TerraWeave: Startup Pitch

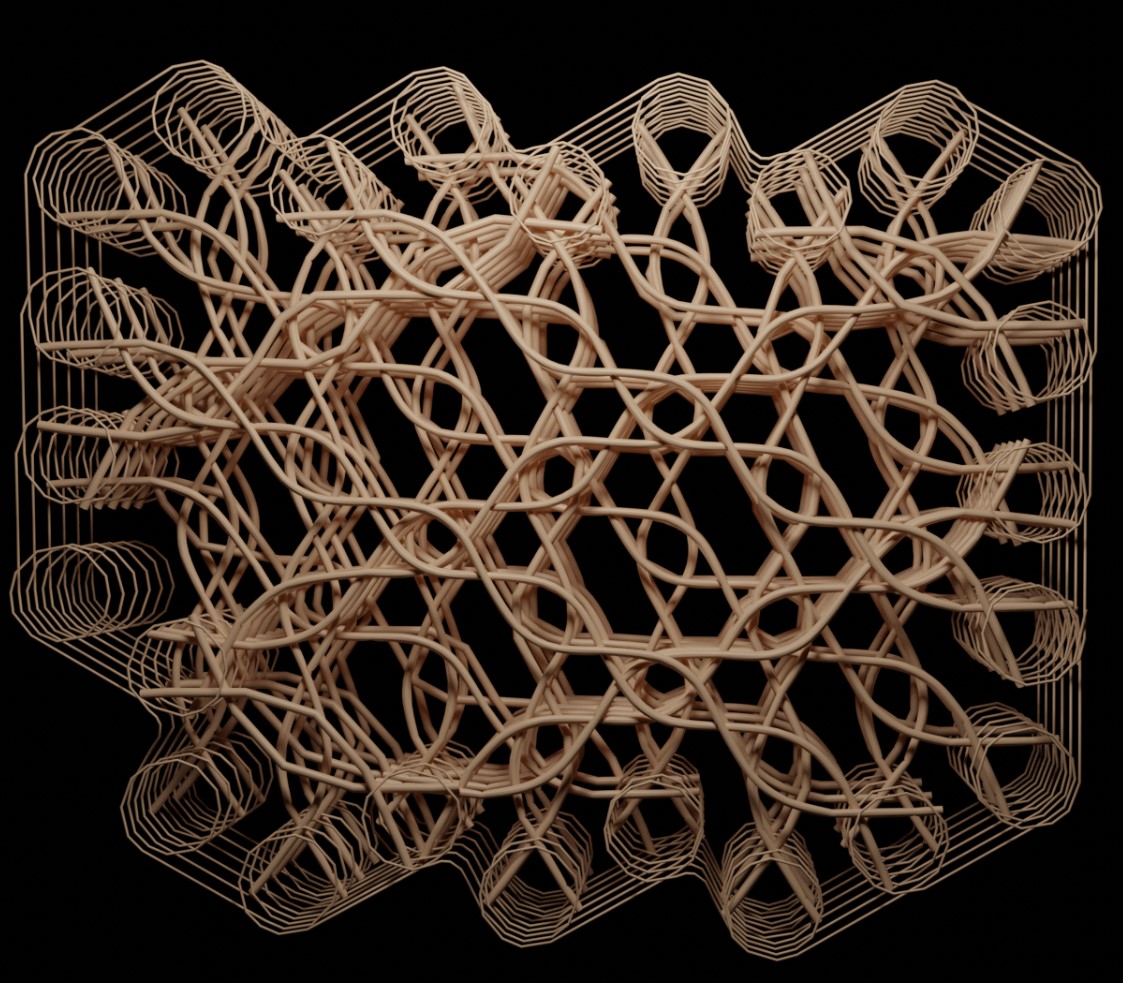

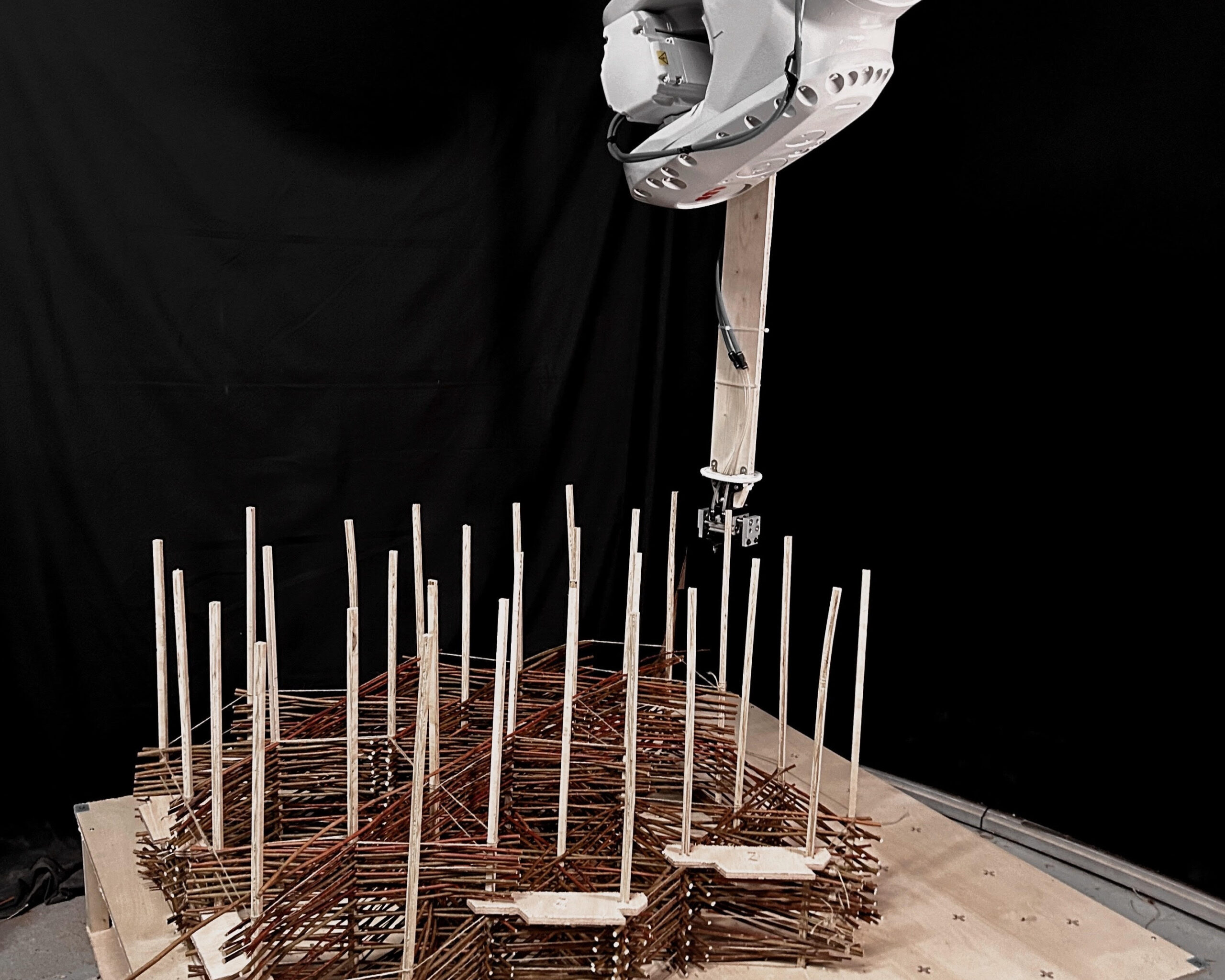

The Problem The built environment is responsible for 42% of annual global CO₂ emissions. Within this, building operations and construction alone contribute nearly one-third. Yet, current construction methods lack flexibility, efficient resource use, and environmentally friendly solutions. This is the context that drove our project. Terraweave Solution TerraWeave integrates robotics, wattle and daub construction and … Read more