GLOBAL WASTE GENERATION

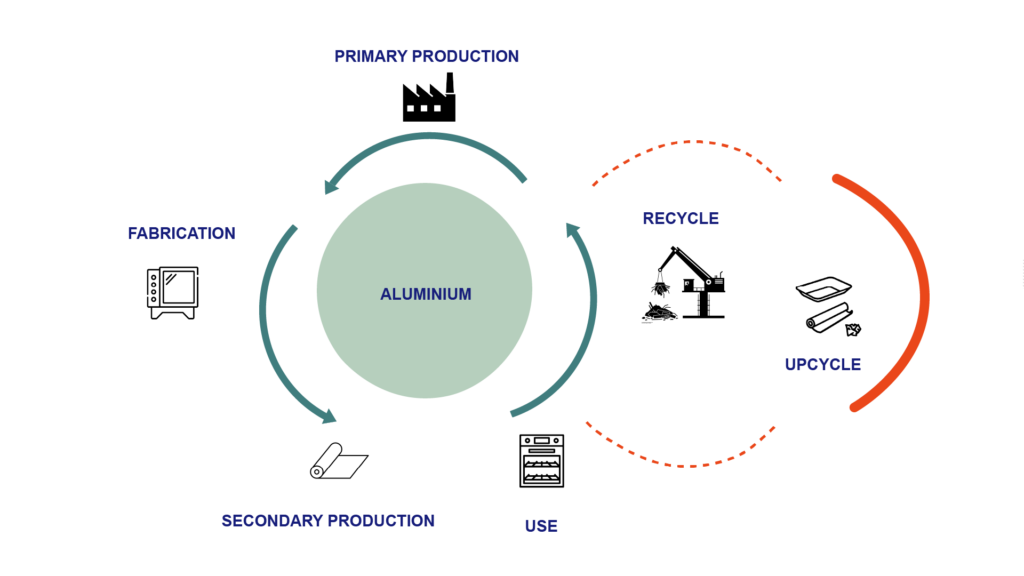

LIFE CYCLE

This project takes into account the potential of Aluminum and branches out just before recycling to reduce energy consumption in comparison to recycling. Although aluminium is highly recyclable, and energy efficient that only 5% of energy is needed to recycle it in comparison to primary production.

It is still energy intensive due to melting processes and the collection and transportation of it.

The project focuses on the re-use of aluminum, the strategy is to branch out from recycling and upcycle the aluminum scrap from machinery and equipment this modified lifecycle of Aluminum can be repeatedly implemented even after the end of life of upcycling.

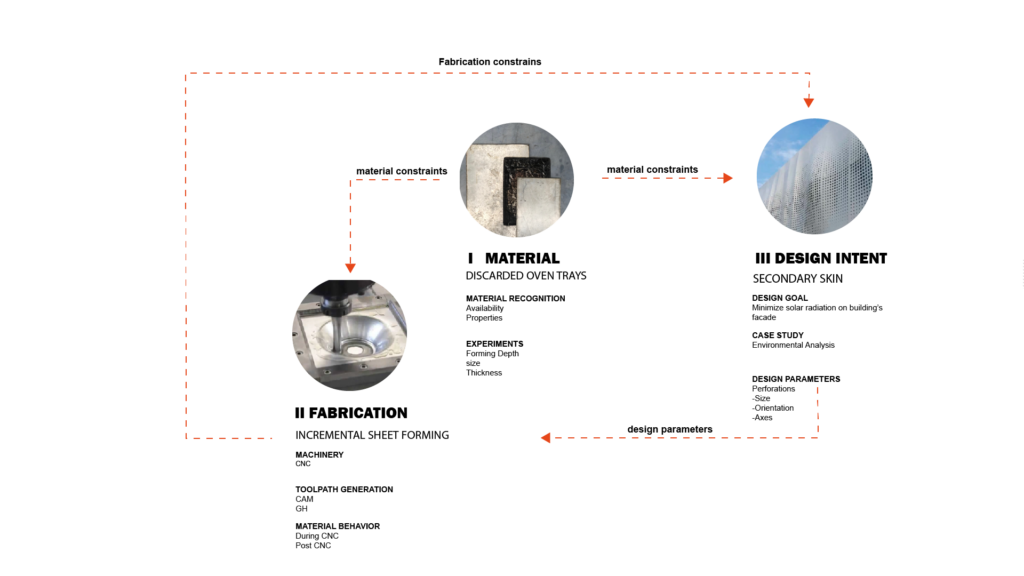

Mapping the Research

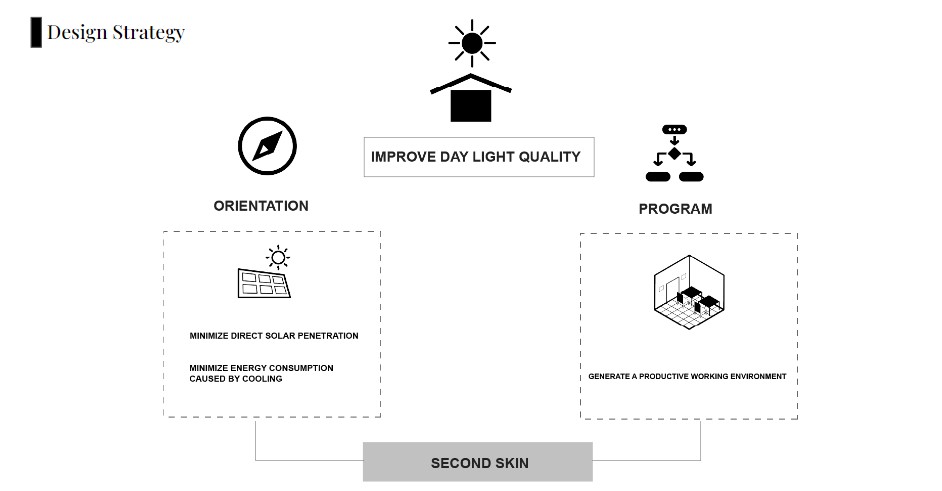

DESIGN STRATEGY

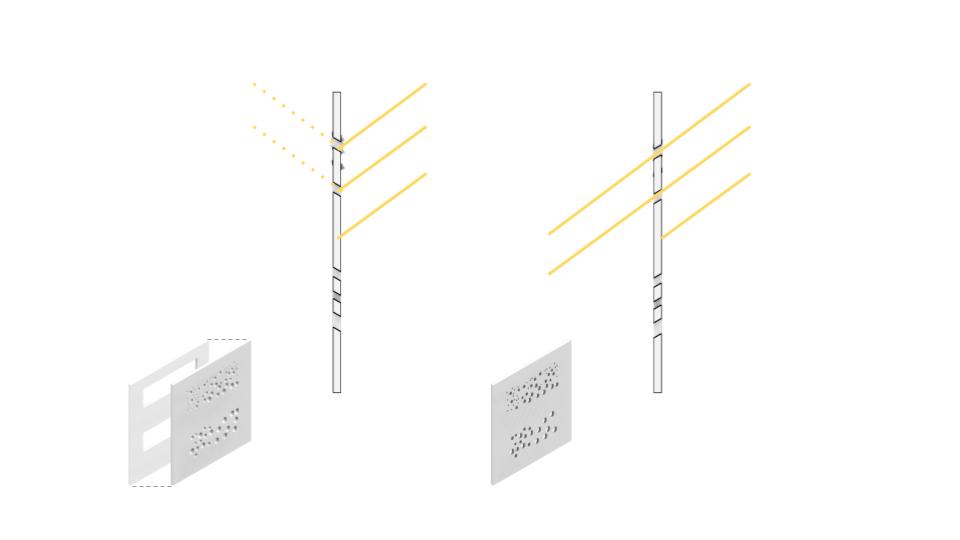

The main goals that informs the design strategy is the improvement of daylight quality and reduction of heat gain through the facade. This strategy relies on two main factors:

1. Orientation

2. The Spatial Program.

When it comes to orientation the main goal is to minimize direct solar penetration while still maintaining diffused daylight, as well as minimizing the energy consumption of the cooling systems of the building by reducing heat gain through the facade. When it comes to the program the goal is to foster a productive working environment so the intervention does not affect productivity.

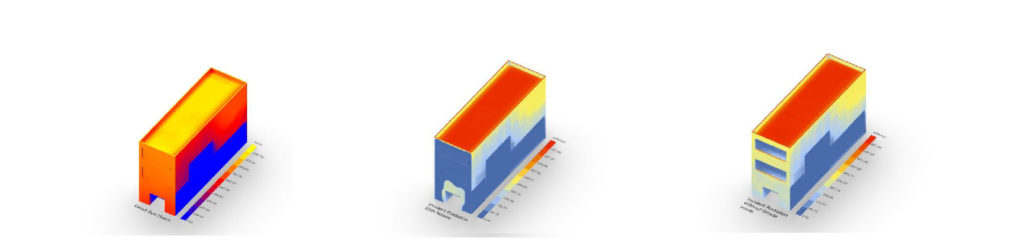

- Cultural del Centre d’Influència Catòlica

- Location : Gracia, Barcelona

- PROGRAM : Cultural & Educational

- ORIENTATION : South-East facing Main facade

- SIZE 5 x 10 m

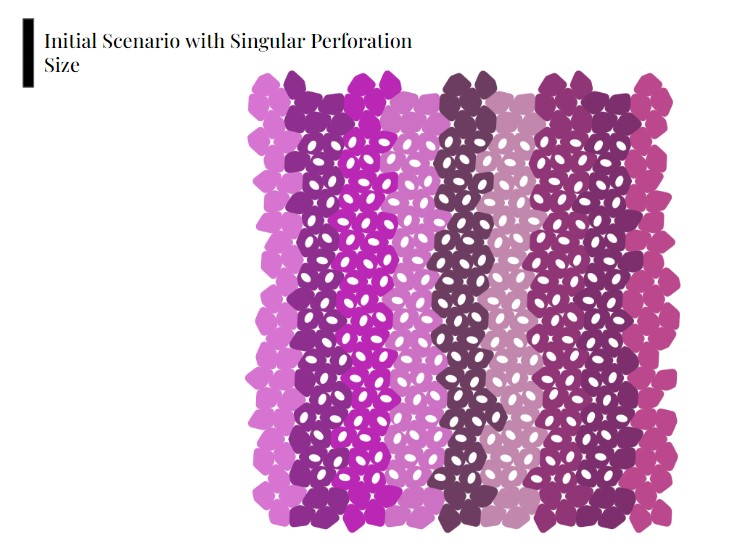

The designed facade responds to incident radiation from the environmental analysis conducted on the building by utilizing the optimum placement of the perforations based on the parameters of the size of the perforations, it’s rotation, axes and amount of protrusion.

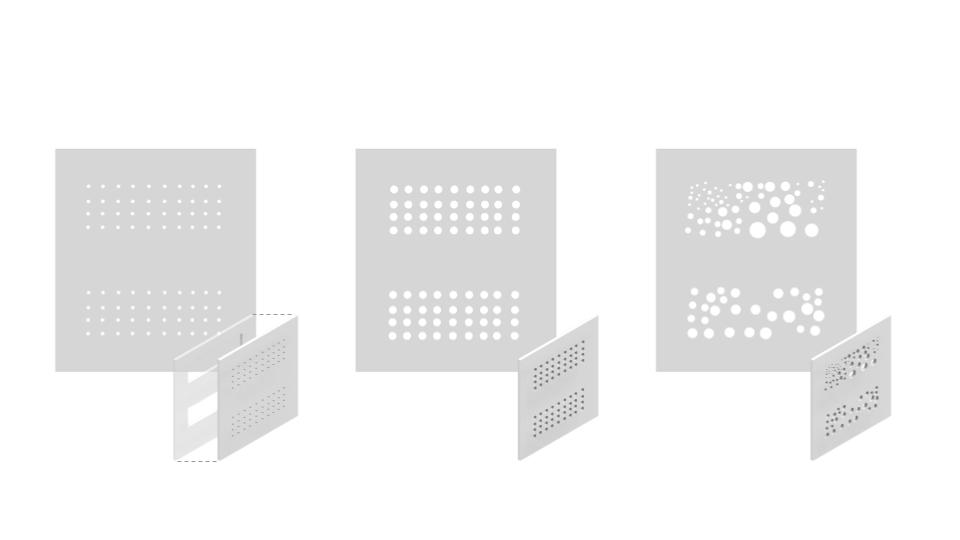

DESIGN PARAMETERS

Optimization of these perforations is based on the following parameters:

- the size of the perforations,

- their rotation,

- their axes

- the amount of protrusion.

The rotations especially are to ensure that the goal of letting in diffused light without the heat gain is met.

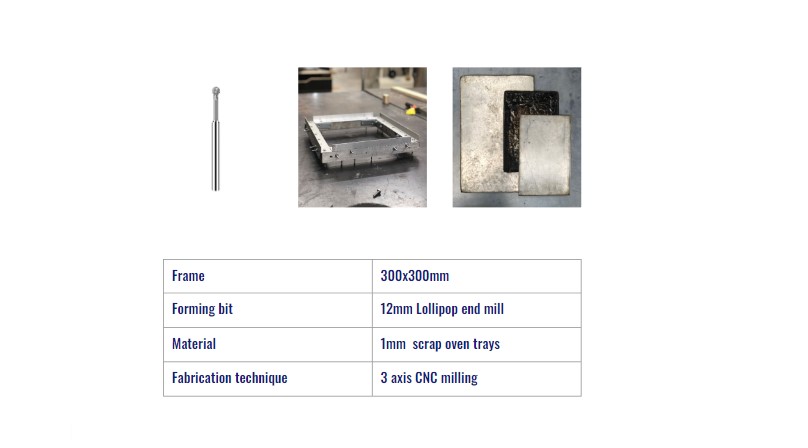

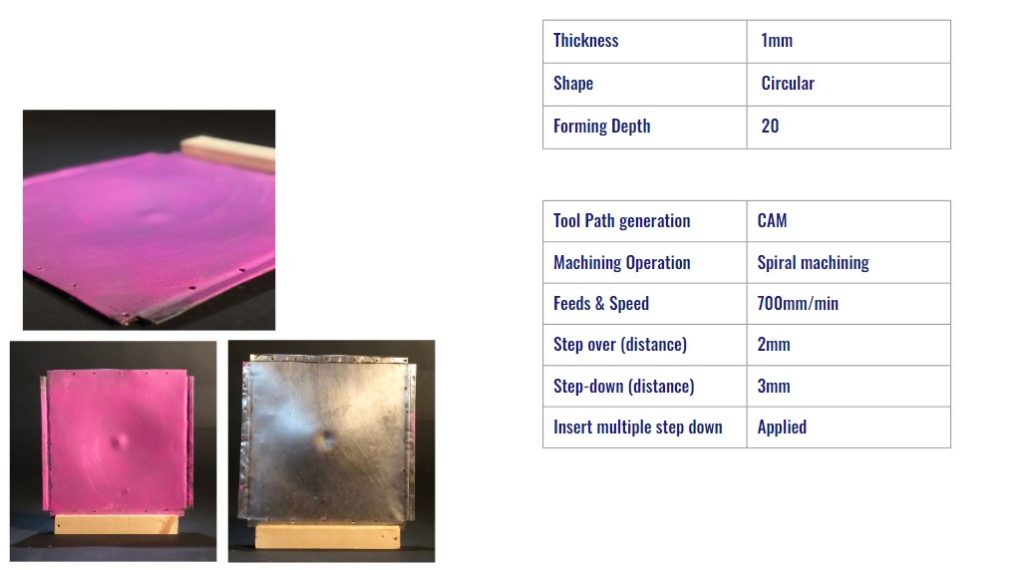

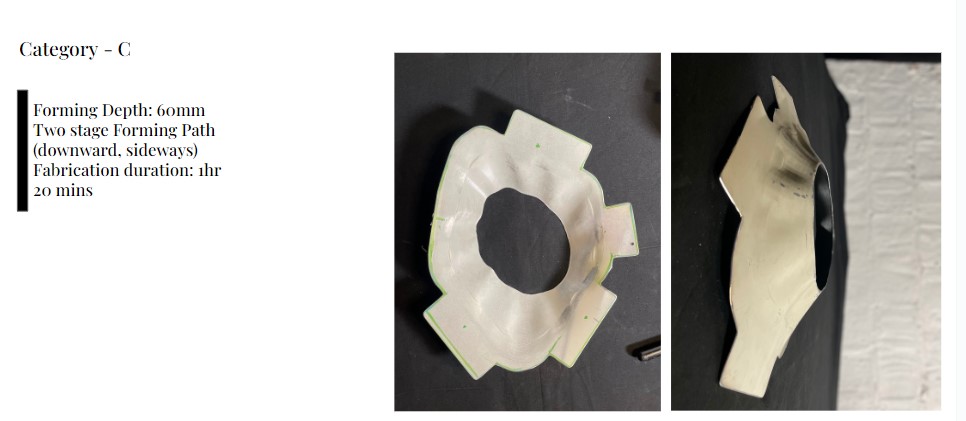

MATERIAL EXPLORATIONS

The initial experiment was conducted with oven trays.

Tool path was generated with CAM program.

The size is kept constant and small as much as possible to understand the phenomena.

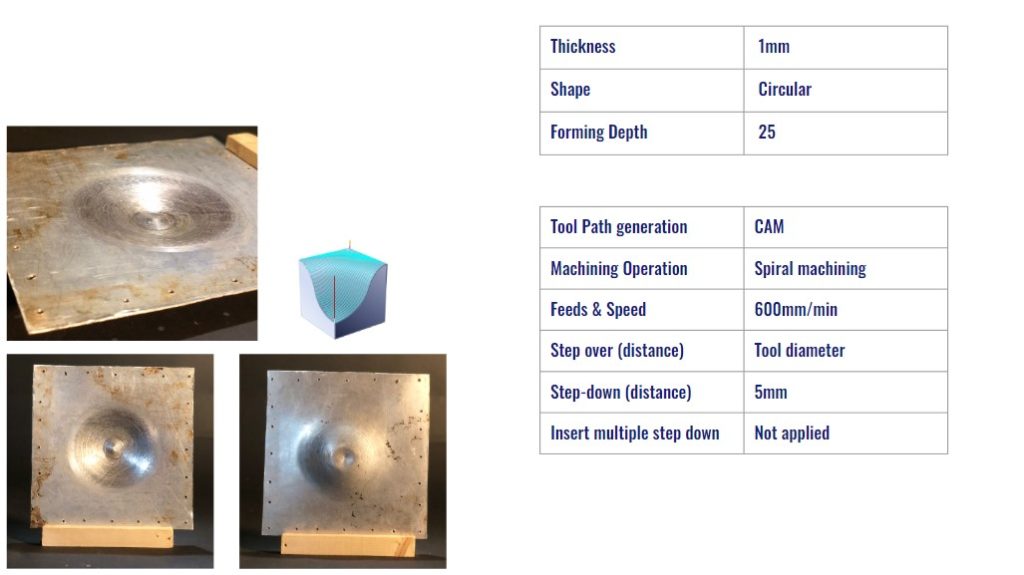

For the first test, Desired forming depth were 25 mm. In the forming process machine had trouble to execute due to its capacity and it wasnt able to complete it.because of the cam settings were not ideal for this execution.

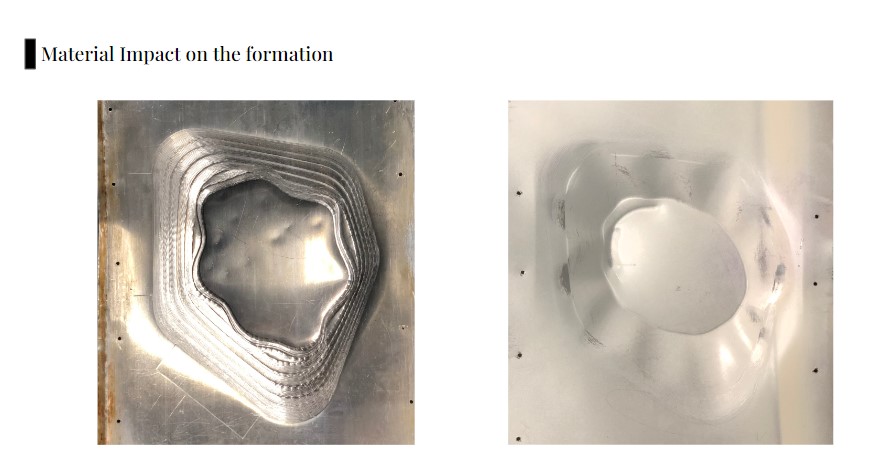

Material informative design

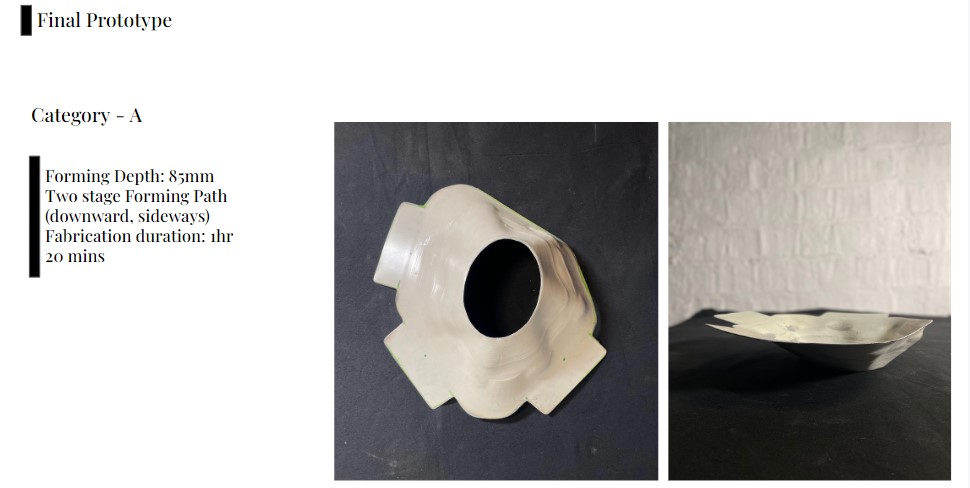

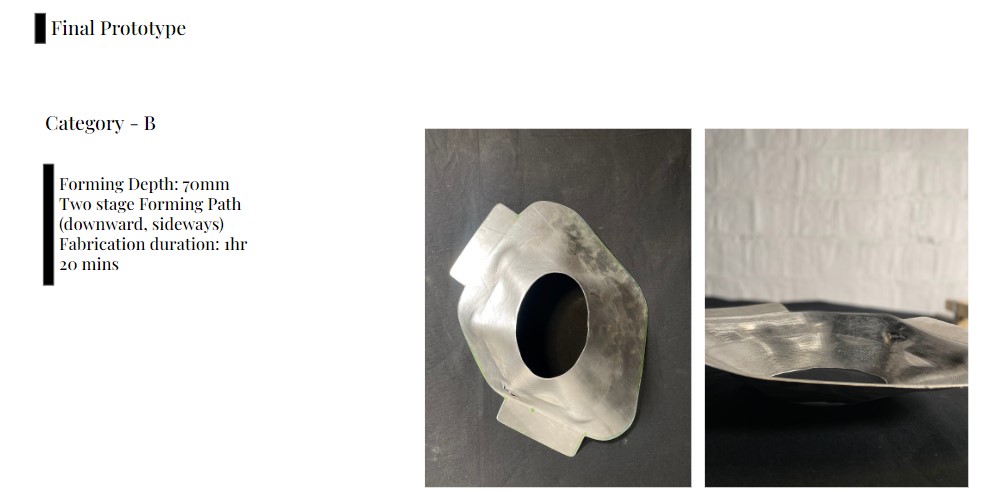

The idea of multiple step down application is to gradually form the sheet to the desired shape rather than trying to achieve the final shape in a single pass.

In conclusion choice of values depends on the desired outcome such as the degree of deformation, surface quality, and accuracy of the formed part, as well as the material properties and the capabilities of the forming equipment.

If the right parameters are set for the forming process, it is possible to minimize the uncomplete part in the center of the shape.