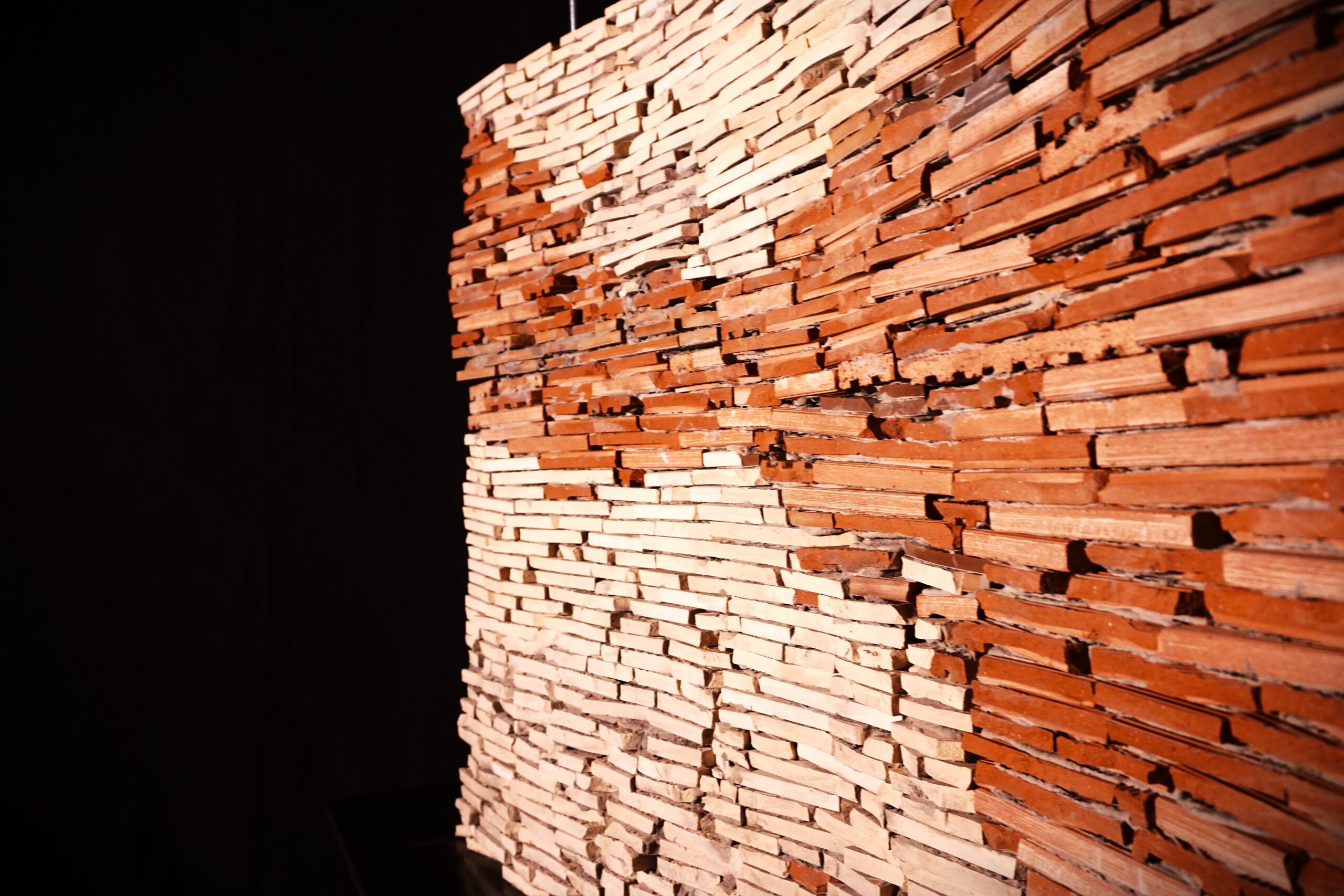

Timber Narratives

Building on the principles of disassembly explored last semester, this phase of the Timber Narratives project delves deeper into advanced data-driven design strategies. We now capture and utilize timber colour values through enhanced scanning technologies, integrating this data into our designs. Additionally, we’ve implemented machine learning with logistic regression for precise categorization of timber for … Read more