1 | Impetus

2 | Concept

The underlying phenomena that inspired the project were acoustic standing waves and cantilever vibrations. These principles represent the intricate interplay of physics in shaping patterns and movements in materials, serving as the foundation for the development of the device. By harnessing these phenomena, our project aims to explore novel ways of manipulating physical systems for creative and practical outcomes.

Here, the concept of the project is linked to a real-world demonstration of 24Hz sine waves manipulating water flow, capturing mesmerizing physics in action through the flow of water. The team extrapolated this concept to design a device capable of similar captivating outputs.

3 | Prototype 00

4 | Physics Explained

In the project’s initial experimentation stage, the focus was on the foundational physics of the device. Key areas of investigation included nozzle design, which influences fluid breakup height; the effects of cantilever vibrations on system stability; and the role of sinusoidal waves in shaping liquid behavior. Early experiments emphasized understanding these core principles to inform subsequent iterations. Our team also began to identify potential challenges, such as balancing fluid dynamics with vibration control, while laying a scientific basis for further prototyping.

Nozzle Design and Breakup height

Cantilever Vibration Functions

Sinusoidal Wave Induced in Liquid

5 | Prototype 01

Here, the project takes a significant step forward with the assembly of VibeInk.2000, the first working prototype. A detailed schematic accompanies the assembled model, showcasing the integration of mechanical and electronic components. This prototype represents the culmination of the initial design and testing phases, where theoretical concepts were translated into a physical device. It also serves as a testbed for exploring the interactions between components, refining their functions, and identifying areas for improvement in future iterations.

The VibeInk.2000 is a machine that leverages the principals of vibrational excitation and fluid dynamics to generate rhythmic paint patterns. By applying controlled vibrations at specific frequencies, the system oscillatory motion in the paint, modeled by the mathematical equations governing fluid excitation, such as Navier-Strokes equations. These vibrations create standing waves and fluid instabilities, leading to the formation of periodic, spatially coherent patterns. The system utilizes resonance and harmonic frequencies to precisely control the flow of the paint, producing intricate and repeating designs based on the interaction of vibrational energy with the fluid’s viscosity and surface tension.

A DC motor with an off-center load creates oscillatory motion due to the uneven distribution of weight. The off-centre load causes vibrations, producing repetitive motion at a specific frequency. This effect is used in applications that require controlled oscillation, such as vibration systems or balancing mechanisms.

The goal scorer is a mechanical system driven by a servo motor, which provide precise control and movement. These motors allow the system to perform accurate, fast movements, mimicking a goal-scoring action. With the help of actuators, the system reacts quickly, ensuring each attempt is powerful and precises, showcasing the potential of robotics in sports.

6 | Components

A. Chassis

The chassis is introduced as the backbone of the device, engineered for durability, stability, and modularity. Its design ensures that the system remains robust during operation, especially when subjected to vibrations and fluid movement. There is an emphasis on the material selection and assembly methods, which balance strength with accessibility. A well-designed chassis was critical for maintaining the alignment of components, protecting sensitive parts, and enabling efficient troubleshooting and upgrades.

B. Connectors

The connectors are pivotal for the device’s structural integrity and functionality, ensuring secure and reliable assembly. The design of the details were to prioritizes ease of use while maintaining tight tolerances for performance. Connectors not only physically link components but also play a role in the overall modularity of the system, enabling quick replacements or adjustments.

C. Fluid Transmission System

The fluid transmission system is the heart of the device, responsible for delivering liquid consistently and efficiently. The design minimizes turbulence and ensures steady pressure from the fluid receptacle to the nozzle. Achieving laminar flow is a key objective, as it directly impacts the system’s ability to produce clean and reproducible patterns through our varying frequencies. The system’s modularity and adaptability also allow for future enhancements, such as electronically actuated valves or alternative nozzle designs.

D. Shaker

The shaker is presented as the core component that generates vibrations, driving the system’s dynamic effects. Its mechanical and electronic configurations are designed to produce precise oscillations, which are crucial for inducing standing waves or other fluid behaviors. We had a few challenges related to fine-tuning the shaker’s frequency and amplitude, as well as its impact on overall system stability. This component exemplifies the project’s blend of mechanical ingenuity and electronic control.

E: Hitter

The hitter interacts directly with the fluid, amplifying the effects of the shaker and adding another layer of complexity to the system. We explore its role in modulating vibrations and influencing fluid patterns. The hitter’s design is still experimental, with opportunities for optimization to improve precision and consistency. By focusing on this component, the team aims to expand the system’s range of possible effects, enabling more intricate and versatile outputs.

F: Electronics

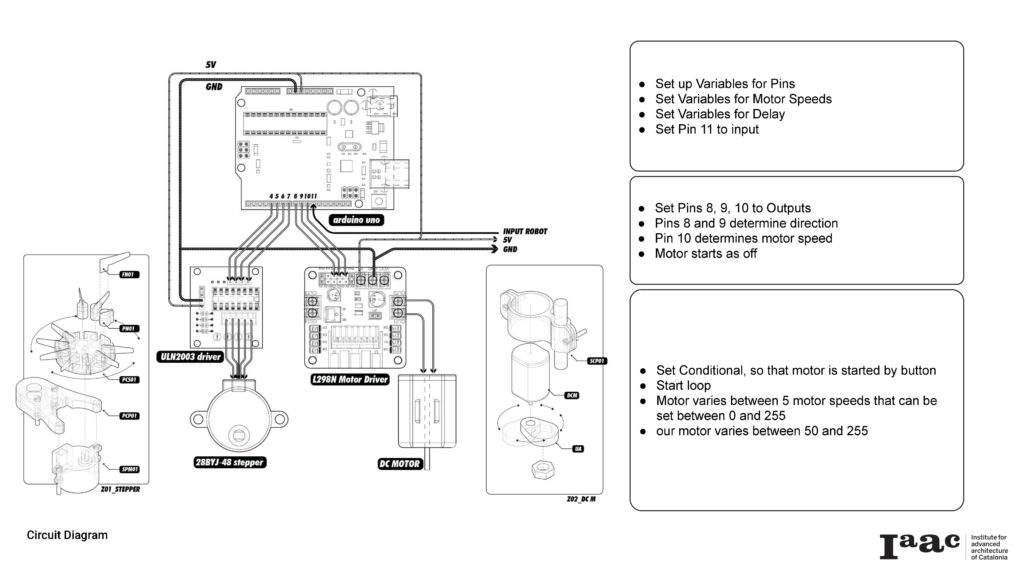

The electronics section details the system’s control architecture, including the motor, potentiometer, and driver circuitry. The circuit diagram provides a visual overview, while the code logic explains how different speeds, directions, and delays are implemented. This highlights the importance of a robust electronic foundation for achieving reliable and programmable performance. The integration of analog and digital components reflects the team’s focus on precision and flexibility.

7 | Circuit Diagram

This is a circuit diagram showing the manner in which the Arduino diagram is wired. Each element, from the input pins to the motor speed variables, is carefully annotated to explain its purpose. The logic ensures that the motor operates within a defined range, responding to user input for fine control. The modular design and positioning on the outside of the chassis wall allows for easy future enhancements, such as additional sensors or feedback mechanisms, to improve functionality.

8 | Output

A. Test 1: Hand Spilled

Early trials involved manually spilling liquid to observe basic patterns and reactions, providing an initial sense of the system’s potential.

B. Test 2: Small Robot

Using a small robotic setup allowed for more controlled and precise interactions, demonstrating the device’s ability to produce repeatable effects.

C. Test 3: Large Robot

Scaling up to a larger robotic system tested the device’s performance under more demanding conditions, revealing areas for optimization.

8 | Limitations

Challenges faced during the project included difficulty in producing clear standing wave patterns and the uncertain relationship between system variables like motor frequency and fluid behavior. The efficacy of the hitter design remains unproven, and ensuring consistent reproducibility is an ongoing challenge. By identifying these limitations, our team sets the stage for targeted improvements in future iterations.

9 | Future Optimization

Proposed optimizations focus on advancing both the hardware and software aspects of the system. Key ideas include experimenting with nozzle shapes to refine flow dynamics, mapping frequencies to create diverse motion patterns (e.g., musical applications), and ensuring consistent fluid pressure with enhanced receptacle designs. The integration of electronically actuated valves represents a significant step toward achieving greater control and precision. These enhancements aim to expand the system’s versatility and reliability.

10 | References

- Cantilever beam vibration mode shape functions | download scientific diagram. Available at: https://www.researchgate.net/figure/Cantilever-beam-vibration-mode-shape-functions_fig1_261145369 (Accessed: 11 November 2024).

- byjgagneastro, P. (2020) The physics of kettle streams, Coffee ad Astra. Available at: https://coffeeadastra.com/2020/05/23/the-physics-of-kettle-streams/ (Accessed: 11 November 2024).

- Figure 2. (a) the sinusoidal perturbation applied on a parameter P, and… Available at: https://www.researchgate.net/figure/a-The-sinusoidal-perturbation-applied-on-a-parameter-p-and-the-square-wave-function_fig2_271724917 (Accessed: 11 November 2024).

- Portillo, D. https://www.researchgate.net/figure/Oscillatory-fluid-motion-within-a-fluidic-oscillator-at-various-phase-angles-PH_fig1_353538440