Ambient Public Mood Beacons-MRAC01

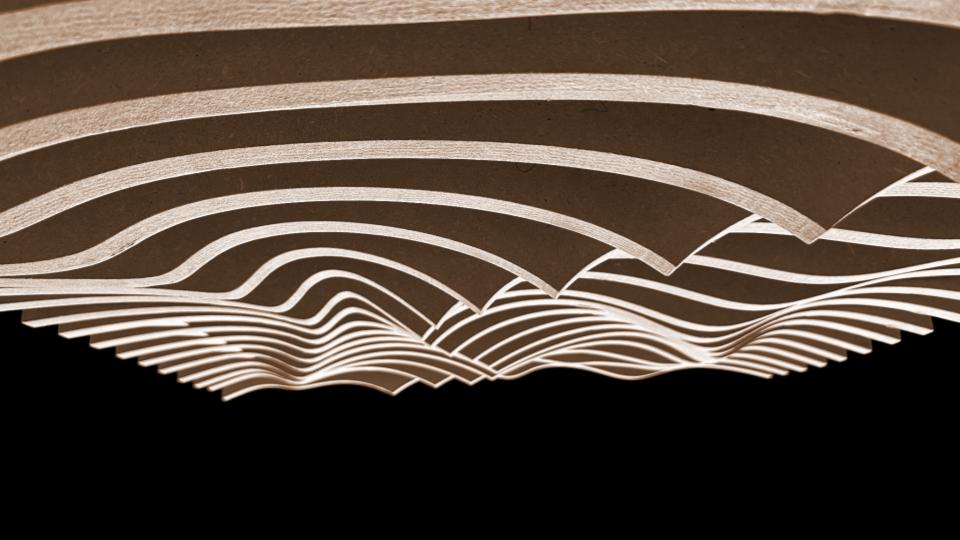

‘Urban Sensing Begins: The City Meets Its Beacons’ PLACEMENT — The Sensing GroundThe first beacons are placed along the park’s circulation spine silent observers that begin listening to the city’s rhythm. Sound, motion, and presence data start forming an invisible map of human interaction.At this stage, the system is not reactive, it’s learning.It introduces itself … Read more