CONTEXT

Every year, there is about $10 trillion in construction-related spending globally, equivalent to 13 percent of GDP. This makes construction one of the largest sectors of the world economy. The sector employs 7% of the world’s working population and, by building the structures in which we live and work, which create our energy, materials, and goods, and on which we travel, has an impact well beyond its own boundaries. Construction matters. The construction industry is responsible for executing essential infrastructure for the well-being and economic progress of society. Having a multiplier effect and influence over other sectors like manufacturing, transportation, real estate and technology.

PROBLEM

There is a productivity challenge in the construction industry due to the lack of experience, informality, limited access to financial support, lack of technical knowledge, it is a highly fragmented market mainly divided into two big sections: Small companies and Big infrastructure companies. In addition to this The complexity of large-scale projects can overwhelm management, leading to poor coordination and ove rsight. Furthermore, the average age of workers is 40 and because of that they are more resistant to new workflows. Isolated workflows are also a big reason why the productivity problem is happening. Despite the potential of new technologies to improve productivity, the construction industry has been slow to adopt innovative tools, materials, and methods (Laszig et al., 2020).

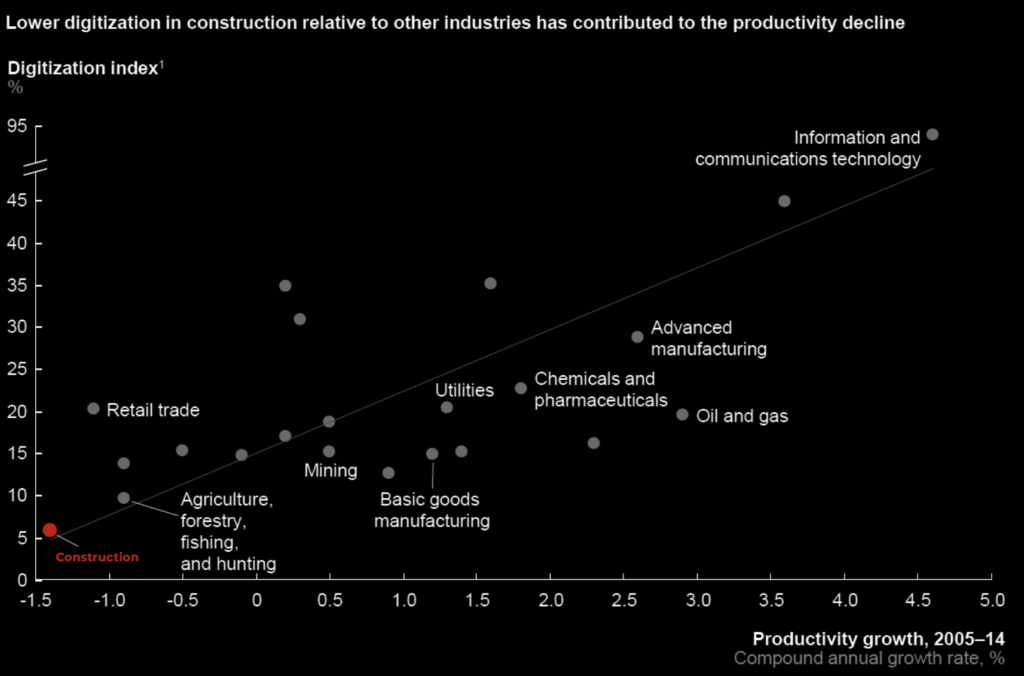

There is a strong correlation between the level of digitization in a sector and its productivity growth. The construction industry still lacks an integrated platform that combines all aspects of construction, from project planning to design to construction to operations and maintenance. Also, many stakeholders in the production value still rely on isolated workflows to handle their projects.

Projects suffer from major time and cost overruns due not only to insufficient attention to design at an early stage, but also to an inability to execute projects effectively. Poor communication, a lack of sufficient and deliberate front-end loading, and low adherence to collaborative planning processes lead to high levels of change orders during the life cycle of projects.

SCOPE

This thesis aims to develop and evaluate computer vision framework for tracking construction progress for small-scale sites in Mexico. The study will conduct a series of experiments that will help understand the technology available and seek to explore how to extract data from the construction site prioritizing affordability, ease of use and scalable solutions, the framework will address adoption barriers for subcontractors and architects. The study will not include close systems solutions and prioritizes user-friendly, cost-effective implementations adhering to Lean Startup principles.

RESEARCH QUESTIONS

How can computer vision assist small-scale architectural firms or subcontractors in extracting data from the construction site for post-analysis that allows them to transfer knowledge from project to project? By empowering them, they are able to document and manage deviations effectively, as well as not depend on high-skilled project managers, and improve decision-making, thus overcoming resistance to the adoption of new technology due to its intimidating learning curve and costs.

SYSTEM PROPOSAL

Use computer vision to extract data from the construction site for post analysis and use the collected data to identify and understad productivities bottle improving decision making efforts. By doing so it could be possible to transfer the lessons learn in past projects and try to predict how future activities could perform. Seeking to create over time a system that checks if a schedule is realistic or not. Making suggestions to reschedule activities improve the probability of success.

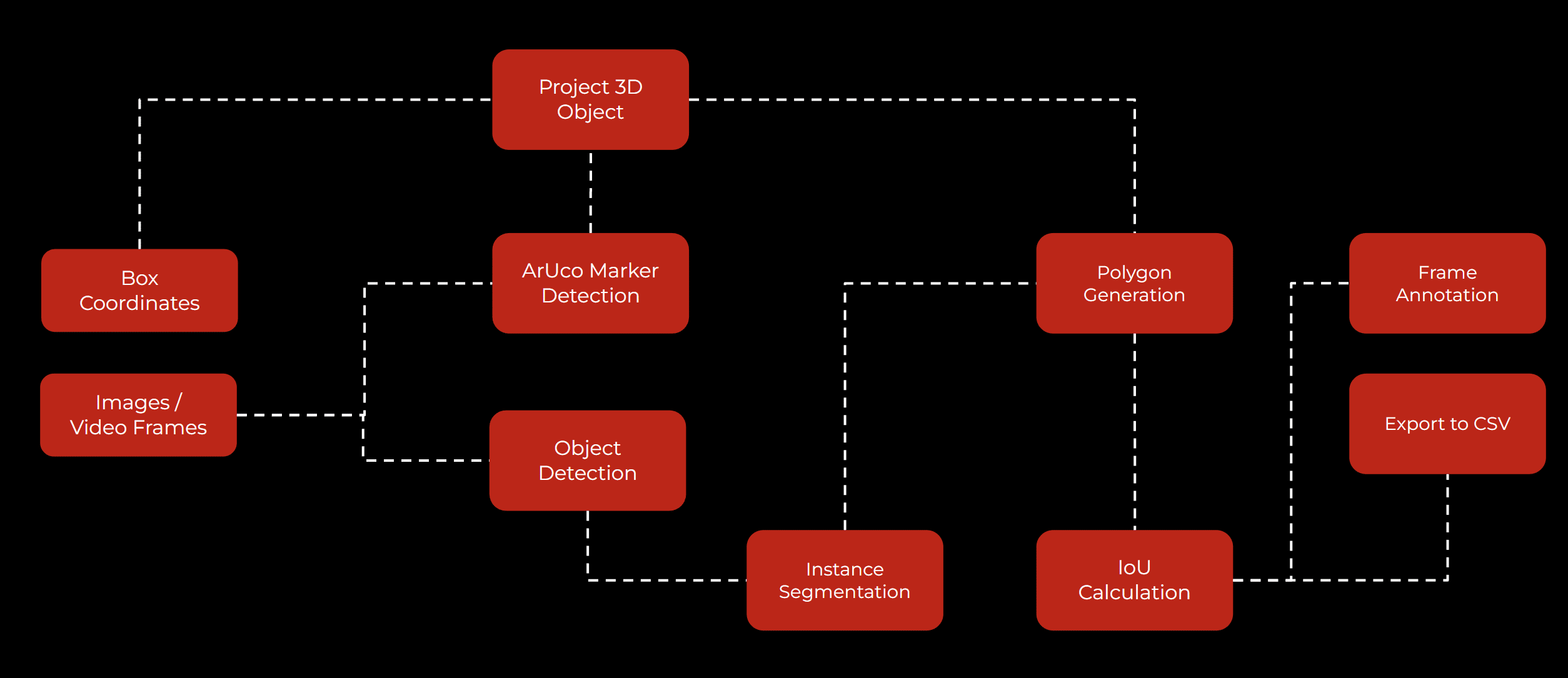

SYSTEM ARCHITECTURE

STATE OF THE ART

Doxel.ai

Doxel is a progress tracking solution that it already exist on marker helping teams to comunicate the status of the project on site using hard data. Doxel helps simplifying the complexity of decision making by integrating data anayltics, enableling a quick response keeping the project on budget and on shcedule.

The companie uses a combination of reality capture technolody and artificial intelligence to track progress on site. Using 3D lidar scanners and 360 cameras to capture data waltinkg through construction site. Once the data is collected AI algorithms analyze the data and compare it with the project BIM model looking for elements that are placed or not and if they are installed the next question answered is if it’s correctly installed.

Based on this anaysis, doxel generates progress dashboard and alerts. In this dashboard the user can see the status of the project making it easy to identify what’s on schedule and what’s not.

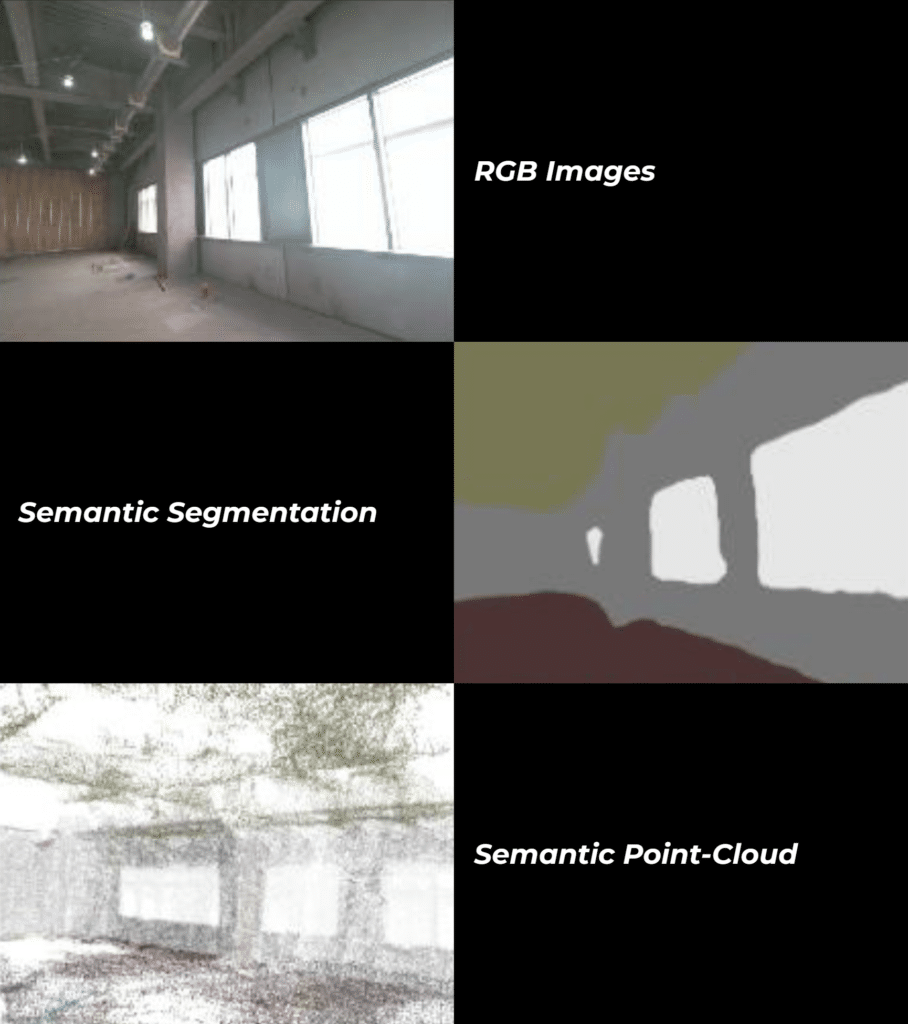

Real-Time Construction Progress Monitoring Framework levering Semantic SLAM

The paper introduces a real-time construction progress monitoring framework using Semantic SLAM (Simultaneous Localization and Mapping) integrated with robotic systems. The proposed system enables efficient identification and monitoring of structural components during on-site inspections by leveraging advanced deep learning models for semantic segmentation. The framework aligns real-time collected point cloud data with 4D BIM models to evaluate construction progress dynamically. It aims to mitigate delays and rework by automating data collection and real-time analysis, enhancing construction project efficiency.

Key Points

1. Develop a framework for automated real-time progress monitoring.

2. Use Semantic SLAM to enable simultaneous navigation, mapping, and semantic labeling of site components.

3. Compare site data with 4D BIM schedules to track progress and visualize updates.

4. Reduce project delays by identifying and addressing critical issues early.

EXPERIMENT SET-UP

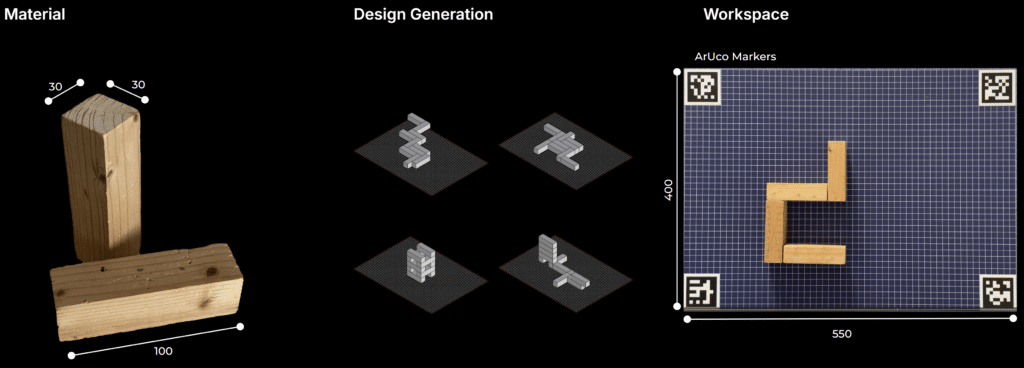

In order to start learning how to extract data from the construction site first complexity needs to be reduced. For this a predictible geometry is being used to extract data. The construction of a jenga tower is a perfect scenario. A series of random assembly sequence are being created to test the tracking system. The workspace is a flat surface with a 10 mm grid background for placing elements reference. In order to visualize and track the location of a physical object ArUco Markers are beeing placed in a specific location.

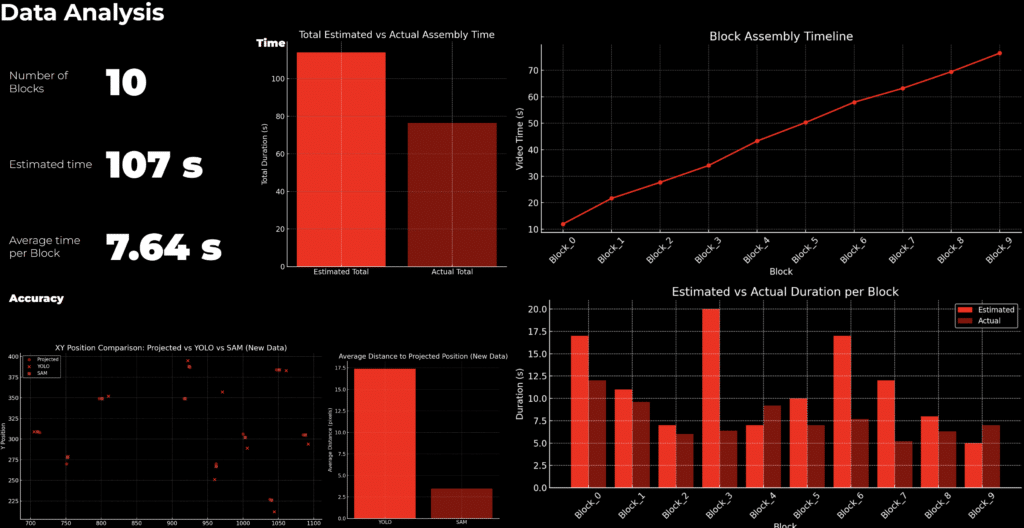

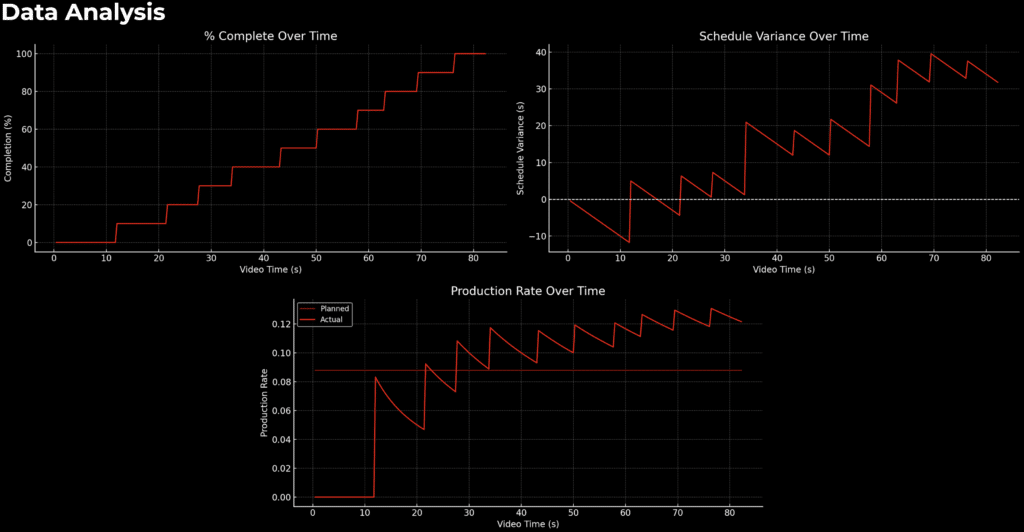

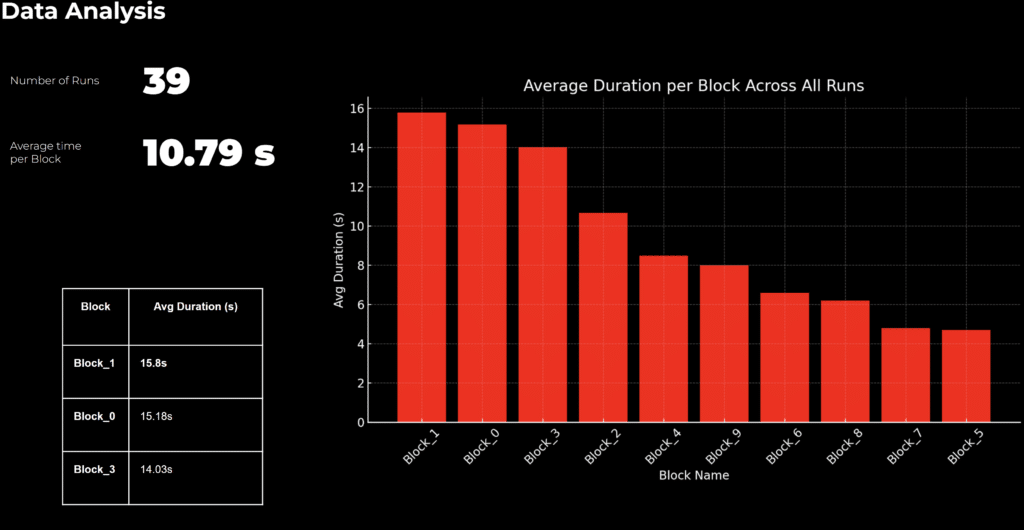

RESULTS

We start collecting data by running the workflow multimple times with diffetrent assembly sequence. This workflow tracks if a physical object is in a projected location.