The design & fabrication course focused on inculcating hands-on experience in utilizing advanced machines such as CNC routers, 3D printers, and traditional carpentry tools. In this class, we were taught how to use various technologies to fabricate our designs into the final product.

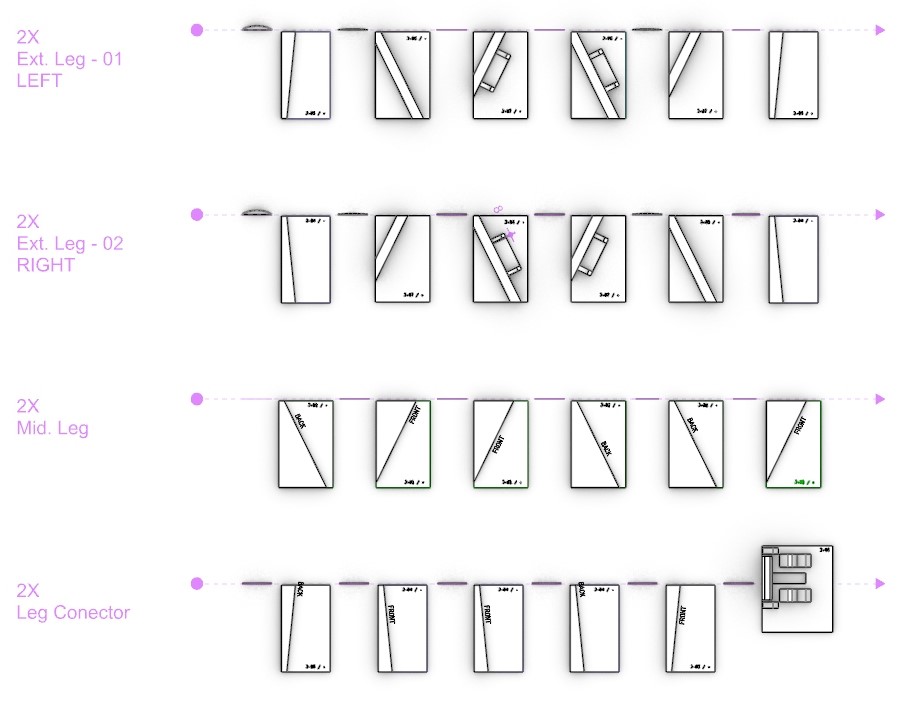

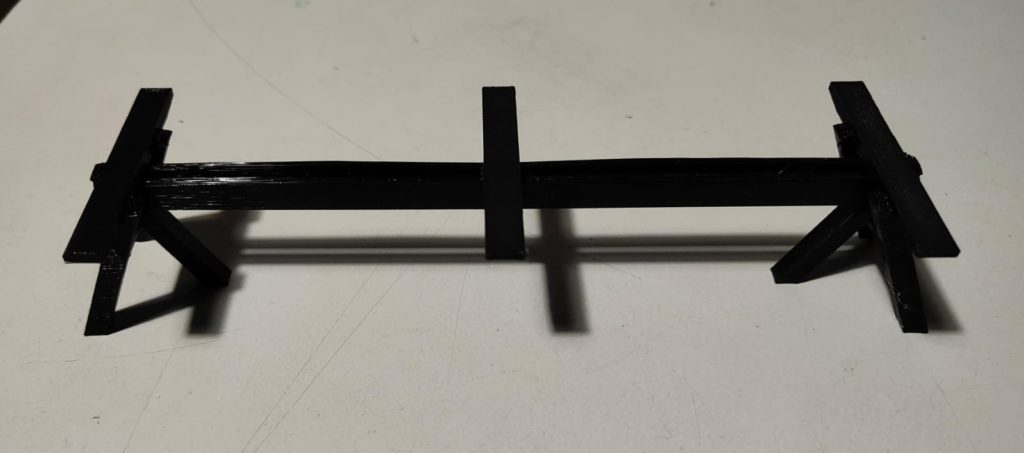

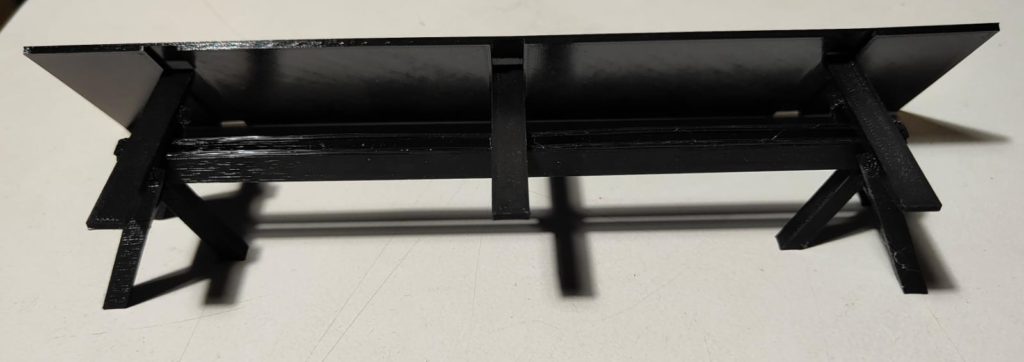

For this program, we started with prototyping the structure of our Table. We started with digitally designing the structure and its elements. This included the legs, connectors, and stretchers. The idea was to get accustomed to the machines and at the same time understand the stability and the strength of the structure.

We used various machines for the prototyping, mainly:

- Planar

- Table Saw

- Circular Saw

- Band Saw

- CNC Milling

- 3D Printing

While making these components we learned that there is a requirement of custom-made jigs to be able to achieve the desired angles for the legs of the table. Initially we began with designing the jigs by drawing it out on a plank of wood and cutting it on the table saw. But this resulted in loss of accuracy of the measurements. So then with the help of the CNC Machine, we cut out the components of the jigs, in order to get precise measurements eliminating the concept of human errors.

Apart from prototyping the legs, we also used the 3-D printer to make a 1:100 scale model of the table, in order to test out the structure and the top surface.

Testing out and fabricating the various components of our table not only helped us understand the functionality, durability, and aesthetic appeal of our design, but also helped us learn how to operate various machinery available in the FABLAB.