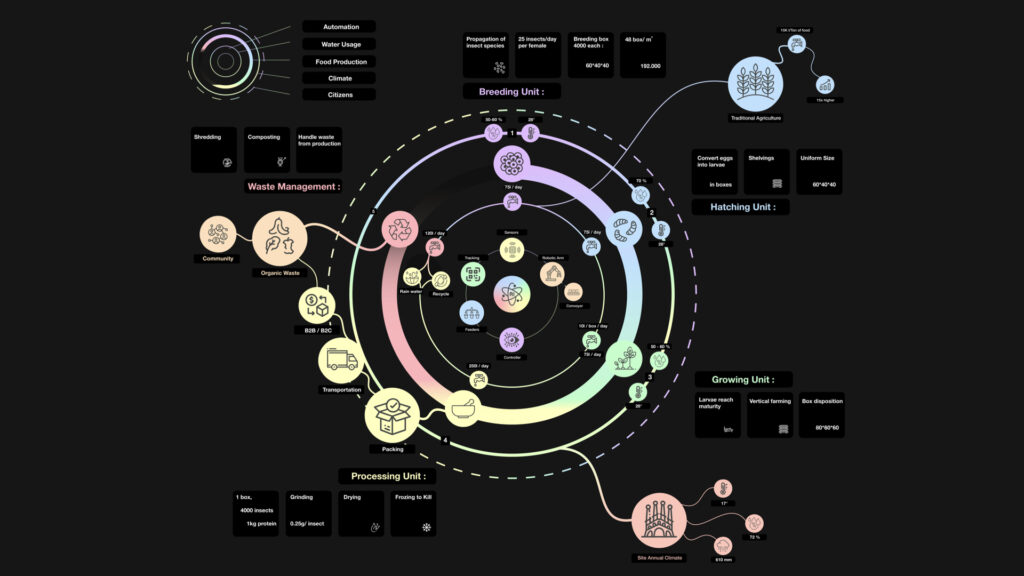

For our production, we’ve chosen to work with house crickets and yellow mealworms that had a life cycle that fits with the climate of Barcelona and has also one of the best nutritional value.

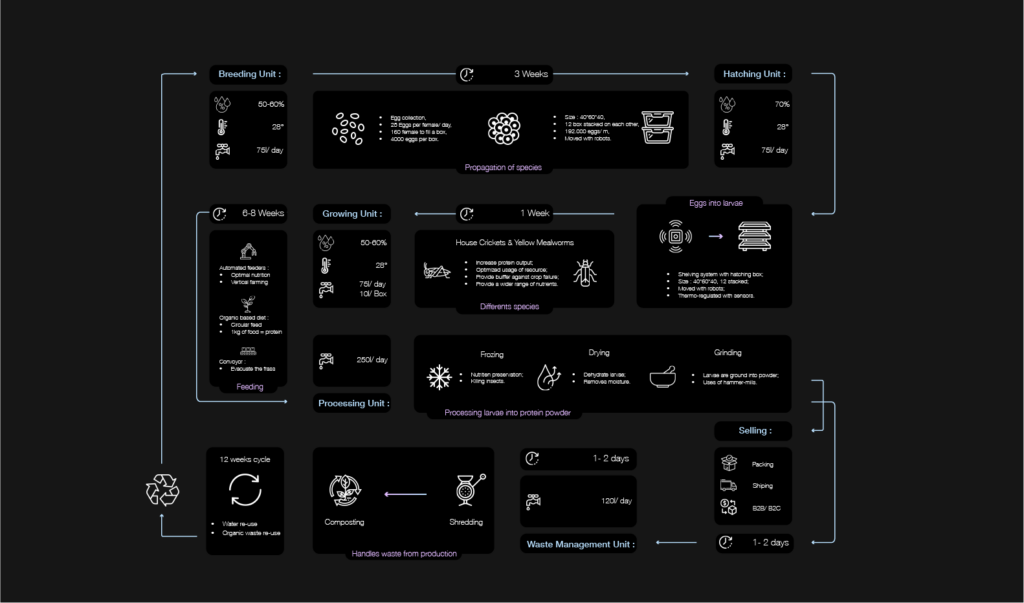

First of all, what is incredible with insect is the ratio between, the feeding needed and the final product which is one to one. To get this final product, we have 5 steps that makes up a process of 12 weeks. Trough this process, insect will be in boxes which would make easier the moves between the different steps. and It start with breeding unit, where insects are still in eggs. This would the transfer from one step to the other. Then we goes to the hatching unit followed by the grading part, which is the longest part of the process. After this, they are transform into powder in the processing unit. Finally, we close the process with the waste management unit that will create the loop. This is process, reduce by 90% the need in water to produce 1 ton of protein in compare to traditional agriculture.

Regarding the boxes, they have a size of 60*40*40 cm and can welcome up to 4000 insects in each. Each insect produce around 0.25 gr of protein, that means that each boxes will convert into 1 kilos of protein.

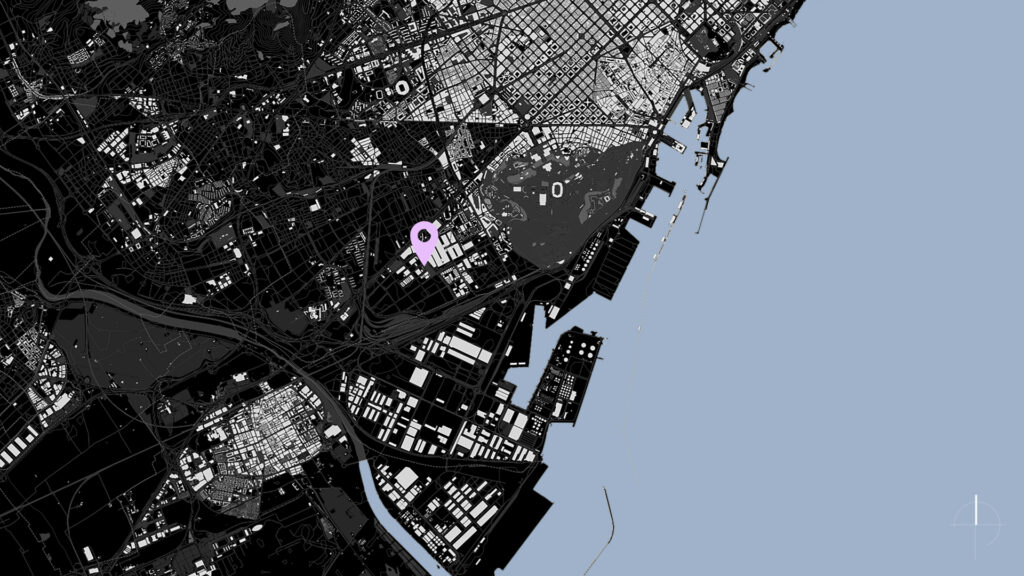

Site Analysis :

Our site is located between the commercial port of Barcelona and the Montjuic. We can see that the surrounding building are more massive and with and industrial typology in compare to the residential area in the south.

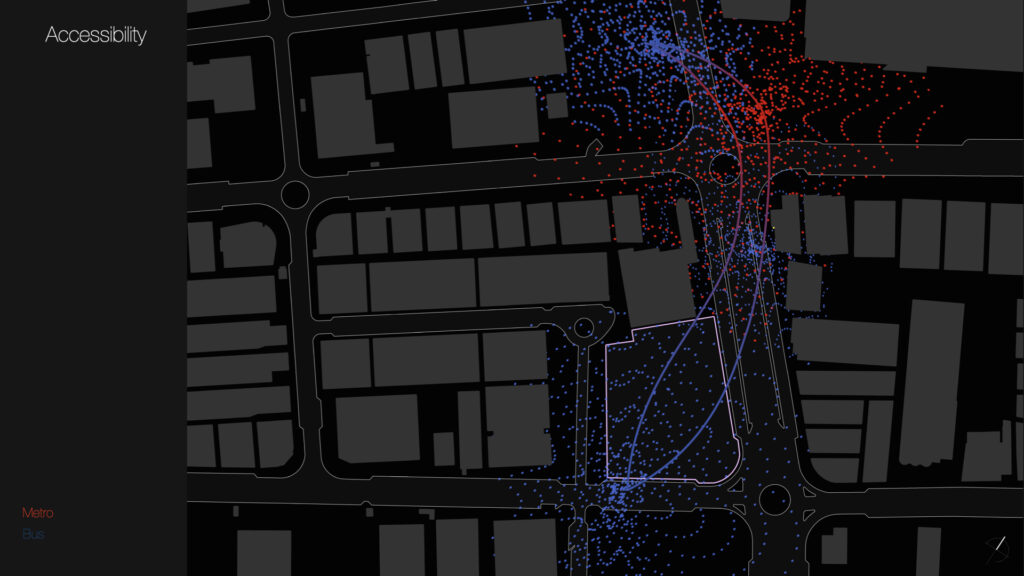

Let’s have a closer look, this is the anylisis of the flow of people, especially the user of the public transport. The site is close to the metro station, served by the line L9 south, which is the airport connecting line. And on the side the blue dots are the bus stops that surround the site, from this transport point we came to this area, in between the two lines. Representing the most important flow of people.

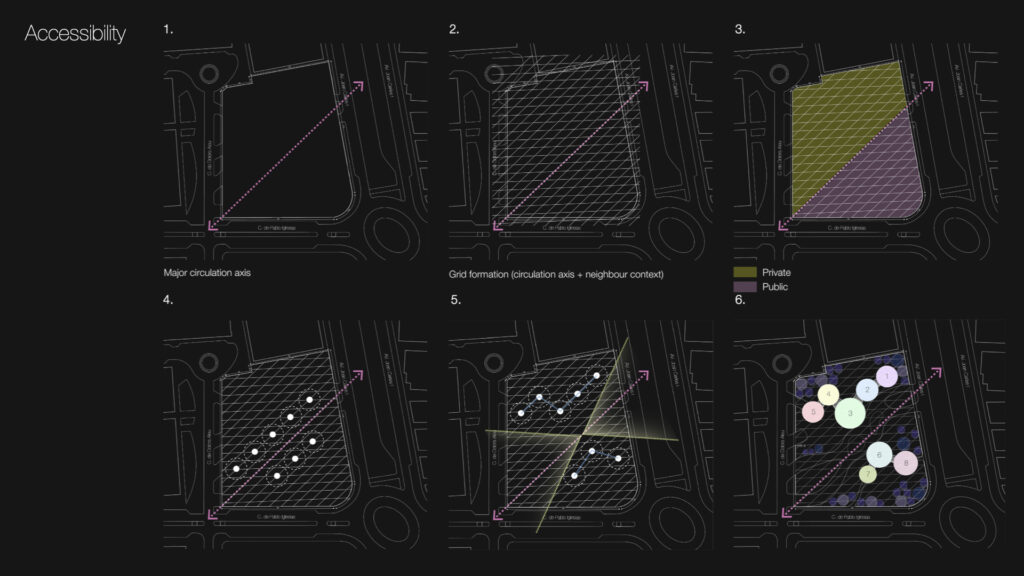

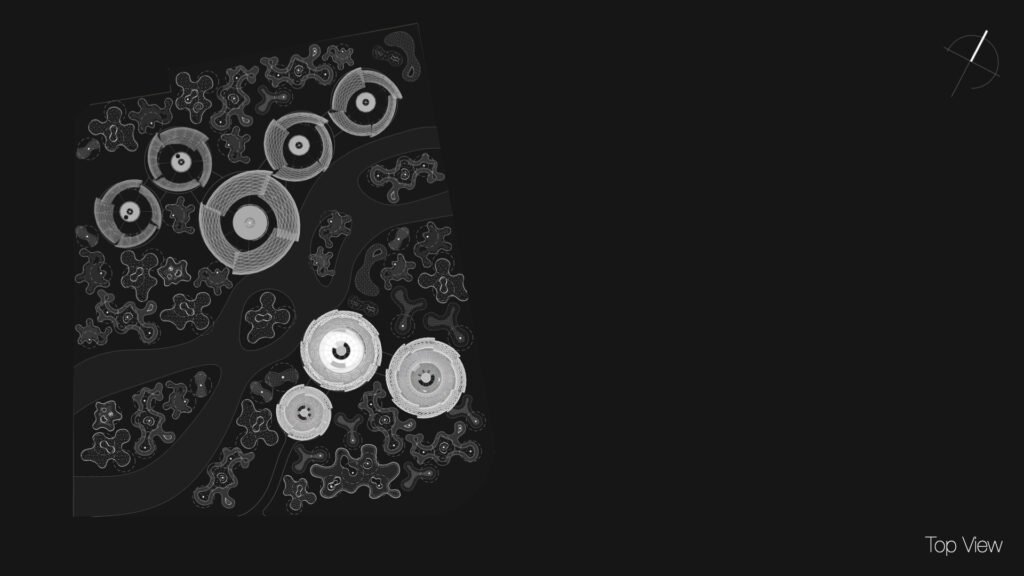

Aside to this, we developed a grid that combine the orientation of this axis ans the orientation of the surrounding building. This, ended up in two area; the yellow one would be dedicated to the production part, while the pink one would be for public usage. Then We developed the layout of our building according to these yellow axis that created a free space around the entry on our site, this increasing at the same time the sun exposition of each building.

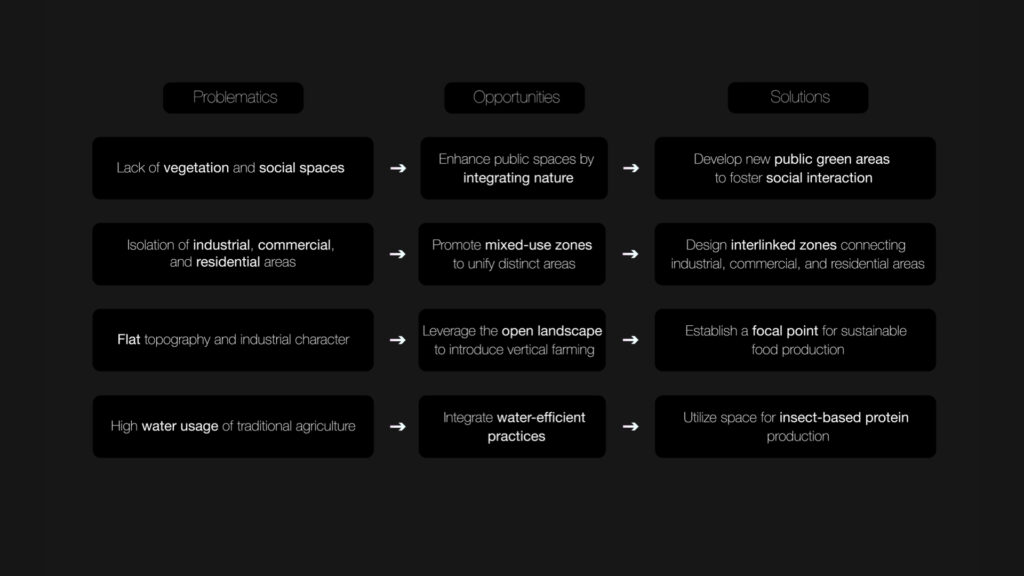

From this analysis, we identified the 4 following problematic, which we’ll try to solve trough these solutions.

Morphological Research :

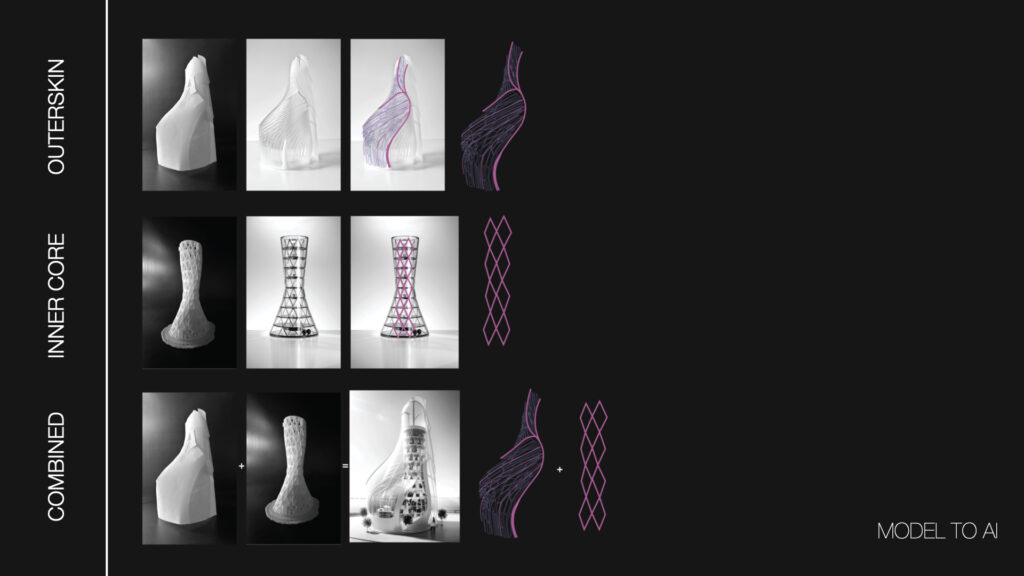

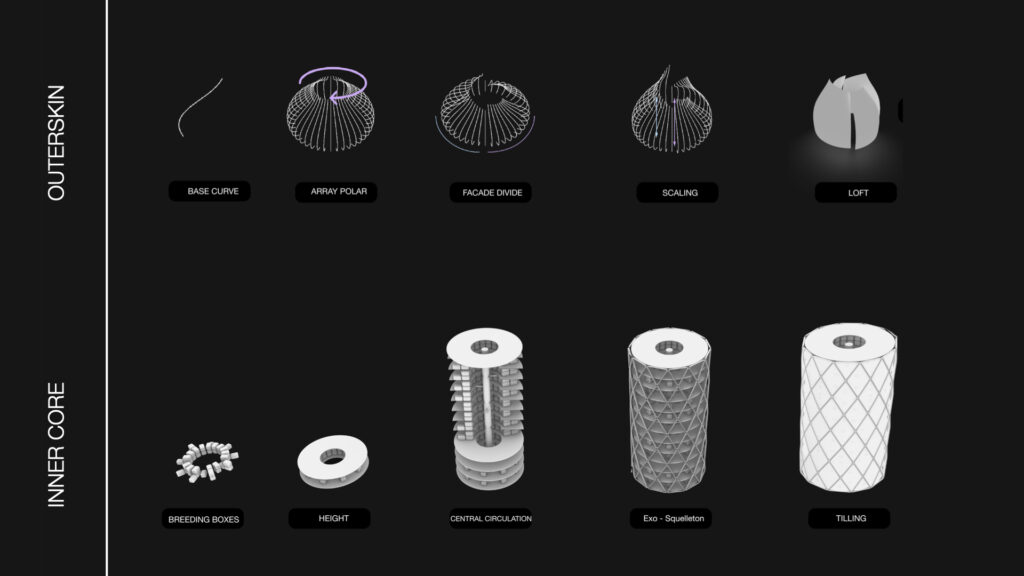

According to our need we developed a concept as a base for our design research. This concept combine a vertical circulation that’s inside the inner core. Those part combined are straight dedicated to the insects. Around this, we have a intermediate area that’s defined by an outer skin. This part has, as a main uses the development of an organic area that can produced feed for our factory. Then, we combined both part, which are connected by an free plan groundfloor.

Starting from those model, we used comfyUI and extracted design rules. Those offered us a really interesting a combination. Going from a pattern inspired by the insects wings, which could be linked with voronoi; to a straight, rationalised grid composed of diamond.

Project Proposal :

Our production part is then declined in 5 parts to which we added 5 other function, there are respectively a shop, a teaching area, a restaurant, and finally a laboratory that is inside our HQ.

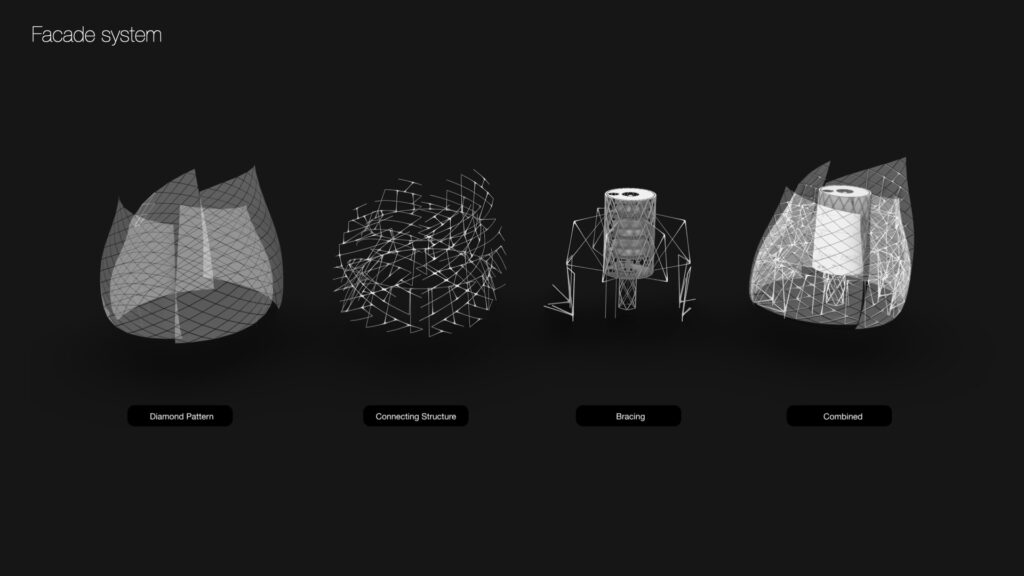

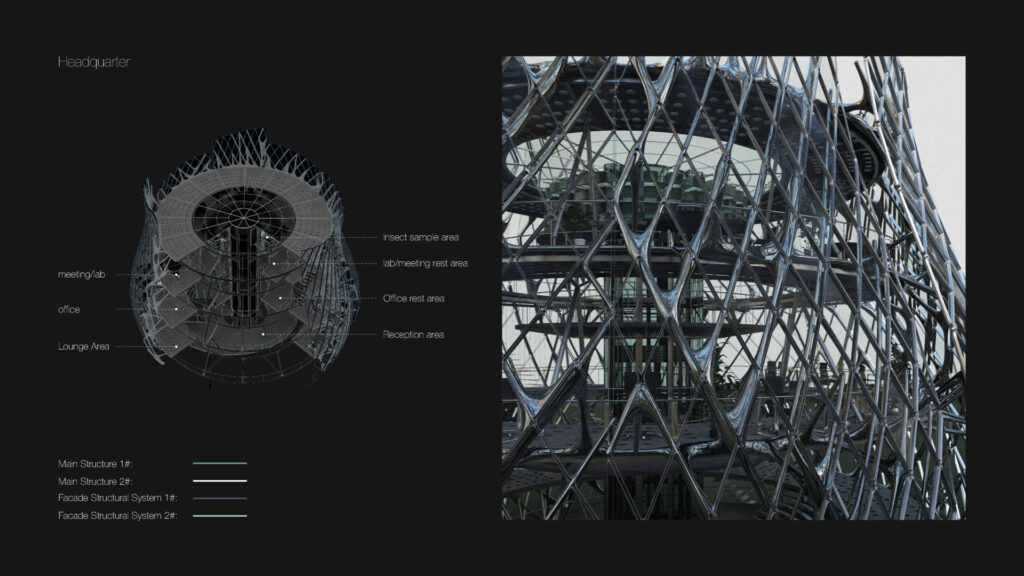

For our outerskin, the development is based on a curve that we arrayed and lofted after a division. While our inner core, is based on the size of our breeding boxes. Each floors is separated by 90 centimetres that allows us to stack two boxes, the radius allows a disposition of 18 boxes. The center holes, is dedicated to the central robot, that represent the vertical circulation. To make this process easier, with worked on an exosqueletton, exosquelleton that is based on the design rules we extract from comfyUI.

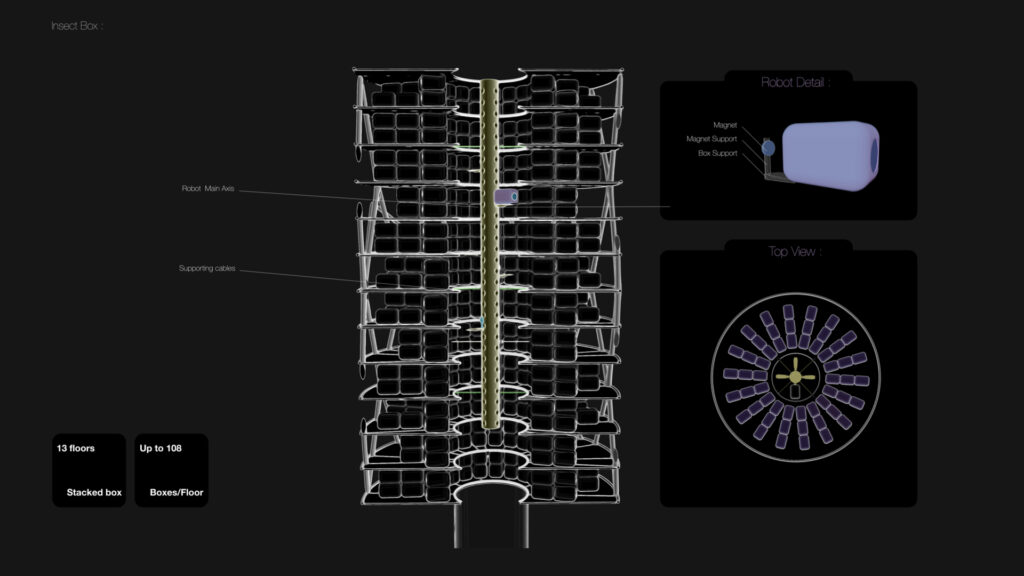

Regarding how our building works; we have then the robot which has a central axis around which 4 platform with a magnet are. The core itself, is composed of 13 floors and can have up to 108 boxes per floor for the growing unit and up to 72 for the others.

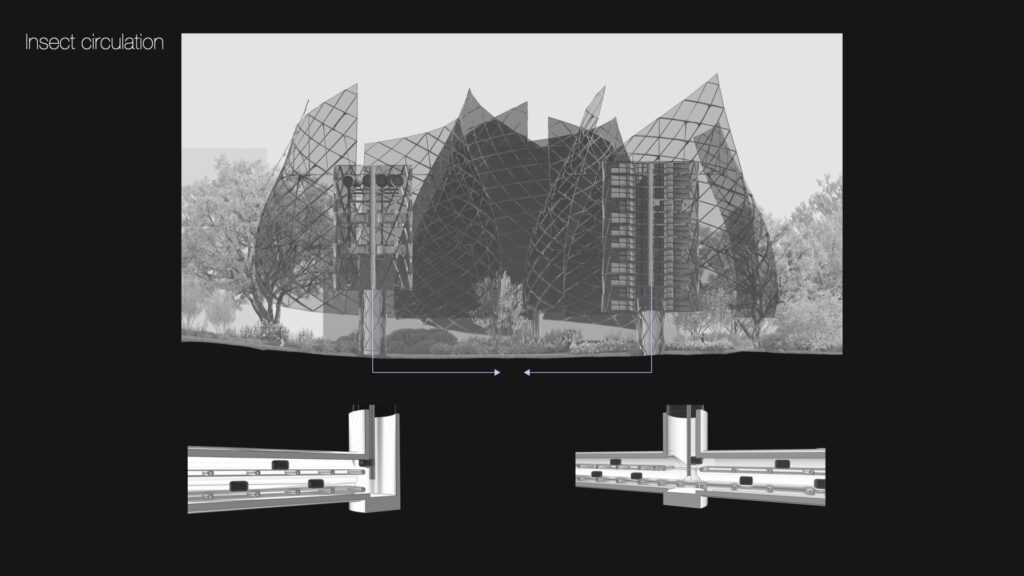

Each building are connected by a tunnel, these are composed of two conveyors that moved the boxes between each unit.

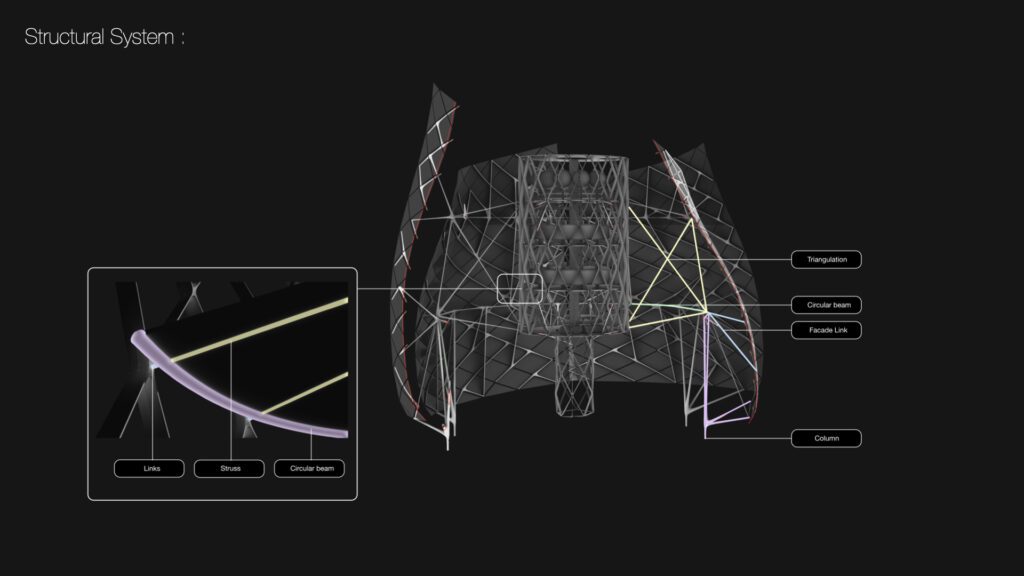

The facade is declined into 3 layers, first we have the skin itself that takes back the diamond pattern to unify our architectural style on one hand and also for the structural capacity of the diagrid on the other hand. The second layer is our connecting structure that is the inbetween with the inner core. Then, we add a triangulation to cope with bracing.

For our structure, our inner core is supported by the central columns and by the structure of the facade. The facade, is self-supported and is linked to the inner core by triangulation to cope with wind charges. The green circular beams, located in between, it’s characterise, as all the structural element located in-between, by a circular morphology that spread the loads better.

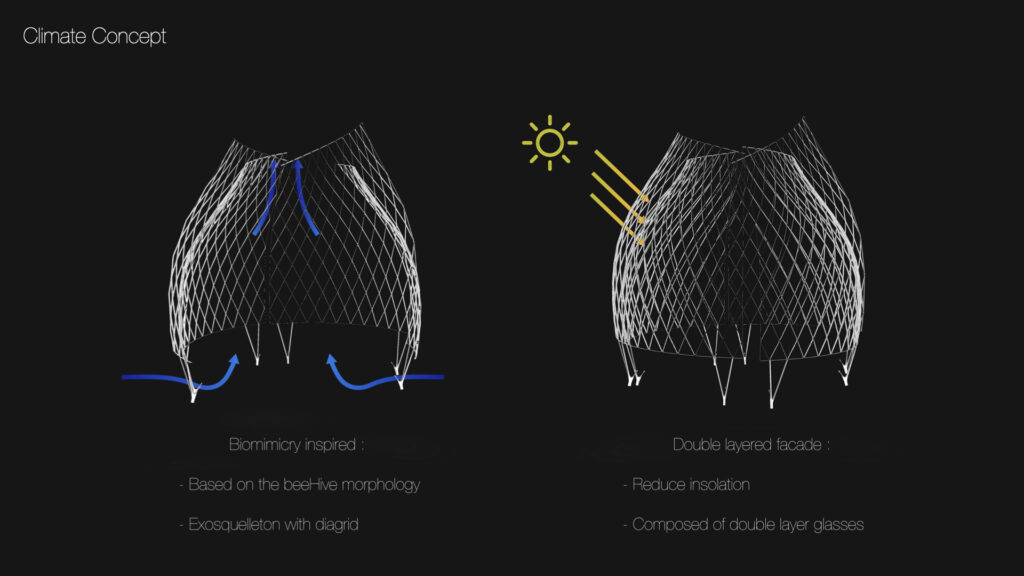

Our morphology, which is getting closer as soon as we get closer to the top is inspired by bimomicry, especially from the bee hive and this contribute to increase the ventilation with a better gesture of the air flow, regarding the materiality, the diamond are filled with double layers glasses that reduce the insolation almost during the summer which prevent the usage of AC.

Public Part :

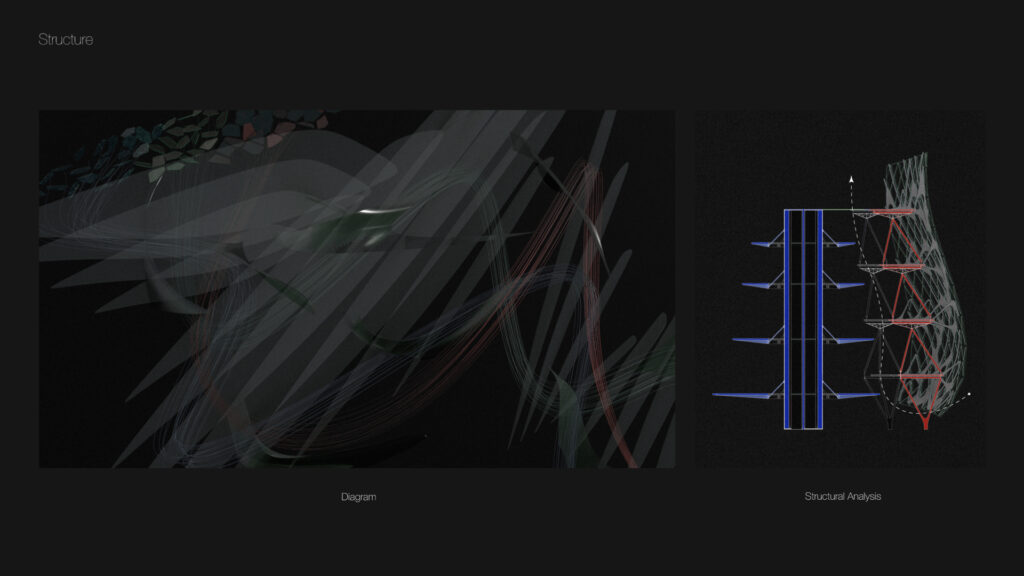

This diagram illustrates the structural design of public buildings inspired by the wings of insects. Using ComfyUI iterations, we developed the patterns for the building’s façade. But we didn’t want the concept to stop at just surface decoration—we wanted every architectural element, from the columns to the slabs and ceilings, to come together and embody the same lightness and delicacy as insect wings, thin and almost weightless.

We studied and deconstructed insect wings, fascinated by how their multiple layers unfold, much like the layered floors of a building. The structure itself mirrors the efficiency and strength of its wing framework. Inspired by Voronoi-like structures, we applied an algorithm to create the façade’s support system—achieving a balance between strength and lightness.

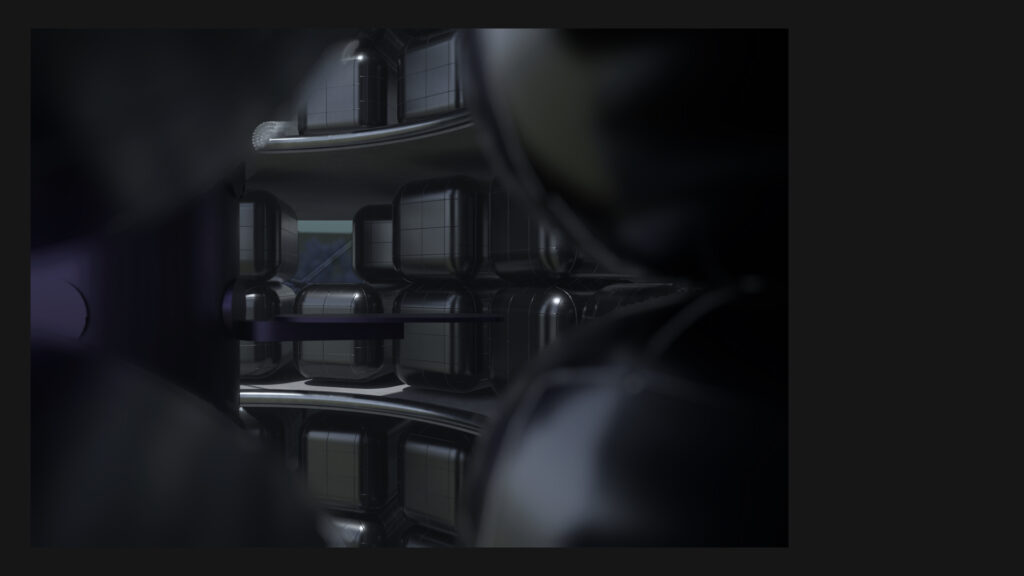

Manipulating the offset slabs creates a unique spatial experience, allowing people to feel as though they’re wandering through a steel forest—a space that’s both dynamic and immersive.

This is the headquarters section. On the right, you can see a rendering that carries the same feeling conveyed by the diagram I showed you on the last slide. The floor slabs appear incredibly light as if floating in the air. The organic, skeletal support structure efficiently and powerfully holds up the glass curtain wall, much like the wings of an insect.

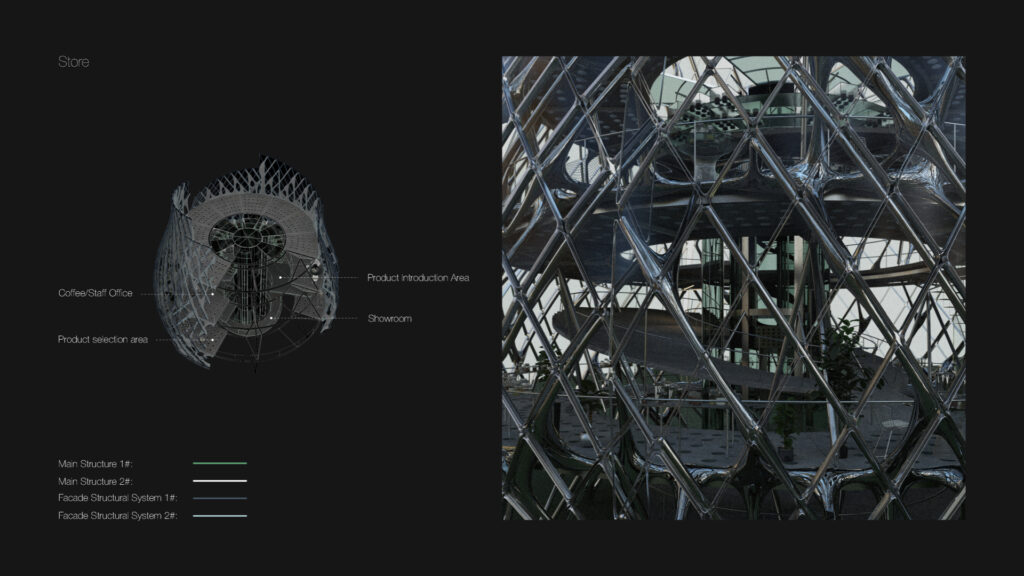

For the store section, we use angled, staggered floor slabs to create an area where customers can learn about our insect-based products. Imagine walking through this metallic jungle, climbing up the concrete hill, and listening to staff explain the products while watching the transportation pipelines behind them continuously deliver production. It would be such an interesting experience.

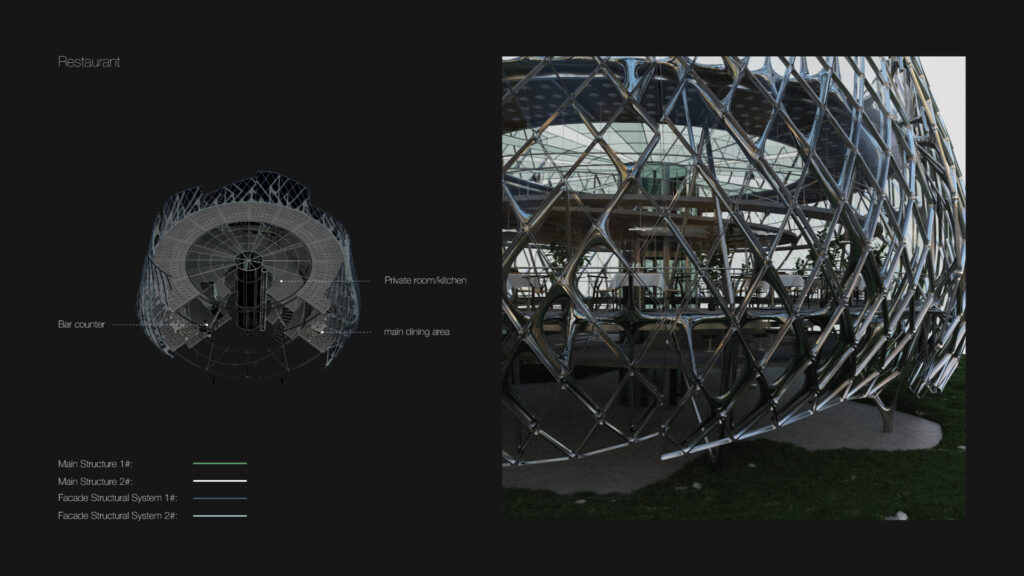

In the restaurant section, the building is delicately supported by metallic “tree trunks.” We also used suspension structures to gracefully hang the walkways, allowing guests to wander through this steel jungle while watching our chefs prepare delicious insect-based dishes. This creates a unique spatial experience that combines movement, interaction, and gastronomy in a one-of-a-kind environment.

Top View :

Renders :