Structural Optimization Process

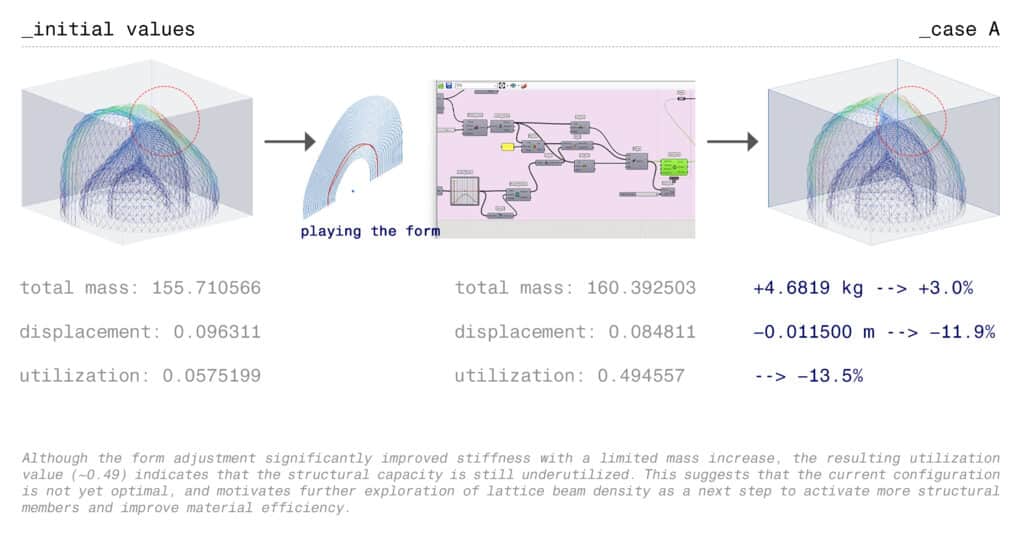

This project investigates the structural optimization and fabrication-aware design of a temporary lattice pavilion. The study focuses on the relationship between architectural form, structural performance, and robotic fabrication constraints, with particular attention to displacement control, material efficiency, and buildability.

The pavilion occupies an 8 × 8 m footprint with a total height of 6 m, and is conceived as a lightweight, continuous lattice structure that defines a single circulation path. Rather than pursuing a purely form-driven outcome, the project evolves through iterative structural evaluations and performance-based decisions.

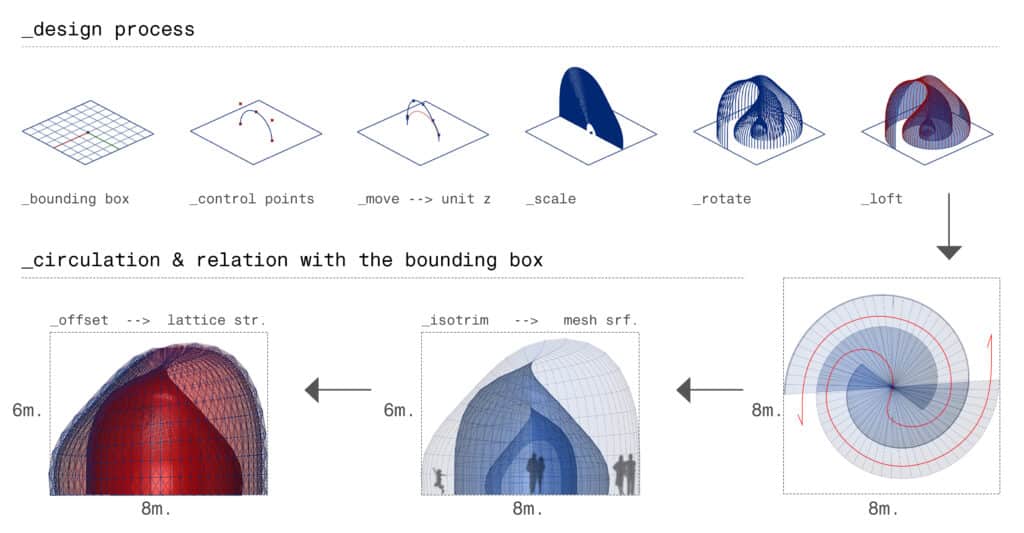

FORM FINDING

Within this boundary, a primary arch curve was generated as the initial geometric driver.

To avoid a rigid or repetitive form, the curve was re-interpolated and manipulated along unit Z values, introducing controlled variations in height and curvature. The curve was then scaled within a defined domain and rotated to generate a single continuous circulation path, reinforcing the pavilion’s spatial continuity.

The resulting surface was converted into a mesh, offset to introduce structural depth, and subsequently transformed into a lattice system using a crystallization-based approach. This process allowed the architectural form to be translated directly into a structural logic.

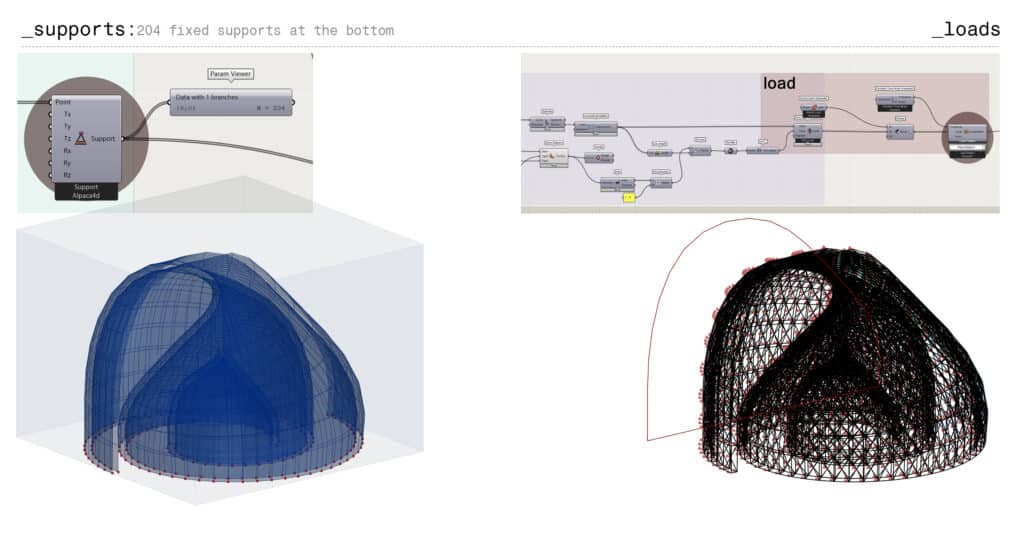

Structural boundary conditions were defined by placing 204 fixed supports at the ground-contact points of the pavilion. These fully restrained supports ensured that all observed displacements originated from the lattice behavior itself, allowing reliable comparisons between different design cases.

Two primary load cases were considered: gravity load representing self-weight, and wind load acting along the Y-axis. Due to the rotated geometry of the pavilion, the wind load was calculated using the projected silhouette area of the mesh. Wind pressure value of 0.08 kN/m² was applied and distributed across all structural nodes, ensuring that the loading conditions responded accurately to the pavilion’s exposed geometry.

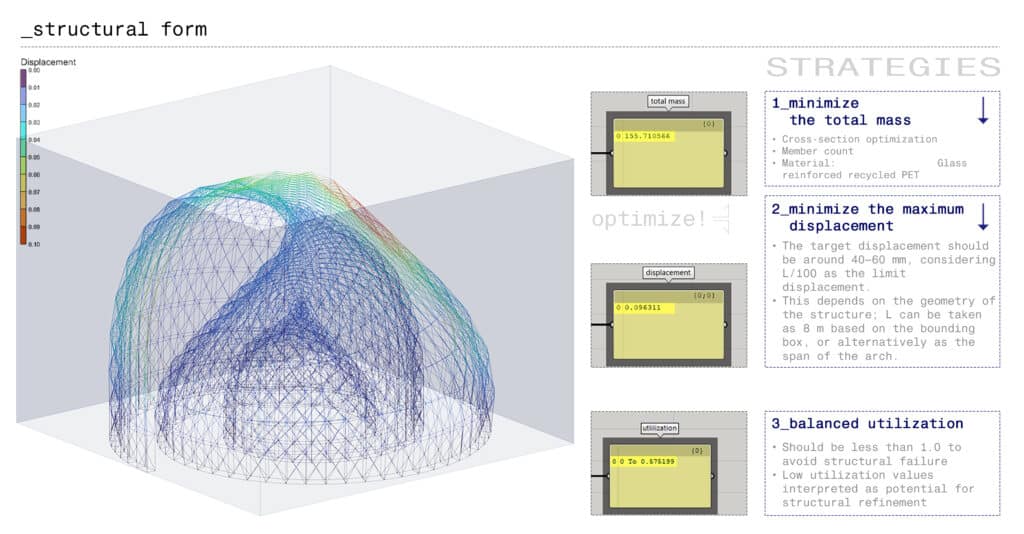

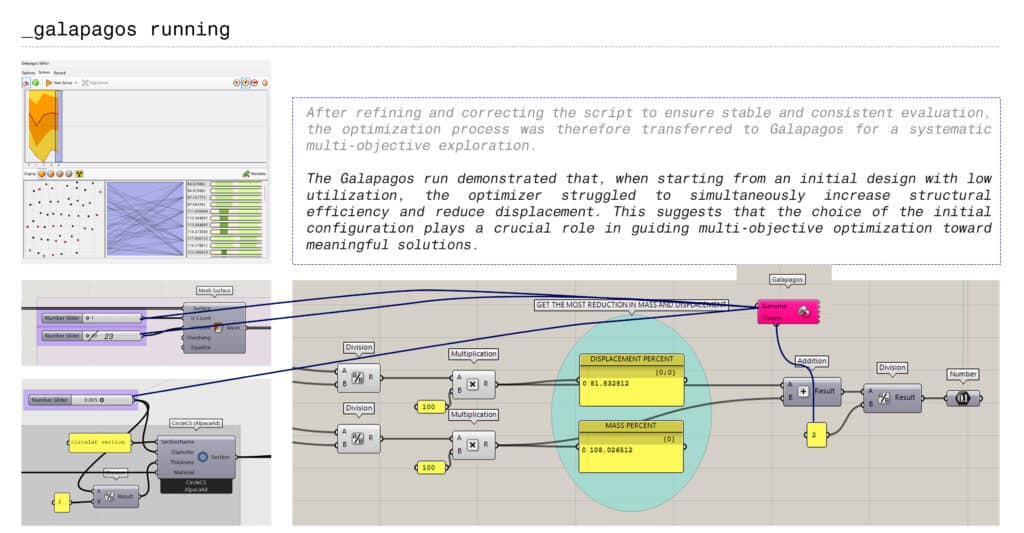

Structural strategies are defined to balance architectural intent with structural efficiency, and are evaluated through a set of performance-driven criteria.

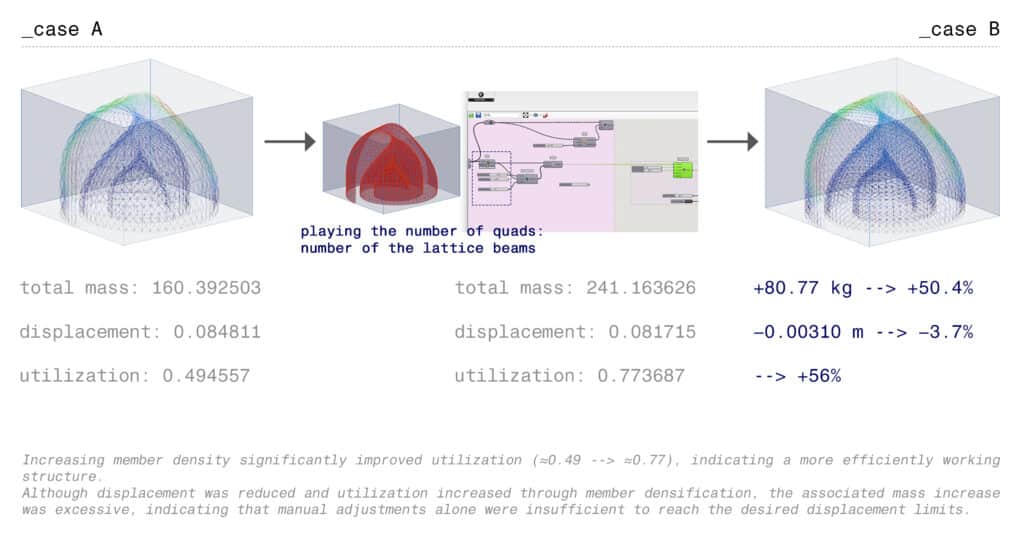

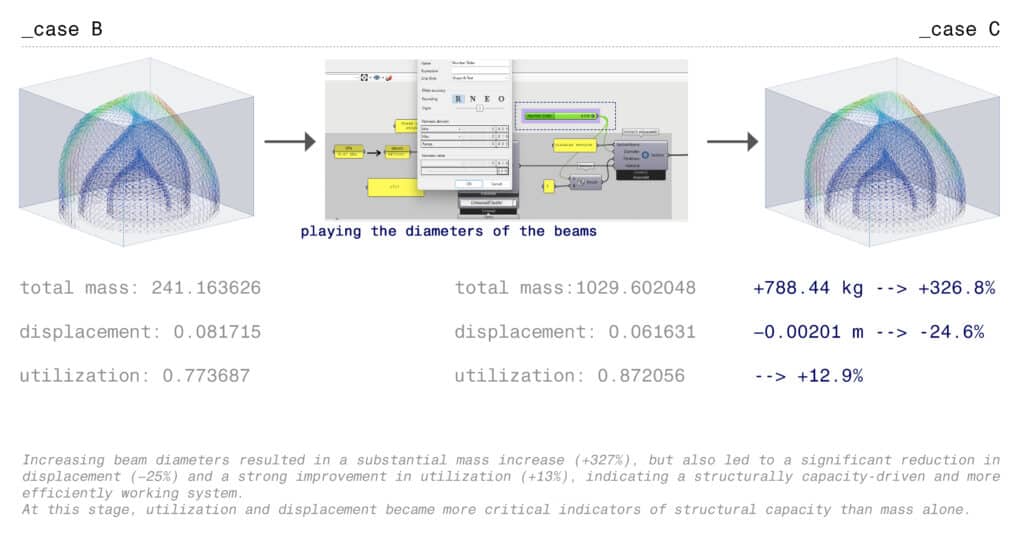

In this project, the optimization strategy is formulated around three primary metrics:

- Total mass, as an indicator of material quantity and overall lightweight intent

- Maximum displacement, representing structural stiffness and serviceability performance

- Utilization, measuring how efficiently the available material capacity is activated

The primary lattice was generated using BC Cubic unit cells, which provide continuous load paths and relatively isotropic structural behavior.

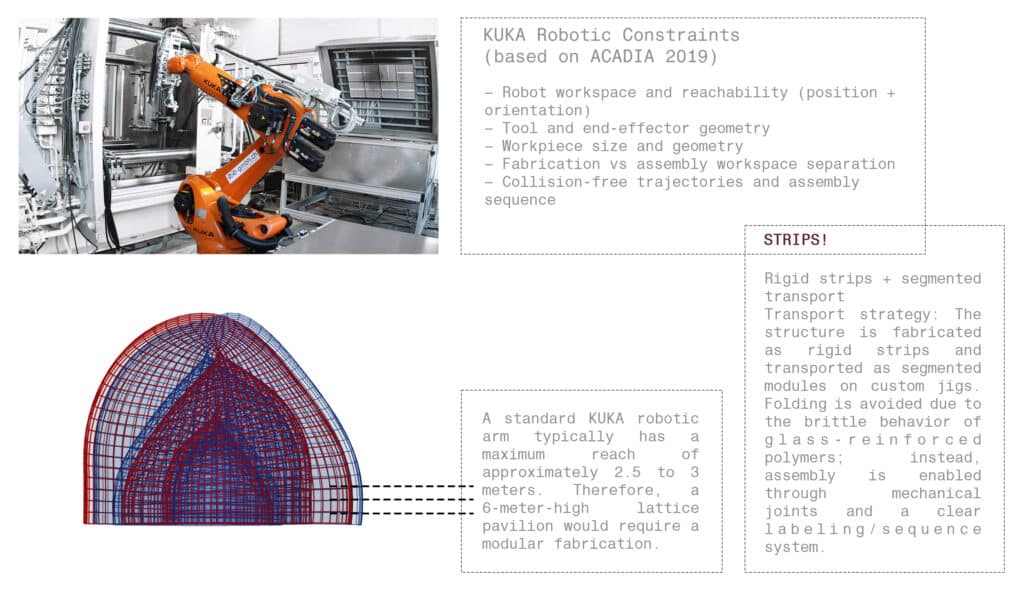

IDEAS ON MANUFACTURING

The pavilion is proposed to be fabricated using glass-reinforced recycled fiber, a material that is stiff and brittle, making post-print folding infeasible.

Given the 2–3 m reach limitation of KUKA robotic arms and the pavilion’s 6 m height, fabrication in a single piece is not possible, and lattice geometries further introduce collision risks during printing.

To address these constraints, the structure is conceived as rigid modular strips, robotically 3D-printed and assembled on site through mechanical joints and a clear labeling and sequencing system.