SITE

FORM INSPIRATION

CONCEPT

The project focuses on devising fabrication protocols for on-site assembly. Through computational tools and algorithms, we engage in a holistic design process, from initial concept to realization, fostering innovation in dynamic architectural forms. The research emphasizes visualizing form-finding processes, fabrication protocols, and assembly logic through diagrams and animations

FORM FINDING

“Project Lineage” represents a exploration that integrates physics simulations with architectural design, utilizing Kangaroo as a computational design tool. Inspired by the natural world, this research initiative delves into the creation of live-interactive installations through the manipulation of forces. The primary goal is to develop a user-friendly interface for real-time force manipulation, aiming to mimic natural behaviors in the form-finding process.

WORKFLOW

CATALOG OF DESIGNS

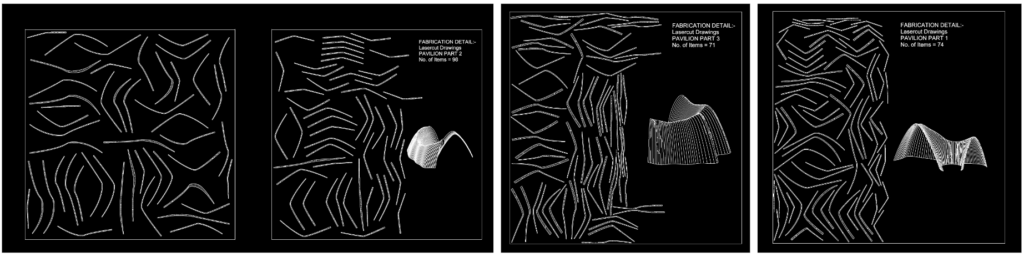

FABRICATION DWG

FABRICATION SEQUENCE

For the fabrication process, Using the Mesh Unroll function, the mesh was transformed into strips, facilitating the creation of laser-cut drawings. This iterative process, guided by computational design principles and tools, allowed for the efficient translation of digital models into tangible fabrication components. By harnessing the capabilities of Grasshopper, Kangaroo, and Mesh Unroll, we streamlined the fabrication workflow, ensuring precision and scalability in producing the components necessary for the realization of the dynamic and inviting pavilion design.

PAVILION PART 1

PAVILION PART 2

PAVILION PART 3

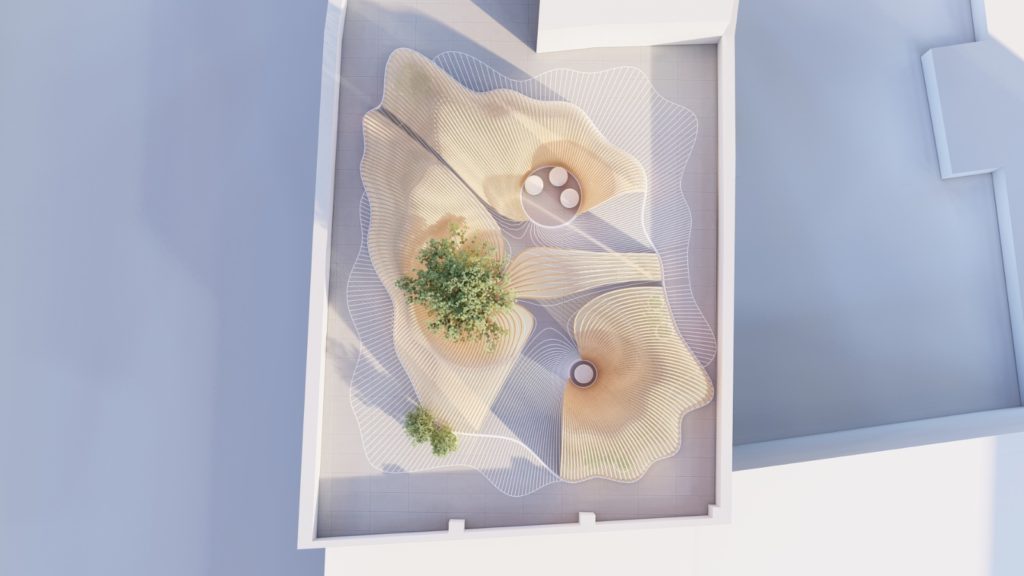

RENDERS

WALKTHROUGH