ChromaEnergon

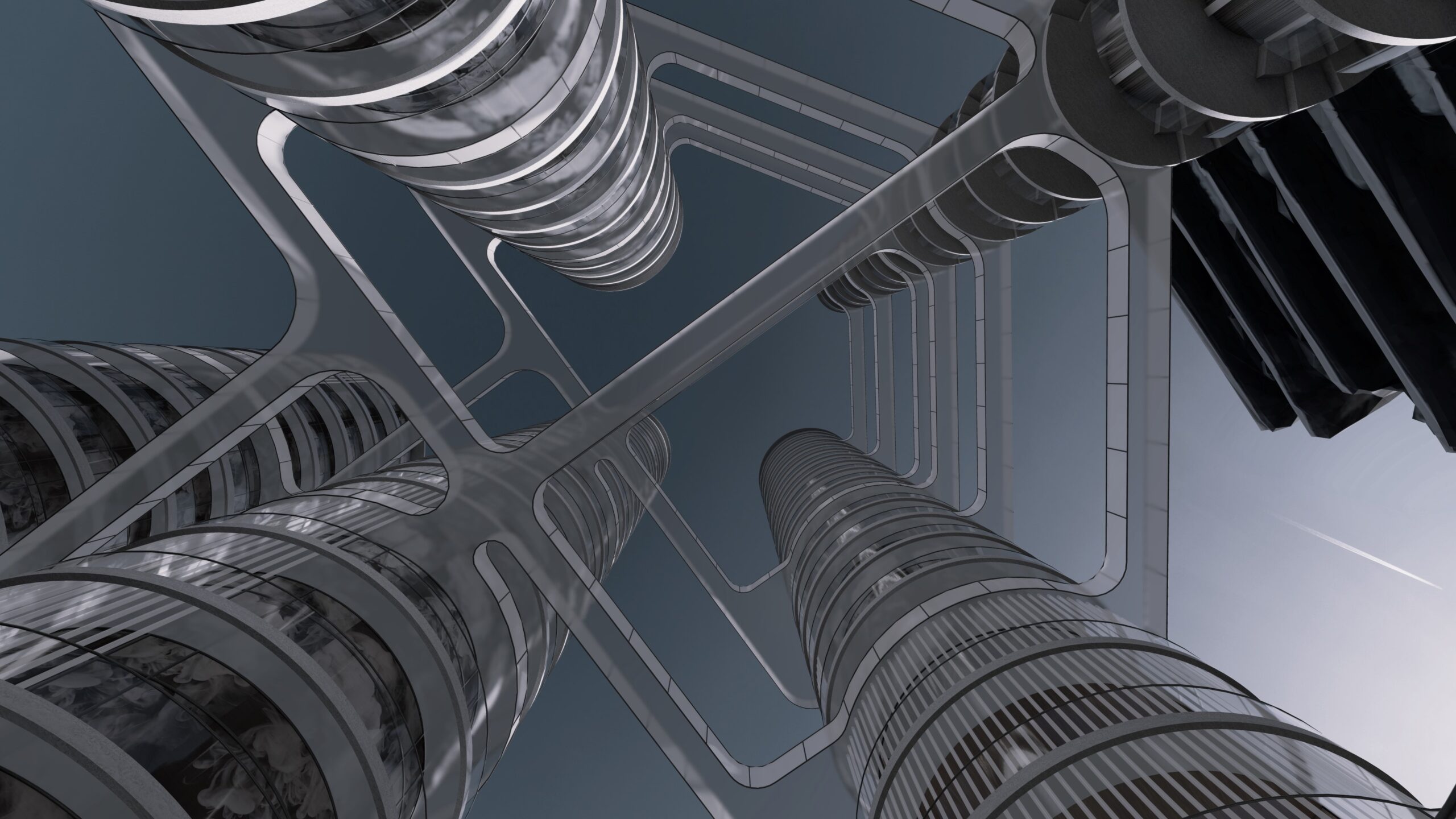

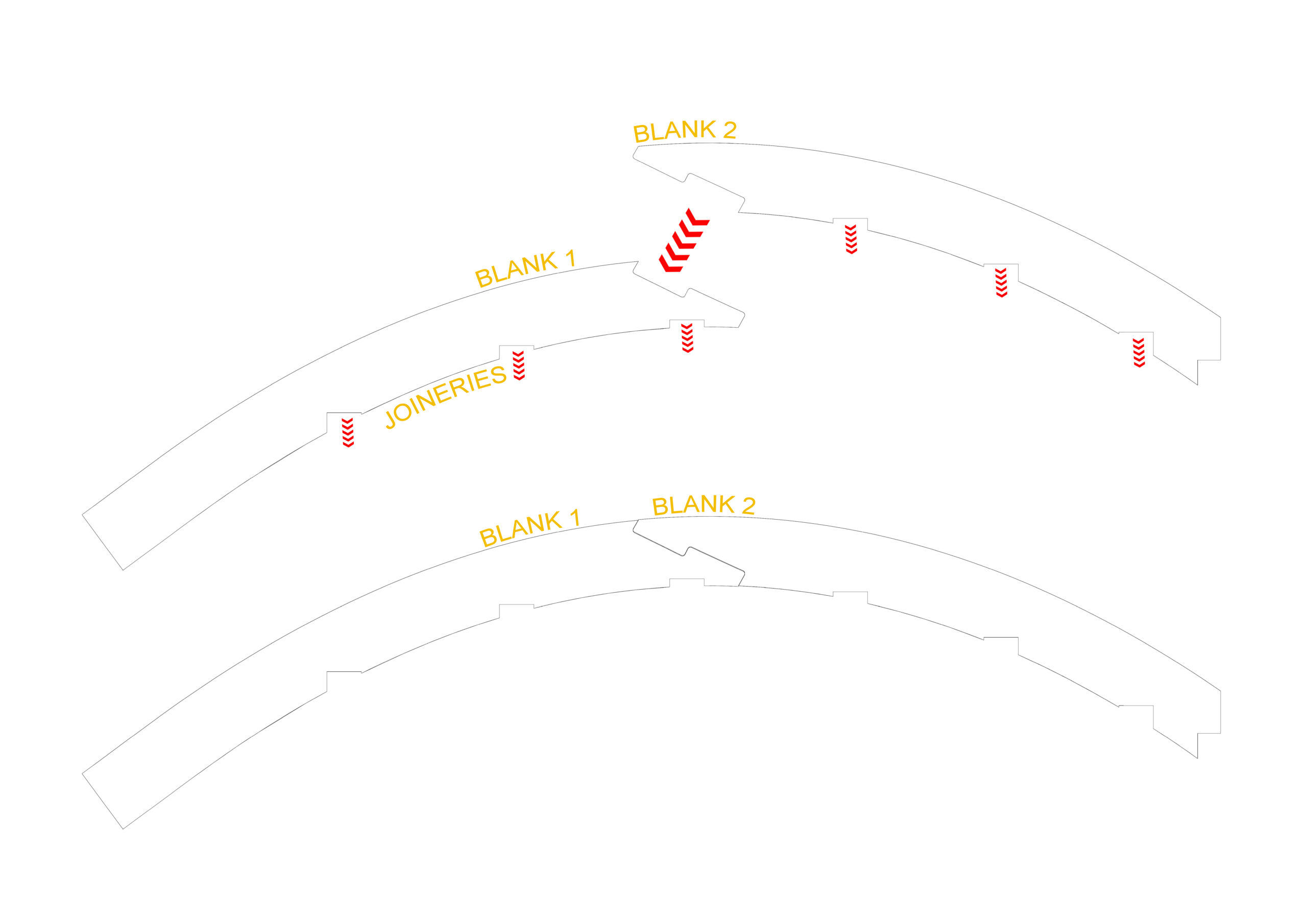

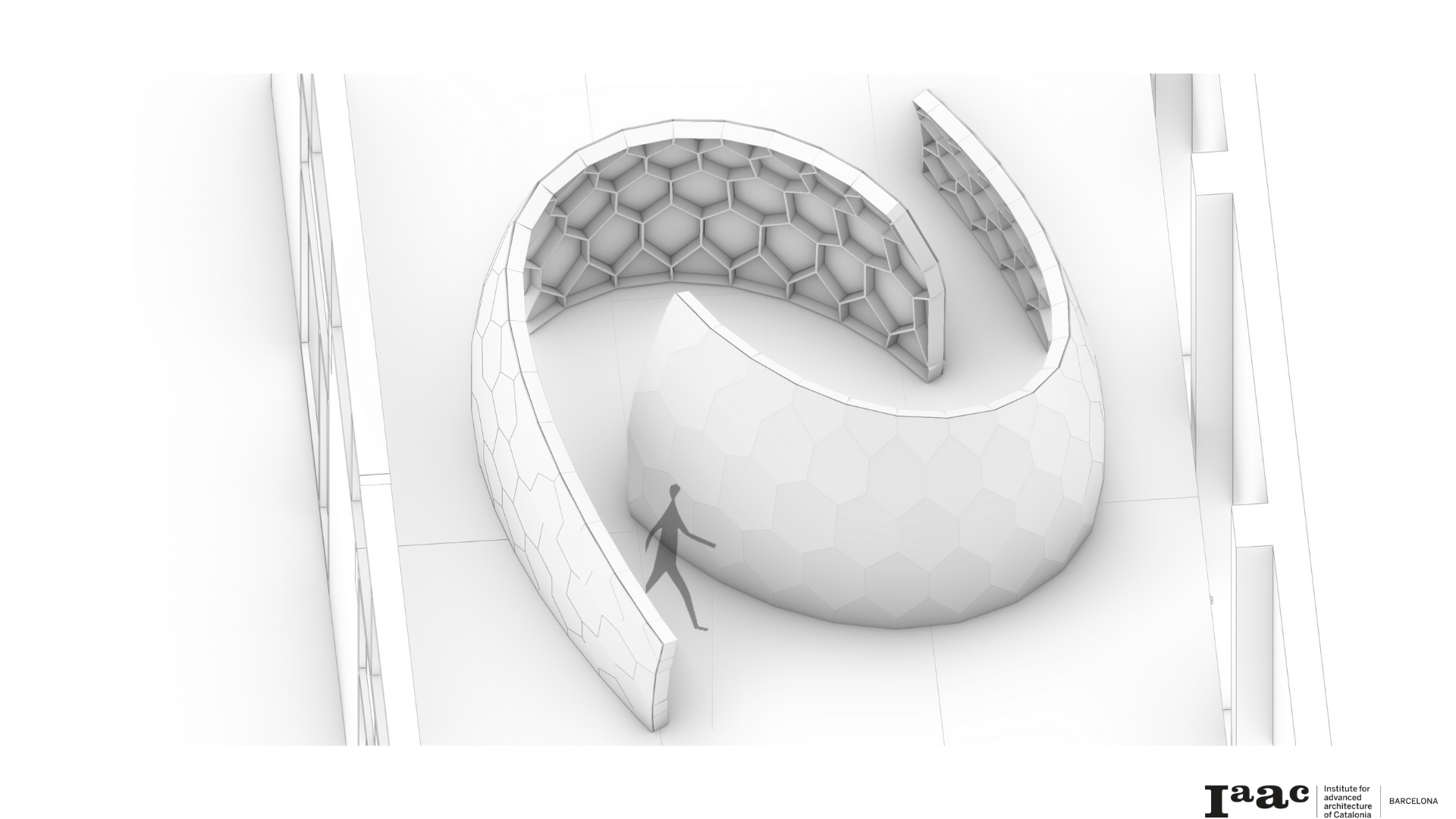

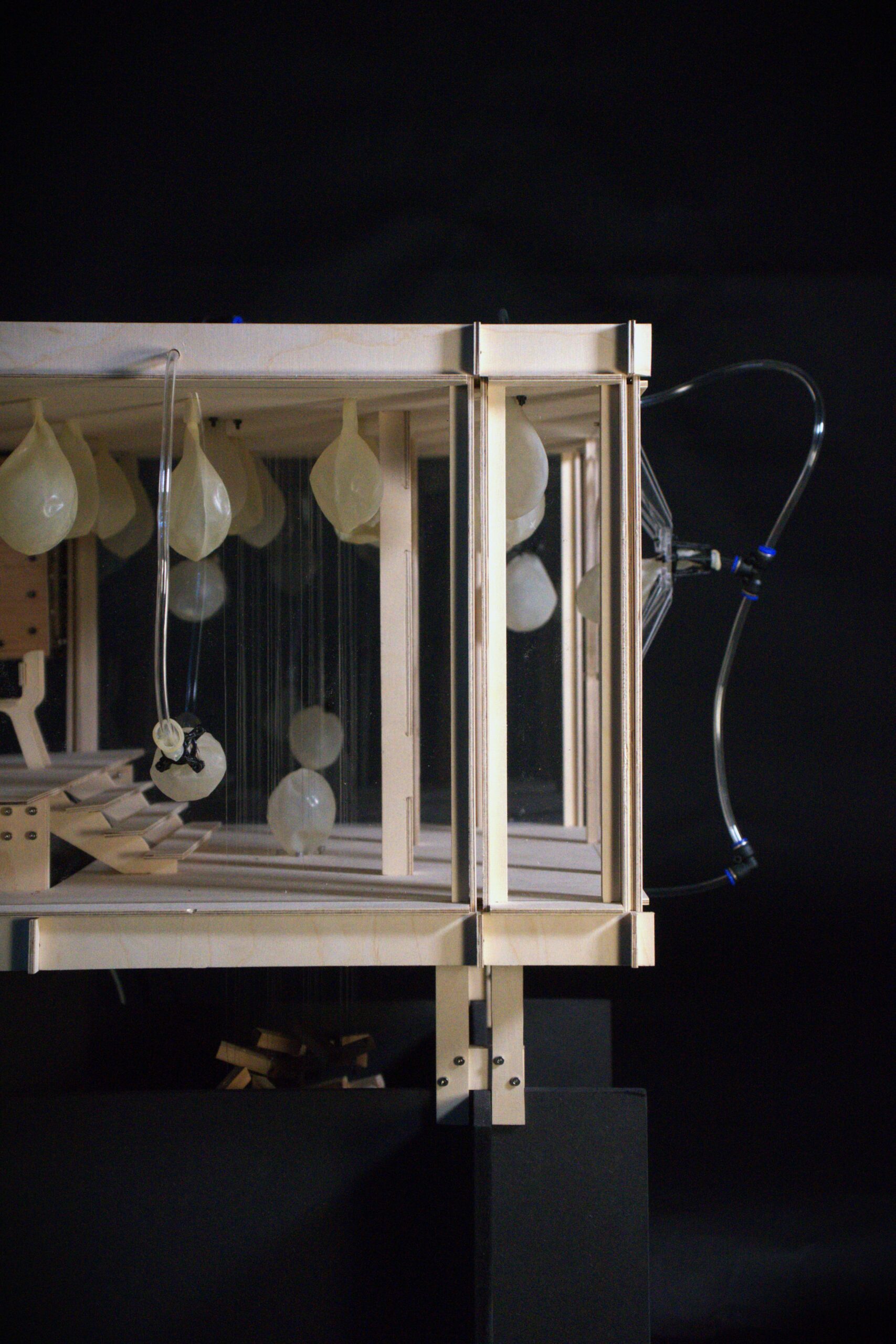

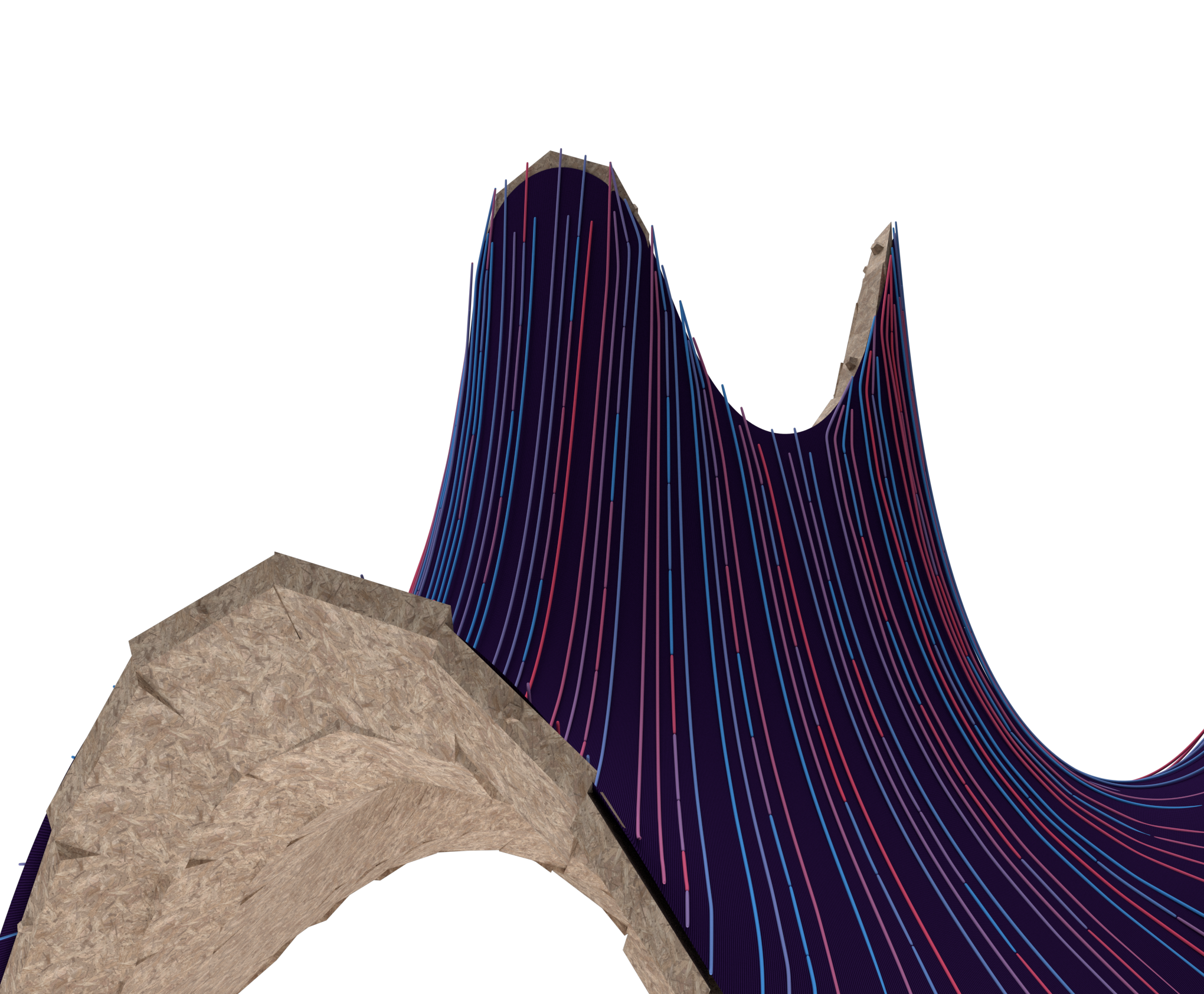

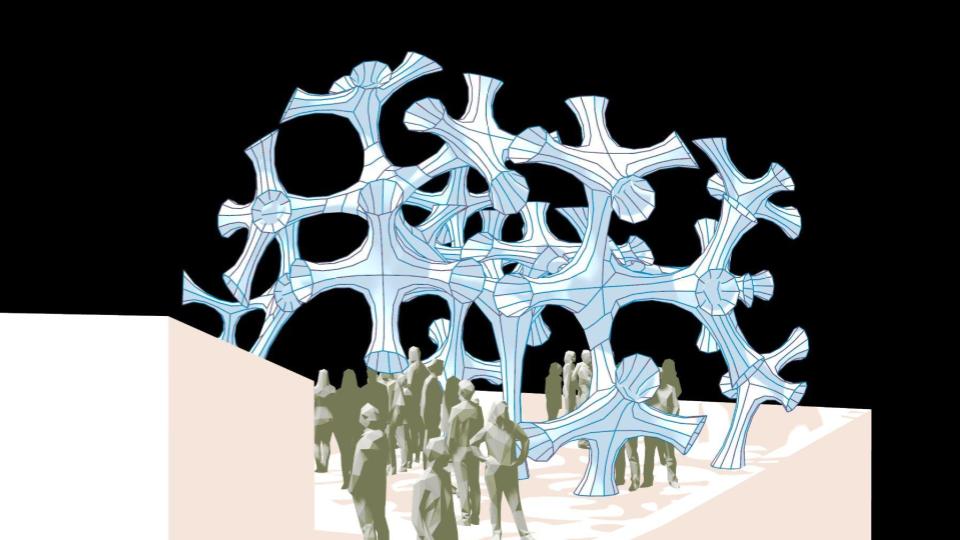

ChromaEnergon represents an innovative approach to student housing architecture that transcends conventional design paradigms tapping the potentials of climatic energy and thermochromic pigments. This concept leverages verticality, slenderness, and dispersed tower structures to create dynamic living environments. By strategically mapping energy into various spaces through the skin which the facade, ChromaEnergon aims to generate unique … Read more