Playscape is a pavilion designed for children, crafted through robotic fabrication and guided by the principles of discrete architecture. The project utilizes timber offcuts—irregular remnants from the construction industry—as the primary material, transforming waste into a functional and playful architectural form.

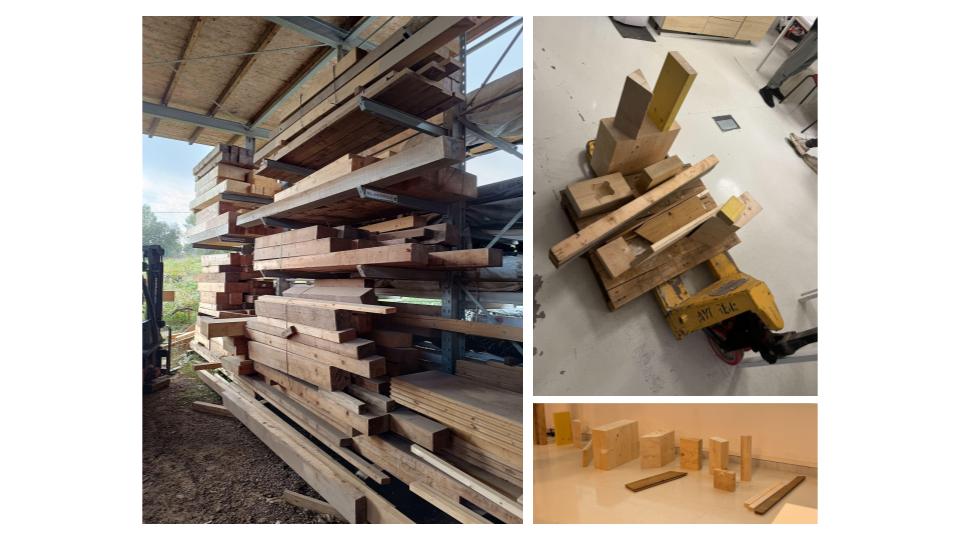

For this workshop, the material provided consisted of irregular wooden beam offcuts which served as the primary resource for the project. The design brief challenged us to leverage robotic fabrication techniques to create a system that transforms these irregular materials into functional architectural elements, demonstrating the capabilities and justification for robotic processes.

Case study

A relevant case study that informed our approach was Kengo Kuma’s Moku Yama project, which utilized wooden sections with dimensions similar to our beam offcuts. Inspired by the efficient use of large cross-sections in Moku Yama, we aimed to minimize material processing and maximize the potential of the timber offcuts. The inherent randomness of Moku Yama’s design provided a compelling precedent, aligning with the added complexity of our project brief, which involved irregular offcuts. Recognizing the challenges of working with these irregularities, we leveraged robotic fabrication as a crucial tool to optimize the construction process. This led us to explore computational design strategies to creatively and effectively utilize the unique properties of the timber offcuts.

The Design Process

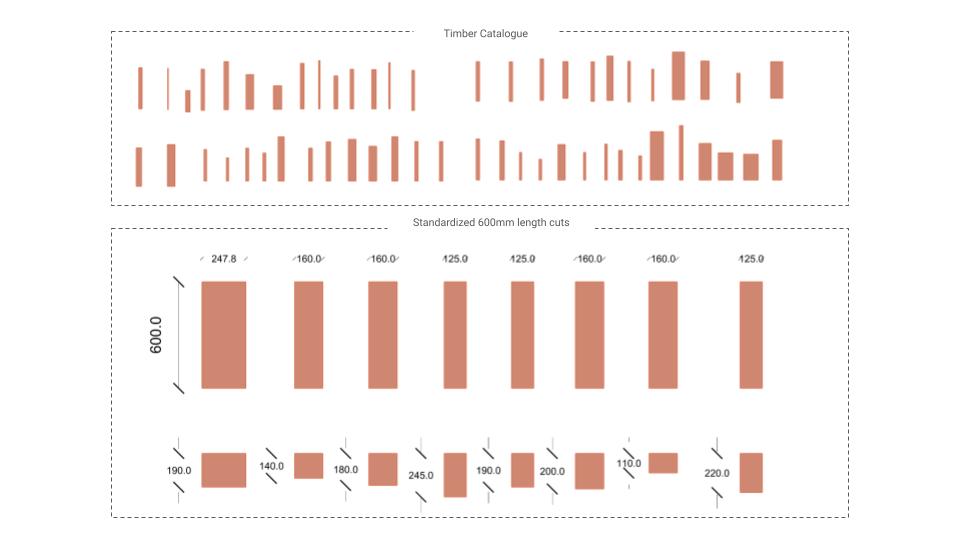

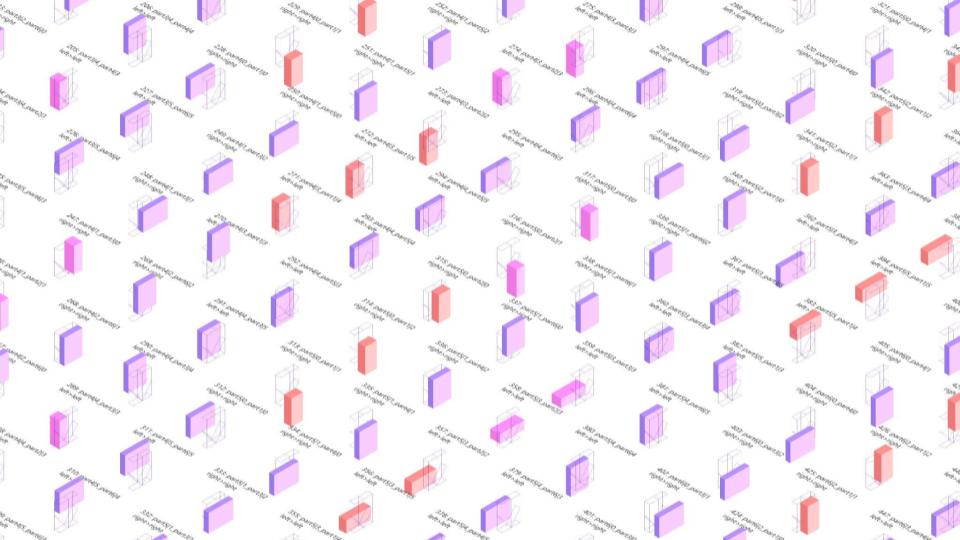

The design process commenced with cataloging the various cross-section sizes available for construction. Once this catalog was complete, a material library was created to organize the data. This information was then input into a Grasshopper script developed to filter the cross sections based on size. Super slender cross sections falling below a designated threshold were set aside for use as dowels and supports. Cross sections exceeding the upper limit were processed to fit within the usable range, ensuring efficient utilization of all available material.

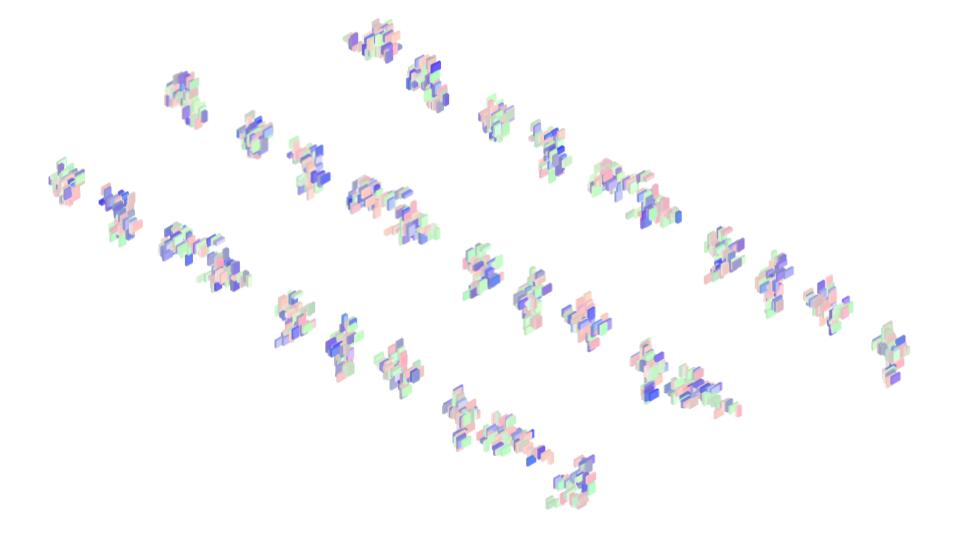

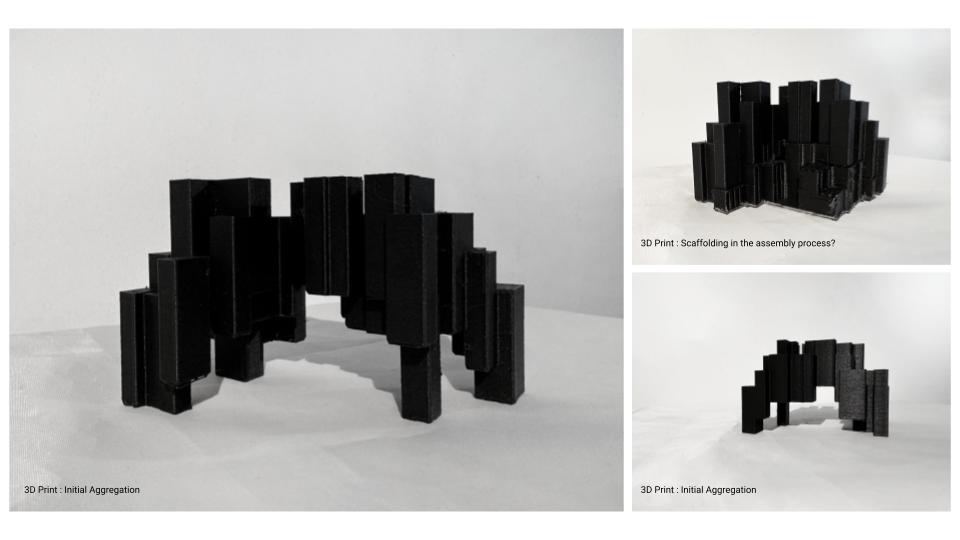

Initial Aggregation Studies and Prototyping

As we developed our aggregation method, we initially focused solely on the cross-sections. However, we quickly realized that the structure was growing vertically at a faster rate due to the longer lengths of the offcuts. This posed a challenge, as it compromised the pavilion’s suitability, particularly with children’s ergonomics in mind. Additionally, in a real-world scenario, the offcuts available for such a project would likely be shorter. With this in mind, we aimed to design a system that could be replicated across various contexts and material conditions.

During the development of the pavilion’s aggregation, we realized that standardizing at least one parameter—the length of the wooden offcuts to 600mm—would significantly streamline the computational process. This standardization not only accelerated the design workflow but also allowed the pavilion to expand more horizontally, enhancing its structural coherence. This fixed length also offered anthropological benefits, making the pavilion more suitable as a climbing structure for children, ensuring both functionality and engagement.

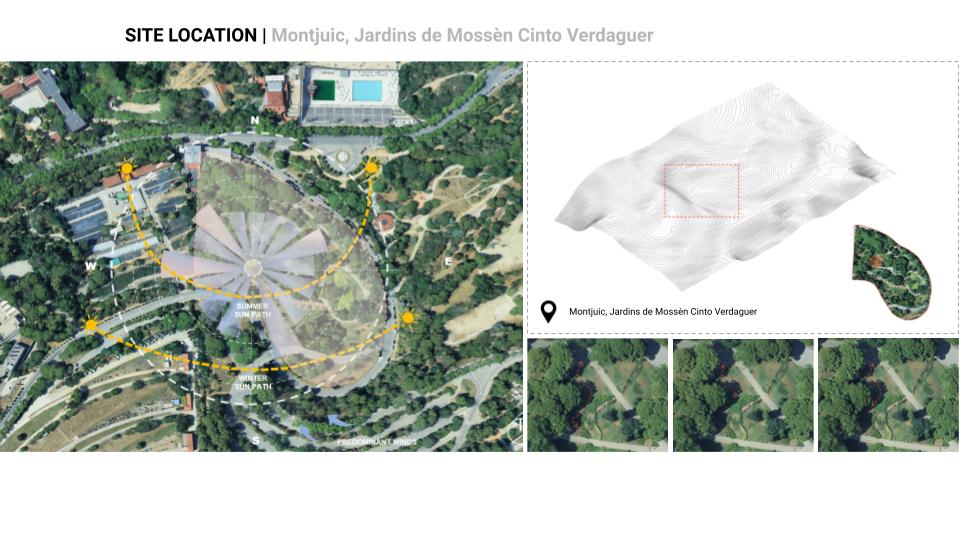

The Site

After contextualizing the project at Montjuïc, specifically at the Jardins de Mossèn Cinto Verdaguer, we began incorporating new parameters into the aggregation to ensure it responded to the surrounding environment. The structure was designed to follow a curve derived from the projections of the surrounding landscape, allowing it to blend seamlessly into the context. We also introduced additional parameters, such as a maximum height limit, to ensure the pavilion remained within a safe range and reduced the risk of injury.