Workshop 1.2: Data To Motion

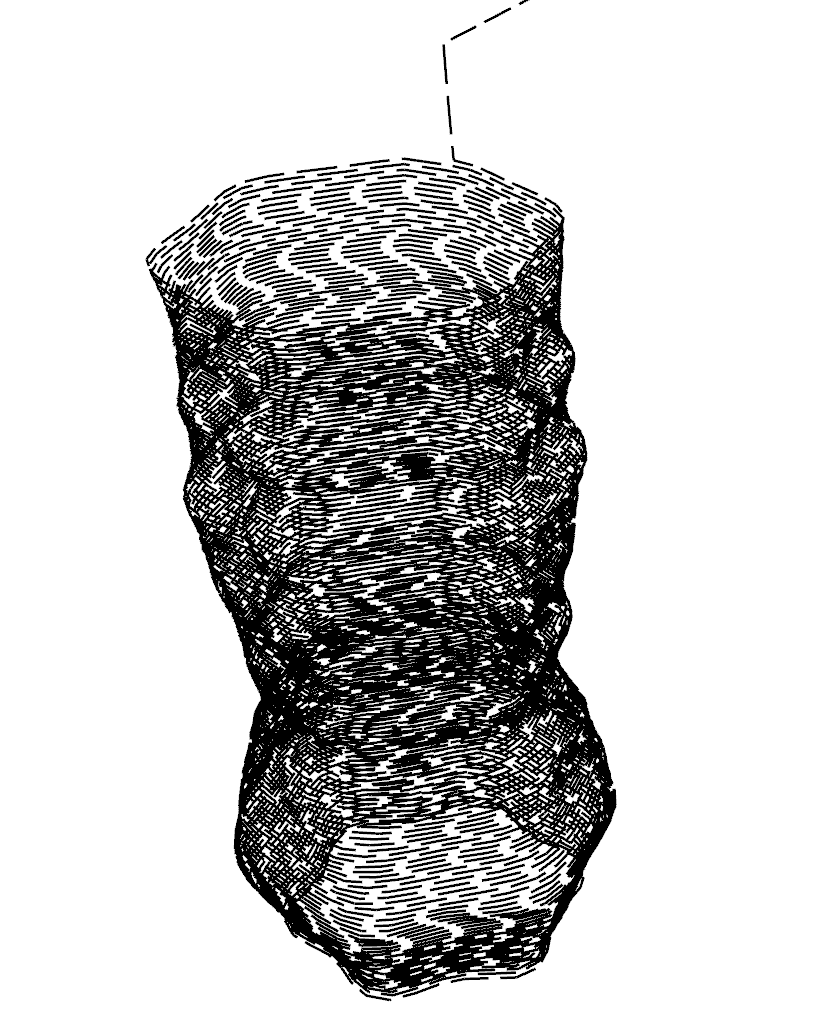

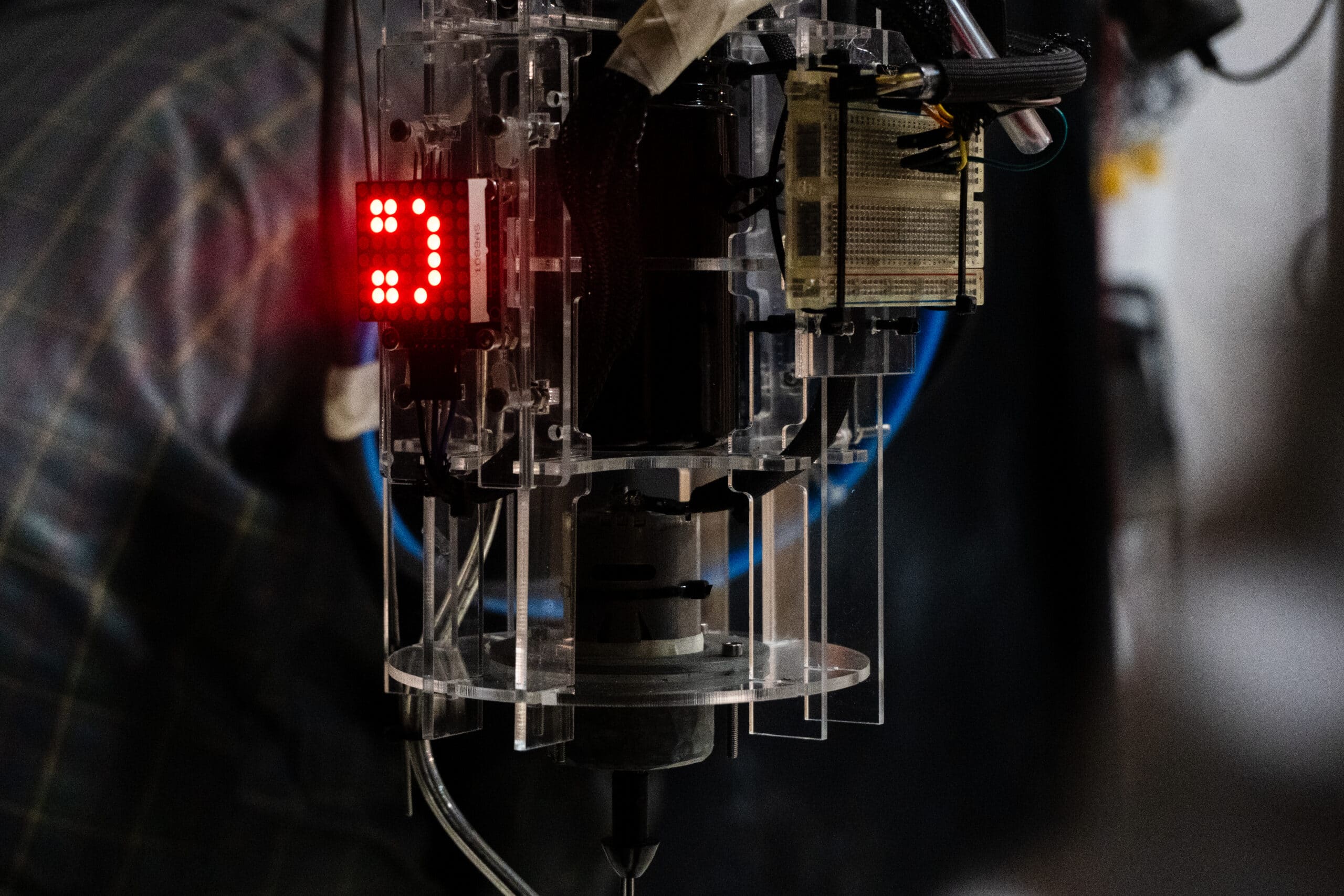

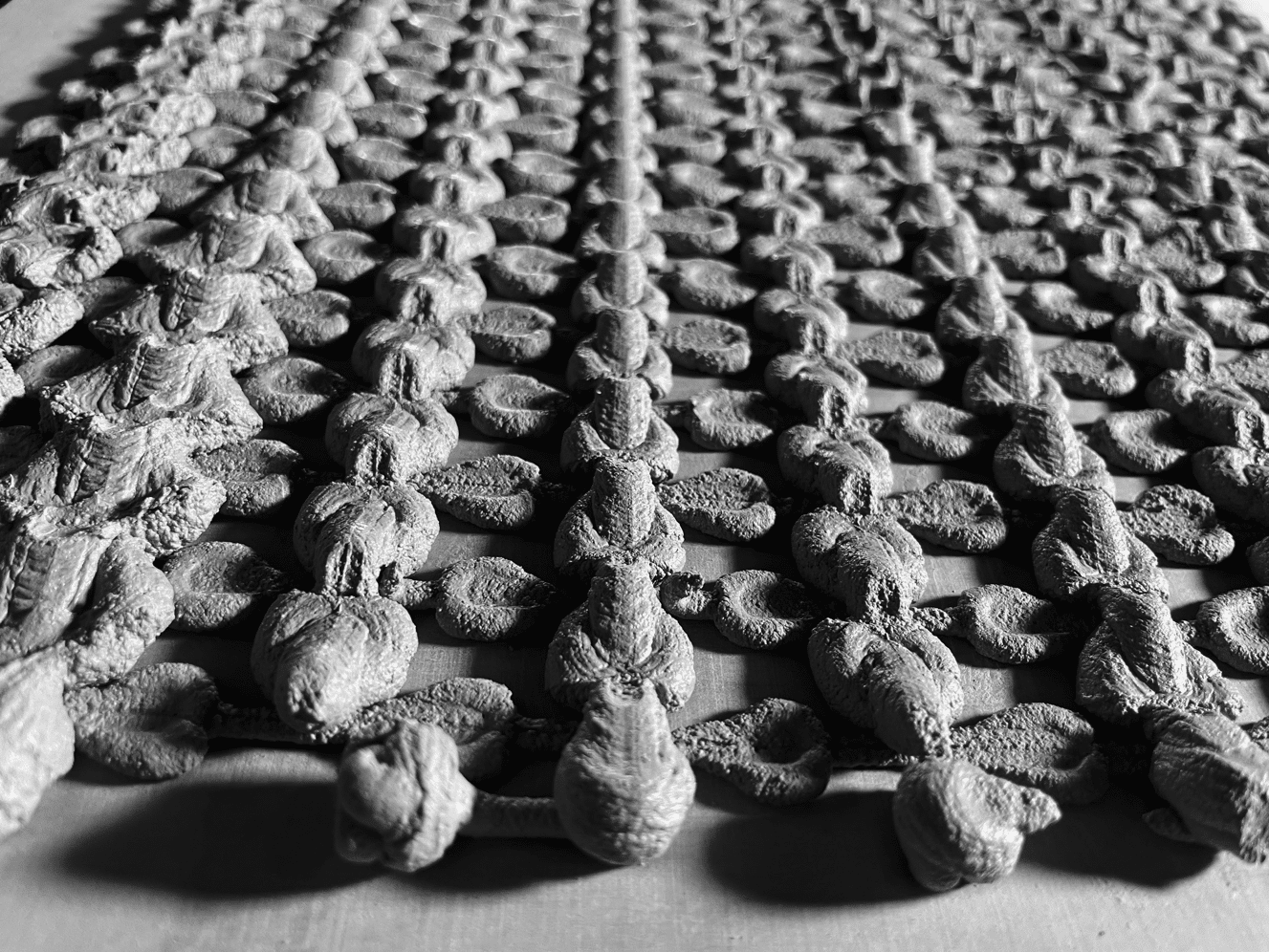

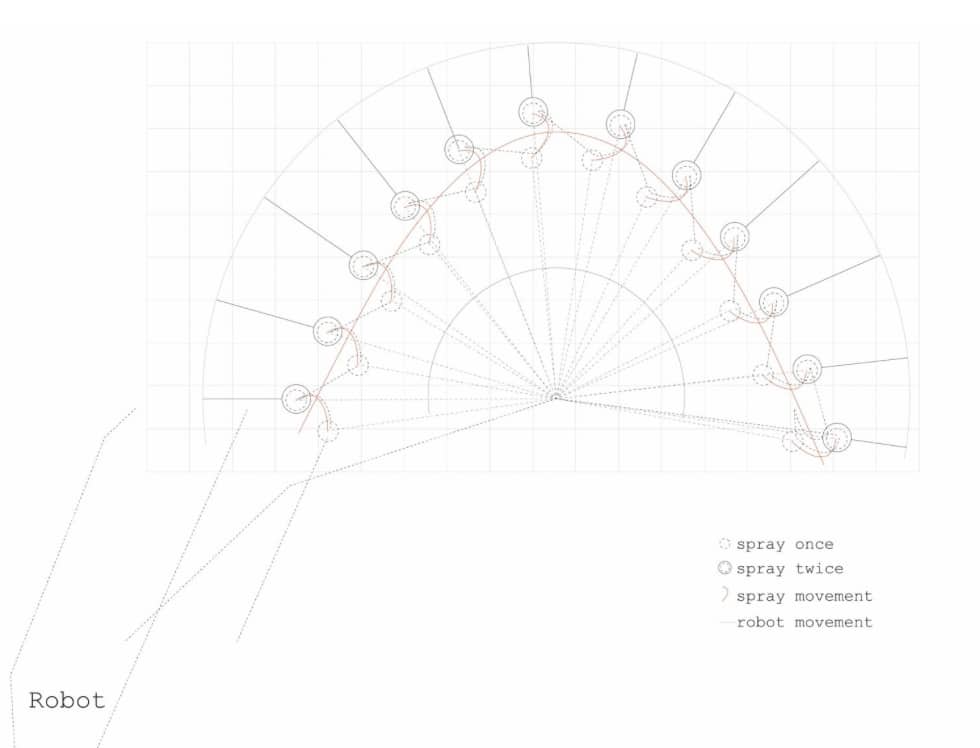

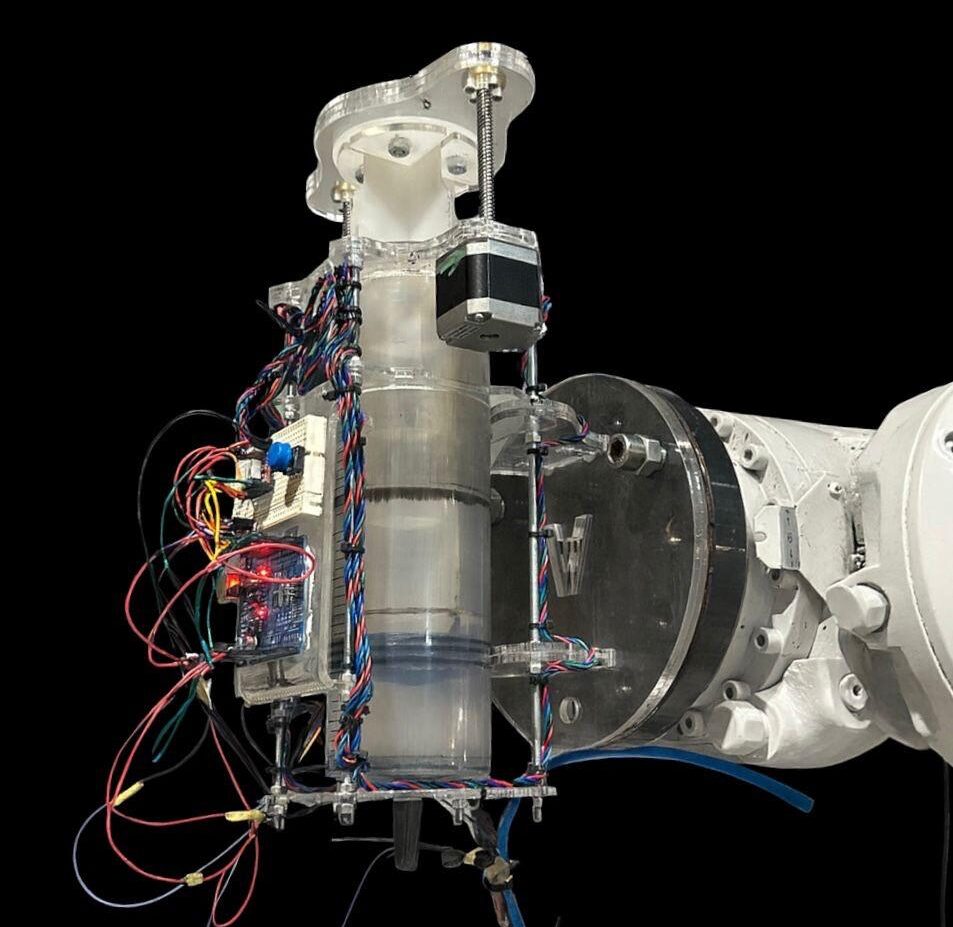

Collaboration with University of Linz Data to Motion: using PCA to represent laughter in a cup The idea for our project was to capture the laughter shared in simple moments of joy and then use the data captured to edify and create vessels which would reflect these memories in their form. The first conceptual proposal … Read more